KMC Controls BAC-7001 User manual

Other KMC Controls Controllers manuals

KMC Controls

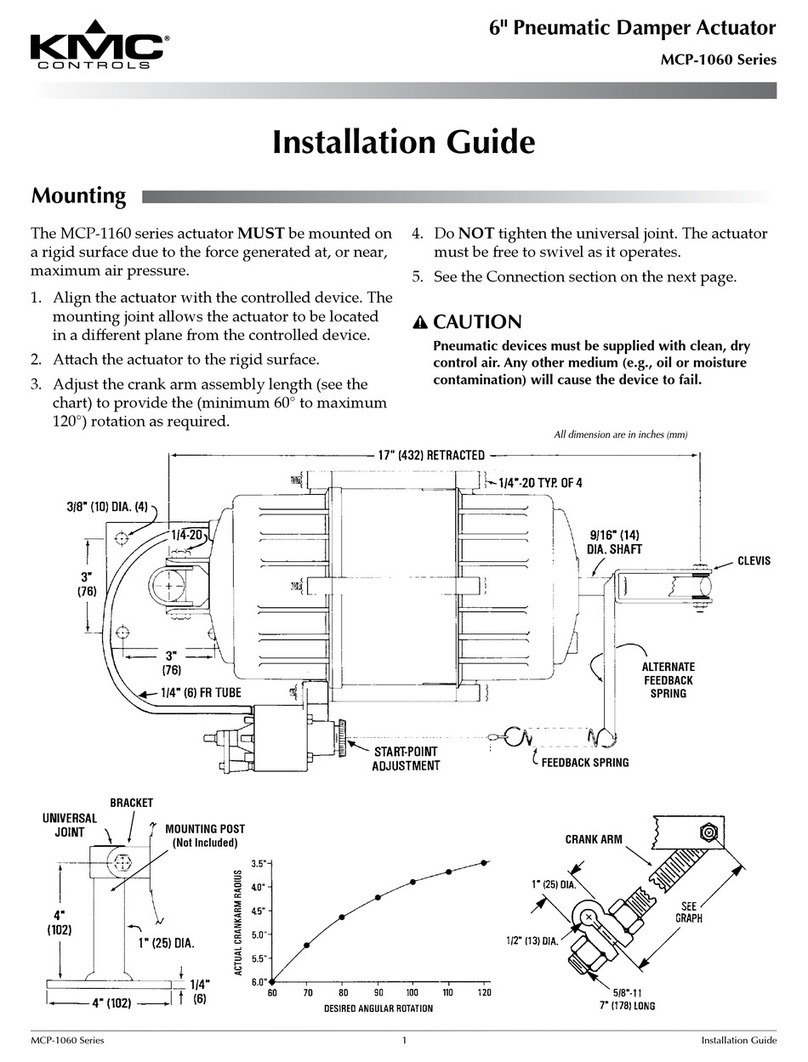

KMC Controls MCP-1060 Series User manual

KMC Controls

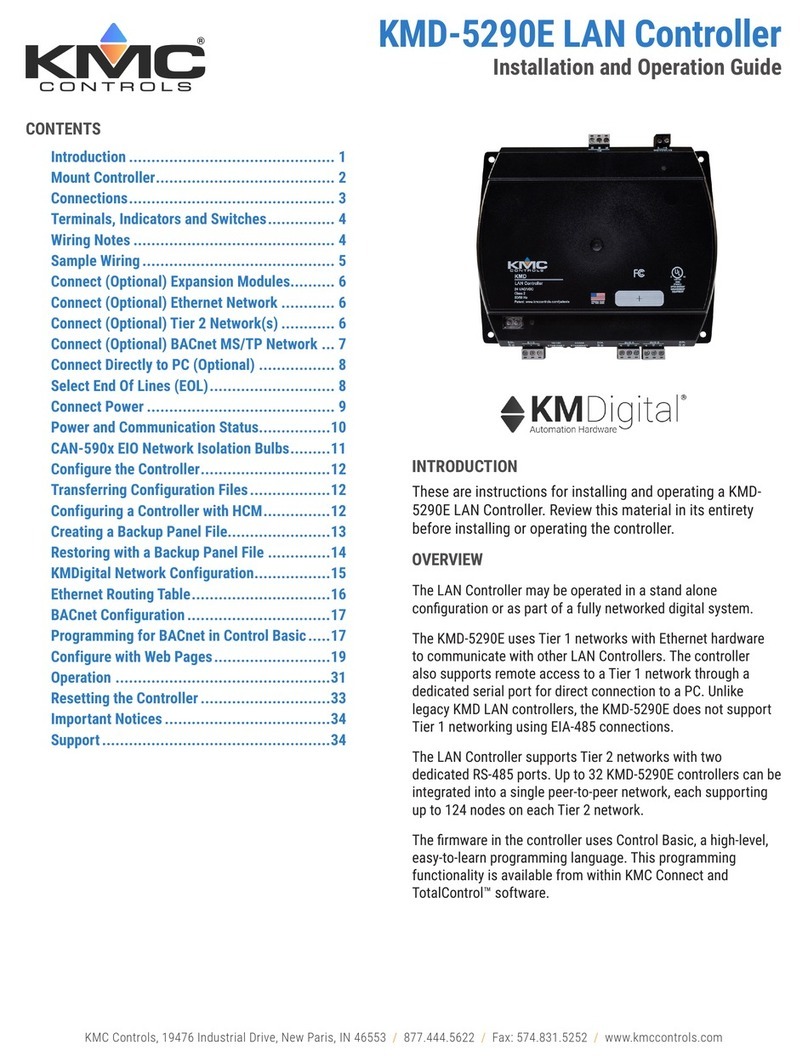

KMC Controls KMDigital KMD-5290E Operating instructions

KMC Controls

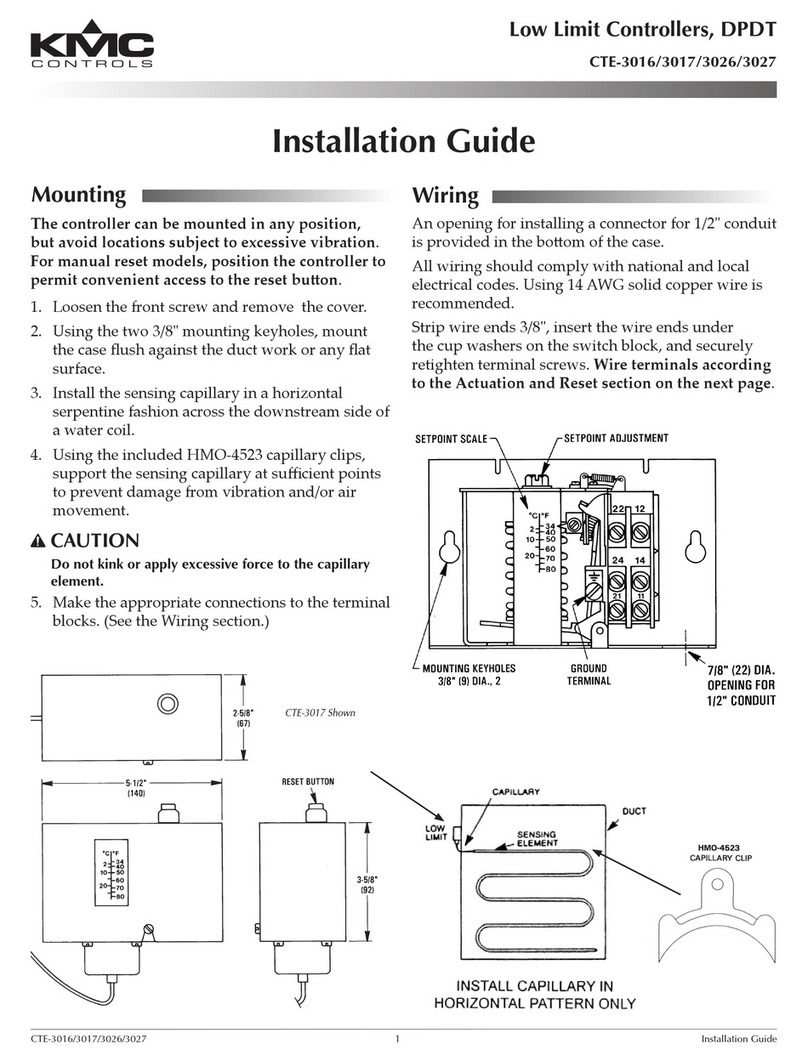

KMC Controls CTE-3017 User manual

KMC Controls

