5

PRODUCT OVERVIEW

DIMENSIONS

INSTALLATIONS

ACTUATORS

COMMUNICATIONS MODULES

ACCESORIES

REPLACEMENTS

MAINTENANCE AND OPERATION

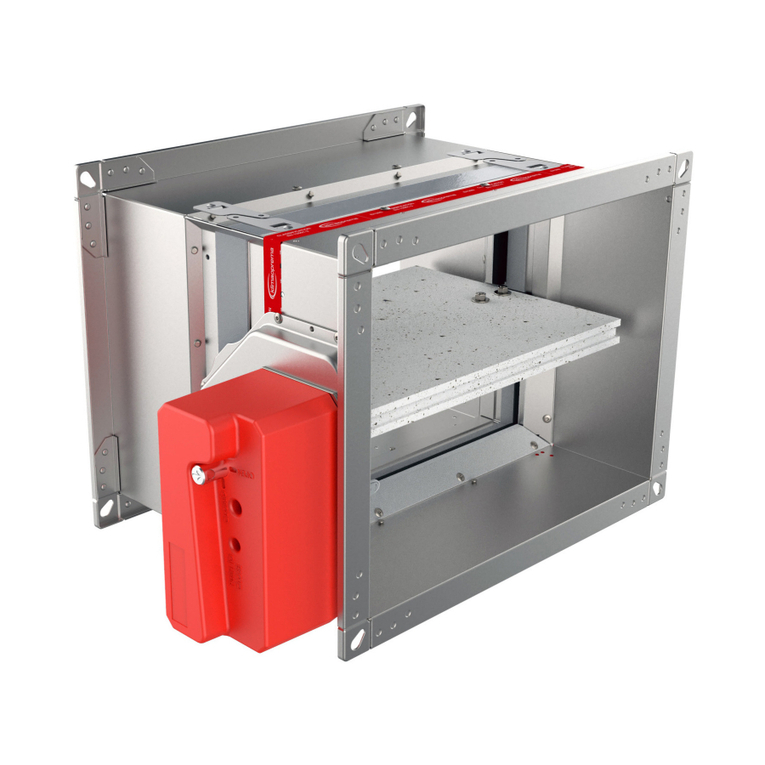

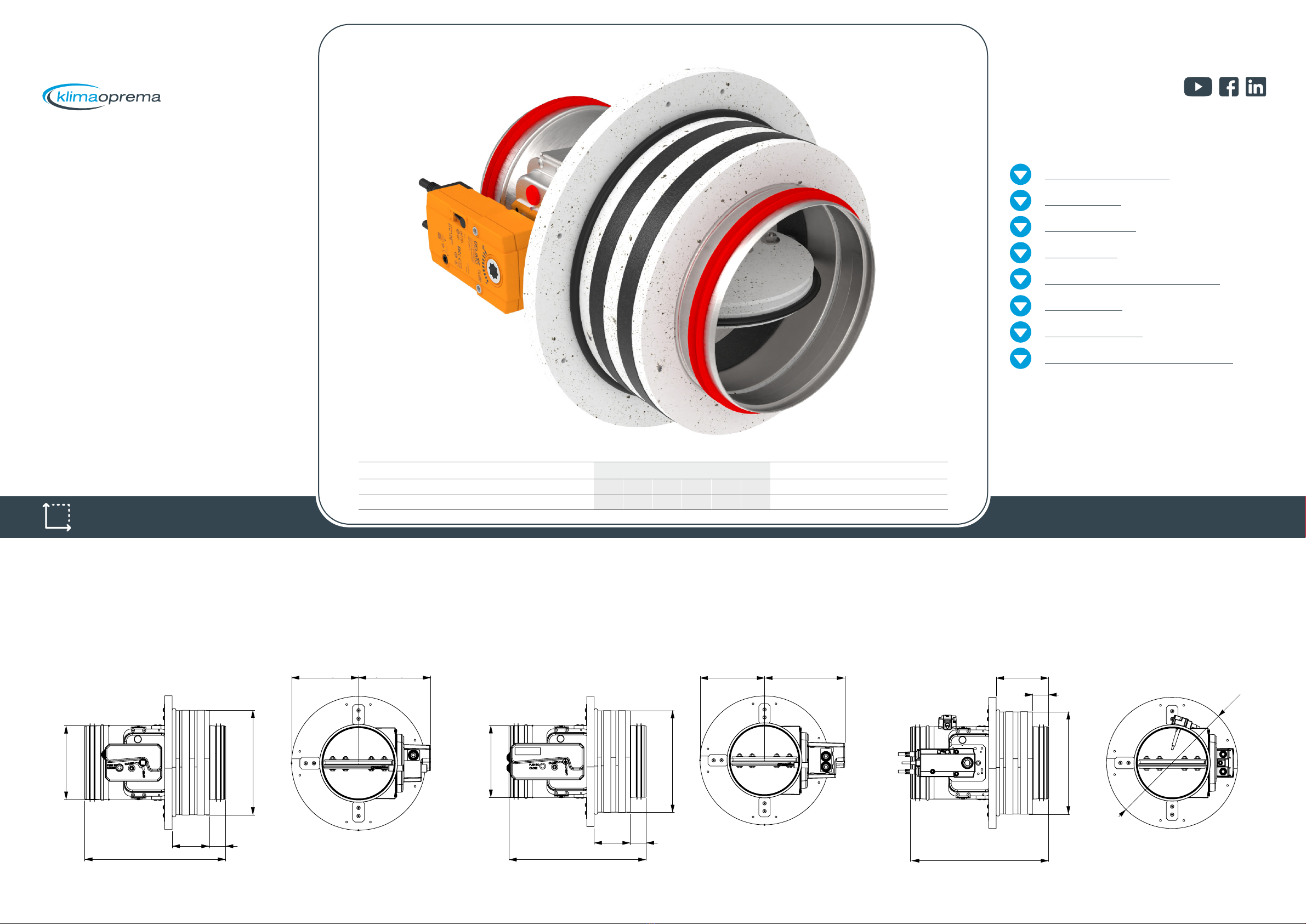

FIRE DAMPER - FDC

MODELS

Casings

Actuators

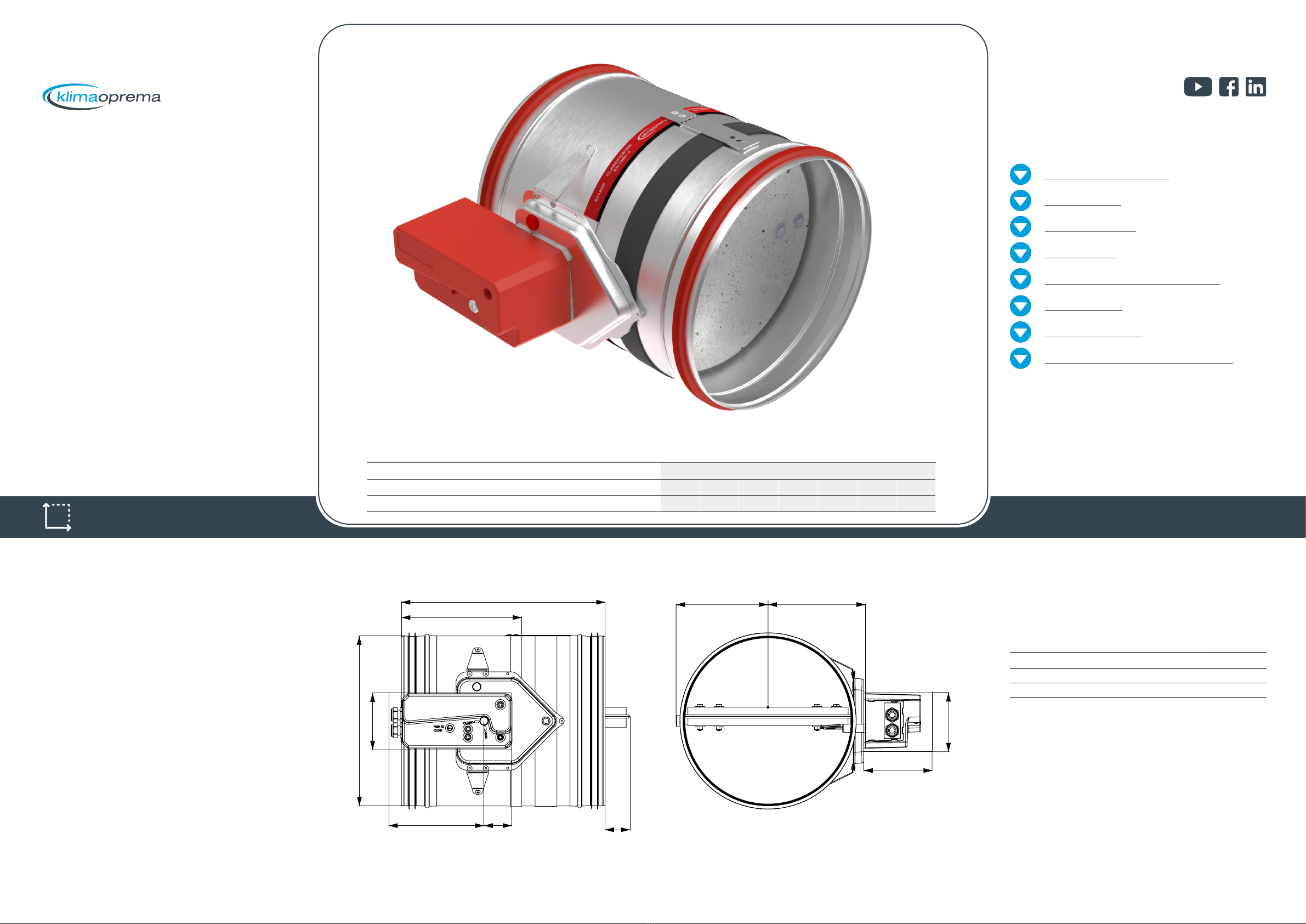

R (R-S)

Manual operating mechanism, optionally with end switches (R-S). In case

of fire, the fire damper closes automatically. Damper closing can be initiated

either by thermal fuse melting, or by manual activation on the operating

mechanism. Upon closure, damper blade is locked in closed position and

can only be opened manually. Thermal fuse melting point is 72°C.

EMS-S

Electromagnetic operating mechanism, comes with end switches as

standard. In case of fire, the fire damper closes automatically. Damper

closing can be initiated either by thermal fuse melting or remotely by

triggering the electromagnet. Electromagnet is constantly under power and

activates closing of the damper blade in case the power cuts out. Upon

closure, damper blade is locked in closed position and can only be opened

manually. Thermal fuse melting point is 72°C.

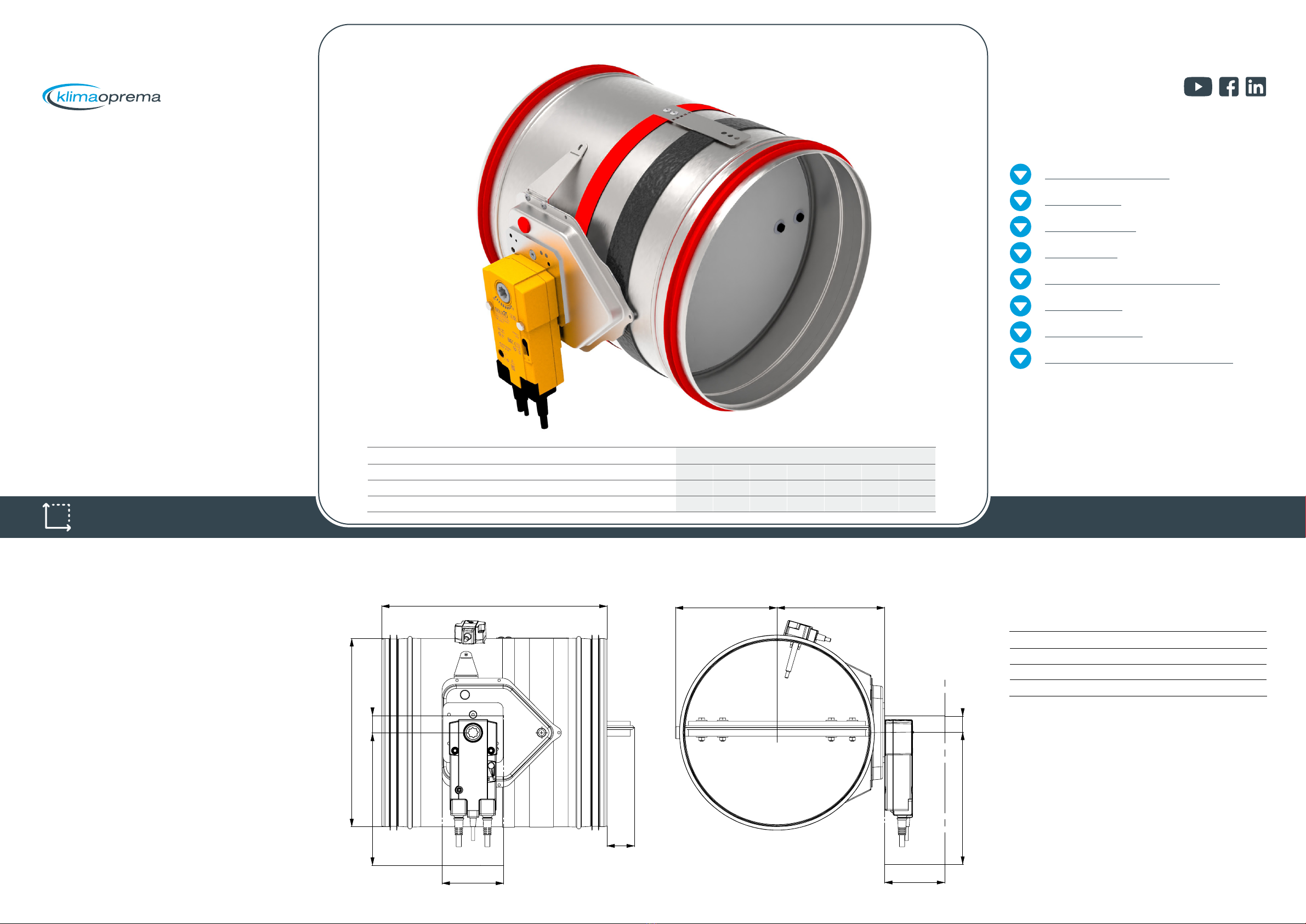

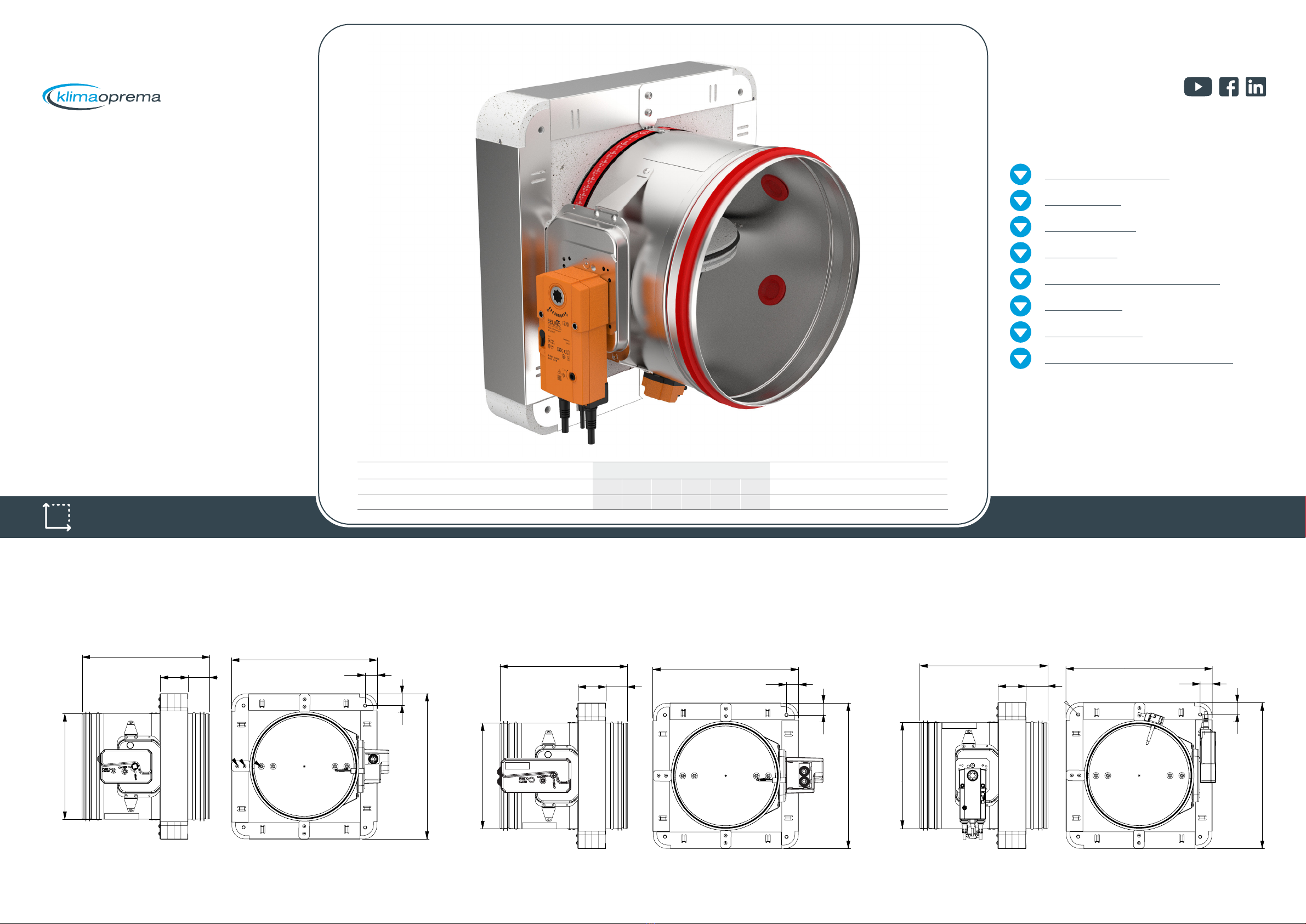

M230-S

Belimo 230V electro motor operating mechanism, comes with integrated

end switches. In case of fire, the fire damper closes automatically.

Damper closing can be initiated either by thermal fuse melting or remotely

by triggering the electro motor. Upon closure, damper blade is locked in

closed position and can be opened by sending a signal to electro motor.

Thermal fuse melting point is 72°C.

M24-S

Belimo 24V electro motor operating mechanism, comes with integrated

end switches. In case of fire, the fire damper closes automatically.

Damper closing can be initiated either by thermal fuse melting or remotely

by triggering the electro motor. Upon closure, damper blade is locked in

closed position and can be opened by sending a signal to electro motor.

Thermal fuse melting point is 72°C.

M24-S-ST

Belimo 24V electro motor operating mechanism, comes with integrated

end switches. In case of fire, the fire damper closes automatically.

Damper closing can be initiated either by thermal fuse melting or remotely

by triggering the electro motor. Upon closure, damper blade is locked in

closed position and can be opened by sending a signal to electro motor.

Thermal fuse melting point is 72°C.

Actuator is additionally equipped with connection socket for easy

connection with power supply and communication modules.

EX

ATEX rated fire dampers are equipped with Schischek ExMax actuators,

Exbox-TT thermal switches and ExBox plenum boxes.

Optionaly casing can be produced in AISI316L stainless steel.

Ordering key

FDC25

Cylindrical fire damper with 25mm damper blade and

fire classification up to EI120S. Sizes range from d100

till d315.

FDC40

Cylindrical fire damper with 40mm damper blade and

fire classification up to EI120S. Sizes range from d355

till d800.

FDC25-APP

Cylindrical fire damper with integrated Applique

installation frame with 25mm damper blade and fire

classification up to EI90S.

Sizes range from d100 till d315.

FDC25-MF1

Cylindrical fire damper with integrated MF1 installation

frame with 25mm damper blade and fire classification

up to EI60S.

Sizes range from d100 till d315.

(1) Damper type (2) Dimension (3) Mechanism

type

FDC25 - d250 - M230-S

(1)

(2)

FDC25 - up to d315

FDC40 - d355 till d800

FDC25-APP - up to d315

FDC25-MF1 - up to d315

Damper diameter

d100 till d800

(3) R - manual drive

R-S - manual drive with limit switches

M230-S - electric actuator AC230V

M24-S - electric actuator AC/DC24V

M24-S-ST - electric actuator AC/DC24V with connection

socket

EMS-S - electromagnetic drive

EX - ATEX rated Schischek 230/24V electric actuator

PRODUCT OVERVIEW