1. Prerequired ........................................................................................P 1

1.a - Working principle ........................................................................P 1

1.b - Output signal selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P 1

1.c - Protection tip of the sensor .............................................................P 1

2. Code activation and access to functions...............................................P 2

3. Display and keypad configuration • F100 ..............................................P 3

3.a - Backlight .................................................................................P 3

3.b - Display contrast control .................................................................P 3

3.c - Keypad locking...........................................................................P 4

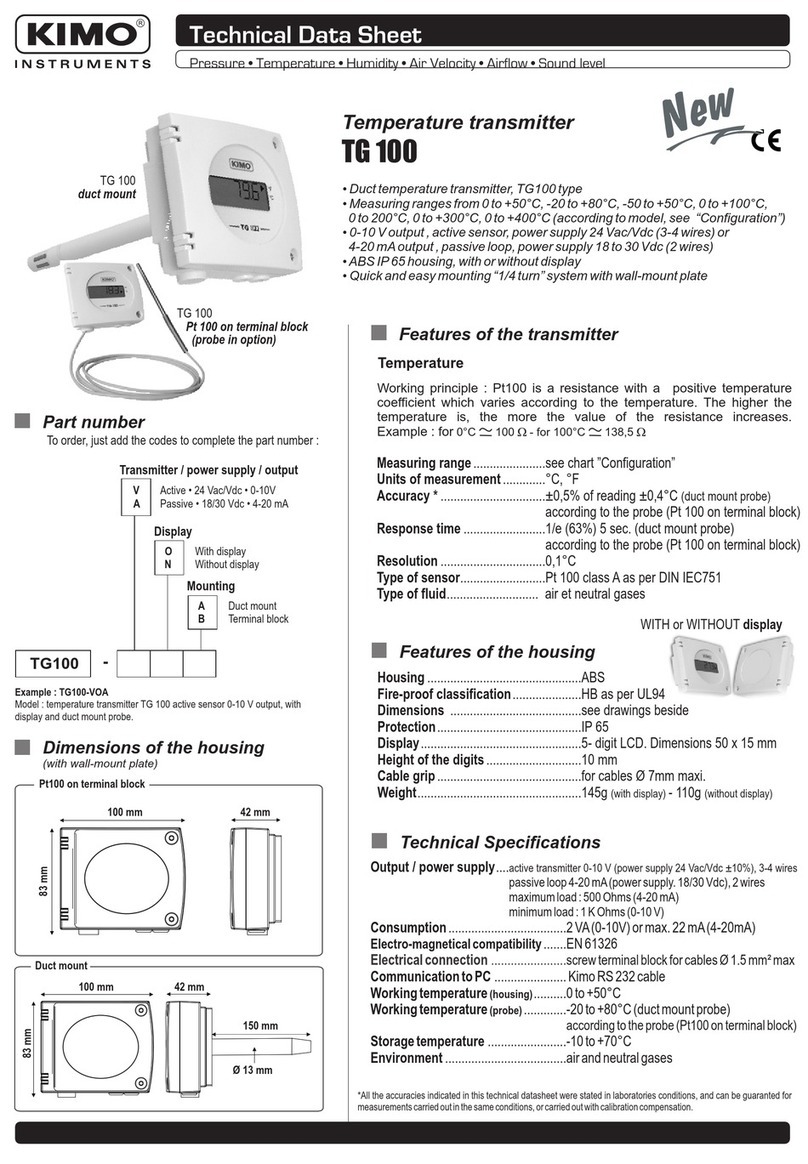

4. Configuring channels and units of measurement • F200 . . . . . . . . . . . . . . . . . . . . . . . . P 5

5. Analogue output management • F300 ...................................................P 6

5.a - Output diagnostics.......................................................................P 7

5.b - Analogue output settings................................................................P 8

6. Relay / Alarm settings • F400..............................................................P 10

6.a - Activation / Deactivation of BEEP alarm..............................................P 10

6.b - Relay security ..........................................................................P 10