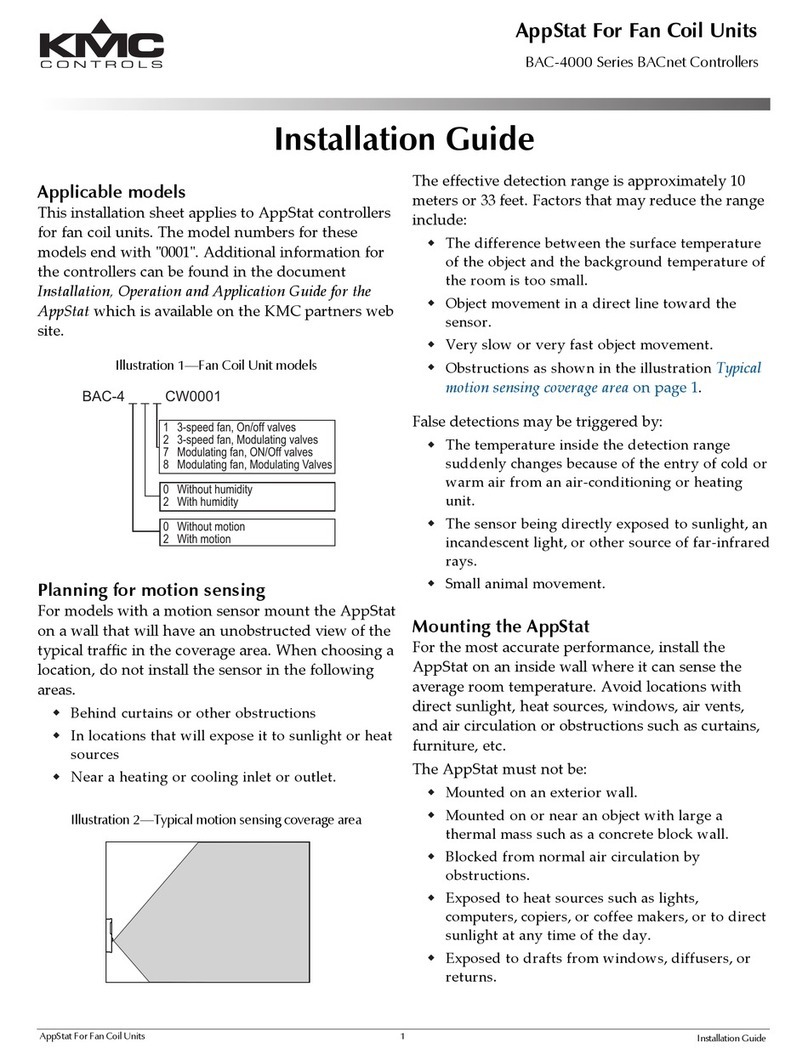

KMC Controls AppStat User manual

KMC Controls

KMC Controls MEP-5062 User manual

KMC Controls

KMC Controls MCP-1040 Series User manual

KMC Controls

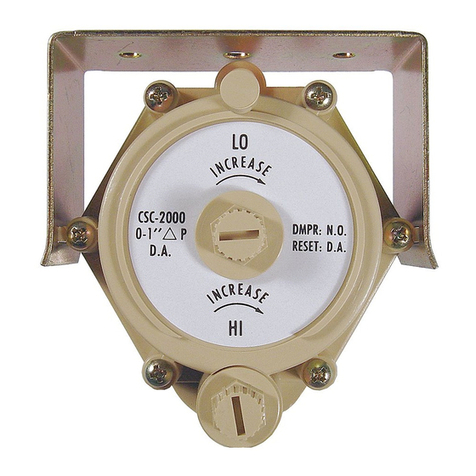

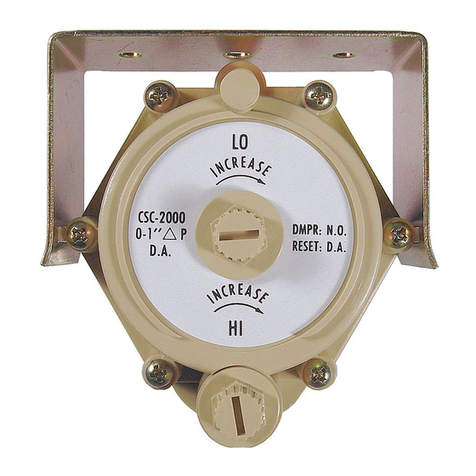

KMC Controls CSC-2000 Series User manual

KMC Controls

KMC Controls BAC-9300 Series User manual

KMC Controls

