wT 2860/02

Page 2

Contents

1Declaration of Conformity.............................................................................3

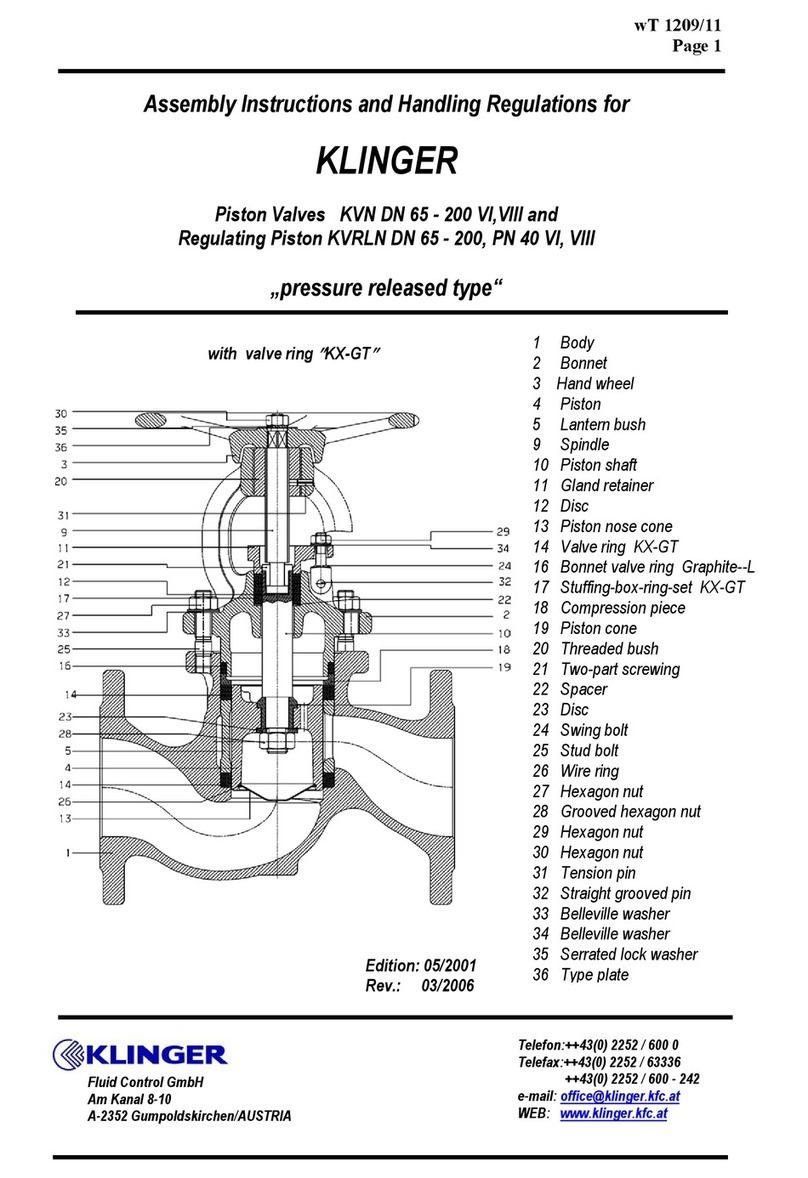

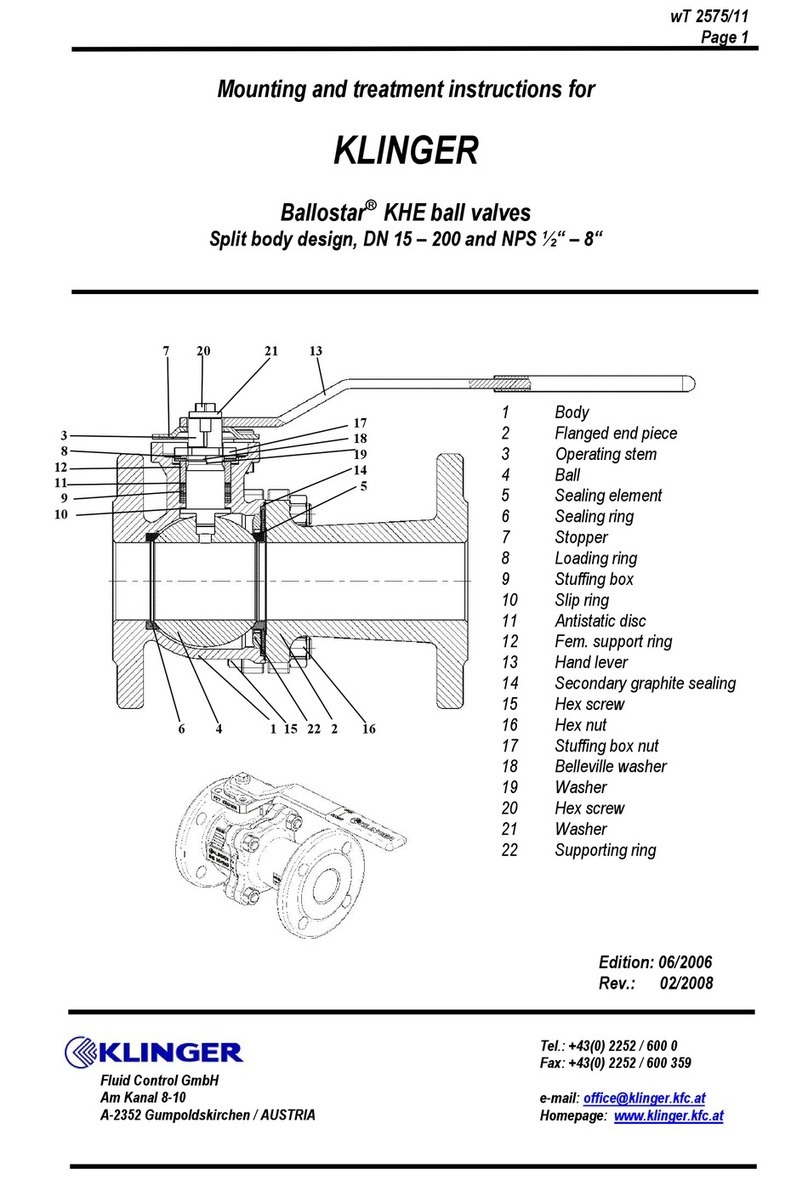

