PORTABLE POWER THREADER OWNER’S MANUAL

1 of 6

ITEM

Power Supply

Power Switch

Spindle Speed

Directional Lever

Gear Head

Support Arm

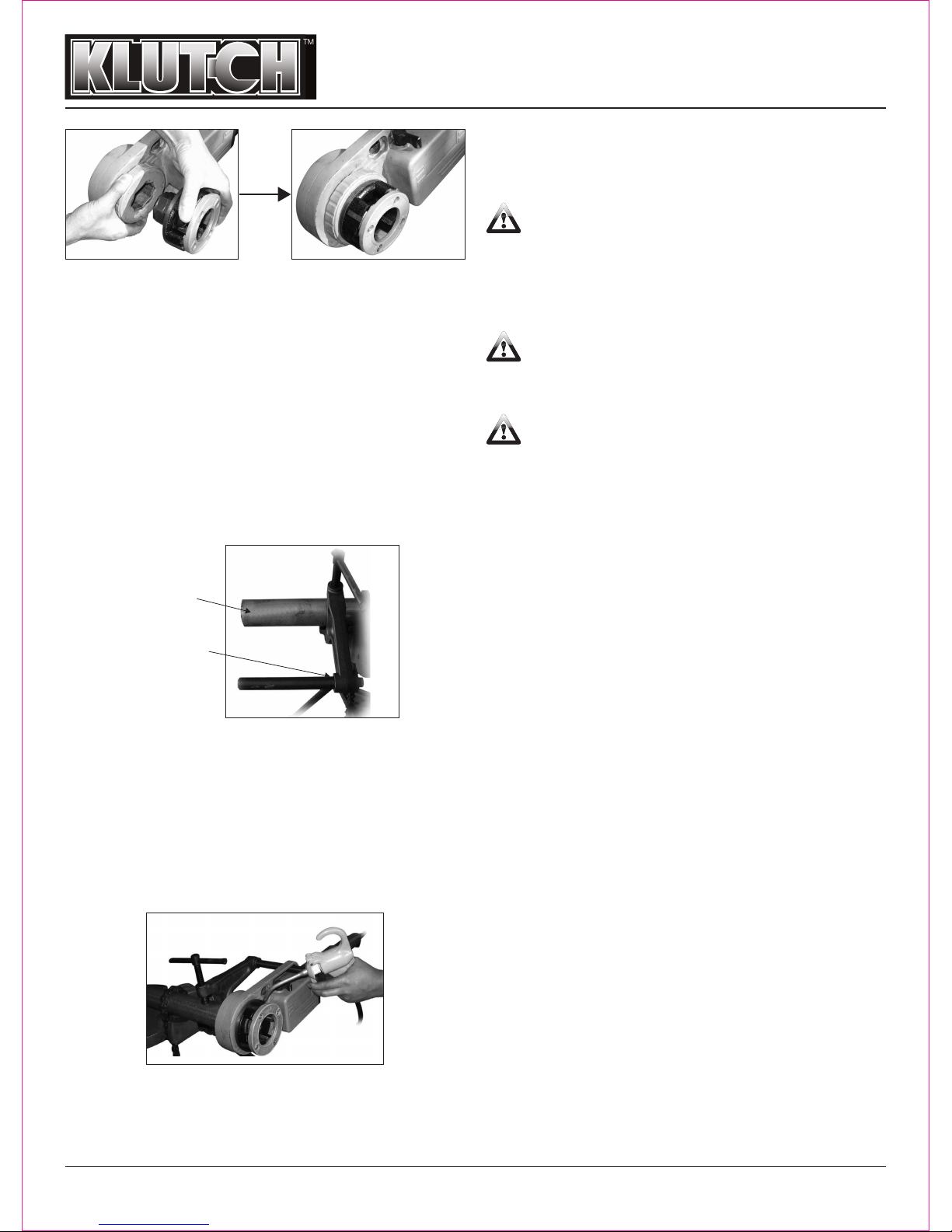

Die Head Adapter

Overall Dimensions

Pipe Die Heads

DESCRIPTION

120V / 50-60Hz / 1.6HP /Single Phase AC / 10Amps

Heavy-Duty Paddle Type

18–28 RPM (Threading), 51 RPM (Reverse)

Mechanical Control (Separate Forward/Reverse Switch)

Die Cast Aluminum Housing

Absorbs Threader Handle Forces

Used with 1/2in. through 2in. Die Heads

29 1/4in. x201/4in. x 22in.

