BA PT 6100 D english / Release 1.0 / 24.09.2010 Page 2 of 34

CONTENT:

1INTRODUCTION..........................................................................................................3

1.1 OPERATING INSTRUCTIONS..............................................................................3

1.2 ORGANISATIONAL MATTERS.............................................................................5

1.3 WARNING NOTICES ............................................................................................6

2SAFETY .......................................................................................................................7

2.1 SUMMARY............................................................................................................7

2.2 SAFETYCONCEPT..............................................................................................7

2.3 RESIDUAL DANGERS........................................................................................10

2.4 WARNINGS.........................................................................................................11

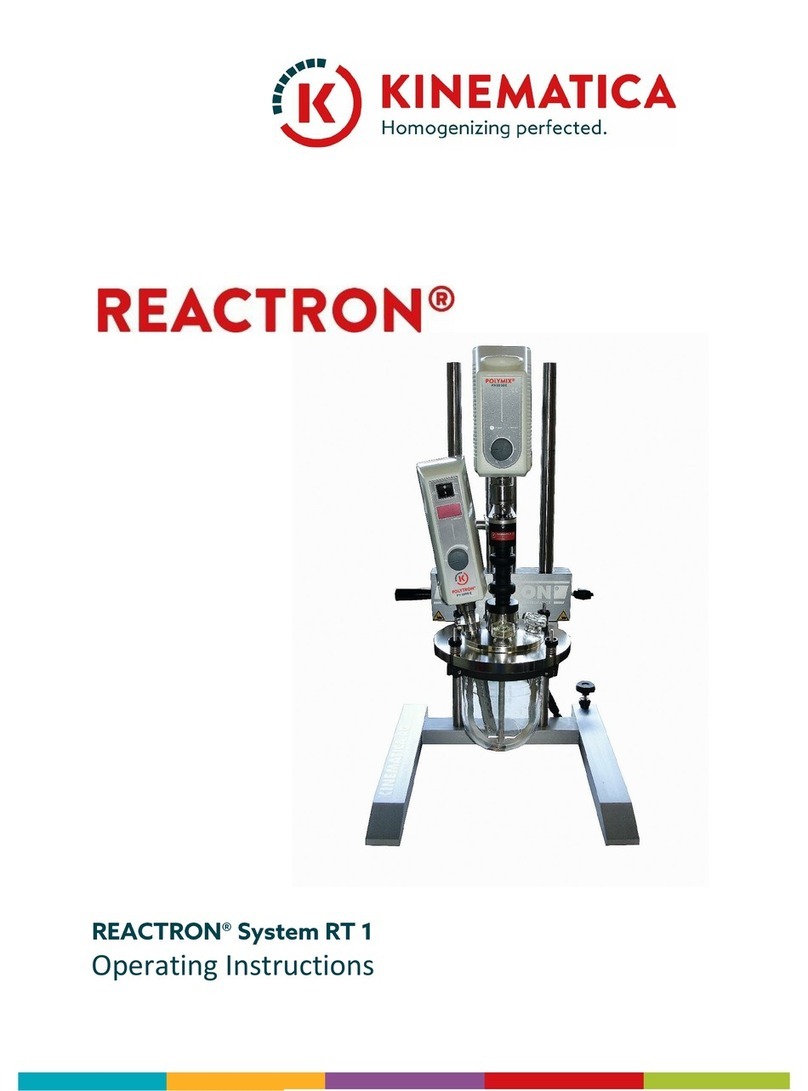

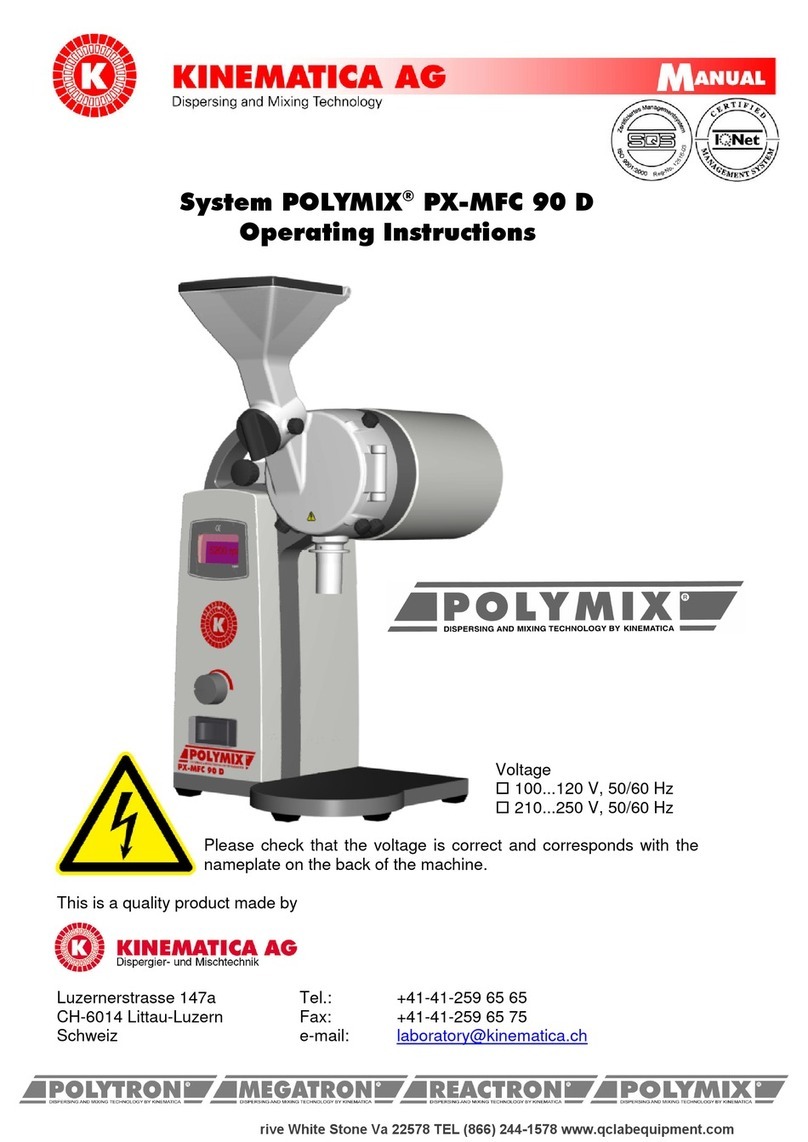

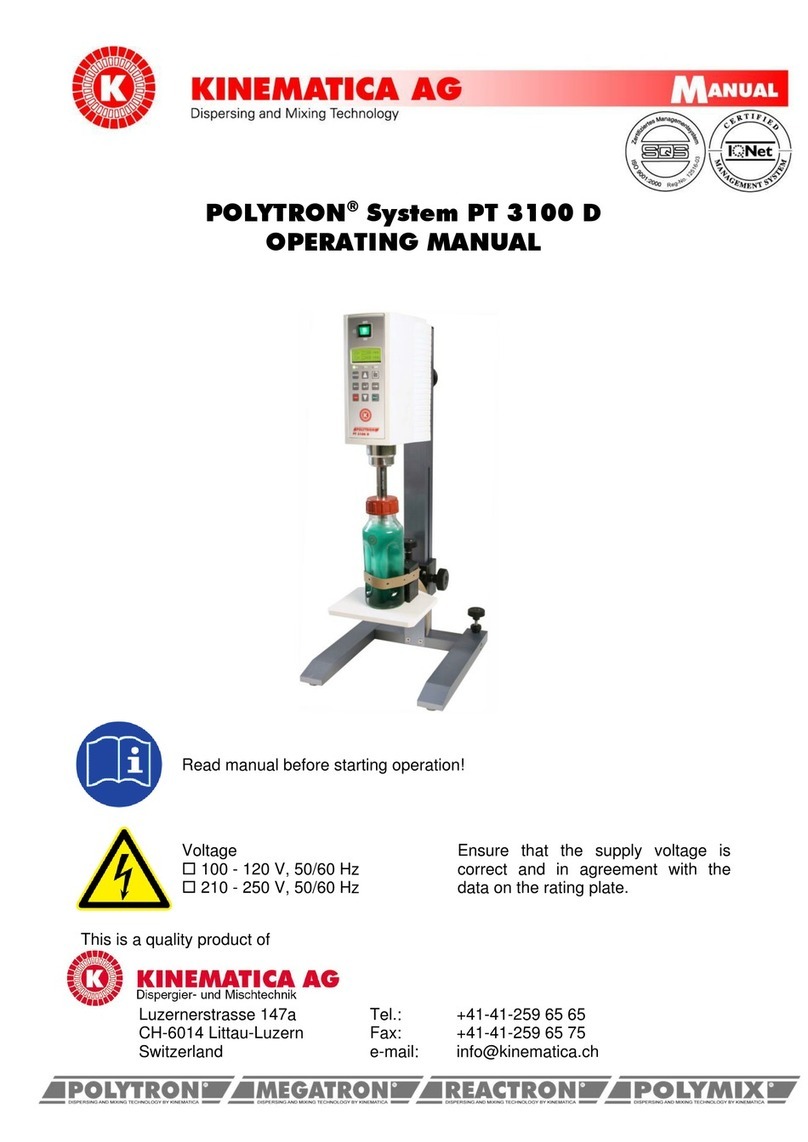

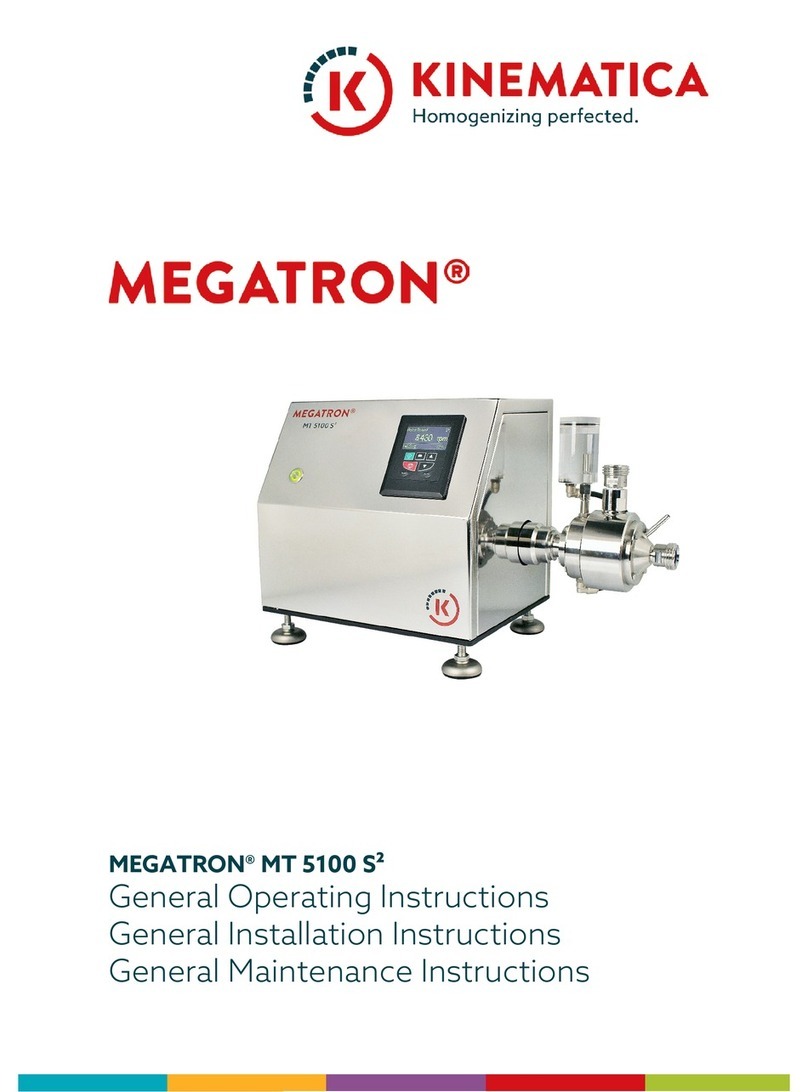

3DESCRIPTION OF THE EQUIPMENT.......................................................................13

3.1 OVERVIEW.........................................................................................................13

3.2 DRIVE UNIT ........................................................................................................15

3.2.1 OPERATION &CONTROL ..............................................................................16

3.3 STANDS..............................................................................................................18

3.4 POLYTRONDISPERSING-AGGREGATES......................................................19

3.5 TECHNICAL SPECIFICATIONS..........................................................................20

4INSTALLATION .........................................................................................................21

4.1 UNPACK .............................................................................................................21

4.2 ASSEMBLING OFTHE DRIVE............................................................................21

4.3 ASSEMBLING OFTHE STANDS........................................................................22

4.4 STARTING UP.....................................................................................................23

4.4.1 OPERATION IN STANDARD MODE ...............................................................24

4.4.2 OPERATION IN TIMER MODE........................................................................24

4.4.3 OPERATION IN AUTOMATIC MODE USING RS232 INTERFACE.................25

4.4.4 VIEWING PROCESS PARAMETERS..............................................................26

5MAINTENANCE.........................................................................................................27

5.1 DRIVE .................................................................................................................27

5.2 CLEANING AND MAINTENANCE OF THE AGGREGATES................................28

6TROUBLE SHOOTING..............................................................................................30

7ACCESSORIES..........................................................................................................31

8WARRANTY...............................................................................................................31

APPENDIX A. DIMENSIONAL DRAWINGS................................................................32