MultiBase U20 EB | Code number 588.51.740-003 | Version 04.2019 Page 8 of 9

Technical data

As per DIN 4109-1 (sound insulation in building construction),

Section 9, KLAUS Multiparker are in the range of technical

domestic installations (garage systems).

Normal sound insulation:

DIN 4109-1, Section 9, maximum permissible A-rated sound

levels in rooms requiring external protection, generated by

technical domestic installations and commercial businesses

affiliated with the building.

Table 9 shows the values for the maximum permissible A-rated

sound levels in rooms requiring external protection, generated

by technical domestic installations and business affiliated with

the building. As per line 2, the maximum sound level in living

rooms and bedrooms must not exceed 30 dB (A). User noises

are not subject to the re uirements (DIN 4109-1, Section 9).

The following measures are required to comply with this value:

– Sound protection package according to offer/order

(KLAUS Multiparking GmbH)

– Minimum sound insulation of the building of min. R’w= 57 dB

(service/item to be provided by the customer)

Increased sound insulation (special agreement):

VDI 4100 (sound insulation in building construction)

Assessment and proposals for enhanced sound insulation.

Agreement: Maximum sound level in living rooms and

bedrooms 25 dB (A). User noises are not subject to the

re uirements (see VDI 4100, Paragraph 1, Scope of

application – Notes).

The following measures are required to comply with this value:

– Sound protection package according to offer/order

(KLAUS Multiparking GmbH)

– Minimum sound insulation of the building of min. R’w= 62 dB

(service/item to be provided by the customer)

Note: User noises are basically noises that can be individually

influenced by the user of our Multiparking systems. These

include, for example, driving on the platform, slamming vehicle

doors, engine and brake noises.

Sound insulation

To be performed by the customer

Any constraints that may be necessary according to DIN EN ISO

13857 in order to provide protection for the park pits for pathways

directly in front, next to or behind the unit. This is also valid during

construction. Safety grids on the systems are, if necessary, optionally

available against surcharge.

Safety fences

Consecutive numbering of parking spaces.

Numbering of parking spaces

Any required lighting, ventilation, fire extinguishing and fire alarm

systems as well as clarification and compliance with the relevant

regulatory requirements.

Building services

In the middle of the pit a floor drain with connection to the cable

network or a pump sump is to be provided. The water is to be

drained with a pump to be provided by the customer. rom the

pit corners/bearing surface of the lifting columns an incline to the

floor drain/pump sump is necessary.

or reasons of environmental protection we recommend to paint

the pit floor, and to provide oil and petrol separators in the

connections to the public sewage network.

To divert large amounts of water from the court area, we

recommend that the customer install a water drainage channel

around the periphery of the pit.

Drainage

In compliance with DIN EN 14010, 10 cm [4’’] wide yellow-black

markings compliant to ISO 3864 must be applied by the customer

to the edge of the pit in the entry area to mark the danger zone.

Marking

Suitable electrical supply to the main switch must be provided by

the customer during installation. The functionality can be monitored

on site by our fitters together with the electrician. If this cannot be

done during installation for some reason for which the customer

is responsible, the customer must commission an electrician at

their own expense and risk.

In accordance with DIN EN 60204 (Safety of Machinery. Electrical

Equipment), grounding of the steel structure is necessary, provided

by the customer (distance between grounding max. 10 m [32’’-10’]).

Electrical supply to the main switch / Foundation earth connector

– Mounting of contactor and terminal box to the wall valve, complete

wiring of all elements in accordance with the circuit diagram

– Costs for final technical approval by an authorized body

– Main switch

– Control line from main switch to hydraulic unit

If the following are not included in the quotation, they will

also have to be provided / paid for by the customer:

The customer must provide a cable duct (Helfamin-tube) from

pit floor to operating device. The location of the control element

must be specified according to the project (control stand, house

wall, etc.).

Operating device

In general, a crane must be supplied by the customer for

installation of the telescope columns.

Hook clearance min. 700 cm [23’’] over access level, crane load

approx. 1400 kg [3086 lbs].

Installing vertical columns

A separate maintenance manhole with manhole cover, ladder

and a connecting passage to the pit must be installed by the

customer. In multiple systems, a shared maintenance manhole

may be sufficient, depending on the project.

Maintenance manhole

The customer must comply with DIN 67528 »Artificial lighting

of parking areas and parking houses« for the parking structure

lighting. The intensity of illumination in the pit and in the

maintenance manhole must be min. 80 Lux.

Lighting

To achieve a constant exchange of air, reduce humidity, prevent

condensation, and reduce vehicle moisture (due to rain, snow, ice,

etc.), it is recommended that the customer consult specialized

engineers for heating, ventilation, and climate control and install

a ventilation system. This will reduce or prevent the hazard of

corrosion and its attendant failures.

Ventilation

Any necessary wall cuttings according to page 2.

Wall cuttings

On-site coating of the uppermost platform according to

sectional drawing on page 2 (maximum weight of customer

coating 250 kg/m2[5933 lbs/ ft2]).

Coating on the uppermost platform

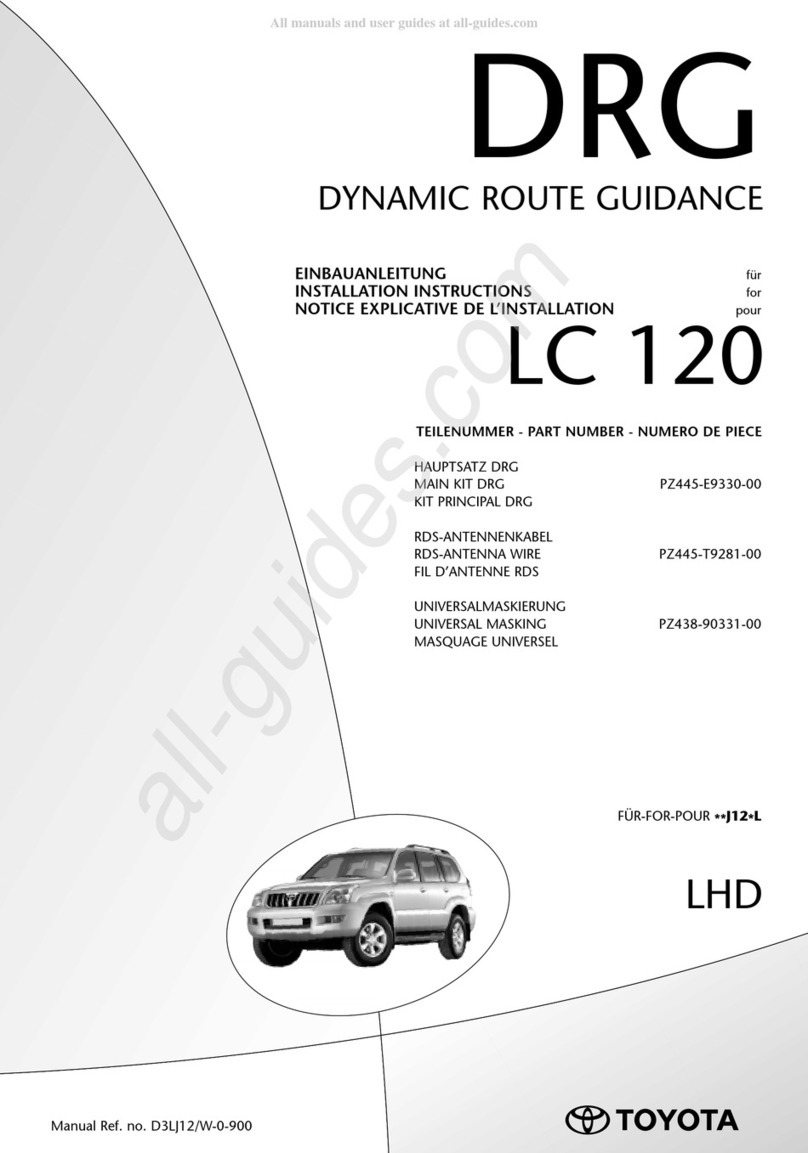

Page 1

Section

Dimensions

Car data

Page 2

Width

dimensions

Page 3

Width

dimensions

Page 4

unction

Approach

Load per

parking sp.

Page 5

Load plan

Page 6

Pit edge

Page 7

Electrical

installation

Technical

data

Page 8

Tec. data

To be perfor-

med by the

customer

Page 9

Description