CSP-4702 3 Installation Guide

Operation Test

To test the CSP-4702 operation:

1. Temporarily disconnect the thermostat signal

wire leading to the “2–10 IN” terminal.

2. Jumper the “2–10 IN” terminal to the “16 VDC

OUT” terminal. The green Open LED should

illuminate, and the shaft drive hub should start

rotating the damper open. The damper should

go to full open unless the maximum limit was

set at the CSP-4702, and then the damper will

only go to the maximum seing. If the damper is

rotating closed, change the direction jumper. (See

Rotation Direction on page 2.)

3. Remove any jumper to the “2–10 IN” terminal.

If there is a normal amount of airow in the

duct at the time (creating a dierential pressure

exceeding the minimum limit), the red Close LED

should illuminate, and the shaft drive hub should

be rotating the damper closed. The damper

should go to full closed unless the minimum limit

was set at the CSP-4702, and then the damper will

only go to the minimum seing. If the damper

is rotating open, change the rotation direction

jumper. (See Rotation Direction on page 2.)

4. Reconnect the thermostat signal wire to the “2–10

IN” terminal.

5. Adjust the thermostat’s setpoint all the way up

(simulating a drop in temperature and a need for

less cooling or more heating) and then all the way

down (simulating a rise in temperature and a

need for more cooling or less heating) and check

that the damper position reacts accordingly.

Min. and Max. Flow Limits

NOTE: If desired, the min. and max. limits can

be set within the thermostat or the CSP-

4702, but do NOT try to set the limits at

BOTH the controller and the thermostat

(or else the limits will not reect either the

controller’s or the thermostat’s limits).

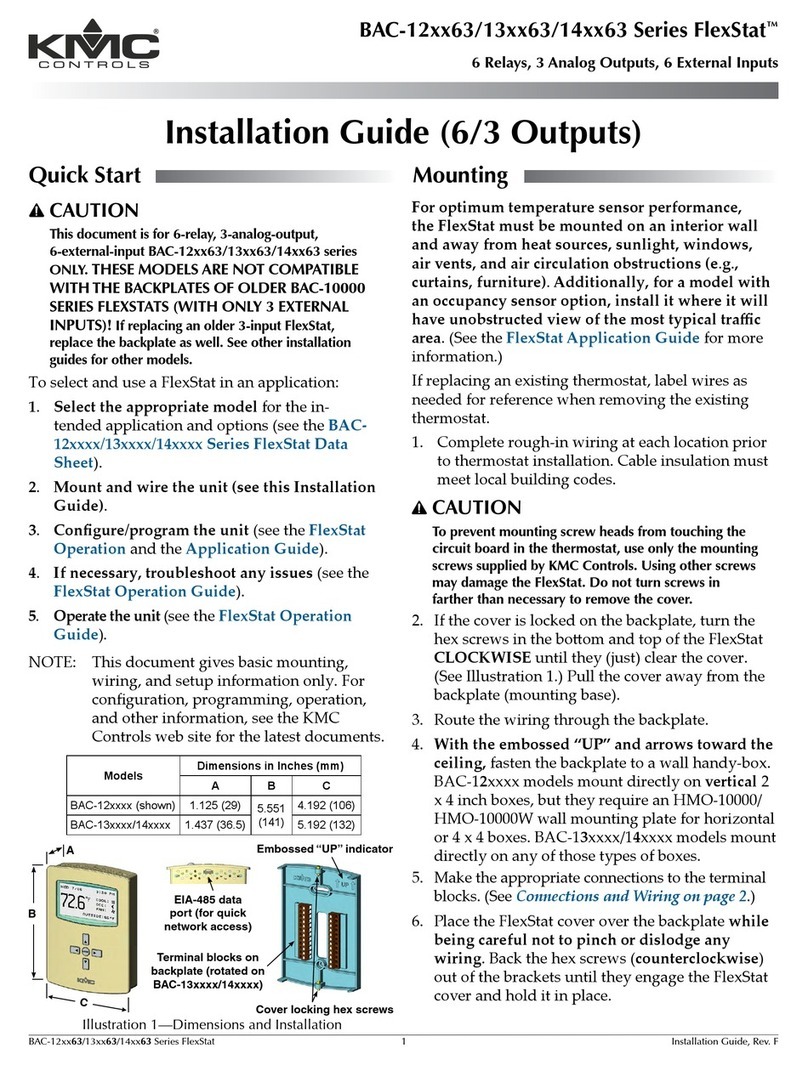

Limits Set at the CSP-4702

To set the minimum and maximum ow limits at the

CSP-4702 (with thermostat supplying 2–10 VDC):

1. Ensure the thermostat output is 2–10 VDC. For

the CTE-5202 thermostat, see the CTE-5202

Applications Guide.

2. Loosen the screw on the conduit ing and lift up

to remove the ing.

