Tolomatic Band Cylinder BC2 Series User manual

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

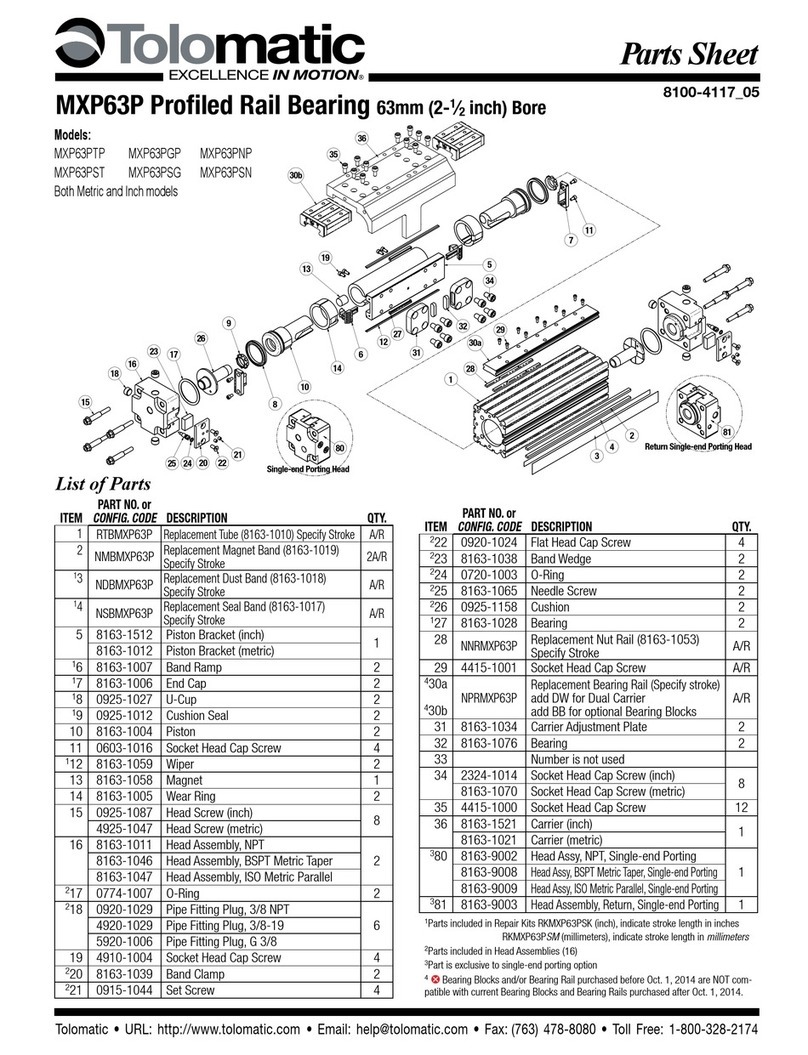

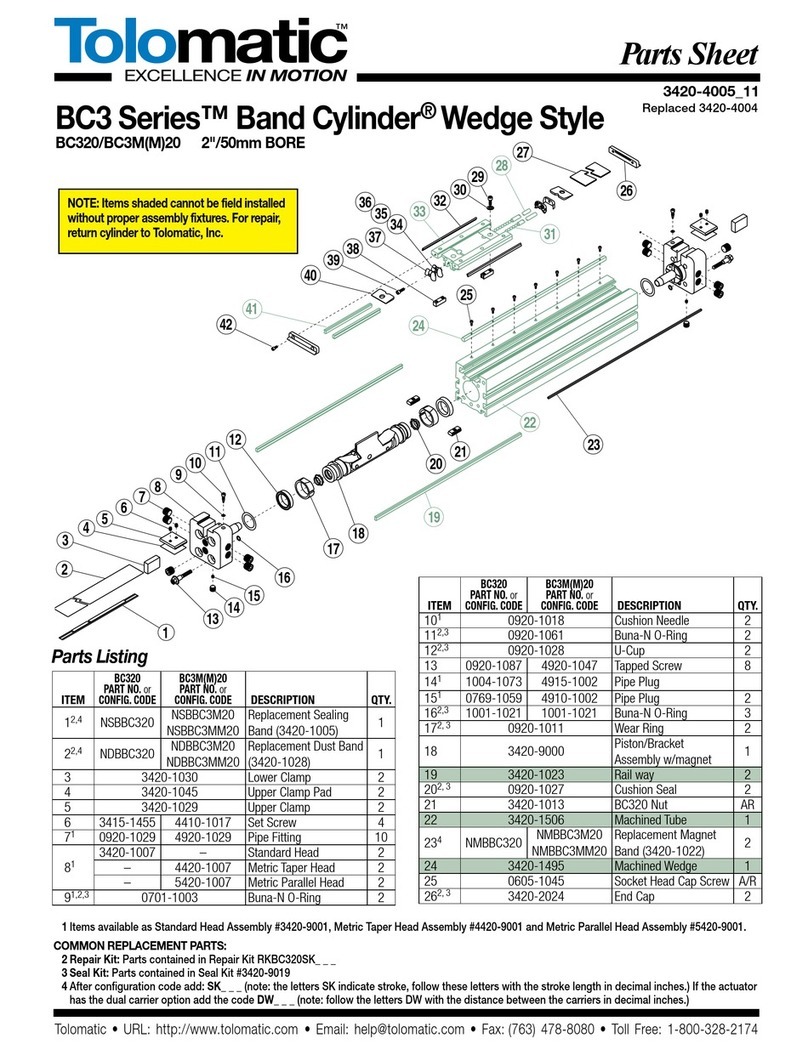

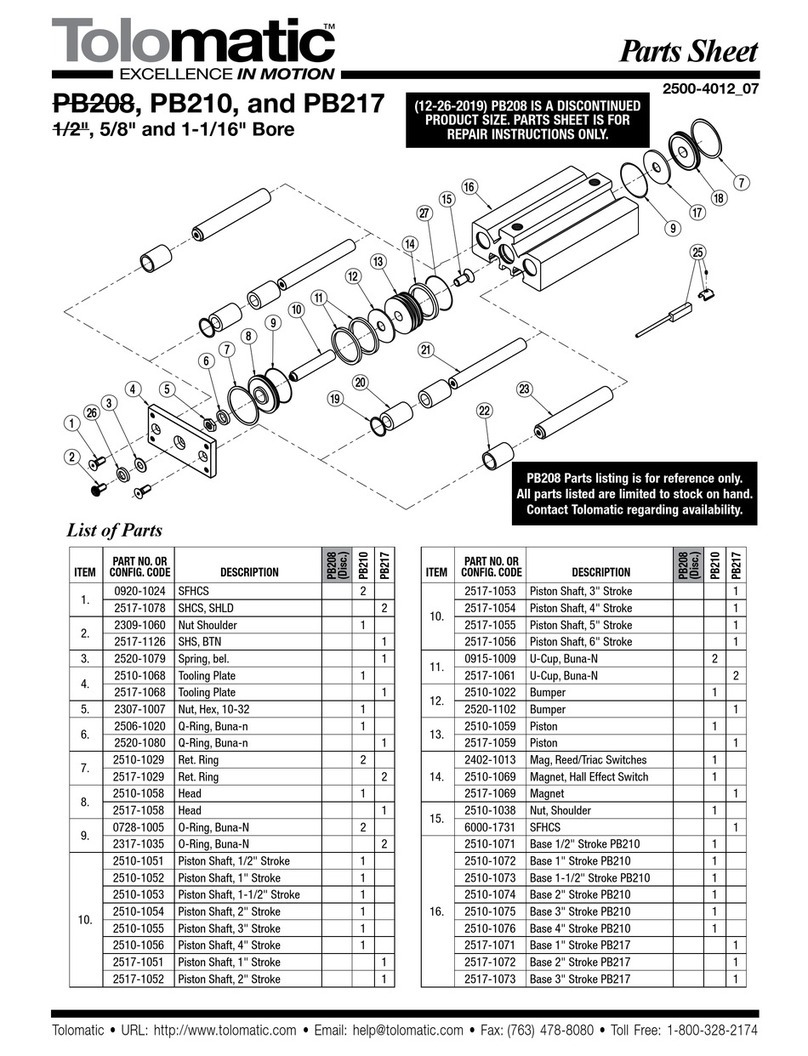

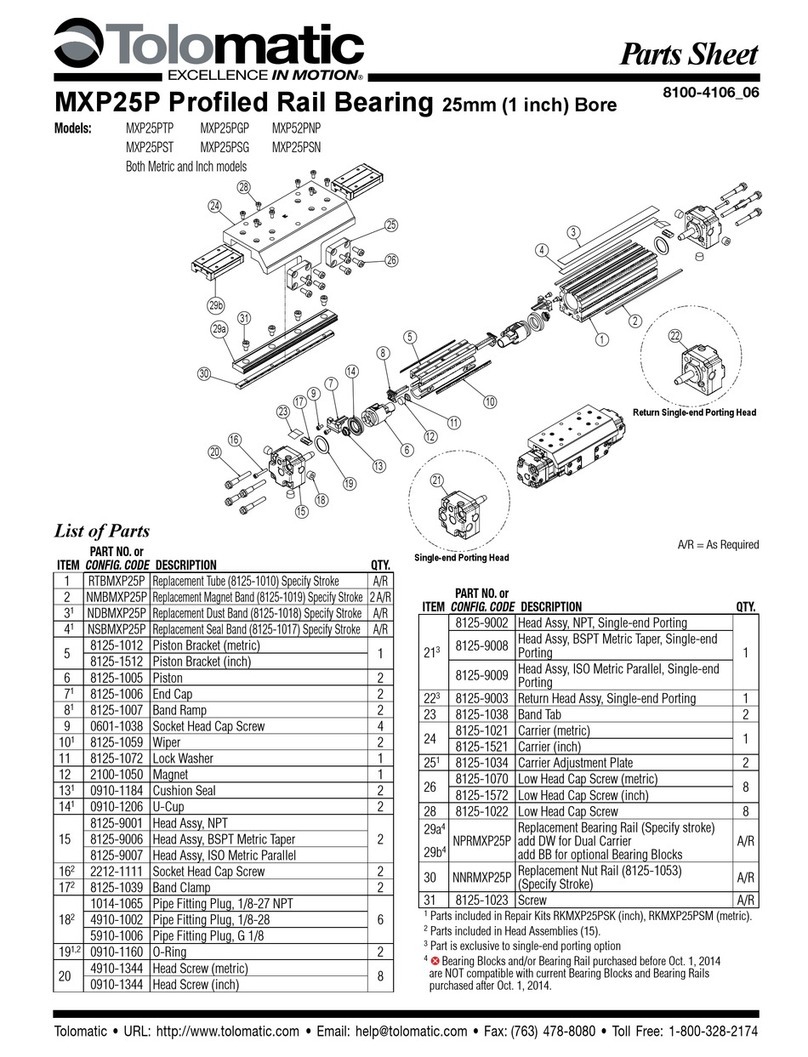

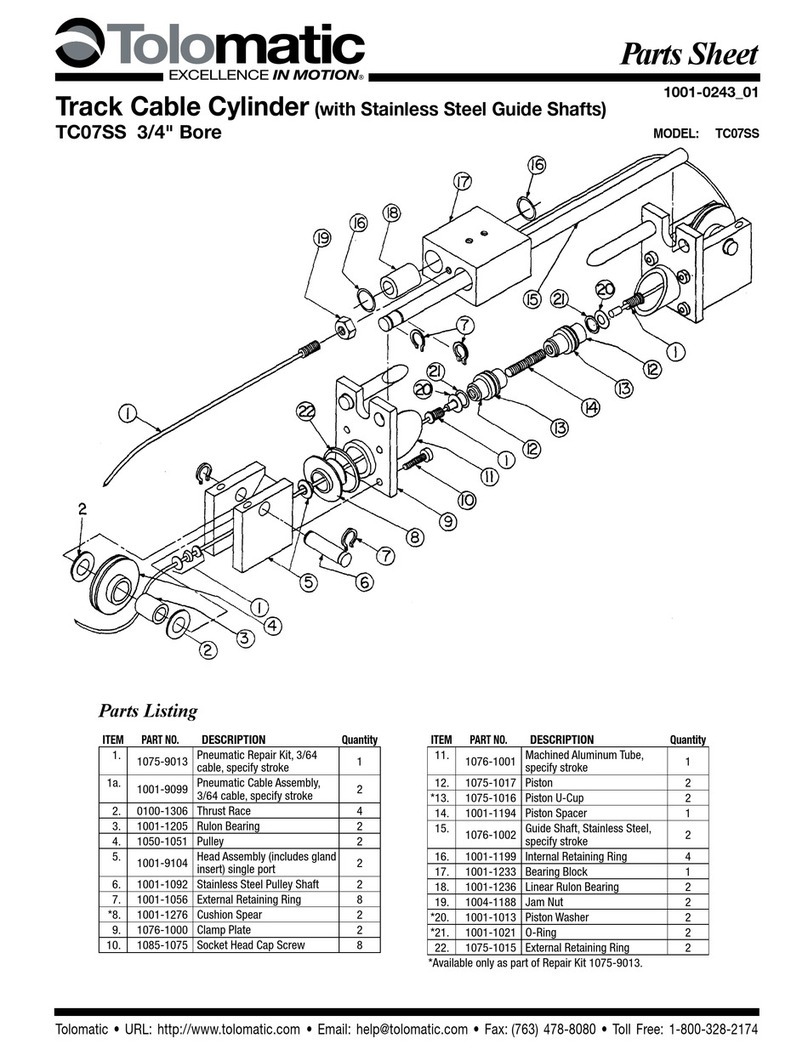

Parts Sheet

0510-4004_10_BC215ps

BC2 Series™Band Cylinder®

BC215, BC2M15, BC2MM15

1-1/2” (40 mm) Bore

19 20

21

22

23

24

25

18

16

13 17

12

15

14

11

10

39

9

8

7

6

2

3

4

5

1

QTY.

ITEM

PART NO. or

CONFIG. CODE

DESCRIPTION

BC215

U.S. Standard

BC2M15 Metric

Taper Rc Heads

BC2M15 Metric

Parallel G Heads

134515-1002 End Cap 2 2 2

230915-1170 Bearing Rod 2 – –

4915-1170 – 2 2

3 0515-1003 Carrier, with

magnet assy.

US Standard

Metric

1 – –

4515-1003 – 1 1

4 0912-1016 Nut 2 – –

4912-1016 – 2 2

5 1004-1144 Washer 2 2 2

6 0910-1081 Socket Head Cap Screw 2 – –

4912-1005 – 2 2

7

0515-9021

Head Assembly

2 – –

4515-9021 – 2 –

5515-9021 – – 2

8 0915-1172 Socket Head Cap Screw 4 – –

4915-1172 – 4 4

93,4

NSBBC215 Replacement Seal Band

specify stroke

A/R – –

NSBBC2M15 – A/R –

NSBBC2MM15 – – A/R

103,4

NDBBC215 Replacement Dust Band

specify stroke

A/R – –

NDBBC2M15 – A/R –

NDBBC2MM15 – – A/R

QTY.

ITEM

PART NO. or

CONFIG. CODE

DESCRIPTION

BC215

U.S. Standard

BC2M15 Metric

Taper Rc Heads

BC2M15 Metric

Parallel G Heads

11 0915-1089 Shoulder Bolt 2 – –

4915-1089 – 2 2

1234515-1012 Band Insert 2 2 2

1330515-1000 Spring 2 2 2

144

RTBBC215 Replacement Tube

specify stroke

A/R – –

RTBBC2M15 – A/R –

RTBBC2MM15 – – A/R

1530915-1178 O-Ring 2 2 2

1610910-1343 Band Clamp 2 – –

4910-1343 – 2 2

1720512-1011 Head Bolt 8 – –

4512-1011 – 8 8

1811301-1172 Socket Head Cap Screw 2 – –

4915-1005 – 2 2

1910910-1178 O-Ring 2 2 2

2010915-1177 Cushion Needle 2 2 2

2130915-1042 U-Cup 2 2 2

22 0915-9013 Piston Bracket Assembly 1 – –

4915-9013 – 1 1

2330915-1110 Wear Ring 2 2 2

2430915-1184 Cushion Seal 2 2 2

251

1004-1073

Pipe Plug

4 – –

4915-1002 – 4 –

5915-1006 – – 4

39 0910-1238 Switch Magnet 1 1 1

1 Items available in Standard Head Assembly #0515-9021

and Metric Taper Head Assembly #4415-9021

and Metric Parallel Head Assembly #5515-9021

2 When replacing the head bolts in actuators manufactured prior to July

1, 2006, the hole for the head bolt will need to be drilled 0.4” (10mm)

deeper to accommodate the longer screw length.

COMMON REPLACEMENT PARTS:

3 Repair Kit: Parts contained in Repair Kit RKBC2(M,MM)15SK_ _ _

4 After configuration code add: SK_ _ _ (note: the letters SK indicate

stroke, follow these letters with the stroke length in decimal inches.) If

the actuator has the dual carrier option add the code DC_ _ _ (note:

follow the letters DC with the distance between the carriers in

decimal inches.)

List of Parts

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

2 – Instructions BC215, BC2M15, BC2MM15 Parts Sheet #0510-4004_10_BC215ps

CYLINDER DISASSEMBLY INSTRUCTIONS

1. Remove Band Cylinder from machinery.

2. Loosen Screw (18).

3. Remove any Foot mounting hardware if present then remove the

four Head Bolts (17) to free Cylinder Heads (7).

4. Remove the three Screws (6, 8), Nuts (4), End Caps (1) and

Bearing Rods (2). Then remove Shoulder Bolts (11) to free the

Carrier Bracket (3),

5. Slide Piston Bracket Assembly (22) out end of tube.

6. Remove top Dust Band (10) by lifting one end and drawing it

back across the entire length of the cylinder.

7. Remove the inner Sealing Band (9) by passing a screwdriver or

similar tool through the slot in the cylinder tube to dislodge the

band from the tube. (Take care in doing this step to make certain

that NO SCRATCHES ARE MADE in the tube bore or slot.)

CYLINDER ASSEMBLY INSTRUCTIONS

1. CLEAN AND LUBRICATE

Thoroughly clean all components, particularly the tube bore slot

and bands. Thoroughly lubricate the tube and all rubber parts

with Magnalube

®

-G grease. Do not use SAE-grade 30-weight

non-detergent oil.

2. READY INNER SEALING BAND

Lubricate rubber strip on both sides of new Sealing Band (9) with

Magnalube-G

®

grease. Insert Band into cylinder Tube (14) by

passing it sideways through slot in tube. With rubber portion facing

up, center band in Tube so equal lengths of Band extend out

both ends.

CAUTION: Metal edges of Sealing Band are sharp. Exercise

caution to avoid injury to yourself or the Band and Tube

when inserting.

3. INSTALL PISTON BRACKET ASSEMBLY

Install new lubricated U-Cups (21) (seal lips facing out) and

Cushion Seals (24) (small end facing out) onto Piston-Bracket

Assembly (22). Install the Wear Rings (23) on the Piston with the

thinner edge and widest part of the flat inward, lining up the

wider flat portion with the band ramp and narrower flat portion

with the flat on the Piston. Place generous amounts of grease

around bore of Tube (14) on one end. Fill indentations on both

sides of Piston with grease and install Piston-Bracket Assembly

into Tube (14) by feeding Sealing Band (9) between Piston and

Bracket. Insert Piston into the greased end of Tube and slide the

length of the Tube to seat the Sealing Band in its groove. Wipe

excess grease from end.

NOTE: If Tube and Piston were greased properly, excess grease

should be present as Piston exits end of tube.

4. TRIM SEALING BAND

With a razor blade, remove rubber from extended band until

flush with the end of tube. With tin snips, trim band to length

indicated on table below. (Tolerance of +/- .032")

Cylinder Size Trim Length From Tube

1-1/2" (40 mm) .656" (16.51 mm)

5. INSTALL HEADS

Install new lubricated O-Rings (19) onto Head (7). Insert Head into

Tube using a slight rocking motion until head is flush with end of

Tube. DO NOT TWIST – twisting the Head when installing can

result in a cut O-ring. Apply Magnalube

®

-G to threads of Head

Bolts (17) and install into head. Torque Bolts to requirements

shown below. (†When replacing the head bolts in actuators

manufactured prior to July 1, 2006, the hole for the head bolt will

need to be drilled 0.4" [10mm] deeper to accommodate the longer

screw length.) Repeat above procedures for second head.

Cylinder Size In.-Lbs. Torque

1-1/2" (40 mm) 100-110 (11.29-12.43 Nm)

6. INSTALL UPPER DUST BAND

With a razor blade, remove any rubber residue on the solid steel

surface of cleaned Dust Band (10). Place Dust Band in slot on

top of Tube (14). Remove rubber from one end of Band flush with

the end of the tube. With tin snips, trim Dust Band to trim length

requirements in Step 4. Insert trimmed Dust Band into Head (7)

positioning band above Band Clamp (16) and tighten Screw (18).

Grasp other end of Dust Band (10) and carefully pull back out of

Tube slot and back over cylinder Head with affixed Band end.

Lubricate Dust Band by filling grooves along both sides of rubber

strip with grease. Press Dust Band back into groove in Tube.

7. INSTALL CARRIER

Position Carrier (3) on Piston-Bracket Assembly (22). Loosely

install Shoulder Bolts (11), Washers (5) and Nuts (4) with screw

heads on port side of cylinder. Install Bearing Rods (2) in Carrier

and place End Caps (1) on Tube. Install Band Insert (12) into

pocket on End Cap (curved portion towards carrier). Insert

Spring (13) into hole of Band Insert (12). Compress Spring and

slide End Cap up to Carrier. Fasten with Screws (6 and 8).

Repeat for other end. Tighten carrier Shoulder Bolts (11) and

Nuts (4).

8. REMOVE SLACK AND AFFIX FREE END OF BAND

Work slack from Bands by moving the Carrier from the Head with

Bands secured to the opposite Head. Remove excess rubber

from free end keeping it flush with end of Tube. Cut to trim length

as before. Secure free end of Band by inserting Band above

Band Clamp (16) and tighten Screw (18).

9. CHECK ASSEMBLY

Run the Carrier Bracket (3) back and forth along the full stroke to

make certain that the cylinder is properly assembled before

applying air.

10. REMOUNT

OPTIONAL ACCESSORY ASSEMBLY INSTRUCTIONS

1. SHOCK ABSORBERS

On assembled cylinder, screw Impact Bolts (29) into top of

carrier End Cap with Loctite #242. Secure Shock Brackets (28) to

cylinder Heads (7) with Socket Head Cap Screws (27) and Loctite

#242. Screw the Shock Absorber (26) into the Shock Bracket (28).

Adjust the Shock Absorber nearest the carrier to bottom out the

shock at its fullest stroke. Back out the shock one full turn and

tighten the Jam Nut. Adjust the other Shock Absorber in the

same manner.

2. TUBE SUPPORTS

Follow cylinder assembly instructions through steps 4. Before

installing second cylinder Head (7) in step 5., slide Tube

Support (48) onto cylinder Tube (14).

3. FOOT MOUNTS

On assembled cylinder, insert Screws (36) through holes in Foot

Mount Bracket (35) and install in holes on cylinder Heads (7).

4. FLOATING MOUNT

Completely assemble cylinder. Place Pin (31), flat side towards

Carrier (3), and between the two center holes. Place Floating

Mount Clamp (32) over Pin (31) and secure to the Carrier (3) with

Screws (34) and Loctite

®

#242. Place Floating Mount Bracket (33)

over Pin (31) and hold in place with a rubber band.

Tolomatic • URL: http://www.tolomatic.com • Email: [email protected] • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

Parts Sheet #0510-4004_10_BC215ps

BC215, BC2M15, BC2MM15 Options – 3

Parts Sheet #0510-4004_10_BC215ps

QTY.

ITEM

PART NO.

DESCRIPTION

BC215

U.S. Standard

BC2M15 Metric

Taper Rc Heads

BC2M15 Metric

Parallel G Heads

SHOCK ABSORBERS5

KIT

0515-9092 Shock Mount Kit3

(Hardware Only)

US Standard

Metric

Shock

Absorber

Kit2

Heavy

Duty

US Standard

Metric

Light

Duty

US Standard

Metric

A/R – –

4515-9092 – A/R A/R

0515-9090 A/R – –

4515-9090 – A/R A/R

0515-9091 A/R – –

4515-9091 – A/R A/R

26

0912-1067 Light Duty Shock 2 – –

4912-1067 – 2 2

0912-1068 Heavy Duty Shock 2 – –

4912-1068 – 2 2

27 2317-1014 Socket Head Cap Screw 4 – –

4915-1171 – 4 4

28 0915-1096 Shock Bracket 2 – –

4915-1096 – 2 2

29 0915-1095 Impact Bolt 2 – –

4915-1095 – 2 2

30 0515-1015 End Cap 2 2 2

FLOATING MOUNT

KIT 0515-9007 Floating Mount Kit US Standard 1 – –

4515-9007 Floating Mount Kit Metric – 1 1

31 0515-1009 Pin 1 1 1

32 0912-1031 Clamp 1 – –

4915-1193 – 1 1

33 0915-9018 Bracket 1 1 1

34 0910-1199 Socket Head Cap Screw 2 – –

4912-1029 – 2 2

FOOT MOUNT

KIT10515-9125 Foot Mount Kit1US Standard A/R – –

4515-9125 Foot Mount Kit1Metric – A/R A/R

35 0915-1150 Mounting Bracket 2 2 2

36 1004-1066 Socket Head Cap Screw 4 – –

4915-1003 – 4 4

SWITCHES

37

CONFIG. CODE ORDERING

Mounting Hardware & FE conn. included

DESCRIPTION CODE

Switch Kit, Reed, Form C, 5m

BT

Switch Kit, Reed, Form C, Male Conn.

BM

Switch Kit, Reed, Form A, 5m

RT

Switch Kit, Reed, Form A, Male Conn.

RM

Switch Kit, Triac, 5m

CT

Switch Kit, Triac, Male Conn.

CM

Switch Kit, Hall-effect, Sinking, 5m

KT

Switch Kit, Hall-effect, Sinking, Male Conn.

KM

Switch Kit, Hall-effect, Sourcing, 5m

TT

Switch Kit, Hall-effect, Sourcing, Male Conn.

TM

NOTE: When ordered female connector & all mounting hardware is included

39 0910-1238 Switch Magnet 1 1 1

TUBE SUPPORTS4

40 4515-1010 Bracket41 1 1

Service Parts Ordering NOTES:

1

Foot Mount Kit contains two foot mount brackets and

mounting hardware.

2

Shock Field Retrofit Kit contains one Shock Absorber and

mounting hardware.

3

Shock Field Mount Kit contains one set of mounting

hardware only.

4

A minimum of 2 (two) Tube Supports required per cylinder.

5

Standard end-of-stroke shock absorbers are designed to

operate without the assistance of the standard band cylinder

cushion. To ensure proper shock absorber performance, make

sure the air cushion is disabled.

A/R = As Required

Switch Ordering NOTES:

To order field retrofit switch and hardware kits for all Tolo-

matic actuators: SW (Then the model and bore size, and type

of switch required)

Example: SWBC215RT

(Hardware and Form A Reed switch with 5 meter lead for 1.5"

bore BC2 band cylinder)

5. SWITCHES

On assembled cylinder, Secure Switch to open port side of cylinder

with a Clamp and Screw. Cycle the carrier over the Switch by hand

to ensure that the carrier does not hit the switch.

NOTE: Form A Reed Switches should not be used in TTL logic

circuits. A voltage drop caused by the L.E.D. indicator will result.

For applications where TTL circuits are used, please contact

the factory.

WARNING: An ohmmeter is recommended for testing Reed

Switches. NEVER use an incandescent light bulb as a high current

rush may damage the switch.

Reed and TRIAC switches are only recommended for signalling

position, not directly powering solenoids. For shifting a solenoid, a

relay or resistor is recommended between it and the Reed Switch.

Switch ratings must not be exceeded at any time.

List of Parts

BC2

OPTIONS

36

26

27 28

29 30

31 32

33

34

40

39

37

35

SHOCK

ABSORBERS

SHOCK

ABSORBERS

FLOATING

MOUNT

TUBE

SUPPORTS

FOOT

MOUNT

SWITCHES

3800 County Road 116, Hamel, MN 55340

http://www.Tolomatic.com • Email: Help@Tolomatic.com

Phone: (763) 478-8000 • Fax: (763) 478-8080 • Toll Free: 1-800-328-2174

8

© 2017 Tolomatic 201708161449

Information furnished is believed to be accurate

and reliable. However, Tolomatic assumes no

responsibility for its use or for any errors that may

appear in this document. Tolomatic reserves the

right to change the design or operation of the

equipment described herein and any associated

motion products without notice. Information in

this document is subject to change without notice.

4 – Switches / Maintenance BC215, BC2M15, BC2MM15 Parts Sheet #0510-4004_10_BC215ps

MAINTENANCE

The Band Cylinder

®

should be kept as clean as possible around the

bands and Carrier Bracket.

LUBRICATION

All Tolomatic Band Cylinders are pre-lubricated at the factory. To

ensure maximum cylinder life, the following guidelines should

be followed.

1. Filtration– We recommend the use of dry, filtered air in our

products. ‘Filtered air’ means a level of 10 Micron or less. ‘Dry’

means air should be free of appreciable amounts of moisture.

Regular maintenance of installed filters will generally keep

excess moisture in check.

2. External Lubricators (optional)– The factory pre-lubrication of

Tolomatic Band Cylinders will provide optimal performance

without the use of external lubrication. However, external

lubricators can further extend service life of pneumatic

actuators if the supply is kept constant.

