Kinematica MEGATRON MT 3100 S2 User manual

Other Kinematica Laboratory Equipment manuals

Kinematica

Kinematica POLYTRON PT 2500 E User manual

Kinematica

Kinematica MICROTRON MB 550 User manual

Kinematica

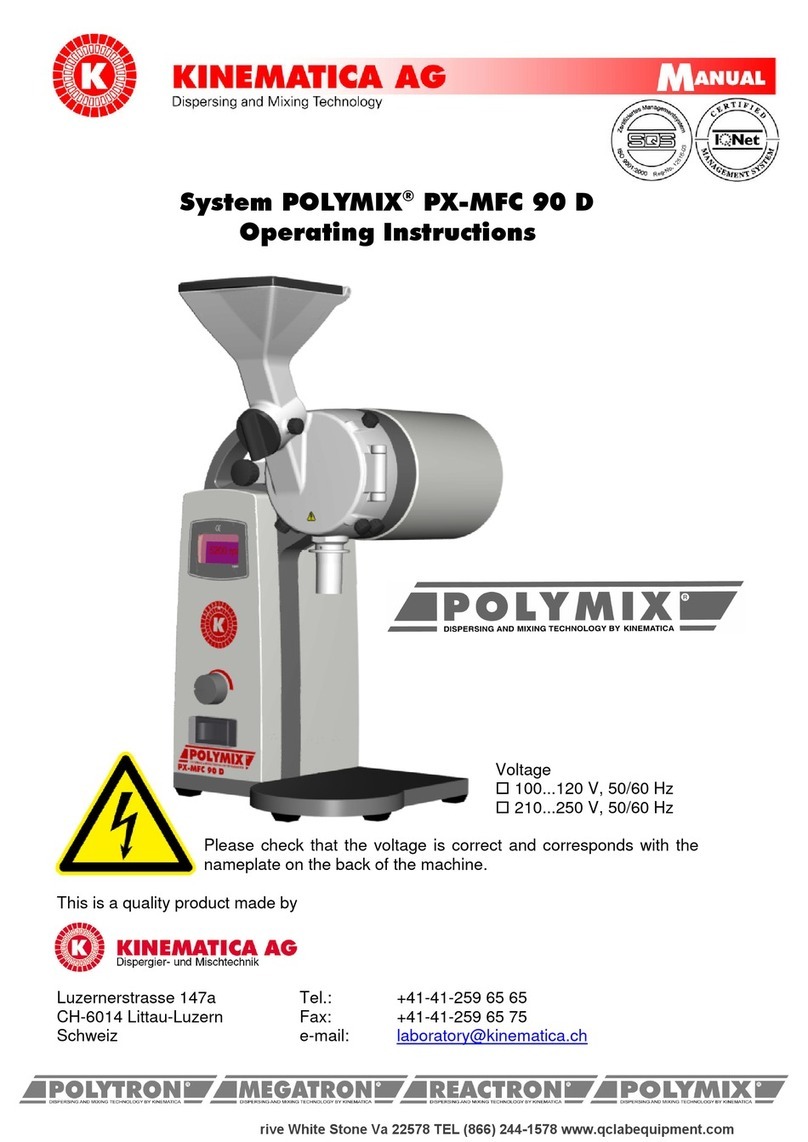

Kinematica POLYMIX PX-MFC 90 D User manual

Kinematica