6.c - Alarm/relay functions and LED colour codes .........................................P 11

6.d - Channel selection for alarms/ relays..................................................P 12

6.e - Alarm mode details.....................................................................P 13

6.f - Alarm mode selection ..................................................................P 15

6.g - Setpoints and time-delay setting ......................................................P 16

7. Pressure measurement configuration • F500 .......................................P 18

7.a - Pressure measurement integration (CP 200) ........................................P 18

7.b - Autozero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P 18

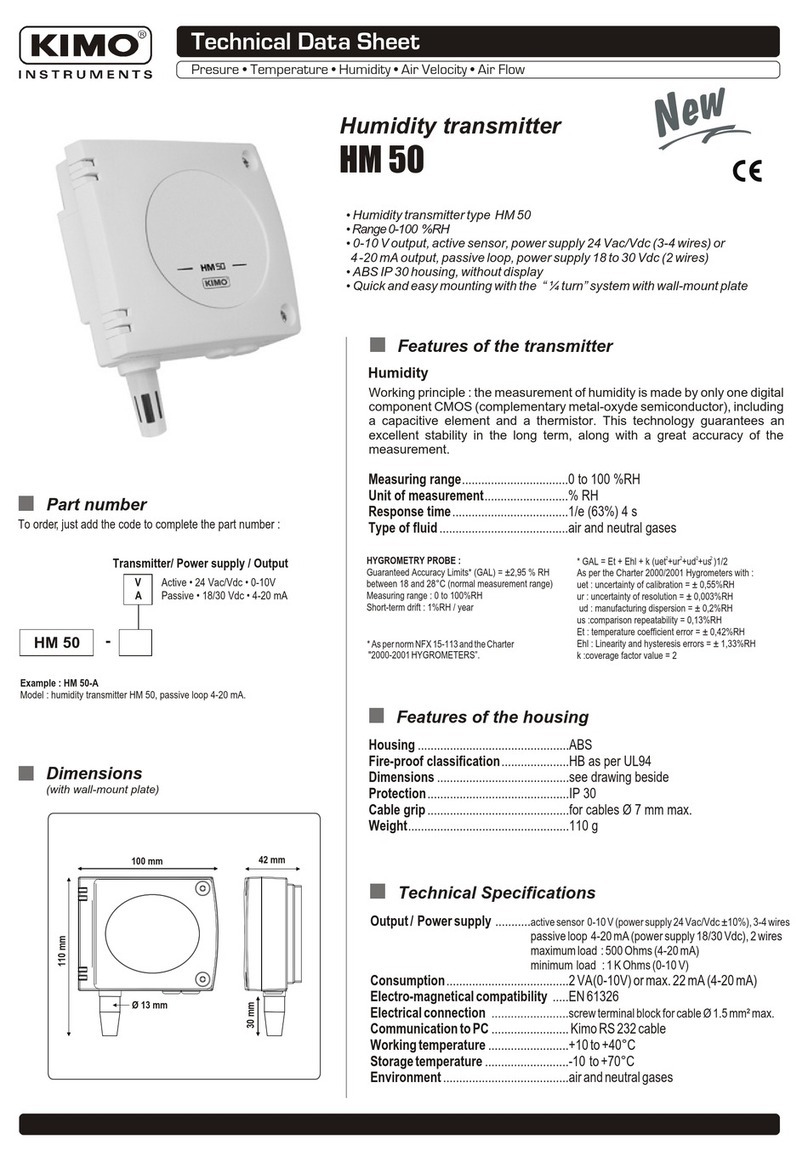

8. Humidity measurement configuration • F500 .......................................P 19

8.a - Offset settings in Humidity and temperature (TH 200) ..............................P 19

9. Air velocity measurement configuration • F600 ...................................P 20

9.a - Temperature compensation (CP 200) ................................................P 20

9.b - Air velocity coefficient selection (CP 200) ............................................P 21

9.c - Air velocity correction coefficient input (CP and CTV 210) ..........................P 22

Table of contents

Class 200 transmitter configuration via keypad