6

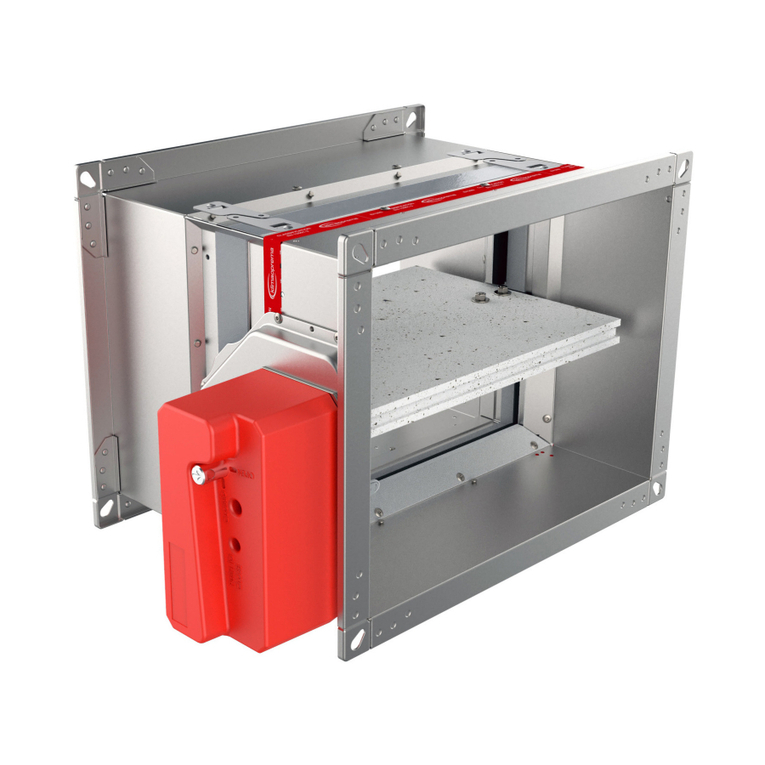

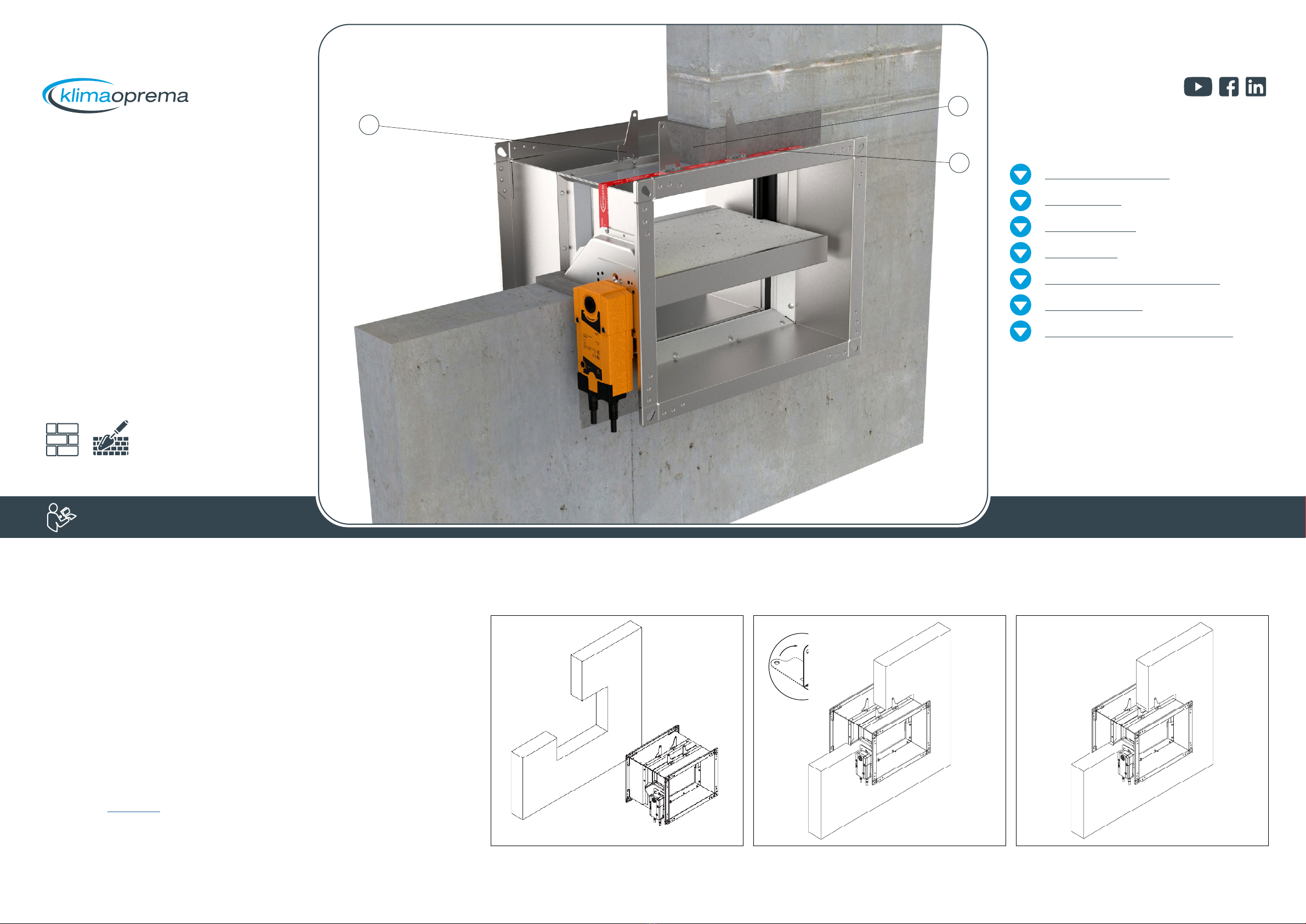

PRODUCT OVERVIEW

DIMENSIONS

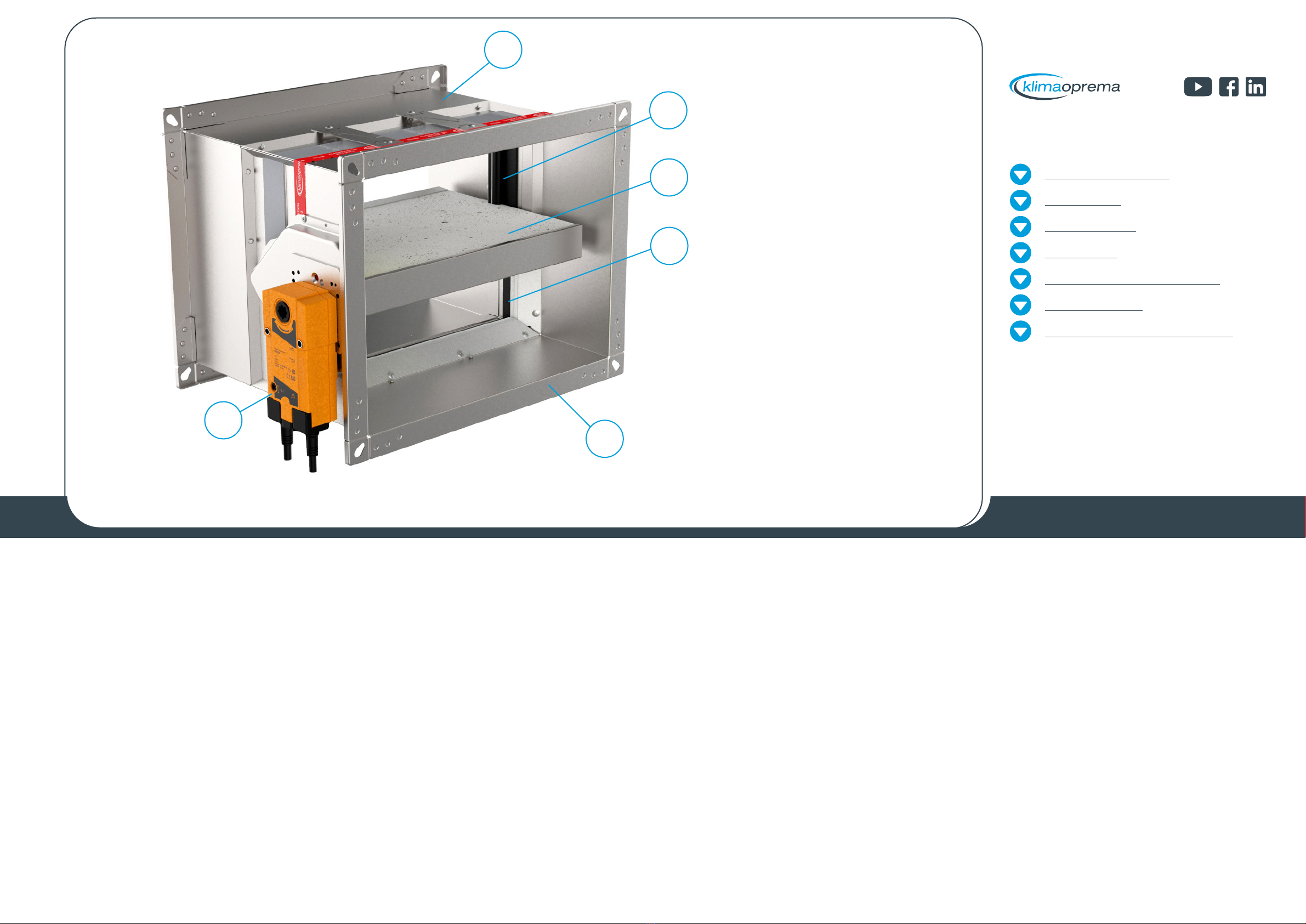

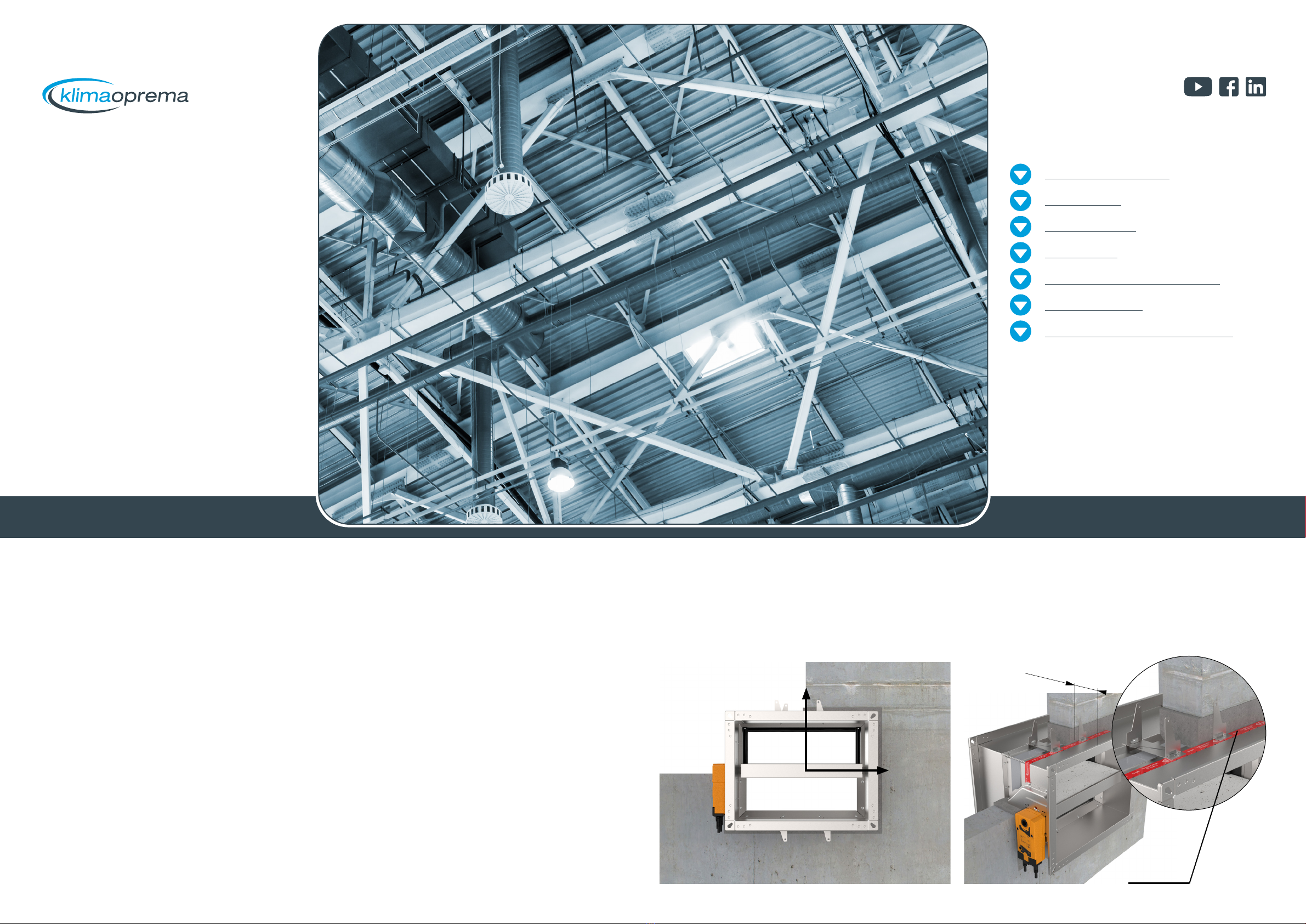

INSTALLATIONS

ACTUATORS

COMMUNICATIONS MODULES

REPLACEMENTS

MAINTENANCE AND OPERATION

DIMENSIONS

FDSD Weight [kg]

H/B 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500

200 6,8 7,5 8,2 8,9 9,7 10,4 11,1 11,8 12,6 14,0 14,7 15,5 16,2 16,2 16,9 17,6 18,3 19,1 19,8 20,5 21,3 22,0 22,7 23,4 24,2 24,9 25,6