Kinematica POLYTRON SYSTEM PT 1300 D User manual

Kinematica

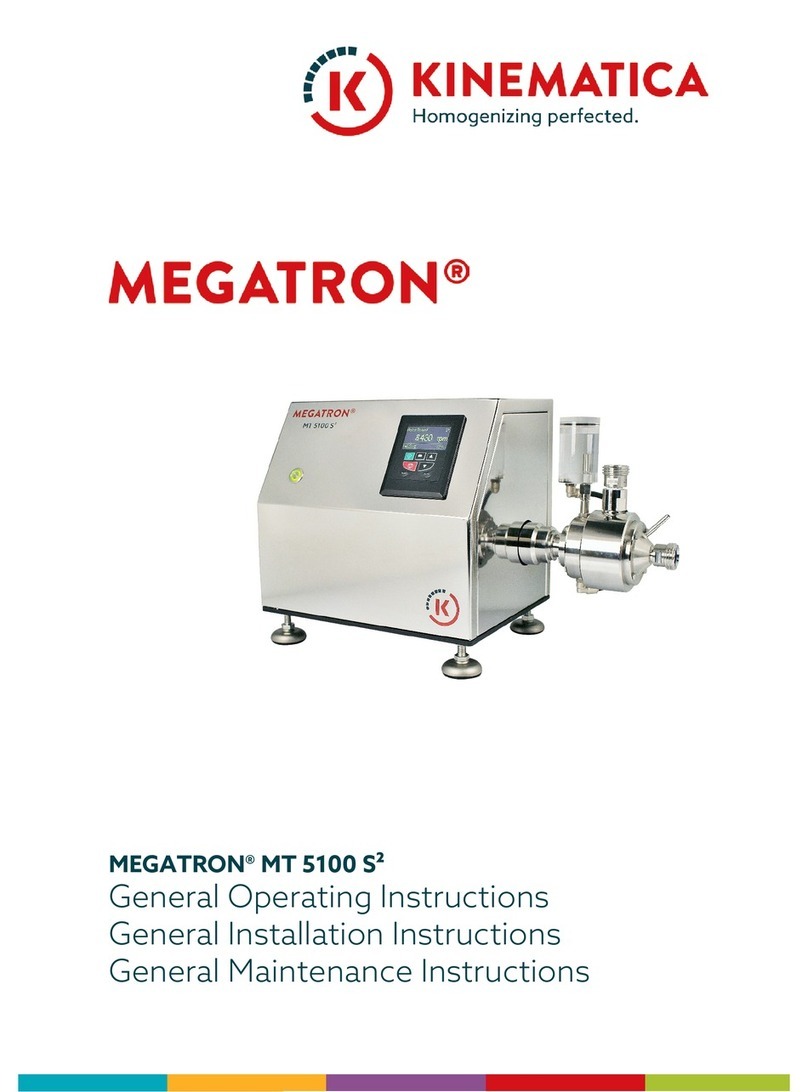

Kinematica Megatron MT 5100 S2 Operating instructions

Kinematica

Kinematica MICROTON SYSTEM MB 950 G User manual

Kinematica

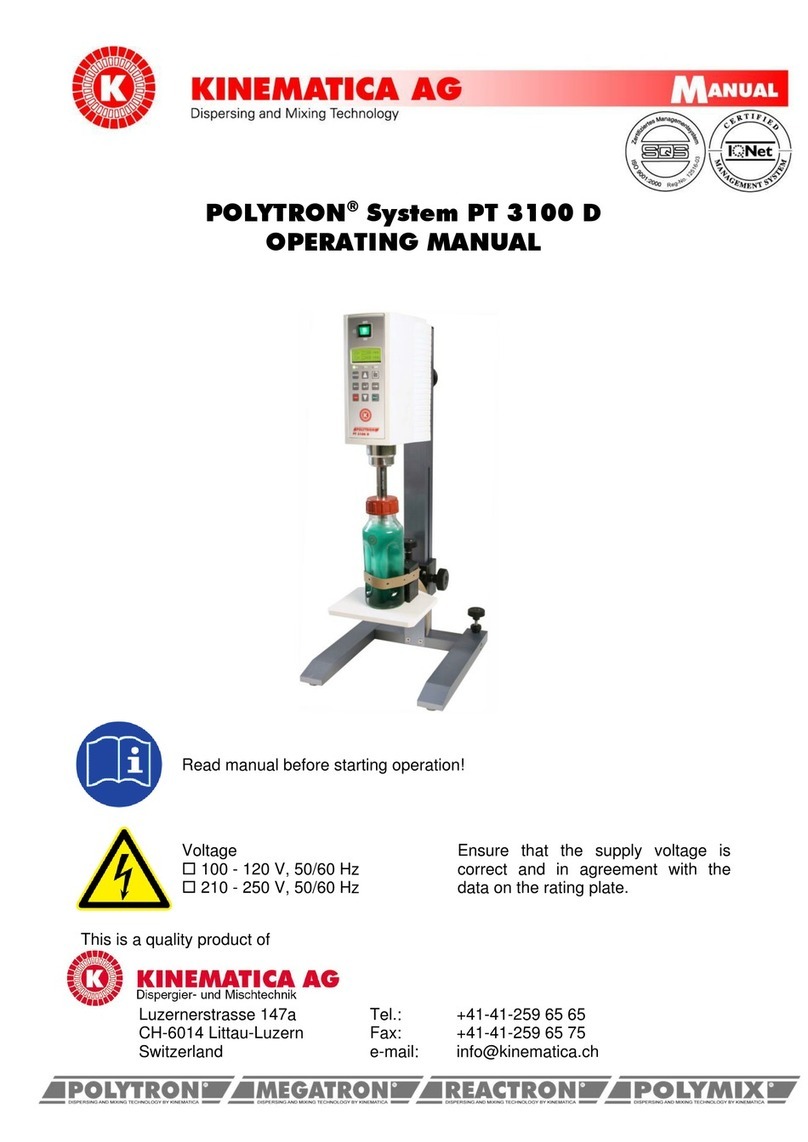

Kinematica POLYTRON PT 3100 D User manual