Oil lubricators, (mist or drop) should supply a minimum of 1

drop per 20 standard cubic feet per minute to the cylinder. As a

rule of thumb, double that rate if water in the system is

suspected. Demanding conditions may require more lubricant.

If lubricators are used, we recommend a non-detergent, 20cP

@ 140˚F 10-weight lubricant. Optimum conditions for standard

cylinder operation is +32˚ to +125˚F (+0˚ to 51.6˚C).

NOTE: Use of external lubricators will wash away the factory

installed lubrication. External lubricants must be maintained in a

constant supply or the results will be a dry actuator prone to failure.

3. Sanitary environments– Oil mist lubricators must dispense

‘Food Grade’ lubricants to the air supply. Use fluids with ORAL

LD50 toxicity ratings of 35 or higher such as Multitherm

®

PG-1 or equivalent. Demanding conditions can require a review

of the application.

CARRIER BRACKET ADJUSTMENT

The tracking tension on the Carrier Bracket may be adjusted by

tightening or loosening the two shoulder bolts and nuts on the

bracket. To tighten or loosen the bolts on the BC215 Band Cylinder

®

models, use an open-end wrench and Allen wrench. Tighten the nut

on the shoulder bolt until there is no lateral movement of the bolt.

Then, equally tighten each nut on the shoulder bolts while moving

the carrier by hand along the length of the stroke. When all lateral

play in the carrier is eliminated and free movement along the length

of the stroke is maintained, the carrier bracket is adjusted properly.

CAUTION

: Make certain not to overtighten the Carrier Bracket

adjustment screws. It is possible to tighten them enough to keep the

Carrier and Piston from moving. Tightening the Carrier Bracket

directly affects the cylinder’s breakaway. The tighter the adjustment

the higher the breakaway.

CUSHION NEEDLE ADJUSTMENT

Adjust the cushion needles in the cylinder heads carefully to obtain

a smooth, hesitation free deceleration for your particular application.

If there are questions on proper adjustment, please consult

Tolomatic, Inc.

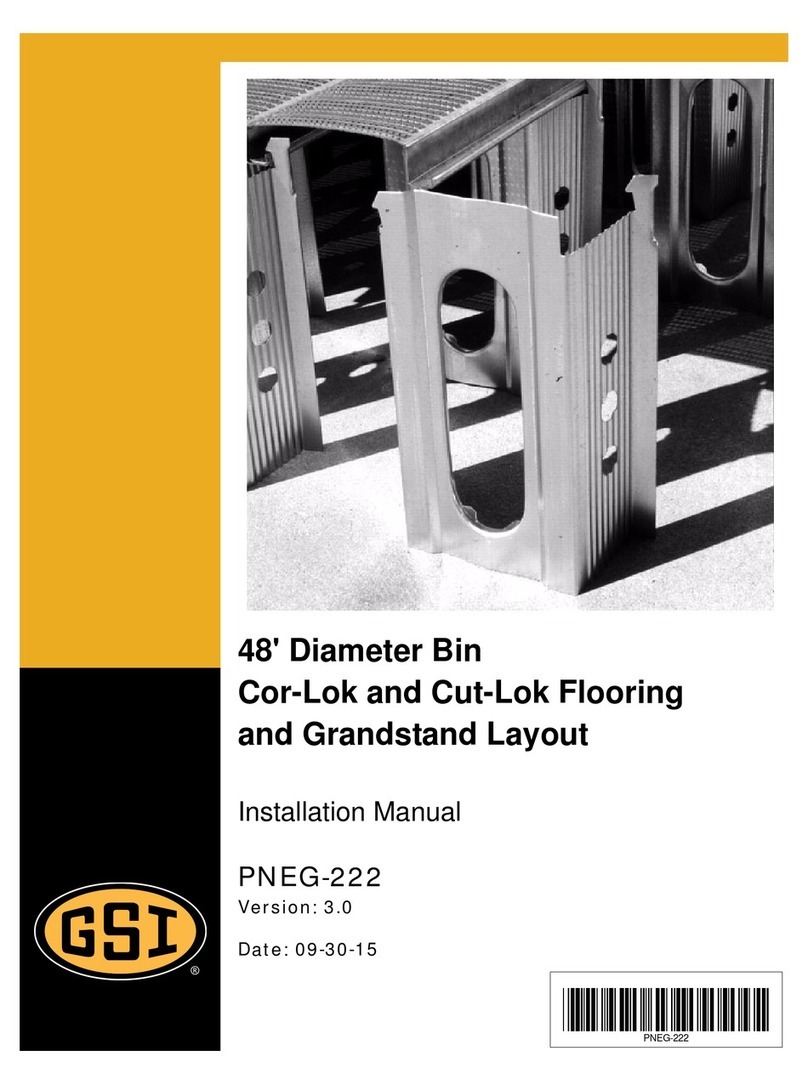

PERFORMANCE

THE NOTCHED

FACE OF THE

SWITCH INDICATES

THE SENSING

SURFACE AND

MUST FACE

TOWARD THE

MAGNET.

THE NOTCHED

GROOVE IN THE

ACTUATOR

INDICATES THE

GROOVE TO

INSTALL THE

SWITCH. CONTACT

TOLOMATIC IF

SWITCHES ARE

REQUIRED ON

ANOTHER SIDE OF

ACTUATOR.

0

50

100

150

200

0100 200 300 400 500

VOLTAGE A.C. or D.C.

CURRENT D.C (mA)

REED FORM A

R

E

E

D

F

O

R

M

C

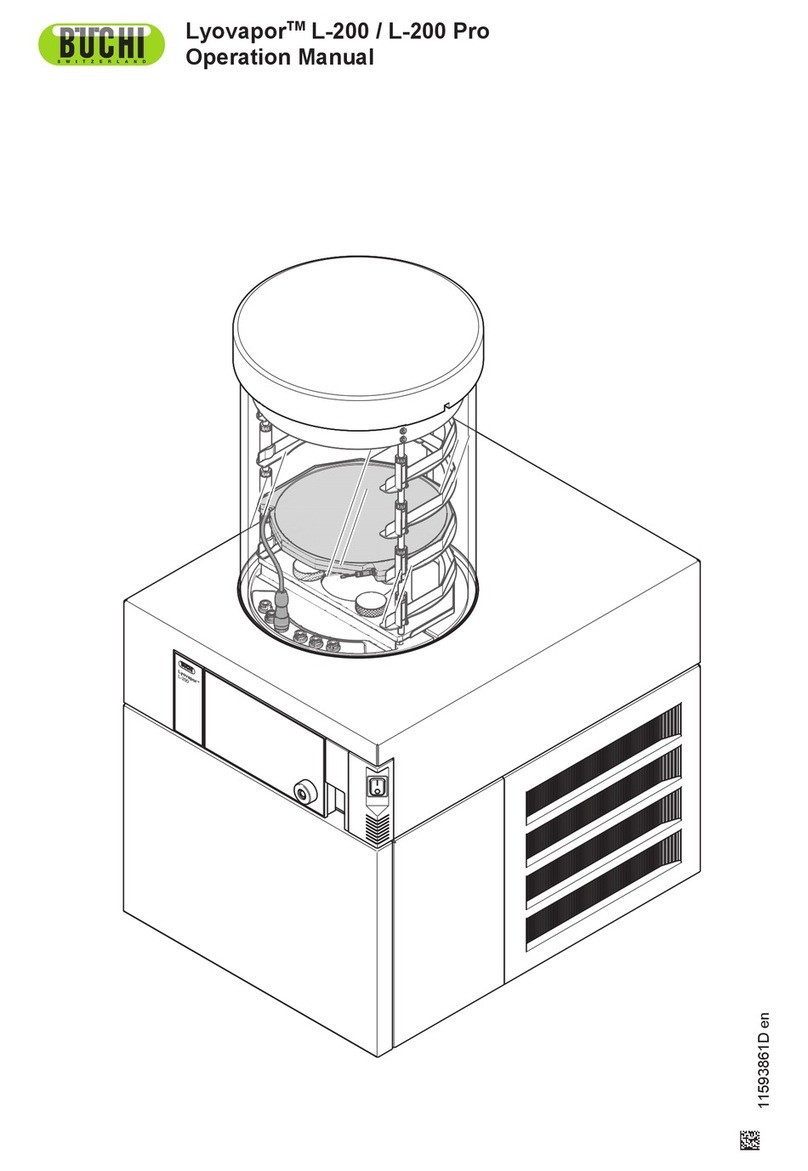

TEMP. vs CURRENT, DC REED VOLTAGE DERATING, DC REEDTEMP. vs CURRENT, AC REED

0

100

200

300

400

500

600

020406080 100 120 140 160

LOAD CURRENT (mA)

