III. Set Function Options and Operating Instructions

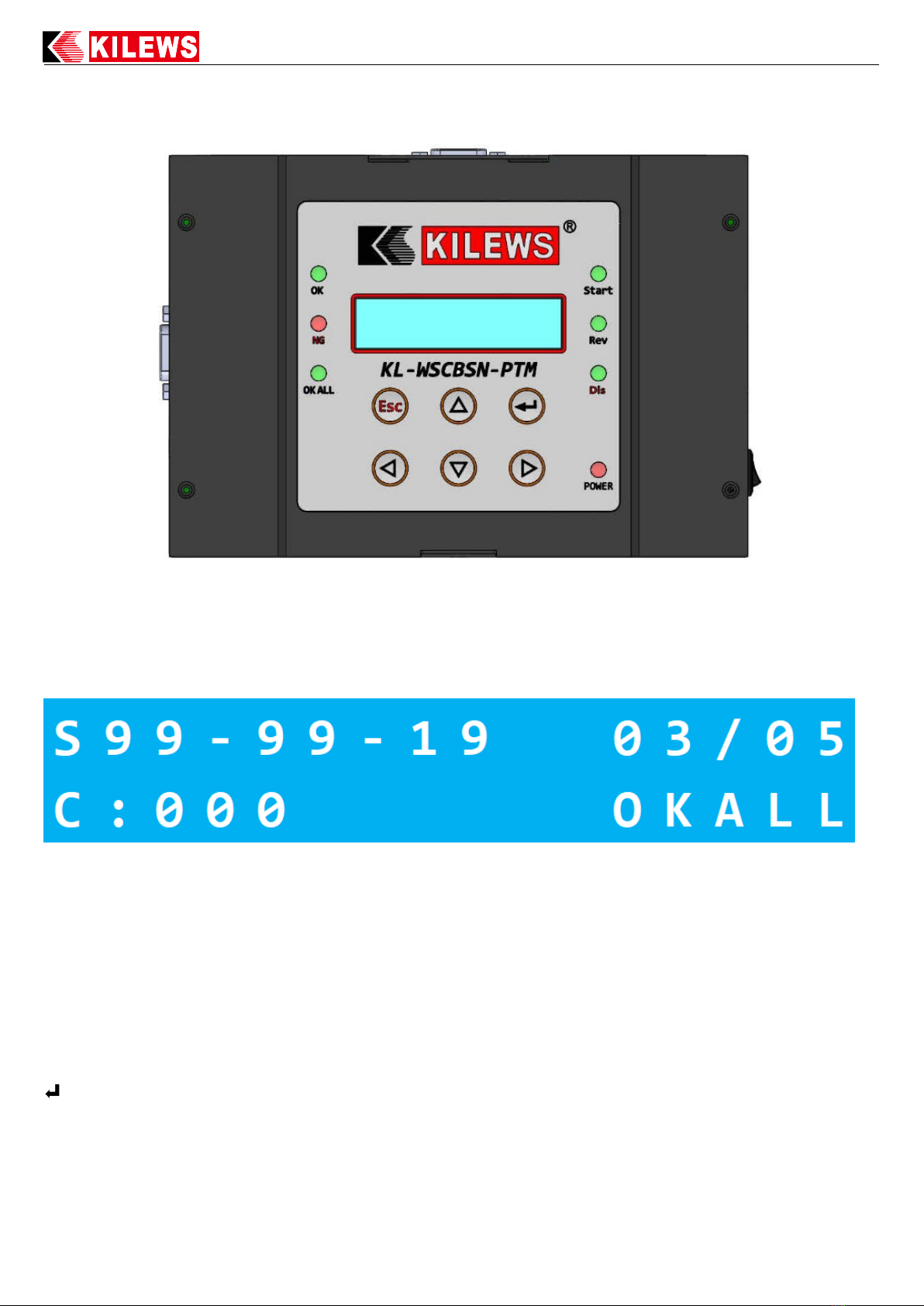

1. After switching on the power, to enter into the function menu, press the “Esc” key on the

panel for 3 seconds, following which password input is required to enter the menu.