Kinematica

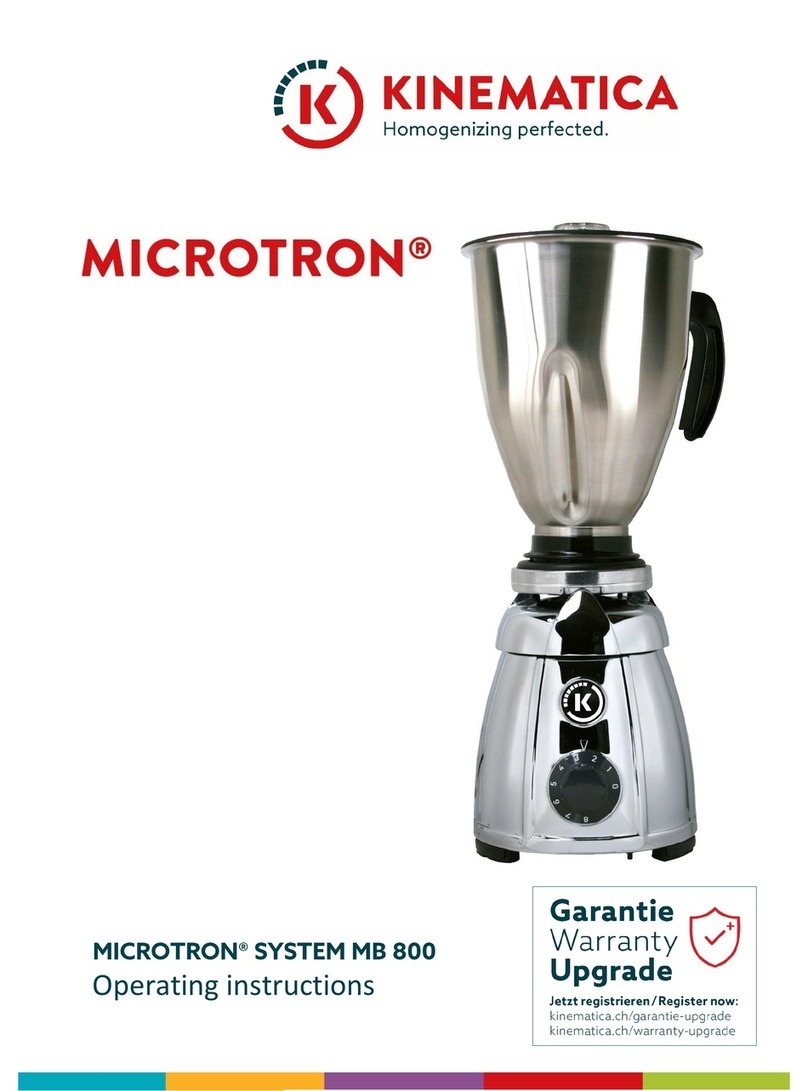

Kinematica Microtron System MB 800 User manual

Kinematica

Kinematica POLYTRON SYSTEM PT 1300 D User manual

Kinematica

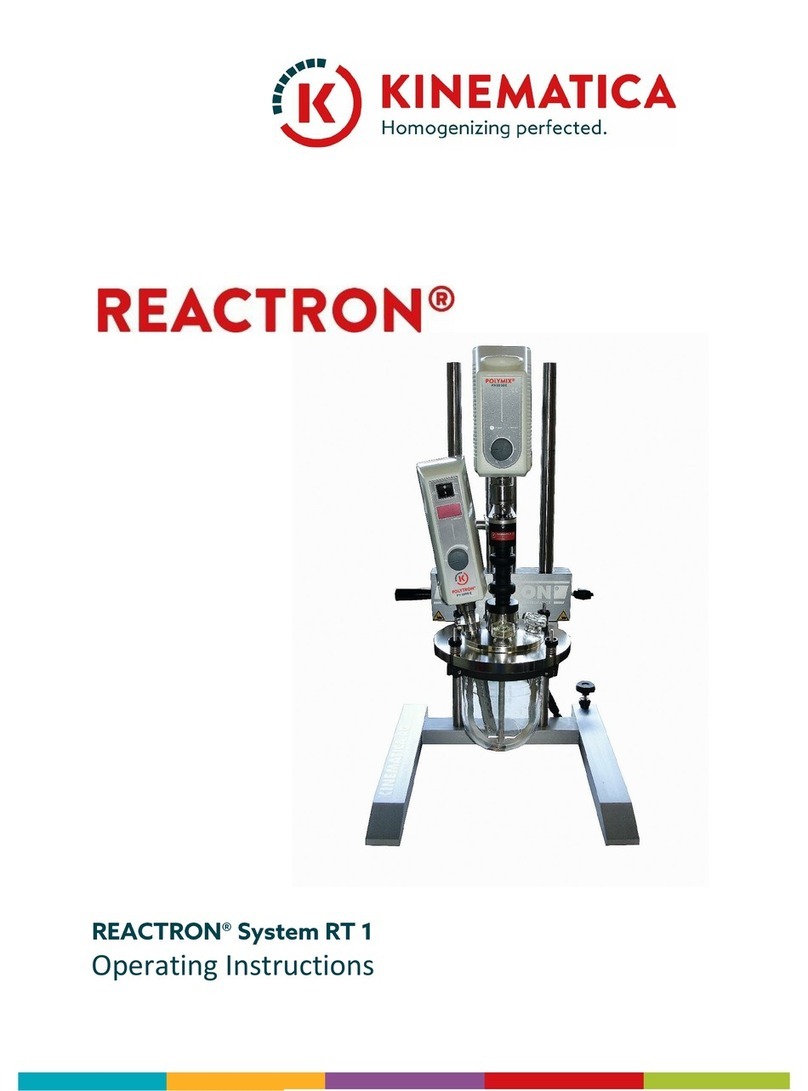

Kinematica Reactron System RT 1 User manual

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual