Table of Contents

1INTRODUCTION ................................................................................ 10

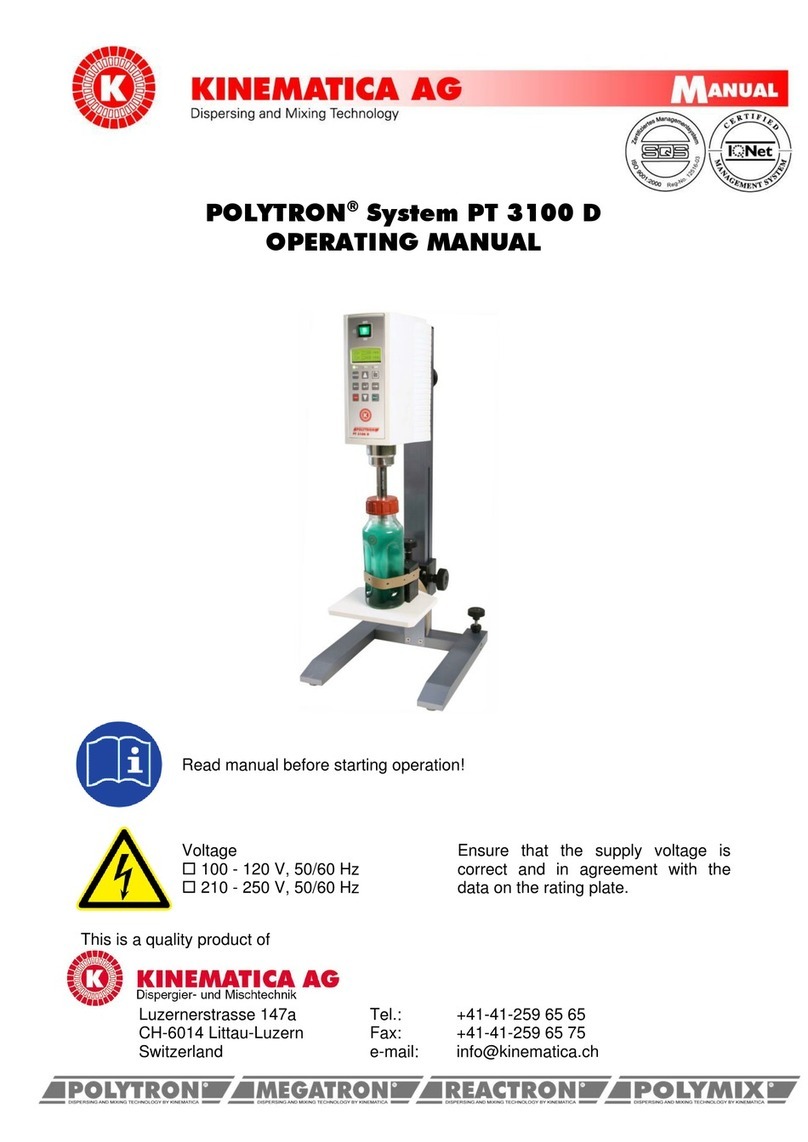

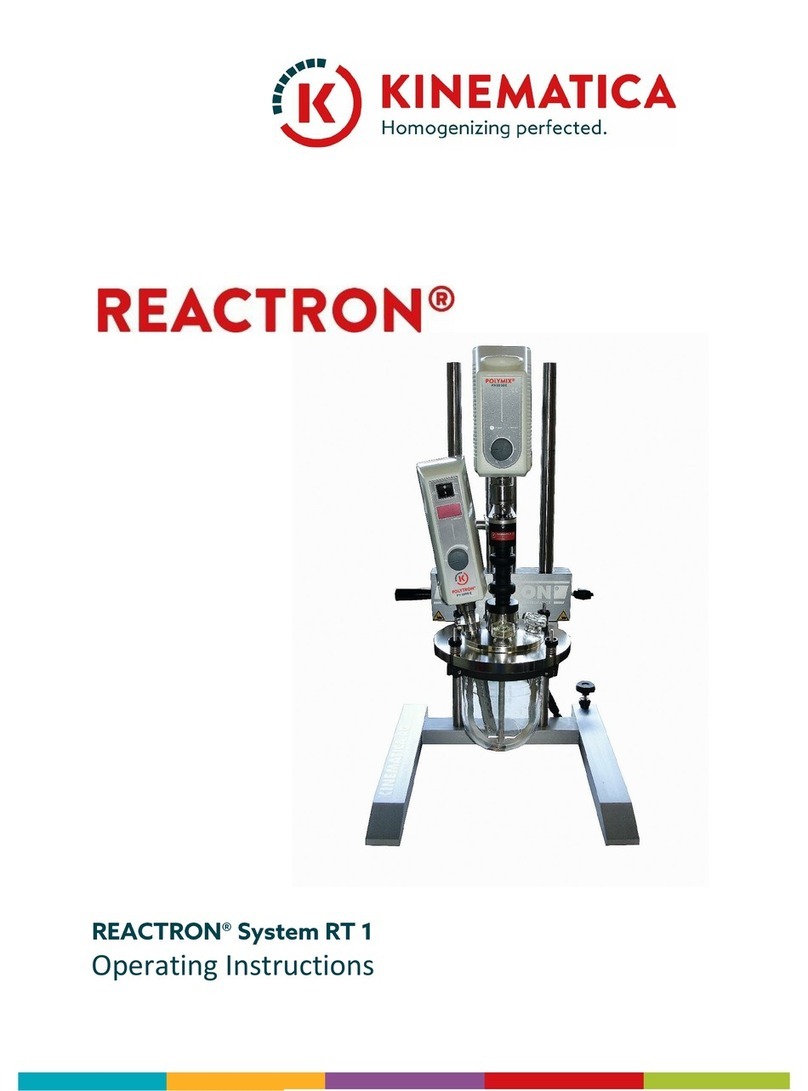

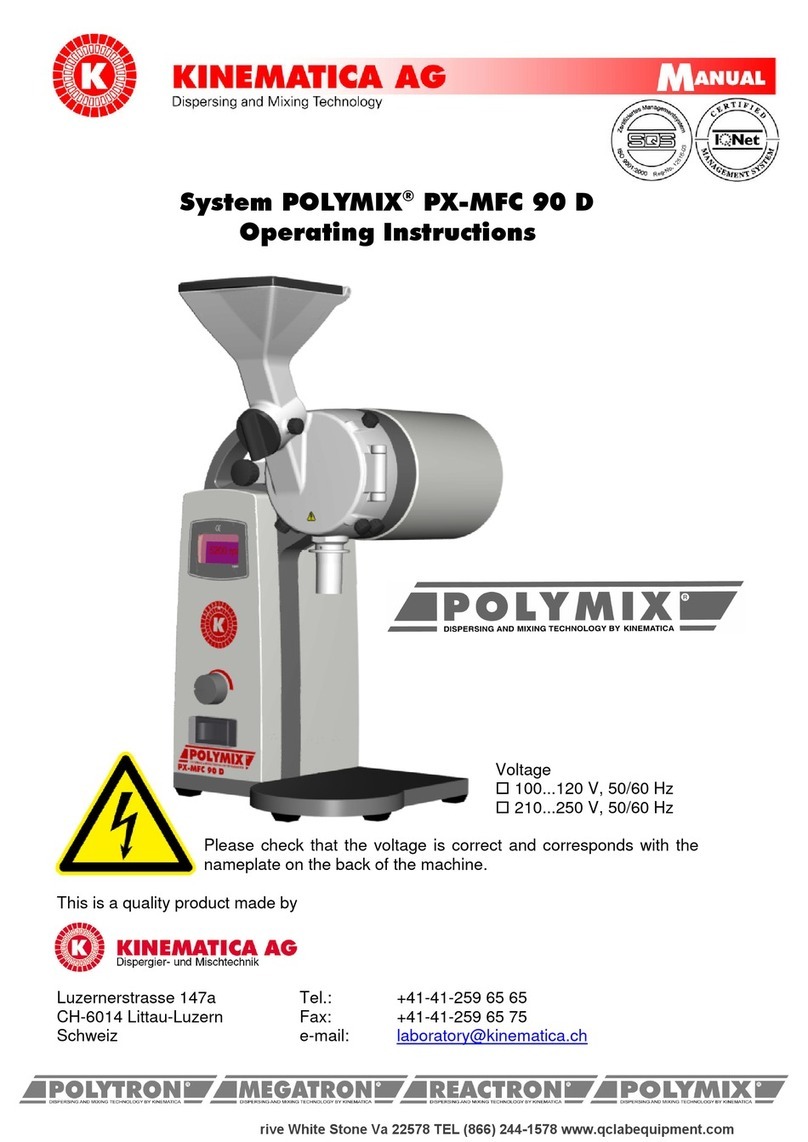

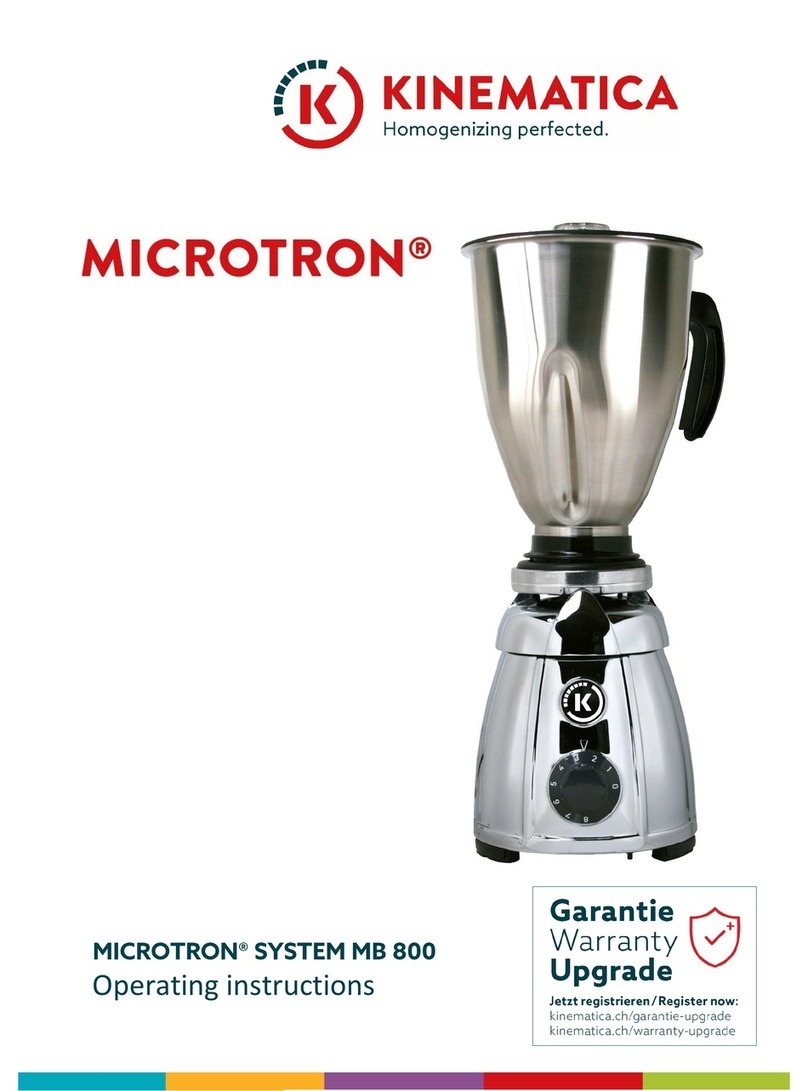

2DESCRIPTION OF THE UNIT.................................................................11

2.1 DRIVE UNIT MB 950 G/MB 950 S...............................................................................................................12

2.1.1 SAFETY CONTROL AND MOTOR PROTECTION ...........................................................................13

2.1.2 CONTROL AND DISPLAY ELEMENTS.............................................................................................14

2.2 MIXAUFSÄTZE MBA ................................................................................................................................ 19

2.2.1 MBA FOR MB 950 G..........................................................................................................................19

2.2.2 MBA FOR MB 950 S...........................................................................................................................20

2.3 SAFETY HUT MBH ....................................................................................................................................21

3INSTALLATION AND START-UP .......................................................... 22

3.1 INSTALLATION .........................................................................................................................................22

3.1.1 MECHANICAL INSTALLATION ........................................................................................................22

3.1.2 ELECTRICAL INSTALLATION ..........................................................................................................22

3.2 START-UP................................................................................................................................................... 23

4CLEANING......................................................................................... 25

5MAINTENANCE WORK ....................................................................... 28

5.1 REPAIR........................................................................................................................................................28

5.2 DISPOSAL /RECYCLING..........................................................................................................................28

6SPARE PARTS .................................................................................... 29

7FAULTS AND REMEDIES...................................................................... 29

8TECHNICAL DATA...............................................................................31

8.1 DRIVE UNITS .............................................................................................................................................31

9WARRANTY....................................................................................... 32