OPERATING TEMPERATURE (F)

REED FORM C

REED FORM A

0

200

400

600

800

1000

020406080 100 120 140 160

LOAD CURENT (mA)

OPERATING TEMPERATURE (F)

TRIAC

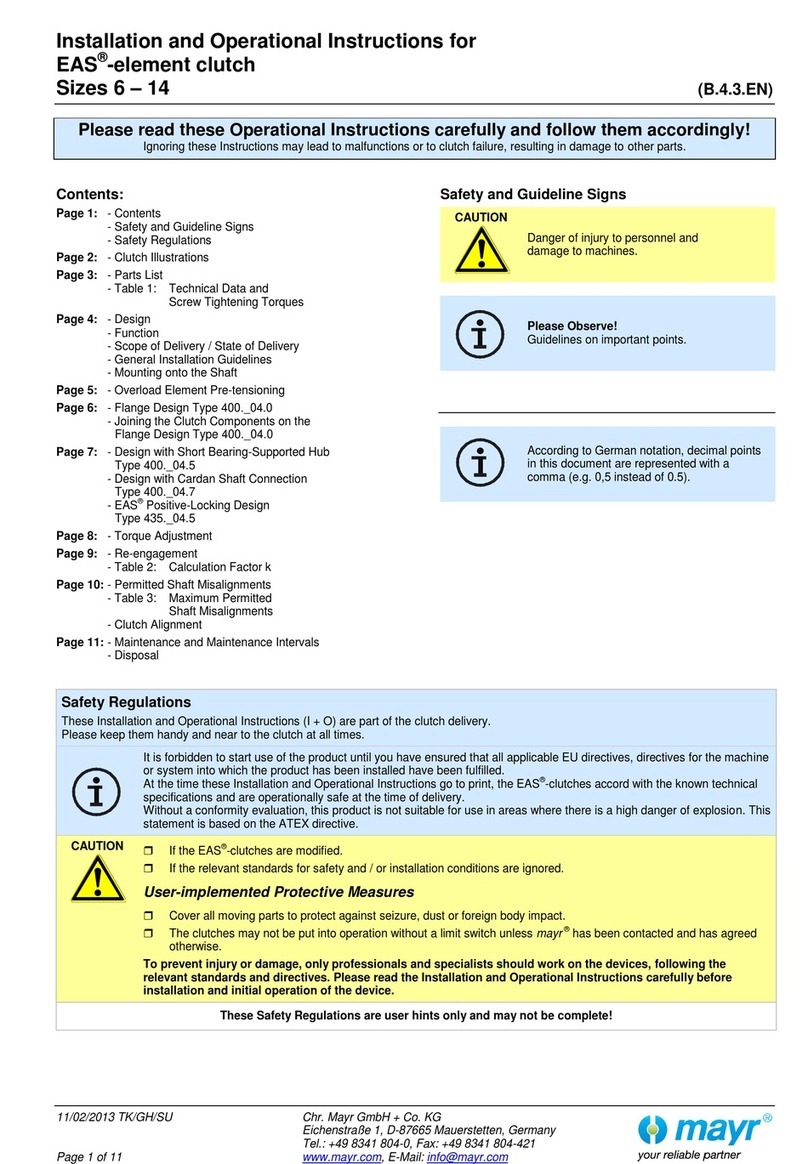

RT & RM DC REED, FORM A

BT & BM DC REED, FORM C

CT & CM AC REED, TRIAC

TT & TM HALL-EFFECT, SOURCING, PNP

KT & KM HALL-EFFECT, SINKING, NPN

REED

SWITCH

LOAD

BROWN

BLUE

(-) (-)

(+)(+)

REED

SWITCH

LOAD

BROWN

BLUE

(-)

(-)

(+)(+)

OR

AC

COM

LOAD

INPUT

TRIAC

SWITCH

120V

ac

Max.

MOV

BROWN

BLUE

REED

SWITCH

COMMON

NORMALL

Y CLOSED

NORMALLY OPEN

BROWN

BLACK

BLUE

HALL-EFFECT

SOURCING

SWITCH

BLACK

LOAD

BROWN

BLUE (-)

(+)

(-)

(+)

HALL-EFFECT

SINKING

SWITCH

BROWN

BLACK

BLUE (-)

(+)

(-)

(+)

LOAD

WIRING DIAGRAMS INSTALLATION INFORMATION

Some actuators may

require switch mount-

ing on a specific side

of the assembly. Call

Tolomatic for details.

Female Connector 5M

SWITCHES

There are 10 sensing choices: DC reed, form A (open) or form C (open or

closed); AC reed (Triac, open); Hall-effect, sourcing, PNP (open); Hall-effect,

sinking, NPN (open); each with either flying leads or QD (quick disconnect).

Commonly used to send analog signals to PLC (programmable logic

controllers), TLL, CMOS circuit or other controller device. These switches are

activated by the actuator’s magnet.

Switches contain reverse polarity protection. QD cables are shielded; shield

should be terminated at flying lead end.

If necessary to remove factory installed switches, be sure to reinstall on the

same of side of actuator with scored face of switch toward internal magnet.

**

WARNING

: Do not exceed power rating (Watt = Voltage X Amperage). Permanent damage to sensor will occur.

*QD = Quick Disconnect; Male coupler is located 6" [152mm} from sensor,

Female coupler to flying lead distance is 197" [5m] also see Cable Shielding specification above

REPLACEMENT OF QD SWITCHES MANUFACTURED BEFORE JULY 1, 1997:

It will be necessary to replace or rewire the female end coupler.

CAUTION: DO NOT OVER TIGHTEN SWITCH HARDWARE WHEN INSTALLING!

CURRENT

Quick disconnect

Wiring

BROWN

BLACK

BLUE

+

-

SIGNAL

OLD

Quick disconnect

Wiring

BROWN

BLACK

BLUE

+

-

SIGNAL

†Shielded from the female quick disconnect coupler to the flying leads. Shield should be terminated at flying lead end.

