T

olomatic

•

URL:

http://www

.tolomatic.com

•

Email:

[email protected] •

Fax:

(763)

478-8080

•

T

oll

Free:

1-800-328-2174

Parts Sheet #8100-4110_06_MXP50NpsParts Sheet #8100-4110_06_MXP50Nps MXP50N Instructions – 3

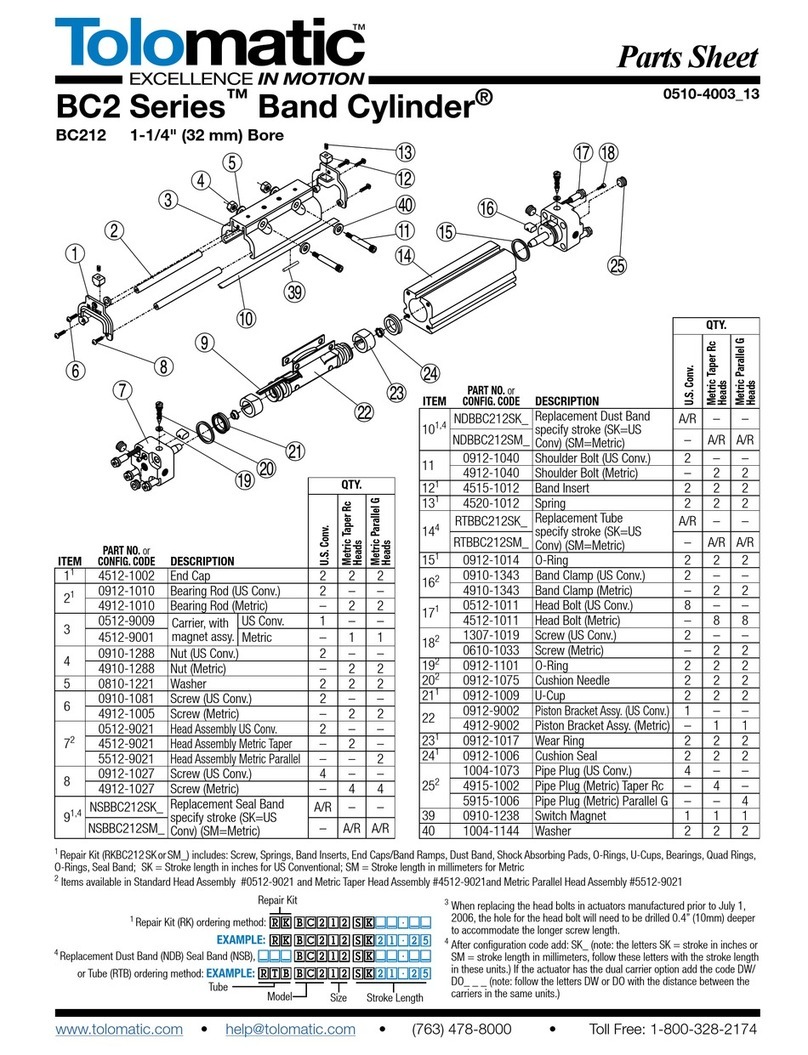

CYLINDER ASSEMBLY INSTRUCTIONS

1. CLEAN AND LUBRICATE

Thoroughly clean all components, particularly the Tube(1) Bore, Tube

Slot, Sealing Band (4) and Dust Band(3). Thoroughly lubricate the

Tube Bore with a thin, uniform layer of RheoGel TEK664 grease.

2. PISTON BRACKET ASSEMBLY

With the Piston Bracket(5) in hand, install the Band Ramps(6), with

small end down, so the ends on each side snaps into the hole of the

Piston Bracket. Slide the Pistons(10) into the Piston Bracket(5) so

the threads on the Piston align with the holes in the Piston Bracket

and secure using Screws(19).

Verify surface of Piston is behind the surface of the

Piston Bracket in both places as shown in diagram.

If not aligned properly the Seal Band(4) life may

be shortened.

Install new lubricated U-Cups (8) (seal lips facing out), and Cushion

Seals(9)(small end facing out).

3. INSTALL SEALING BAND

CAUTION: Metal edges of Sealing Band are sharp. Exercise caution

to avoid injury to yourself while installing. Handle Sealing Band with

care. Do not damage edges while handling.

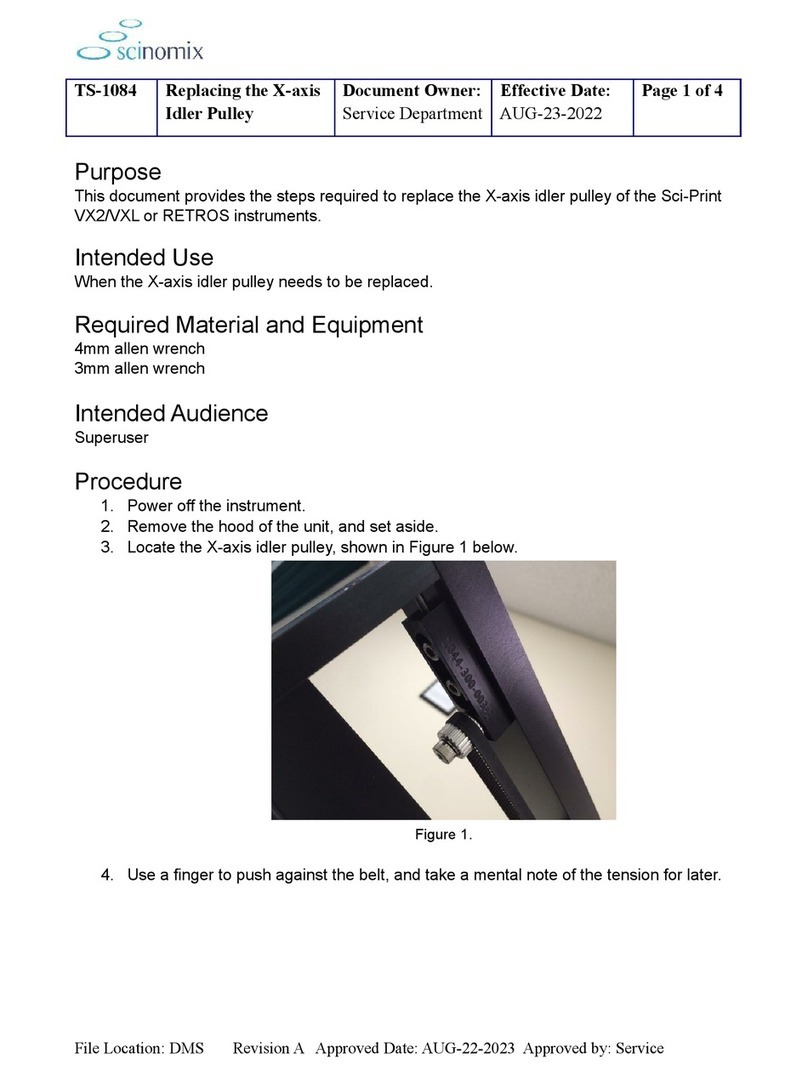

Insert Sealing Band (4) into Cylinder Tube(1) by laying the

Band out along the length of the actuator and passing it

sideways through the slot in Tube. With rubber side facing

up(ground side facing down), position the Seal Band so there

is enough sticking out the end of the Tube as long as a Piston

Assembly.

4. INSTALL PISTON ASSEMBLY

Place generous amounts of grease around bore of Tube(1) and on

exterior surfaces of both Wear Rings(14) on Pistons(10), U-Cups(8)

and Band Ramps(6).

Create a Seal Band Guide Tool by using the 12-inch length of Seal

Band included with repair kit(without rubber), or cut a short length

of the old Seal Band. (Remove the rubber along the entire length of

the Seal Band Guide Tool if needed.) At one inch from one end of the

Seal Band Guide Tool, bend slightly upward. The bend helps to guide

the Seal Band Guide Tool through the Piston Assembly. Determine

which end of the Piston Assembly is going to be inserted into the

Tube(1) first. Insert the bent end of the Seal Band Guide Tool into

the opposite end of the Piston Assembly. Push the Tool through

the opening between the Band Ramp(8) and Wear Ring(14) on the

Piston Bracket(5) and stopping when the Tool exits the end of the

Piston Assembly.

Place the Seal Band(4) on top of the Seal Band Guide Tool. Insert

the Piston Assembly into the Tube(1) until both U-Cups are captured

by the bore in the Tube. Do not force the Piston Bracket into the

Tube and if the Piston Assembly experiences resistance, use a small

screwdriver to press in the ends of the Band Ramps(6) where enter-

ing the Tube. Allow the Seal Band (4) to pass through the Piston

Assembly. Once the Seal Band is though the Piston Assembly, pull

the Seal Band Guide Tool out of the Piston Assembly. Continue

inserting the Piston Assembly into the Tube until the 2nd U-Cup is

inserted into the bore of the Tube.