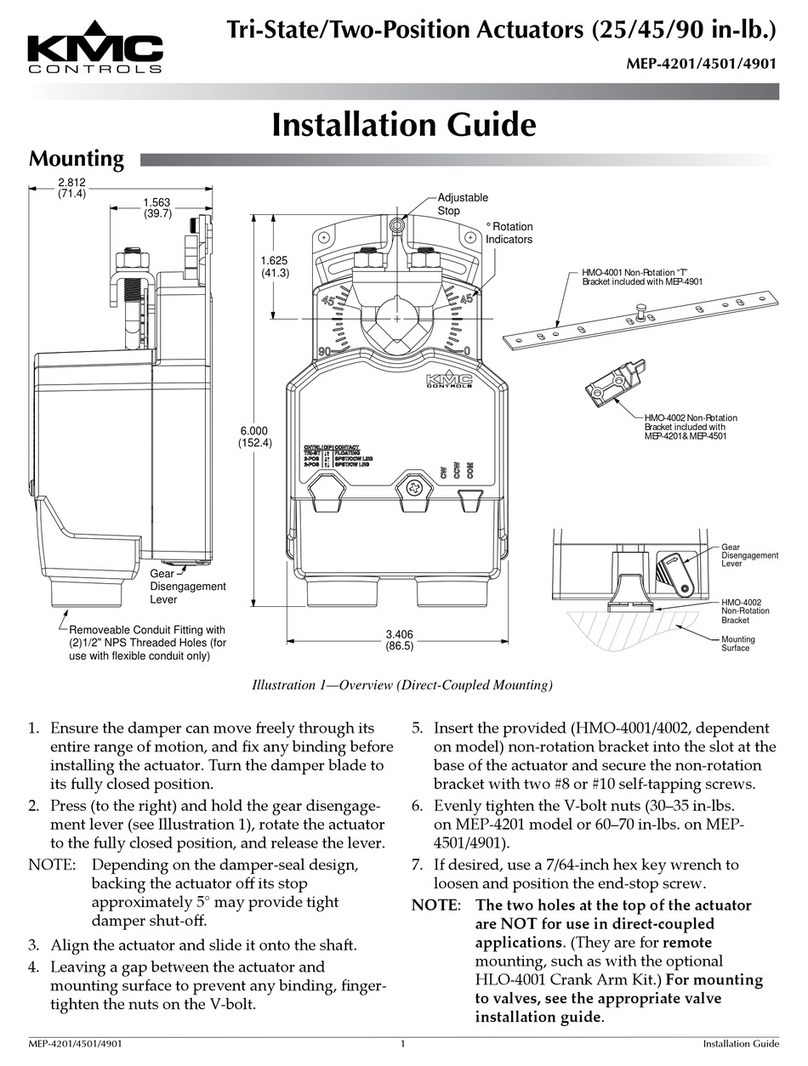

KMC Controls MEP-4201 User manual

KMC Controls

KMC Controls KMD-5210 Operating instructions

KMC Controls

KMC Controls BAC-7302 Operating instructions

KMC Controls

KMC Controls MEP-7 Series User guide

KMC Controls

KMC Controls BAC-5900 Series User manual

KMC Controls

KMC Controls KMD-5290 User manual

KMC Controls

KMC Controls SimplyVAV BAC-8001 User guide

KMC Controls

KMC Controls MEP-3001 Operating instructions

KMC Controls

KMC Controls SimplyVAV BAC-8001 User manual

KMC Controls

KMC Controls KMD-5205 Operating instructions

KMC Controls

KMC Controls BAC-5901C-AFMS User manual

KMC Controls

KMC Controls FlexStat BAC-120063CW-ZEC Operator's manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions