23

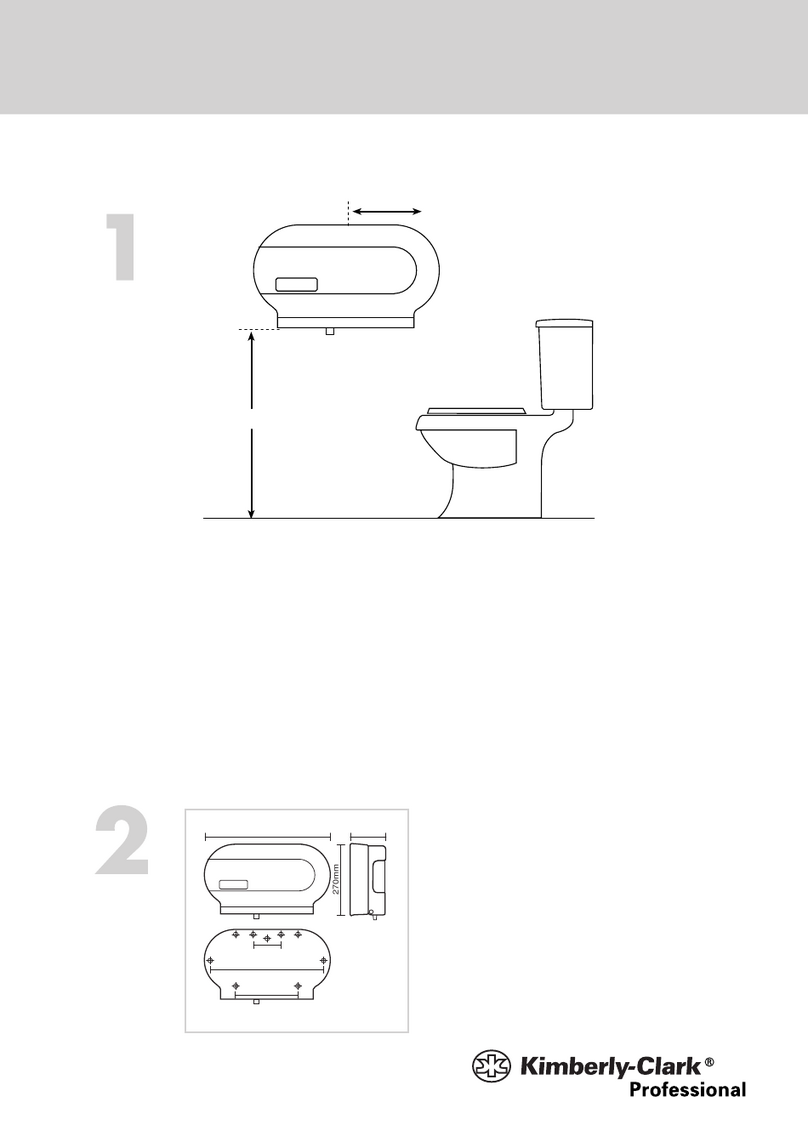

Fig. 2

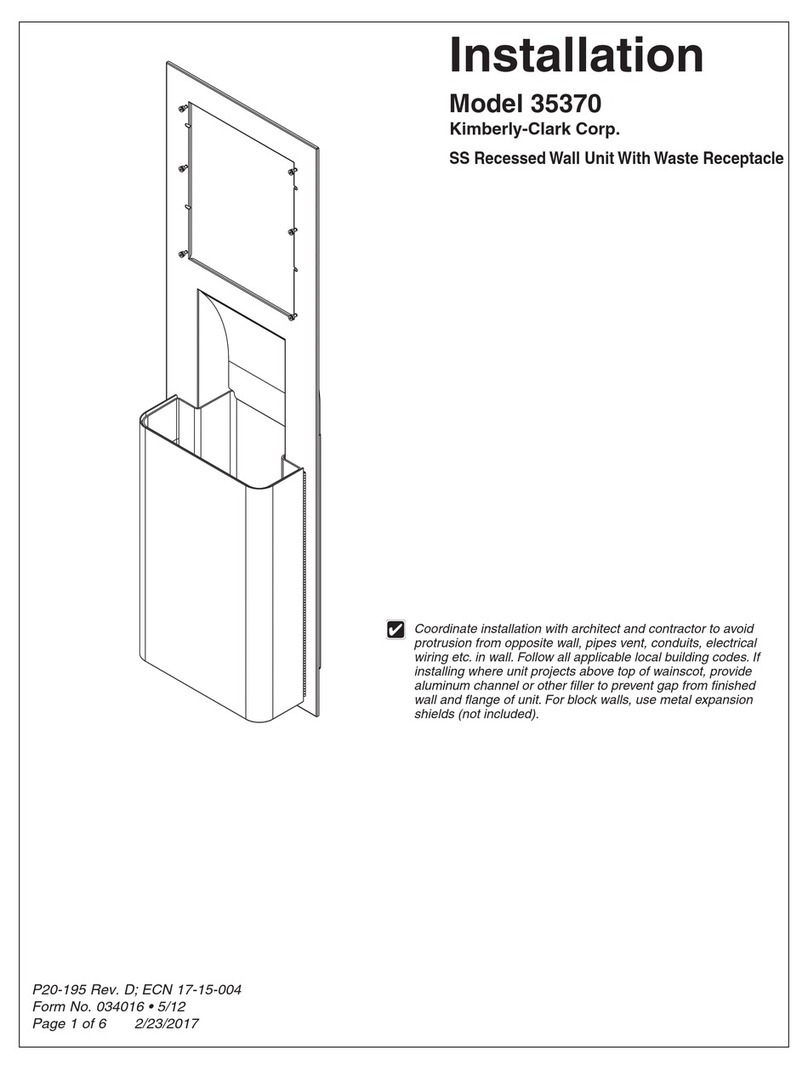

Dispenser Installation

Materials Required: • Power Driver

• Phillips Bit

• Phillips Screwdriver

• Cutting Fluid

• 1” Diameter Hole

Saw (Diamond Bit

for Granite or Stone)

• Clear Silicone Caulk

• Safety Glasses

• Magic Marker

Note: If drilling of the countertop is required, be sure to use an approved KC Installer or other

trained professional.

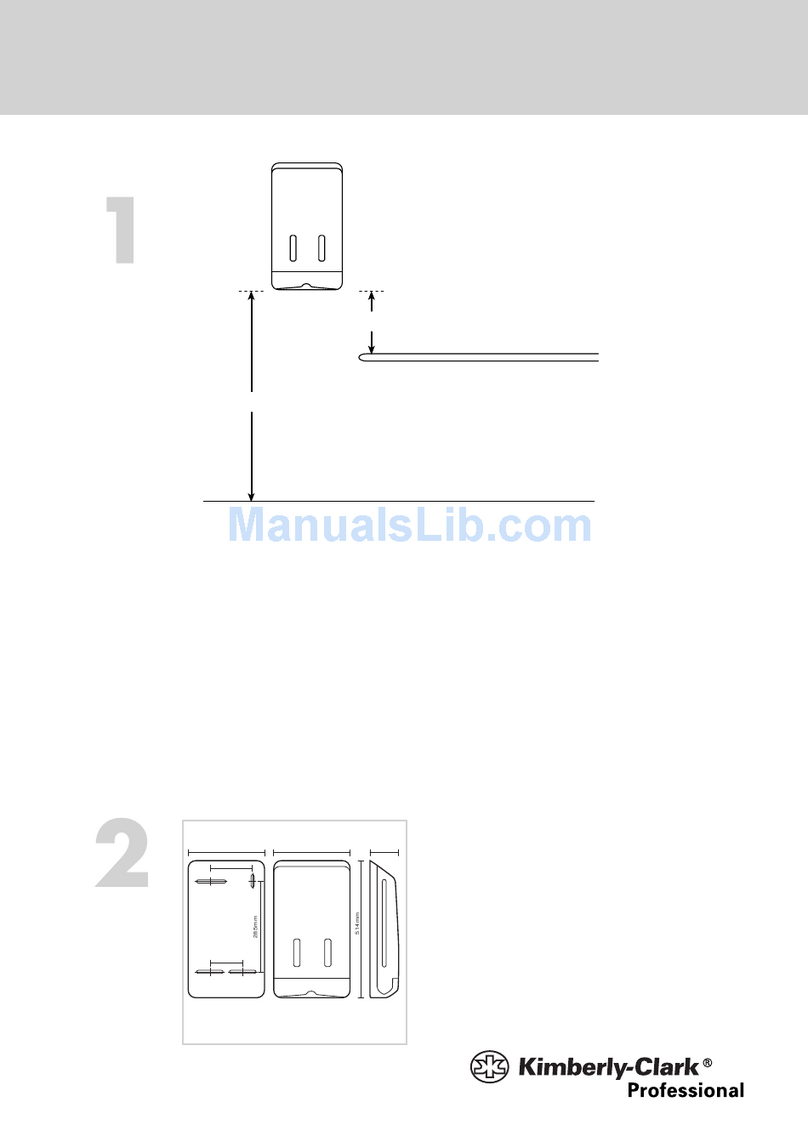

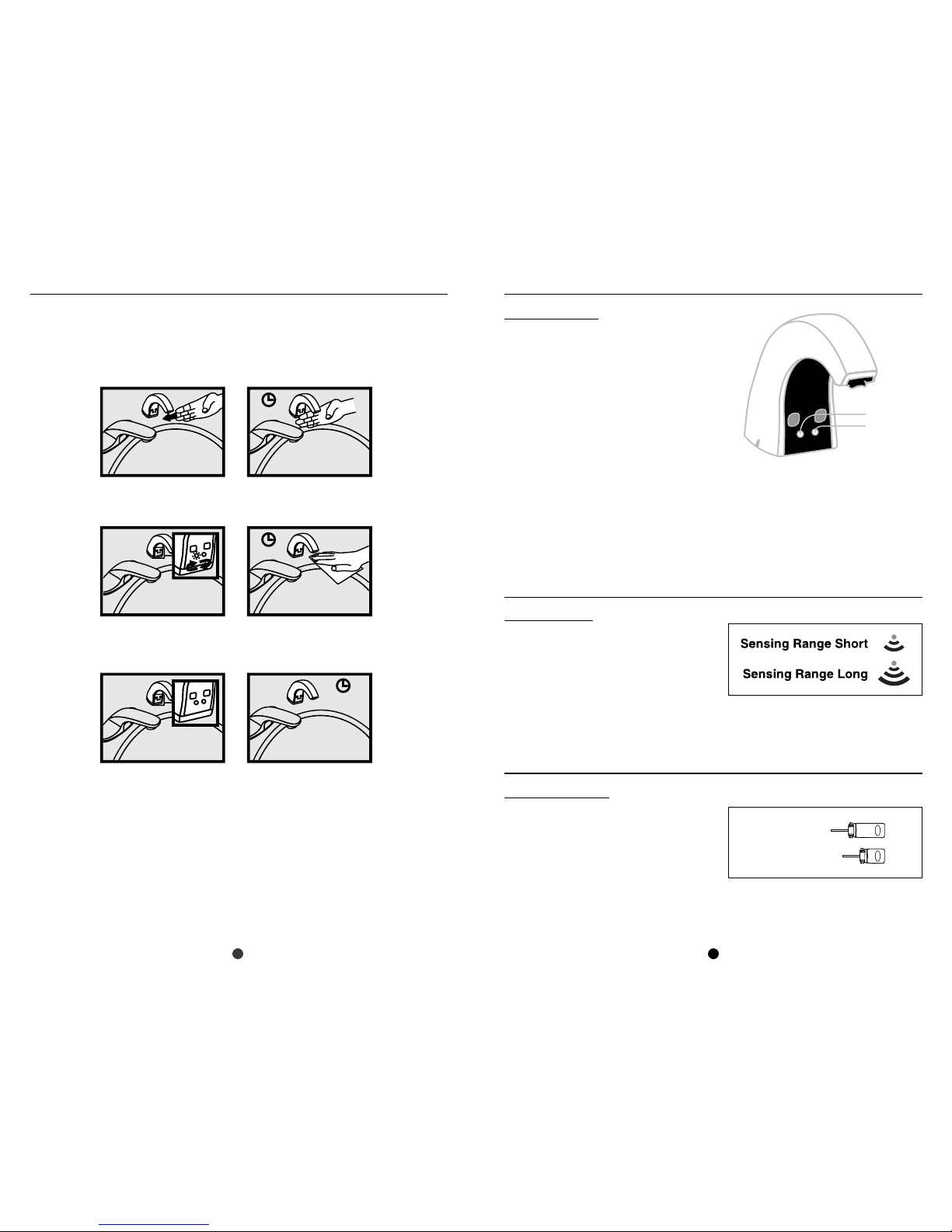

Fig. 4

1. If a 1” hole already exists on the

countertop, go to step 6.

2. If drilling a new hole, it is recommended

the hole be away from the faucet,

preferably in the 10 o’clock or 2 o’clock

position (see gure 1).

3. Use the plastic template provided to

determine the appropriate position from

the sink’s edge, based on what is under

the countertop, the hole should be drilled.

Note the maximum dimension from the

center of the hole to the edge of the sink

is 3.5 inches (see gure 2).

4. Once the location is determined, trace

the 1” diameter hole using a marker

(see gure 3).

5. Drill a 1” diameter hole in the marked

location (see gure 4). Clean the area

around the hole so it is free of debris.

IMPORTANT – Use the proper drill bit for

your surface and use cutting uid to cool

the bit during drilling.

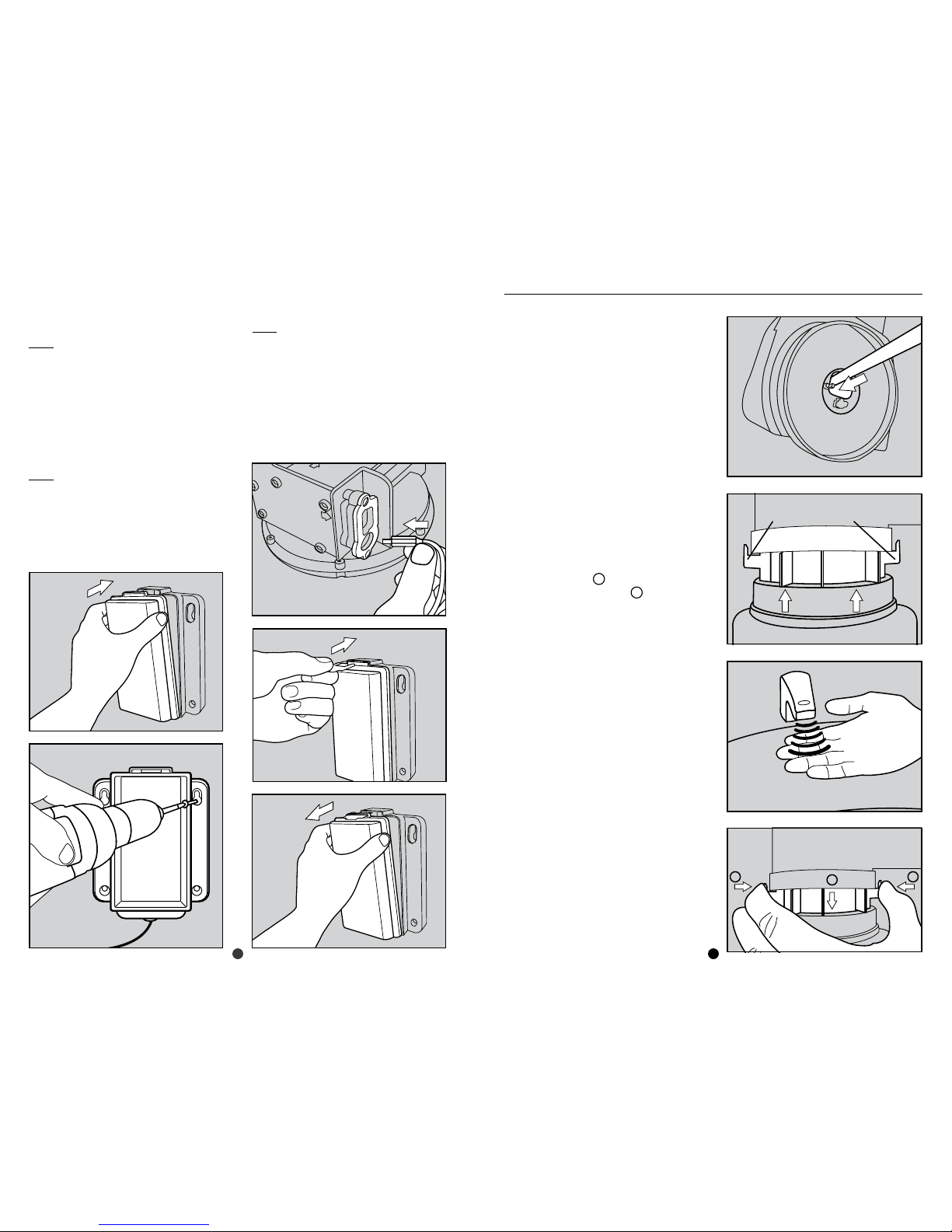

6. Insert the support shaft thru the hole in

the countertop (see gure 5).

7. Rotate the support shaft so the arrow

points toward the sink (see gure 6).

8. Remove the adhesive liner from the

plastic support ring and from the

underside of the countertop, slide it

thru the support shaft and push it until

up until it sticks to the underside of the

countertop (see gure 7).

Note: If the support ring will not sit flush

with the underside of the countertop

due to interference with the sink, use

the optional split support ring provided

instead.

9. Break away the center portion of the

plastic template and discard the piece

removed (see gure 8).

10. Place the plastic template over the

support shaft. Rotate the support shaft

until the exact location of the soap

discharge head is reached. Remove the

template and discard (see gure 9).

11. IMPORTANT – Using a Phillips bit in a

power driver, tighten at full speed the

2 screws on the support shaft until the

plastic heads

break away

. Remove the

remains of the white plastic heads from

the support shaft (see gure 10).

Fig. 1

10:00

Faucet

2:00

Ideal Dispensing

Head Placement

Optional Area

of Installation

Fig. 3

3.5”

Fig. 5

Fig. 9

Fig. 7

Fig. 8

Fig. 6

Fig. 10