11R Type Die Heads: 1/2in., 3/4in., 1in., 1 1/4in., 1 1/2in., 2in.

Keep all electric connections dry and off the ground. To reduce

the risk of electric shock, do not touch plugs or power tools

with wet hands.

PERSONAL SAFETY

Stay alert. Watch what you are doing and use common sense

when operating a power tool.

Do not use the tool when tired or under the influence of drugs,

alcohol, or medications. A moment of inattentiveness while

operating power tools may result in serious personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry or long hair can be

caught in moving parts.

Avoid accidental starting. Be sure the switch is OFF before

plugging in the tool. Carrying tools with your finger on the

switch or plugging in tools that have the switch ON invites

accidents.

Remove all adjusting keys and wrenches. Make a habit of

checking that the adjusting keys and wrenches are removed

from the tool before turning it on.

Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance allows for better control of

the tool in unexpected situations.

Use safety equipment. Eye protection should be worn at all

times when operating this machine. Use ANSI approved

safety glasses. Everyday eyeglasses only have impact resis-

tance lenses. They are NOT safety glasses. A dust mask,

respirator, non-skid safety shoes, a hard hat, or hearing

protection must be used in appropriate conditions.

TOOL USE AND CARE

Use a clamp or other practical method of securing and

supporting

the work piece. Holding the work by hand is unstable and may

lead to a loss of control.

Do not force the tool. Use the correct tool for your

application.

The correct tool will do a better and safer job when used for

that which it was designed.

Make sure the ON/OFF switch functions. Any tool that cannot

be controlled with the switch is dangerous and must be

repaired.