250 6,2 6,9 7,5 8,3 9,1 9,9 10,7 11,6 12,4 13,2 14,0 15,6 16,5 17,3 18,1 18,2 19,0 19,8 20,7 21,5 22,3 23,2 24,0 24,8 25,6 26,5 27,3 28,1 29,0

300 6,9 7,6 8,2 9,1 10,0 10,9 11,8 12,7 13,6 14,5 15,4 17,3 18,2 19,1 20,0 20,2 21,1 22,1 23,0 23,9 24,9 25,8 27,5 28,4 29,3 30,3 31,2 32,1 33,0

350 7,6 8,2 8,9 9,9 10,9 11,9 12,9 13,9 14,9 15,9 16,9 18,9 19,9 20,9 22,0 22,2 23,3 24,3 25,3 26,4 27,4 28,4 30,2 31,2 32,3 33,3 34,3 35,3 36,4

400 8,2 8,9 9,7 10,7 11,8 12,9 14,0 15,1 16,2 17,3 18,3 20,5 21,6 22,8 23,9 25,0 26,2 27,3 28,4 29,5 30,7 31,8 32,9 34,1 35,2 36,3 37,4 38,6 39,7

450 8,9 9,6 10,4 11,6 12,7 13,9 15,1 16,3 17,4 18,6 19,8 22,1 23,4 24,6 25,8 27,1 28,3 29,5 30,7 32,0 33,2 34,4 35,7 36,9 38,1 39,3 40,6 41,8 43,0

500 9,6 10,3 11,1 12,4 13,6 14,9 16,2 17,4 18,7 20,0 21,2 23,8 25,1 26,4 27,8 29,1 30,4 31,7 33,1 34,4 35,7 37,1 38,4 39,7 41,0 42,4 43,7 45,0 46,5

550 10,2 11,0 11,8 13,2 14,5 15,9 17,3 18,6 20,0 21,3 22,7 25,4 26,8 28,3 29,7 31,1 32,5 34,0 35,4 36,8 38,3 39,7 41,1 42,5 44,0 45,5 46,9 48,4 49,8

600 10,9 11,7 12,6 14,0 15,4 16,9 18,3 19,8 21,2 22,7 24,1 27,0 28,6 30,1 31,6 33,1 34,7 36,2 37,7 39,3 40,8 42,3 43,8 45,5 47,0 48,5 50,1 51,6 53,1

650 11,9 11,9 14,0 15,6 17,3 18,9 20,5 22,1 23,8 25,4 27,0 28,7 30,3 31,9 33,5 35,2 36,8 38,4 40,1 41,7 43,3 45,1 46,7 48,3 49,9 51,6 53,2 54,8 56,4

700 11,9 12,9 14,7 16,5 18,2 19,9 21,6 23,4 25,1 26,8 28,6 30,3 32,0 33,7 35,5 37,2 38,9 40,7 42,4 44,2 46,0 47,7 49,4 51,1 52,9 54,6 56,3 58,0 59,8

