Persons Responsible for Safety

– 7KHRSHUDWRURUKLVVDIHW\RႈFHUPXVWZDUUDQW

– that all the relevant regulations, instructions and laws are adhered to;

– WKDWRQO\TXDOL¿HGSHUVRQQHOZLOOZRUNZLWKDQGRQWKHOXEULFDWRUGLVWULEXWRU

– that unauthorized personnel are not allowed to work with and on the lubricator/distributor;

– that the safety regulations are adhered to when mounting the lubricator/distributor or during maintenance.

General Safety Instructions

– We are not laying claim to completeness as regards these safety instructions. Please contact Klüber

Customer Service if you have any queries or problems.

– At the time of delivery the lubricator/distributor is in line with state-of-the-art technology and in principle is

considered to be safe to operate.

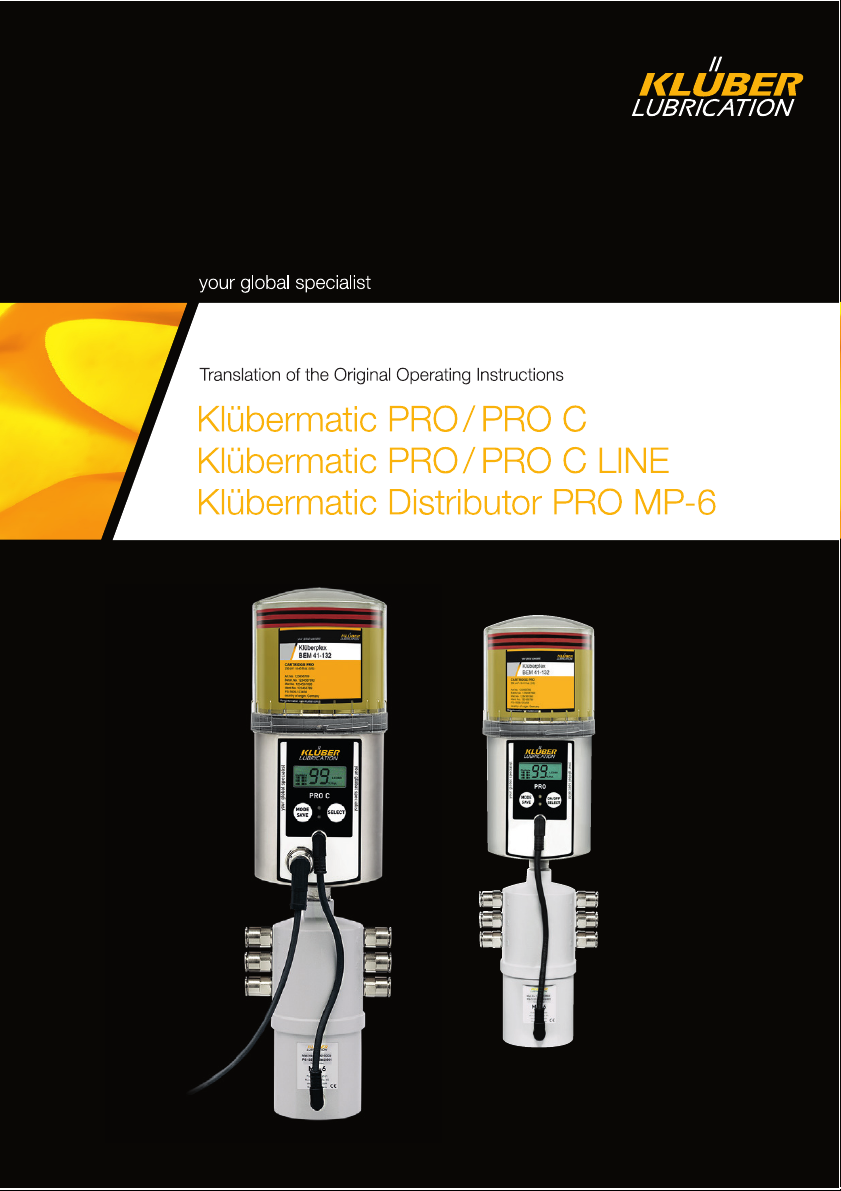

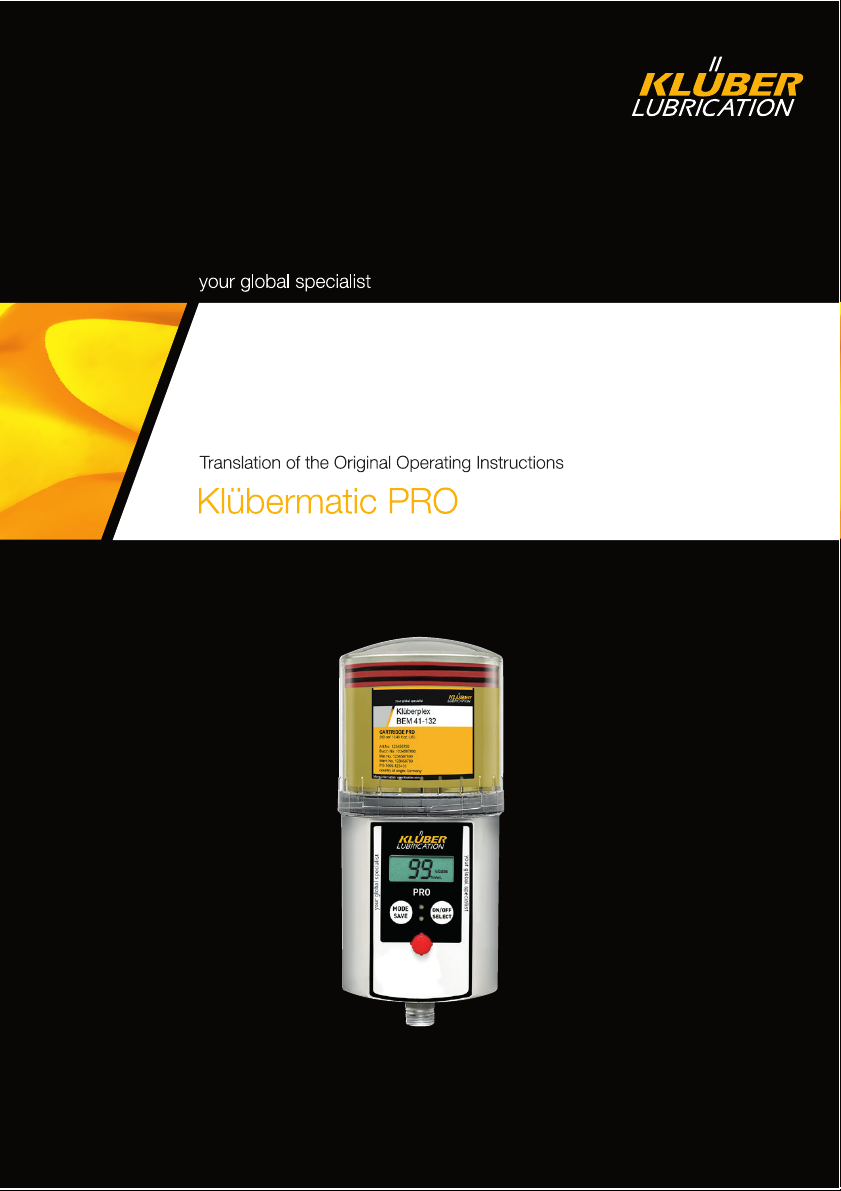

– The distributor may only be used with a lubricator of the Klübermatic PRO range.

– Dangers emanate from the lubricator/distributor for persons, the lubricator/distributor itself and for other

material assets of the operator if

– XQTXDOL¿HGSHUVRQQHORSHUDWHVWKHOXEULFDWRUGLVWULEXWRU

– the lubricator/distributor is used inappropriately and for operations that it was not intended to be used for;

– the lubricator/distributor setting / variation is incorrect;

– the lubricator/distributor is opened by force while in operation;

– the lubricator/distributor is not mounted with the Klübermatic mounting device;

– the tube connection to the lubrication point was not carried out and attached correctly.

– Operate the lubricator/distributor only when it is in perfect condition.

– 5HWUR¿WWLQJFKDQJLQJRUUHFRQVWUXFWLQJWKHOXEULFDWRUGLVWULEXWRULVQRWDOORZHG.OEHUPXVWEHFRQVXOWHG¿UVW

– Only original tube connections and connectors from Klüber can be used on or with the lubrication system

since these will withhold high pressures of up to 25 bar (360psi).