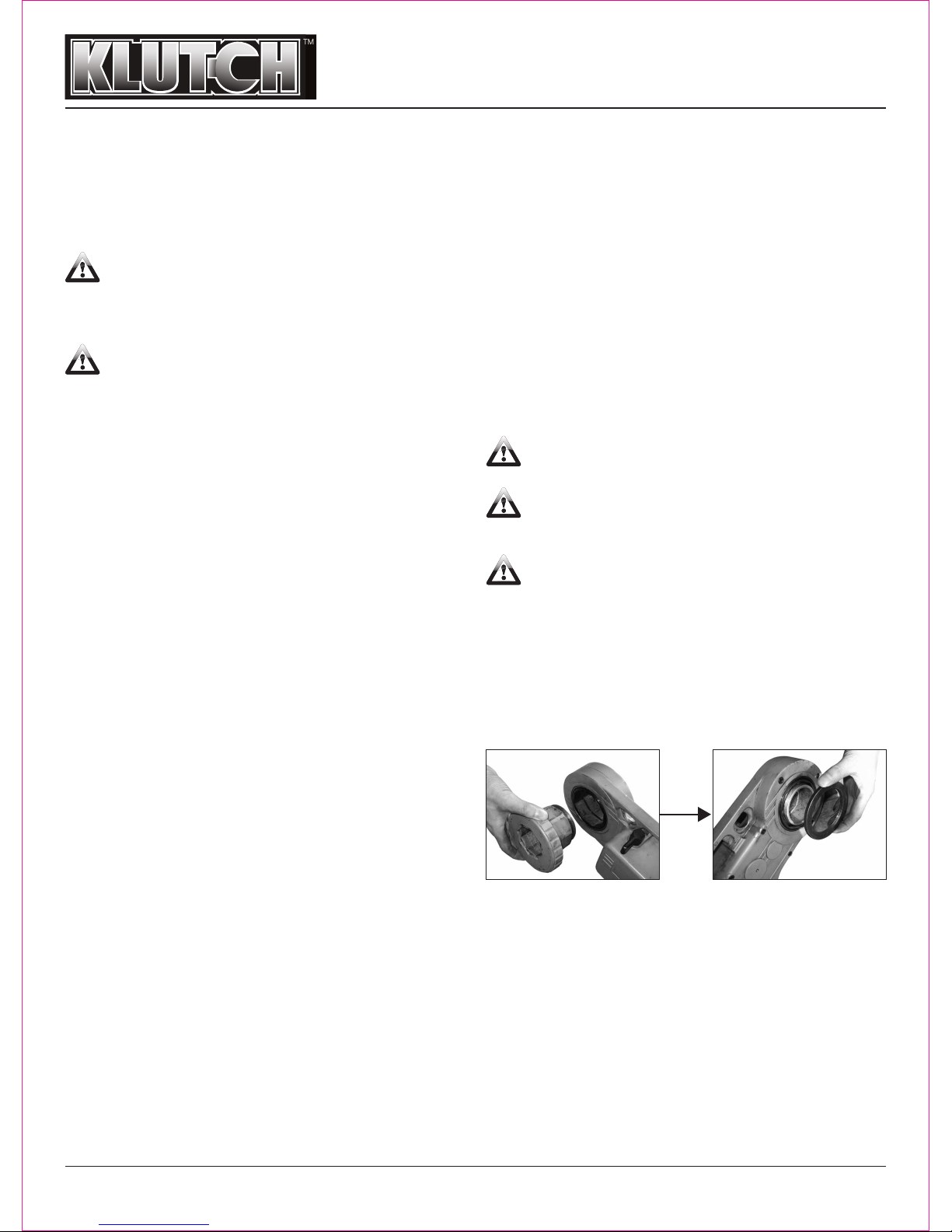

Disconnect the plug from the power source before making

any adjustments, changing accessories or storing the tool.

Such preventive safety measures reduce the risk of starting

the tool accidentally.

Store idle tools out of the reach of children and other

untrained persons. Tools are dangerous in the hands of

untrained

users.

Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edges are less

likely to bind and are easier to control.

Check for poor alignment or binding of moving parts,

breakage

of parts and any other condition that may affect the tool’s

operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Thank you very much for choosing a NORTHERN TOOL +

EQUIPMENT CO., INC., Product! For future reference, please

complete the owner’s record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important

that you read the entire manual to become familiar with this

product before you begin using it.

This machine is designed for certain applications only. Northern

Tool + Equipment strongly recommends this machine is not

modified and/or used for any application other than that for

which it was designed. If you have any questions relative to a

particular application, DO NOT use the machine until you have

first contacted Northern Tool + Equipment to determine if it can

or should be performed on the product.

For technical questions and replacement parts, please call

1-800-222-5381.

TECHNICAL SPECIFICATIONS

GENERAL SAFETY INFORMATION

WARNING: Read and understand all instructions. Failure

to follow all instructions listed below may result in electric

shock,

fire, and/or serious personal injury.

WORK AREA SAFETY

Keep your work area clean and well lit. Cluttered benches

and

dark areas invite accidents.

Do not operate power tools in the presence of flammable

liquids,

gases or dust. Tools create sparks, which may ignite the dust

or fumes.

Keep bystanders, children and visitors away while operating

a tool. Distractions can cause you to lose control.

Keep floors dry and free of slippery materials such as oil.

Slippery floors invite accidents.

ELECTRICAL SAFETY

Avoid body contact with grounded surfaces. There is an

increased risk of electrical shock if your body is grounded.

Do not expose power tools to rain or wet conditions. Water

entering a tool will increase the risk of electrical shock.

Do not abuse the cord. Never use the cord to carry the tool or

unplug the tool from an outlet. Keep the cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electrical

shock.

•

•

•

•

•

•

•