6

Gas detection systems must be correctly specified, installed and maintained in order to be effective.

Anyone undertaking elements of this work should have access to the necessary equipment and be able

to demonstrate competence. This will usually mean having passed a training competency course.

International Gas Detectors run training courses for safety survey, specification , installation and

service aspects of hazardous gas detection systems. In addition IGD can supply test equipment and

calibration gases necessary to undertake this work.

1. A zero grade gas usually instrument air or Nitrogen and a suitable calibration gas mixture is required.

Please the following points

2. The correct gas adaptors must be used to apply gases to detectors when zeroing and calibrating.

Incorrect application of gases can affect calibration results

3. Use equipment and gases traceable to a national standard. Any calibration will only be as good as

the equipment and materials used.

4. IGD supply fixed flow regulators for use with IGD calibration gas bottles which supplies gas at

0.5L/Min

Important Notes

Panel Options

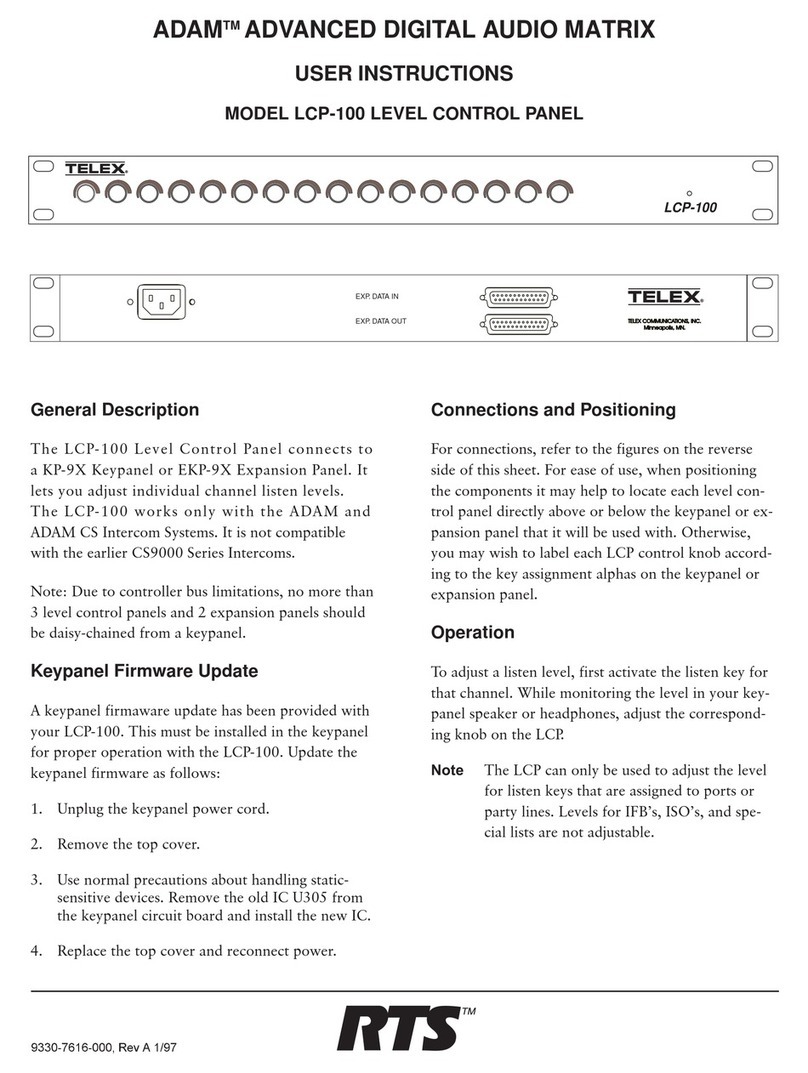

TOCSIN 750 Series Controller

TOCSIN 750 Series Annunciator

Options With:

Display, Relay Output, Digital or

Analogue Input, Flammable Gas Detector

TOCSIN 750 Series Detectors

Flammable Gases, Toxic Gases

Oxygen

TOCSIN 102 Series Detectors 2-WIRE

Flammable Gases, Toxic Gases

Oxygen For ATEX Applications

Part Number

TOC-650-24

TOC-650-150

TOC-650-150BB

TOC-650-150B1

TOC-650-300

TOC-650-300B1

Description

24V DC Control Panel No Internal PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

110/230V AC Control Panel 150W PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

110/230V AC Control Panel 150W PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

Built in 1.2AH Battery Backup

110/230V AC Control Panel 150W PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

Built in 5AH Battery Backup

110/230V AC Control Panel 300W PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

110/230V AC Control Panel 300W PSU

Standard Features inluding

2 x 8 RGB Display and Jog Wheel

4 Relays, 4 Highways

Built in 5AH Battery Backup