– Only an original connecting cable from Klüber can be used to connect the lubricator PRO C to your control

system and your equipment.

– Ambient media, especially chemically aggressive substances, can attack seals and plastic.

Safety Information for Klübermatic PRO / PRO C / PRO/PRO C LINE / Distributor PRO MP-6

Safety during Installation and Maintenance

– (QVXUHWKDWDOOZRUNVWDWLRQVDQGWUDႈFURXWHVDUHFOHDQDQGVDIH

– Ensure that the relevant regulations and guidelines are adhered to when the installation or maintenance

work is carried out in places where danger of falling exists.

– Ensure that the relevant safety and operating instructions are observed when the lubricators are installed

or serviced on machines or in factories (e.g. to stop the machine).

Safety When Handling Lubricants

– $YRLGFRQWDFWRIOXEULFDQWZLWKH\HVVNLQDQGFORWKLQJ

– $YRLGVZDOORZLQJRIOXEULFDQW

– 3UHYHQWOXEULFDQWIURPJHWWLQJLQWRVRLORUVHZHUV\VWHP

– 2EVHUYHVDIHW\GDWDVKHHWVRIOXEULFDQWV

Lubricant data sheets may be obtained from Klüber.

– /XEULFDQWRQWUDႈFZD\VZLOOLQFUHDVHWKHGDQJHURIVOLSSLQJ7KHUHIRUHLPPHGLDWHO\FOHDQOXEULFDQWIURP

ÀRRUVZLWKVSHFLDOFOHDQHU

– 2QO\XVHRULJLQDO352/&IURP.OEHU

Safety When Working on Electrical Equipment

– :RUNVRQHOHFWULFDOHTXLSPHQWPD\RQO\EHFDUULHGRXWE\TXDOL¿HGSHUVRQQHO

– 'DQJHURIVSDUNLQJDQG¿UHKD]DUGLQFDVHRIDVKRUWFLUFXLW

– 'RQRWZRUNRQOLYHSDUWVRIWKHHOHFWULFDOHTXLSPHQW

– Protect live parts of the electrical equipment according to the voltage, frequency and application type by

LQVXODWLRQDQGE\WKHLUSRVLWLRQDQGDUUDQJHPHQW

Safety when Handling Batteries!

– $YRLGFRQWDFWRIEDWWHU\VXEVWDQFHVZLWKH\HVVNLQDQGFORWKLQJ

– $YRLGVZDOORZLQJDQ\OHDNLQJEDWWHU\VXEVWDQFHV

– 'RQRWH[SRVHEDWWHULHVWRH[WUHPHKHDWDQGGRQRWWKURZLQWRRSHQ¿UH

– 'RQRWUHFKDUJHEDWWHULHV

– (QVXUHWKDWUHJXODWLRQVIRUZDVWHGLVSRVDORIEDWWHULHVDUHREVHUYHG

– 2QO\XVHRULJLQDOEDWWHULHVIURP.OEHU

Safety Instructions