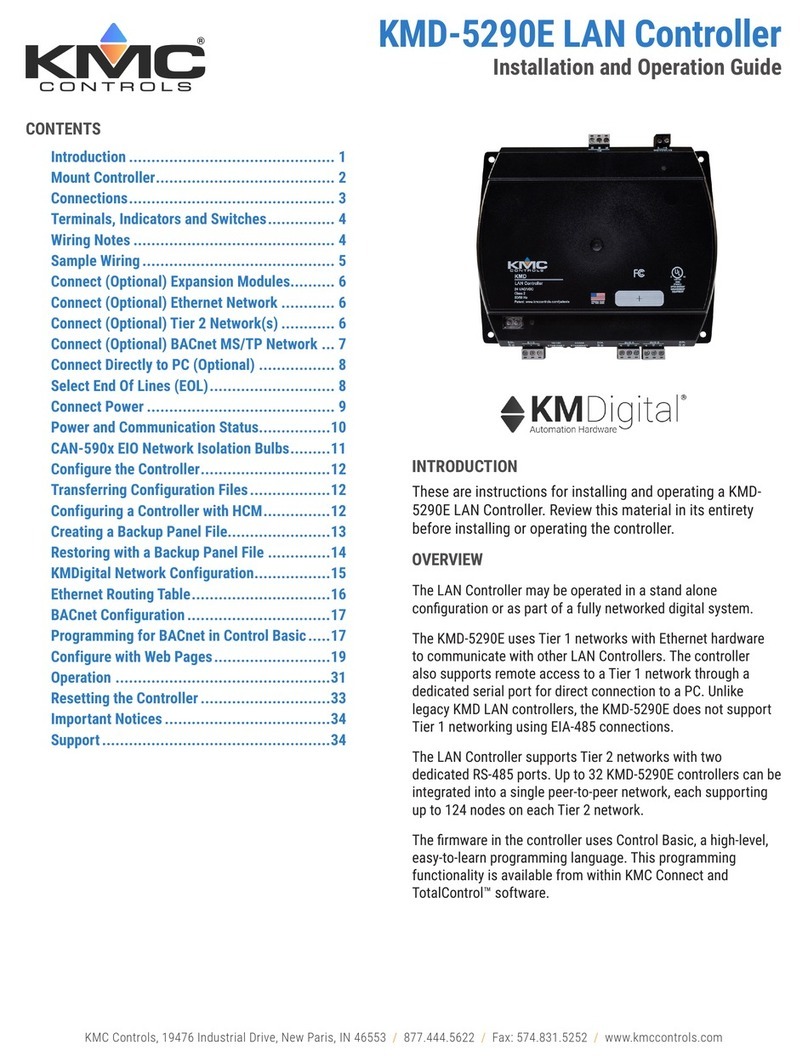

3. Connect a voltmeter to the meter taps. The

middle pin (REF) is the common for the outer

(MIN and MAX) pins.

4. Adjust the MIN potentiometer for the desired

minimum voltage. The factory default is 0 VDC =

0" wc.

NOTE: 1 VDC = 1" wc. If, for example, the desired

minimum is 0.5" wc, set the voltage for 0.5

VDC.

5. Adjust the MA X potentiometer to the desired

maximum voltage. The factory default is 2 VDC =

2" wc.

NOTE: If, for example, the desired maximum is 1.5"

wc, set the voltage for 1.5 VDC.

6. Reinstall the conduit ing and tighten the screw.

Limits Set at the Thermostat

To set the ow limits at the thermostat (with CSP-

4702 potentiometers set at their defaults):

1. Return the CSP-4702 potentiometers to the factory

defaults if necessary (see above).

2. Set the thermostat output limits according to its

instructions. For the CTE-5202 thermostat, see the

CTE-5202 Applications Guide.

NOTE: Voltage from the thermostat = desired ΔP

x (voltage span = 8 VDC)/(pressure span =

2" wc) + 2 VDC. For example, if a minimum

of 0.1" is desired instead of the default 0",

then 0.1 x 4 + 2 (= 0.4 + 2) = 2.4 VDC for the

minimum limit. If a maximum of 1.9" is

desired instead of the default 2", then 1.9 x

4 + 2 (= 7.6 + 2) = 9.6 VDC for the maximum

limit.

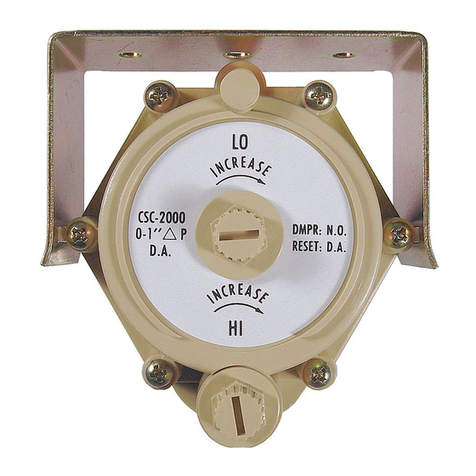

LIMITS

0-2 VDC/ 0-2"H2O

MIN REF MAX

Illustration 4—CSP-4702 Limits Adjustment

Maintenance

No routine maintenance is required. The motors

are permanently lubricated and all internal gear-

train components are oil-impregnated. Careful

installation will also ensure long term reliability and

performance.