Slide new Wipers (12) into the groove on the Piston Bracket(5) until

flush with end. Manually move the Piston Assembly the length of the

Tube until the end of the leading U-Cup extends out of the Tube. Wipe

off any excess grease from the end of the Piston Assembly and the

Tube. Move the Piston Assembly so the U-Cup back into the Tube bore.

Note: If Tube and Piston Assembly were greased properly, excess

grease should be present as the Piston exits the end of the Tube. If

there is no excess grease present, remove the Piston Assembly and

re-grease the Tube, then re-install the Piston Assembly.

5. INSTALL HEADS

CAUTION: Twisting the Head (16) during installation may cut the

O-Ring(17) resulting in excessive leakage during operation.

Install new lubricated O-Ring(17) onto each Head(16). Position

Piston Assembly near the end of the Tube in which the Head is being

installed. Position or trim the Seal Band (4) so 1.25" (31.8mm) is

protruding from the end of the Tube(1). Use a razor blade to cut the

rubber along the end of the Tube then remove all rubber outside the

end of the Tube. Keep the rubber on the Seal Band aligned with the

end of the Head(16). Install Head into Tube using a slight up and

down rocking motion(not side-to-side or twisting) until the Head

is flush with the end of the Tube. Secure Head to Tube by install-

ing Head Screws(15) applying a torque of 190 in-lbs(21.47 N-m).

Verify rubber on Seal Band(4) is still aligned with end of Tube. If not,

use needle nose pliers to pull on Seal Band until aligned. Place Band

Wedge(23) with point of Set Screw down into slot of Head and on

top of Seal Band. Push Band Wedge so it is against the end of the

Tube. Secure Band Wedge with Band Clamp(20), FHCS(22) and Set

Screws(21). Make sure hole in Band Clamp aligns with the Cushion

Needle(25) in Head.

Move Piston Assembly to other end of the Tube and repeat the steps

above to install the other head. Trim Seal Band with tin snips if

needed to achieve 1.25"(31.8mm) from end of Tube. While pulling

Seal Band tightly with needle nose pliers, use razor to cut rubber at

the end of the Tube. Remove rubber from the end of the Seal Band

to the cut just made. Install the Head (16) to the Tube and secure

with the Head Screws(15). Use needle nose pliers to pull on the

Seal Band removing any slack and aligning the rubber on Seal Band

with the end of the Tube. If rubber is past end of Tube, trim excess

rubber. If rubber is not up to end of Tube, pull on Seal Band with

needle nose pliers to remove slack. Secure Seal Band with Band

Clamp, FHCS and Set Screws. Once both ends of the Seal Band

are secured, manually move the Piston Assembly the entire length

of the Tube two times to see if there is any slack or issues with the

Seal Band.

6. INSTALL AND SECURE DUST BAND

Position the Piston Assembly at mid-stroke of the Cylinder. Slide Dust

Band(3) through the upper slot of Piston Bracket(5) and lay on top

of the cylinder tube slot. Position the Dust Band 1.25" (31.8mm)

from each end of Tube. Install End Caps(7) using SHCS (11) into

ends of Piston Bracket(5). Loosen Set Screws(21) and FHCS(22)

on both ends of the Tube. Slide Dust Band (3) between Band

Wedge(23) and Band Clamps(20). Tighten the FHCS then the Set

Screws to secure the Dust Band. Move the Piston Assembly to each

end of the Tube to verify the Dust Band is positioned properly.

7. CHECK ASSEMBLY

Manually push the Piston Assembly back and forth along the entire

length of stroke to make certain that the cylinder is properly assem-

bled before reconnecting to the pneumatic supply. The Piston

Assembly should move consistently with minimal friction along the

stroke. The Dust Band should not kink at end of stroke. If it does,

loosen Set Screws(18) until kinking is eliminated and retighten.

8. REMOUNT THE CYLINDER ONTO THE MACHINE

Be certain any flow controls are in place and adjusted prior to apply-

ing compressed air to the Cylinder.

RUBBER

SIDE

GROUND SIDE