§

Maximum current 500mA (not to exceed 10VA) Refer to Temperature vs. Current graph and Voltage Derating graph

§§

Maximum current 250mA (not to exceed 3VA) Refer to Temperature vs. Current graph and Voltage Derating graph

Reed Switch Life Expectancy: Up to

200,000,000 cycles (depending on load cur-

rent, duty cycle and environmental conditions)

DC REED, AC REED (TRIAC)

AND HALL-EFFECT

QUICK-DISCONNECT

COUPLER - MALE END

QUICK-DISCONNECT

COUPLER - FEMALE END

SPECIFICATIONS

REED DC REED AC HALL-EFFECT DC

ORDER CODE

RT RM BT BM CT CM TT TM KT KM

LEAD 5m QD* 5m QD* 5m QD* 5m QD* 5m QD*

CABLE SHIELDING Unshielded Shielded† Unshielded Shielded† Unshielded Shielded† Unshielded Shielded† Unshielded Shielded†

SWITCHING LOGIC "A" Normally Open "C" Normally Open or Closed Triac Normally Open PNP (Sourcing) Normally

Open NPN (Sinking) Normally Open

MECHANICAL CONTACTS Single-Pole Single-Throw Single-Pole Double-Throw Single-Pole Single-Throw NO, These Are Solid State Components

COIL DIRECT Yes Yes Yes —

POWER LED None None None None None

SIGNAL LED Red Red Red

OPERATING VOLTAGE 200 Vdc max. 120 Vdc max. 120 Vac max. 5 - 25 Vdc

OUTPUT RATING — — 25 Vdc, 200mA dc

OPERATING TIME 0.6 msec max.

(including bounce)

0.7 msec max.

(including bounce) —< 10 micro sec.

OPERATING TEMPERATURE -40°F [-40°C] to 158°F [70°C] 0°F [-18°C] to 150°F [66°C]

RELEASE TIME 1.0 msec. max. — —

ON TRIP POINT — — 150 Gauss maximum

OFF TRIP POINT — — 40 Gauss minimum

**POWER RATING (WATTS) 10.0

§

3.0

§ §

10.0 5.0

VOLTAGE DROP 2.6 V typical at 100 mA NA — —

RESISTANCE 0.1 Ω Initial (Max.) — —

CURRENT CONSUMPTION —1 Amp at

86°F [30°C]

0.5 Amp at

140°F [60°C] 200 mA at 25 Vdc

FREQUENCY —47 - 63 Hz —

CABLE MIN.

BEND

RADIUS

STATIC 0.630" [16mm]

DYNAMIC Not Recommended

SWITCHES

There are 10 sensing choices: DC reed, form A (open) or form C (open or

closed); AC reed (Triac, open); Hall-effect, sourcing, PNP (open); Hall-effect,

sinking, NPN (open); each with either flying leads or QD (quick disconnect).

Commonly used to send analog signals to PLC (programmable logic

controllers), TLL, CMOS circuit or other controller device. These switches are

activated by the actuator’s magnet.

Switches contain reverse polarity protection. QD cables are shielded; shield

should be terminated at flying lead end.

If necessary to remove factory installed switches, be sure to reinstall on the

same of side of actuator with scored face of switch toward internal magnet.

**

WARNING

: Do not exceed power rating (Watt = Voltage X Amperage). Permanent damage to sensor will occur.

*QD = Quick Disconnect; Male coupler is located 6" [152mm} from sensor,

Female coupler to flying lead distance is 197" [5m] also see Cable Shielding specification above

REPLACEMENT OF QD SWITCHES MANUFACTURED BEFORE JULY 1, 1997:

It will be necessary to replace or rewire the female end coupler.

CAUTION: DO NOT OVER TIGHTEN SWITCH HARDWARE WHEN INSTALLING!

CURRENT

Quick disconnect

Wiring

BROWN

BLACK

BLUE

+

-

SIGNAL

OLD

Quick disconnect

Wiring

BROWN

BLACK

BLUE

+

-

SIGNAL

†Shielded from the female quick disconnect coupler to the flying leads. Shield should be terminated at flying lead end.

§

Maximum current 500mA (not to exceed 10VA) Refer to Temperature vs. Current graph and Voltage Derating graph

§§

Maximum current 250mA (not to exceed 3VA) Refer to Temperature vs. Current graph and Voltage Derating graph

Reed Switch Life Expectancy: Up to

200,000,000 cycles (depending on load cur-

rent, duty cycle and environmental conditions)

DC REED, AC REED (TRIAC)

AND HALL-EFFECT

QUICK-DISCONNECT

COUPLER - MALE END

QUICK-DISCONNECT

COUPLER - FEMALE END

SPECIFICATIONS

REED DC REED AC HALL-EFFECT DC

ORDER CODE

RT RM BT BM CT CM TT TM KT KM

LEAD 5m QD* 5m QD* 5m QD* 5m QD* 5m QD*

CABLE SHIELDING Unshielded Shielded† Unshielded Shielded† Unshielded Shielded† Unshielded Shielded† Unshielded Shielded†

SWITCHING LOGIC "A" Normally Open "C" Normally Open or Closed Triac Normally Open PNP (Sourcing) Normally

Open NPN (Sinking) Normally Open

MECHANICAL CONTACTS Single-Pole Single-Throw Single-Pole Double-Throw Single-Pole Single-Throw NO, These Are Solid State Components

COIL DIRECT Yes Yes Yes —

POWER LED None None None None None

SIGNAL LED Red Red Red

OPERATING VOLTAGE 200 Vdc max. 120 Vdc max. 120 Vac max. 5 - 25 Vdc

OUTPUT RATING — — 25 Vdc, 200mA dc

OPERATING TIME 0.6 msec max.

(including bounce)

0.7 msec max.

(including bounce) —< 10 micro sec.

OPERATING TEMPERATURE -40°F [-40°C] to 158°F [70°C] 0°F [-18°C] to 150°F [66°C]

RELEASE TIME 1.0 msec. max. — —

ON TRIP POINT — — 150 Gauss maximum

OFF TRIP POINT — — 40 Gauss minimum

**POWER RATING (WATTS) 10.0

§

3.0

§ §

10.0 5.0

VOLTAGE DROP 2.6 V typical at 100 mA NA — —

RESISTANCE 0.1 Ω Initial (Max.) — —

CURRENT CONSUMPTION —1 Amp at

86°F [30°C]

0.5 Amp at

140°F [60°C] 200 mA at 25 Vdc

FREQUENCY —47 - 63 Hz —

CABLE MIN.

BEND

RADIUS

STATIC 0.630" [16mm]

DYNAMIC Not Recommended

REPLACEMENT OF QD SWITCHES

MANUFACTURED BEFORE JULY 1, 1997:

It will be

necessary to

replace or

rewire the

female end

coupler.

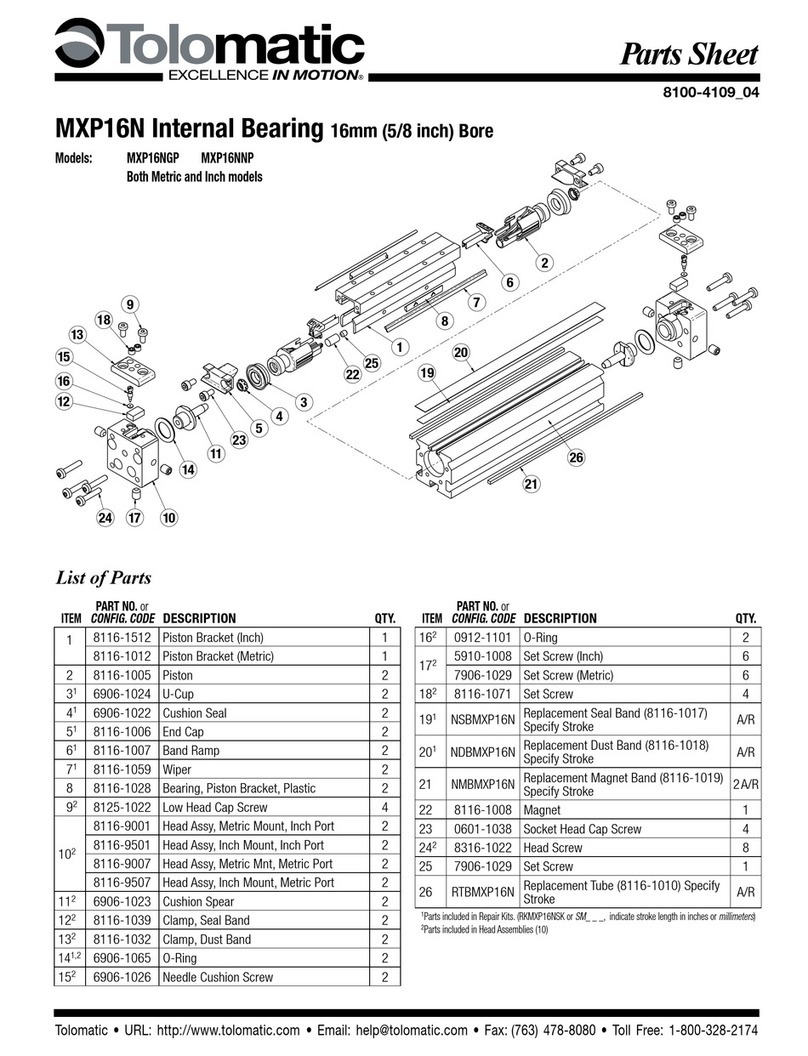

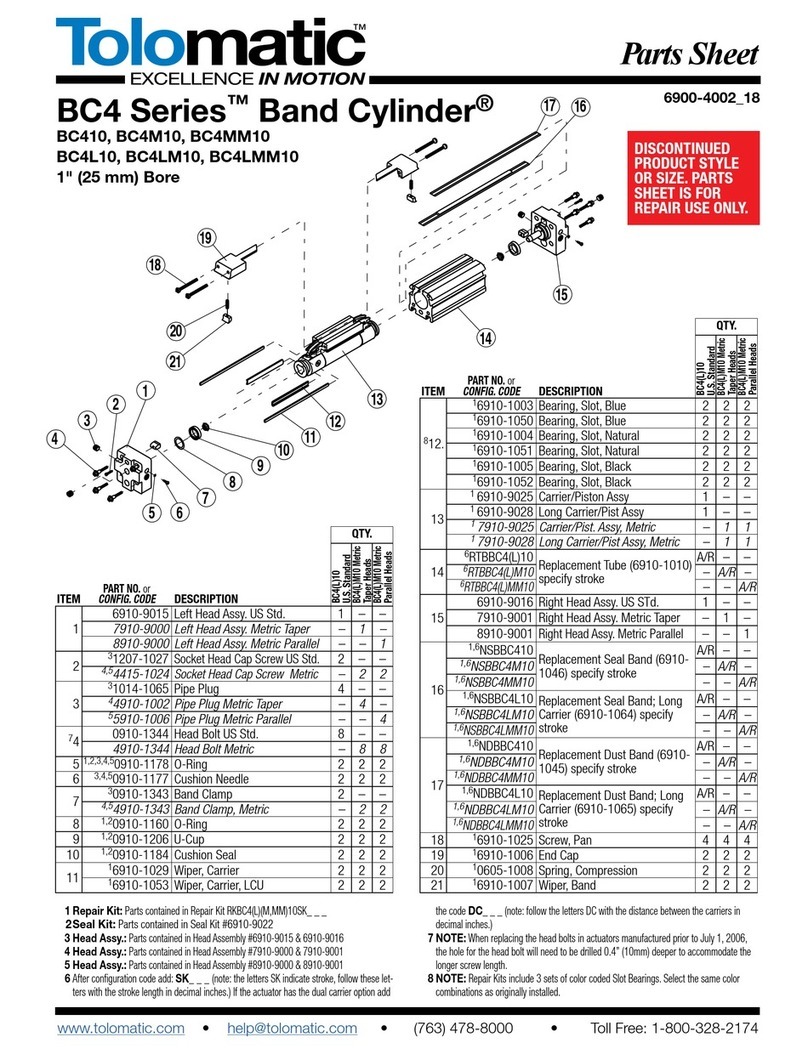

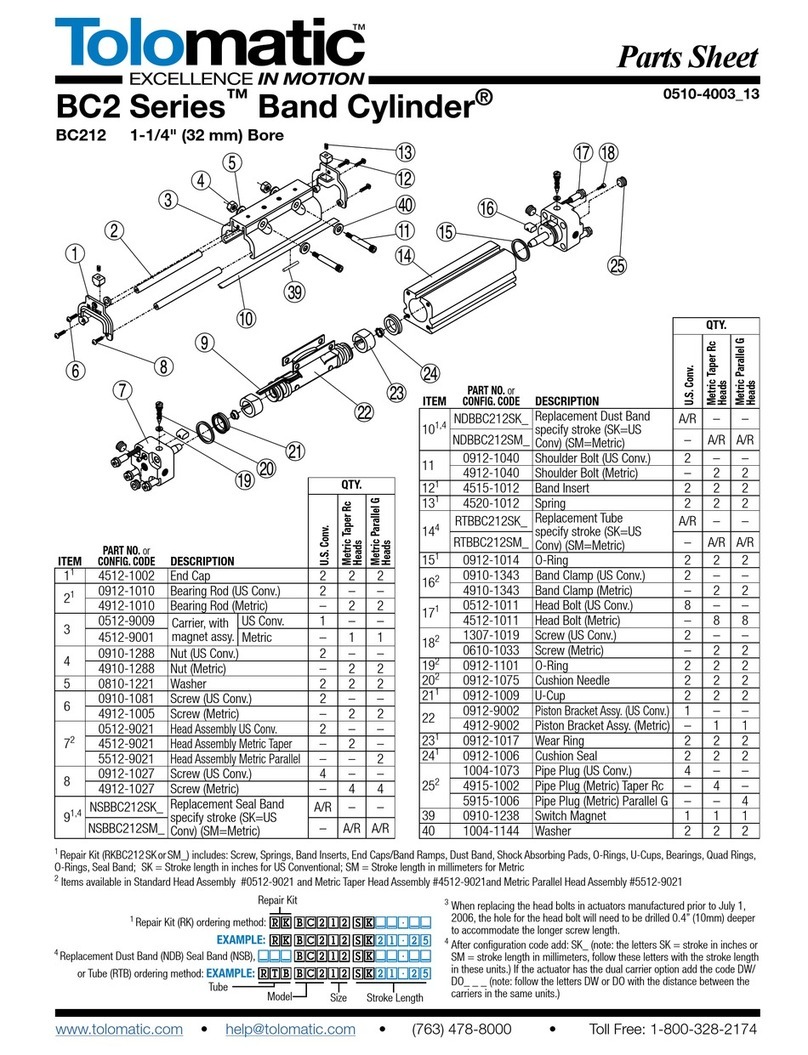

This manual suits for next models

3

Other Tolomatic Industrial Equipment manuals

Tolomatic

Tolomatic PB208 User manual

Tolomatic

Tolomatic MXP16N User manual

Tolomatic

Tolomatic BC4 Series User manual

Tolomatic

Tolomatic Band Cylinder BC2 Series User manual

Tolomatic

Tolomatic TC15 User manual

Tolomatic

Tolomatic LS10 User manual

Tolomatic

Tolomatic MXP50N User manual

Tolomatic

Tolomatic MXP25PTP User manual

Tolomatic

Tolomatic MXP32N Series Use and care manual

Tolomatic

Tolomatic TC07SS Use and care manual