TABLE OF CONTENT

1 INTRODUCTION..................................................................................................................8

1.1 INTENDED USE................................................................................................................................................9

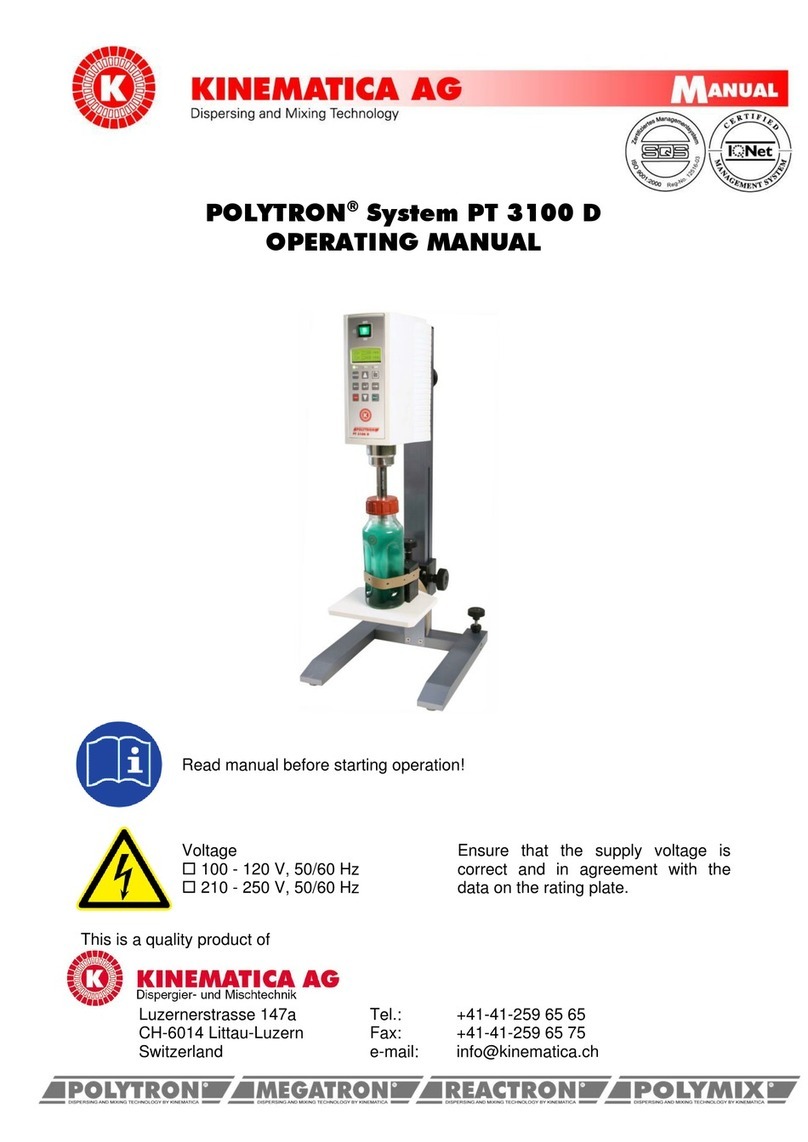

2 DESCRIPTION OF THE DEVICE ..........................................................................................10

2.1 OVERVIEW ..................................................................................................................................................10

2.2 FUNCTION OF THE KEYBOARD ..........................................................................................................................12

2.3 TECHNICAL DATA..........................................................................................................................................12

3 WORKING WITH THE PT 1300 D.......................................................................................13

3.1 UNPACKING.................................................................................................................................................13

3.2 INSTALLATION AND COMMISSIONING................................................................................................................14

4 MAINTENANCE.................................................................................................................16

4.1 MAINTENANCE OF THE BASE STATION...............................................................................................................16

4.2 MAINTENANCE OF THE HANDHELD UNIT............................................................................................................16

5 TROUBLE SHOOTING........................................................................................................16

5.1 ERROR MESSAGES .........................................................................................................................................17

5.1.1 DRIVE OVERLOAD..........................................................................................................................................17

5.1.2 THERMAL OVERLOAD PROTECTION ...................................................................................................................18

5.1.3 BLOCKING PROTECTION..................................................................................................................................18

5.1.4 HALL SENSORS..............................................................................................................................................18

6 ACCESSORY.......................................................................................................................19

6.1 DISPERSING AGGREGATES...............................................................................................................................19

6.2 STANDS ......................................................................................................................................................20

6.3 HOMOGENIZING VESSELS................................................................................................................................20

7 WARRANTY.......................................................................................................................22

8 DISPOSAL..........................................................................................................................23