750 12,9 12,9 15,5 17,3 19,1 20,9 22,8 24,6 26,4 28,3 30,1 31,9 33,7 35,6 37,4 39,2 41,1 42,9 44,8 46,7 48,5 50,3 52,1 54,0 55,8 57,6 59,4 61,3 63,1

800 13,9 13,9 16,2 18,1 20,0 22,0 23,9 25,8 27,8 29,7 31,6 33,5 35,5 37,4 39,3 41,3 43,2 45,2 47,2 49,1 51,0 52,9 54,9 56,8 58,7 60,6 62,6 64,5 66,4

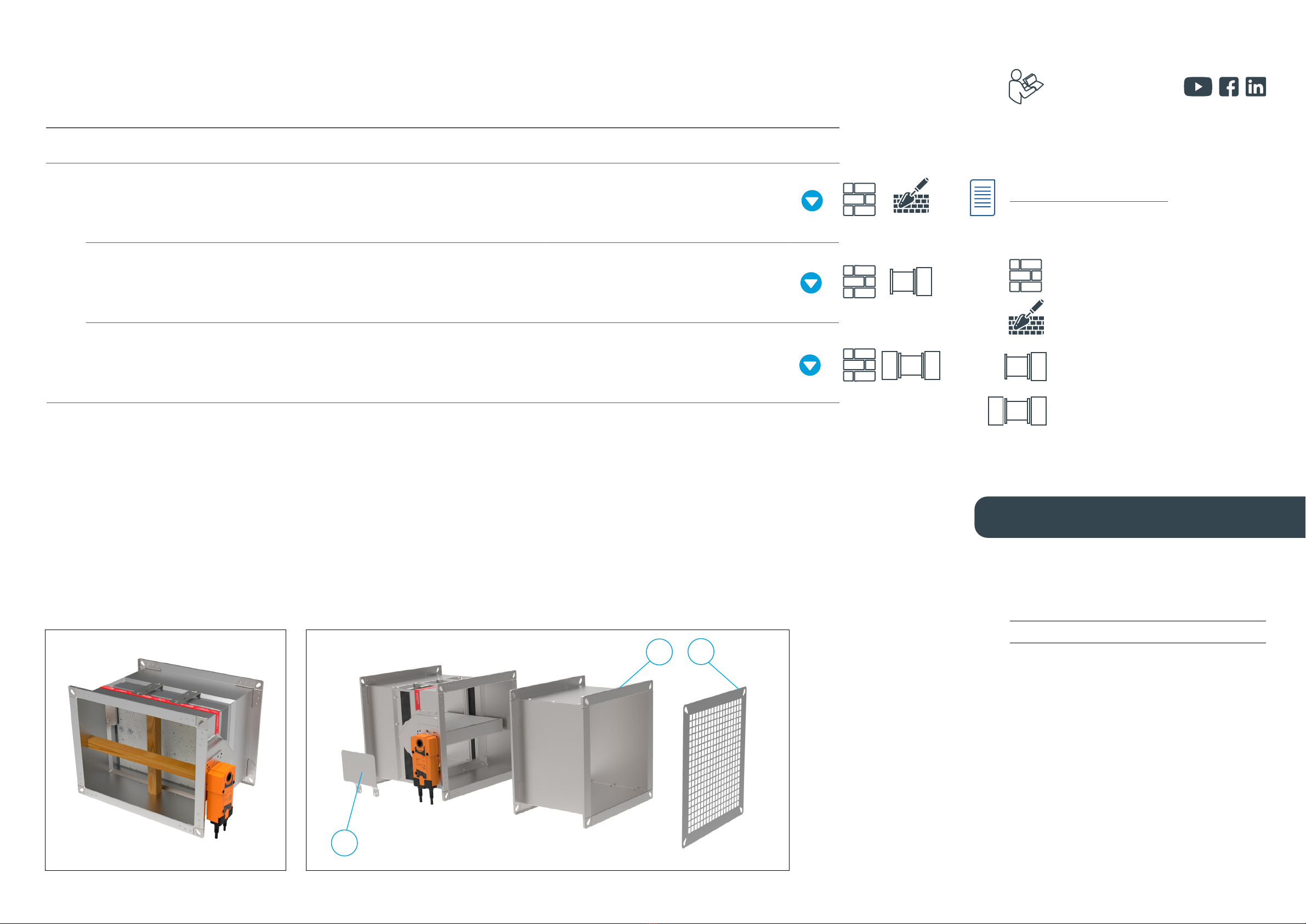

Pressure drop tables

ZETA VALUES FDSD

H/B 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050 1100 1150 1200 1250 1300 1350 1400 1450 1500