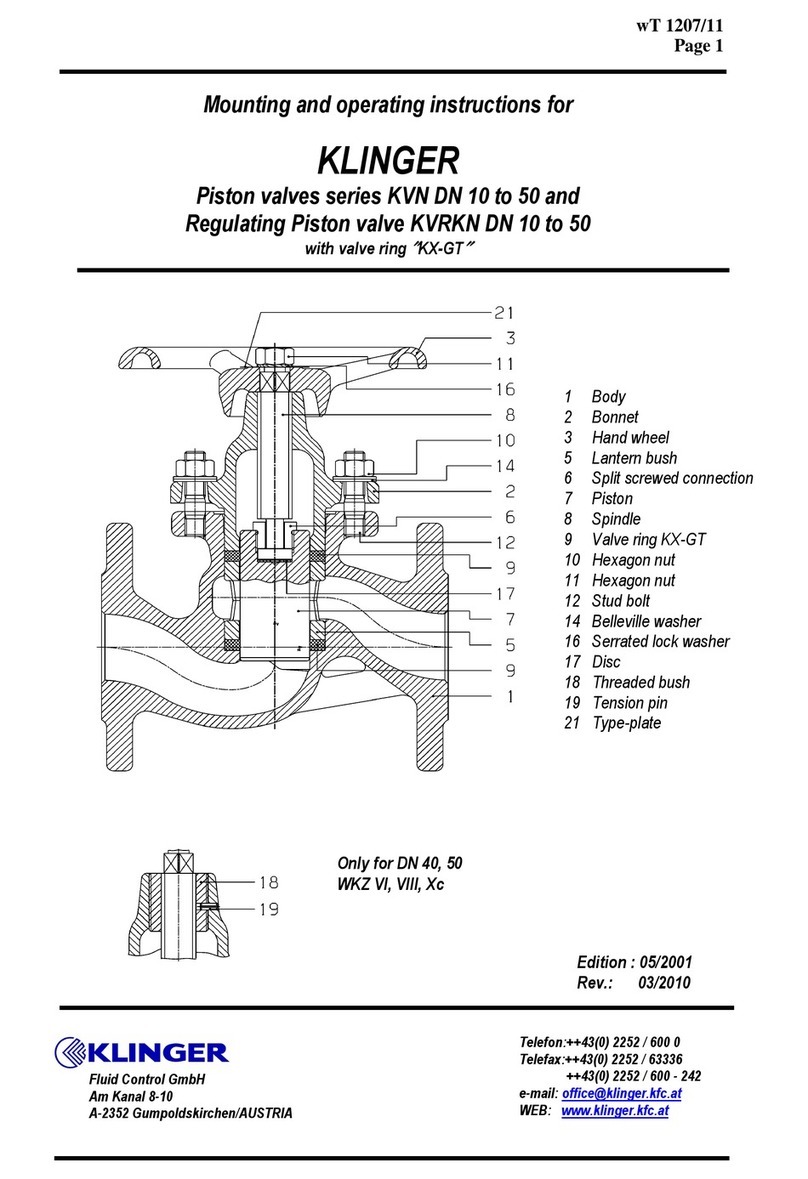

2Individual Parts Designation .........................................................................4

3Proper Use ..................................................................................................5