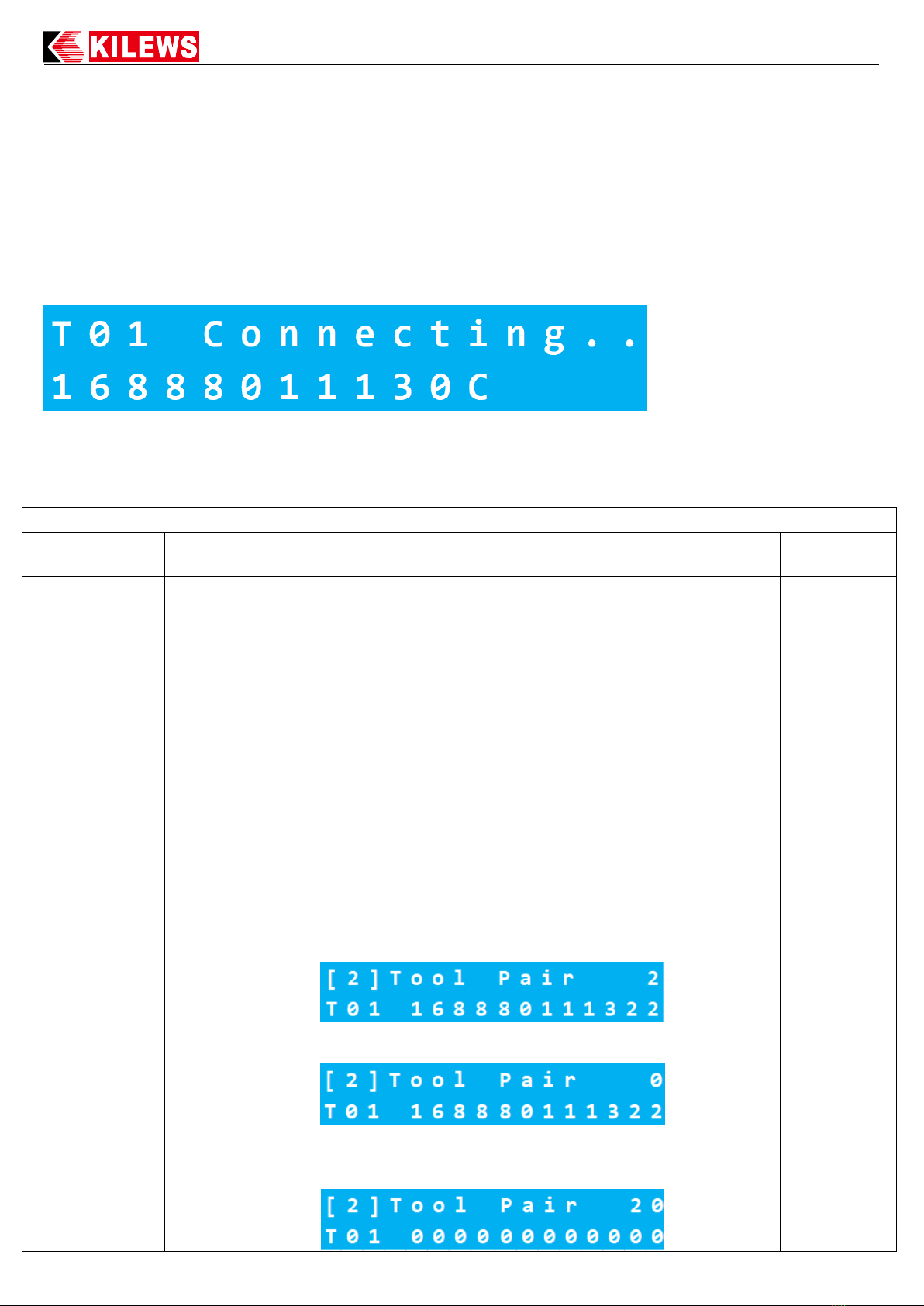

2. Open Bluetooth of PTM and connect PTM to WSCBSN.

3. After setting, press "ESC". It will show PTM connecting as below

4. When the PTM does not run for over 30 mins, it will enter the sleep mode. Press trigger to

activate.

xxxxxxxxxxxx

(1). Search PTM list and find PTM Bluetooth MAC number,

it is able to choose PTM by order via [2] Tool Pair. For

example: A-3 168880111302, “A” mean total 9 PTM, “3”

mean the 3rd PTM, “168880111302” mean MAC number.

Press Up/Down to check, and confirm by Enter.

(2). We suggest to connect PTM to WSCBSN one by one.

Follow first step to detect 2nd, 3rd. WSCBSN is able to detect

19 PTM.

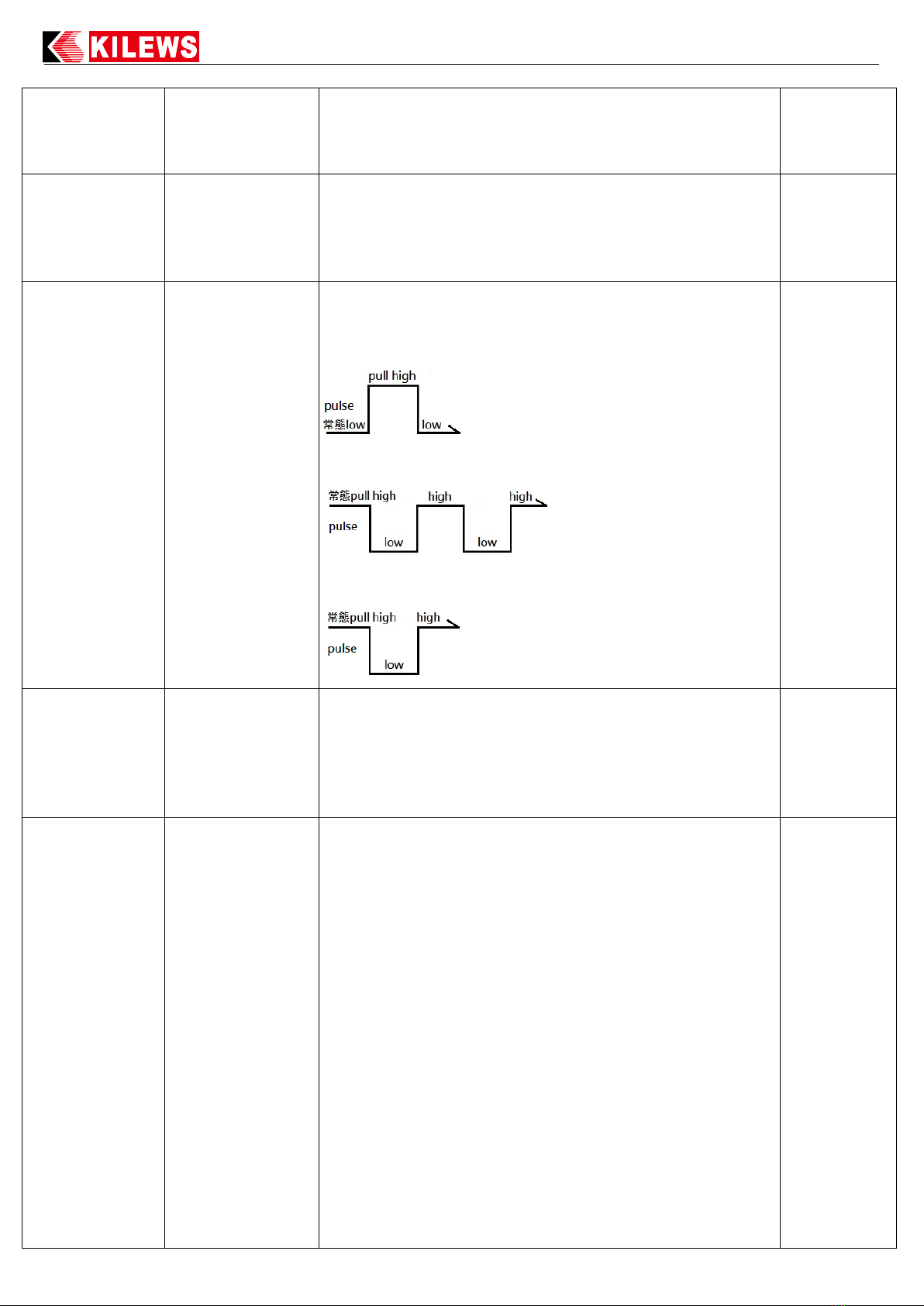

(3). If user take Bluetooth dungle of PTM to WSCBSN, it

will became Master. After user take Bluetooth dungle to

PTM. It have to close PTM Bluetooth and open again. That

Bluetooth dungle will become Slave and able to dected by

WSCBSN by Query Tool function.

MAC number of

Tools

(1). Press left/right to select PTM(T01...T02...etc), and press

enter to let MAC number blink. And then press up/down to

select Tool Pair 1~19 and press enter to save.

(2). While MAC number blink, Tool Pair number become 0,

it means PTM match MAC number completed.

(3). While MAC number blink, select Tool Pair 20 and MAC

number is 000000000000. Press enter the Matched PTM and

its MAC number will be cleared.