200 11,64 9,56 7,48 6,91 6,33 5,71 5,09 5,06 5,04 4,75 4,46 4,45 4,44 4,42 4,39 4,11 3,84 3,83 3,81 3,80 3,79 3,74 3,69 3,69 3,69 3,67 3,66

250 8,58 7,11 5,65 5,20 4,76 4,29 3,82 3,80 3,78 3,56 3,33 3,32 3,31 3,29 3,27 3,07 2,86 2,85 2,84 2,83 2,83 2,80 2,78 2,78 2,78 2,77 2,76

300 5,51 4,67 3,83 3,50 3,18 2,86 2,55 2,54 2,53 2,36 2,20 2,19 2,18 2,17 2,15 2,02 1,89 1,88 1,86 1,86 1,86 1,86 1,86 1,86 1,86 1,86 1,86

350 4,47 3,78 3,10 2,84 2,58 2,32 2,07 2,05 2,03 1,91 1,78 1,77 1,76 1,75 1,75 1,64 1,53 1,52 1,52 1,51 1,51 1,51 1,51 1,51 1,51 1,51 1,51

400 3,42 2,89 2,37 2,17 1,98 1,78 1,59 1,56 1,53 1,45 1,36 1,35 1,34 1,34 1,34 1,26 1,17 1,17 1,17 1,16 1,15 1,15 1,15 1,15 1,15 1,15 1,15

450 2,91 2,47 2,02 1,85 1,67 1,50 1,33 1,31 1,30 1,23 1,15 1,15 1,14 1,14 1,14 1,07 1,00 1,00 1,00 0,99 0,97 0,97 0,97 0,97 0,97 0,97 0,97

500 2,40 2,04 1,68 1,52 1,36 1,21 1,07 1,07 1,07 1,00 0,94 0,94 0,94 0,94 0,94 0,88 0,82 0,82 0,82 0,81 0,80 0,80 0,80 0,80 0,80 0,80 0,80

550 2,13 1,81 1,48 1,35 1,22 1,09 0,97 0,95 0,93 0,88 0,82 0,82 0,82 0,82 0,82 0,76 0,71 0,71 0,71 0,70 0,70 0,70 0,70 0,70 0,70 0,69 0,68

600 1,86 1,57 1,28 1,18 1,08 0,97 0,87 0,84 0,80 0,76 0,71 0,70 0,69 0,69 0,69 0,64 0,59 0,59 0,59 0,59 0,59 0,59 0,59 0,59 0,59 0,58 0,57

650 1,10 1,02 0,93 0,85 0,77 0,74 0,70 0,66 0,62 0,62 0,61 0,61 0,61 0,57 0,53 0,53 0,53 0,53 0,53 0,53 0,52 0,52 0,52 0,51 0,50

700 0,93 0,85 0,78 0,72 0,67 0,63 0,60 0,57 0,53 0,53 0,53 0,53 0,53 0,50 0,47 0,47 0,47 0,47 0,47 0,46 0,45 0,44 0,44 0,44 0,44

750 0,75 0,71 0,65 0,60 0,58 0,56 0,53 0,50 0,49 0,47 0,47 0,47 0,44 0,42 0,42 0,42 0,42 0,42 0,41 0,40 0,40 0,40 0,40 0,40

800 0,63 0,58 0,54 0,53 0,52 0,49 0,46 0,44 0,41 0,41 0,41 0,39 0,36 0,36 0,36 0,36 0,36 0,36 0,35 0,35 0,35 0,35 0,35

SMOKE CONTROL DAMPERS

BEN-24/230 BEE-24/230

Pressure drop values are described with the “Zeta” values for

each size. The exact pressure drop in [Pa] is calculated using

the following formula: Δp [Pa]= ζ * v² * 0,6

where ζis Zeta value from the tables below, v is airflow

velocity in [m/s]

H

B