4Testing of KLINGER Valves..........................................................................5

5Labeling of the Valves ..................................................................................5

6Safety Instructions .......................................................................................6

6.1 General Notes on Safety.............................................................................. 6

6.2 Safety Instructions for Operators ................................................................. 6

6.3 Hazard Warnings......................................................................................... 7

7Technical Data.............................................................................................9

7.1 Material codes............................................................................................. 9

7.2 P/T Diagrams .............................................................................................. 9

7.3 Tightening Torques ................................................................................... 10

7.4 Table of Weights ....................................................................................... 11

8Transportation and Storage .......................................................................12

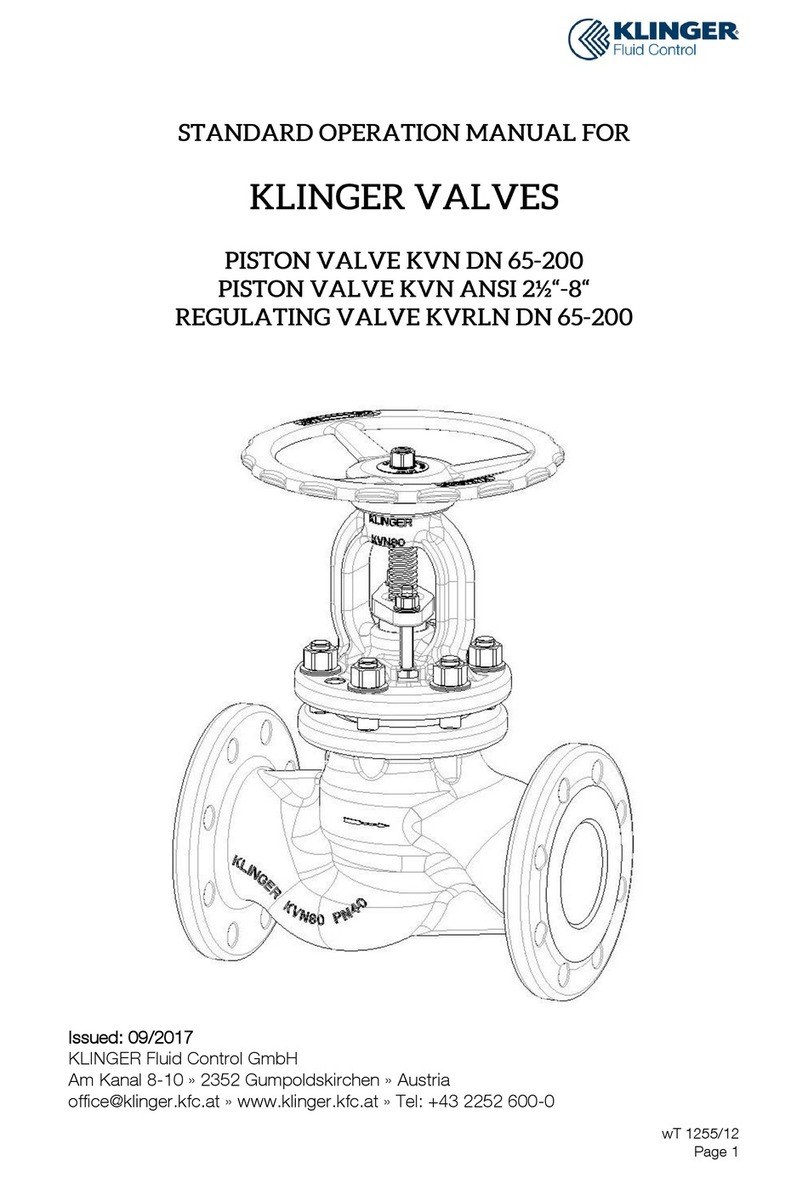

9Operating Principle ....................................................................................13

10 Mode of Operation.....................................................................................14

11 Installation and Putting into Service Regulations .........................................17

11.1 Welding Instructions.................................................................................. 17

12 Service and Maintenance...........................................................................18

12.1 Disassembly.............................................................................................. 18

12.1.1 Disassembly for Seal Exchange at the Operating Stem......................... 18

12.1.2 Disassembly of Individual Parts for Exchange of Sealing Elements ........ 19

12.1.3 Disassembly of the Sealing Element ..................................................... 21

12.2 Assembly .................................................................................................. 22

12.2.1 Standard Lubricants............................................................................. 22

12.2.2 Installation of the Sealing Element......................................................... 22

12.2.3 Assembly of the Individual Parts ........................................................... 23

12.2.4 Inspection of Axial Orientation of the Ball .............................................. 24

13 Actuator Mounting .....................................................................................25

13.1 Fitting the Actuator.................................................................................... 25

14 Spare Parts List .........................................................................................26

15 Disposal ....................................................................................................31