CSC-3000 Series Pneumatic VAV Reset Volume Controllers 4 Applications Guide

Adjustments and Calibration

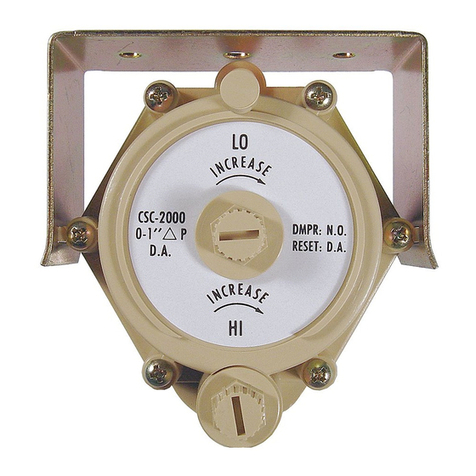

Damper Action

The damper action is factory-set at Normally Open

(N.O.). To change to Normally Closed (N.C.), per-

form the following steps:

1. Loosen the damper selection screw.

2. Turn the selection dial clockwise until the “NC”

arrow aligns with the “DAMPER” arrow.

NOTE: Accuracy in the alignment of the arrows is

very important. Make this adjustment as

exact as possible.

3. Tighten the selection screw. Be sure the

screw is tight (2 to 4 in-lbs. of torque), but if

overtightened, the plastic will strip out.

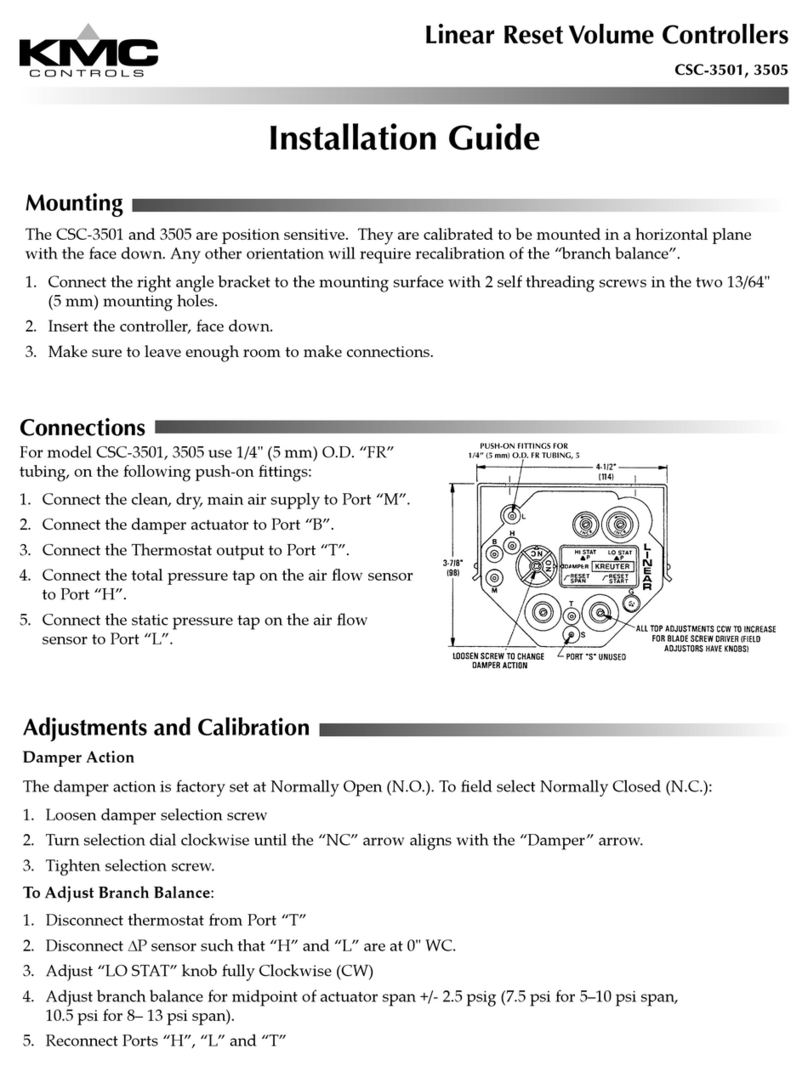

DIRECT RESET Minimum and Maximum

Determining the Type of Reset

The following table shows when Direct Reset or

Reverse Reset is required. Determine the reset type

based on the temperature of the primary air entering

the VAV box and whether the thermostat in the space

is direct or reverse acting.

3 psig 8 psig 13 psig

Thermostat Pressure

Max. Airflow

Min. Airflow

Reset Start Point (8 psig)

Reset Span (5 psig)

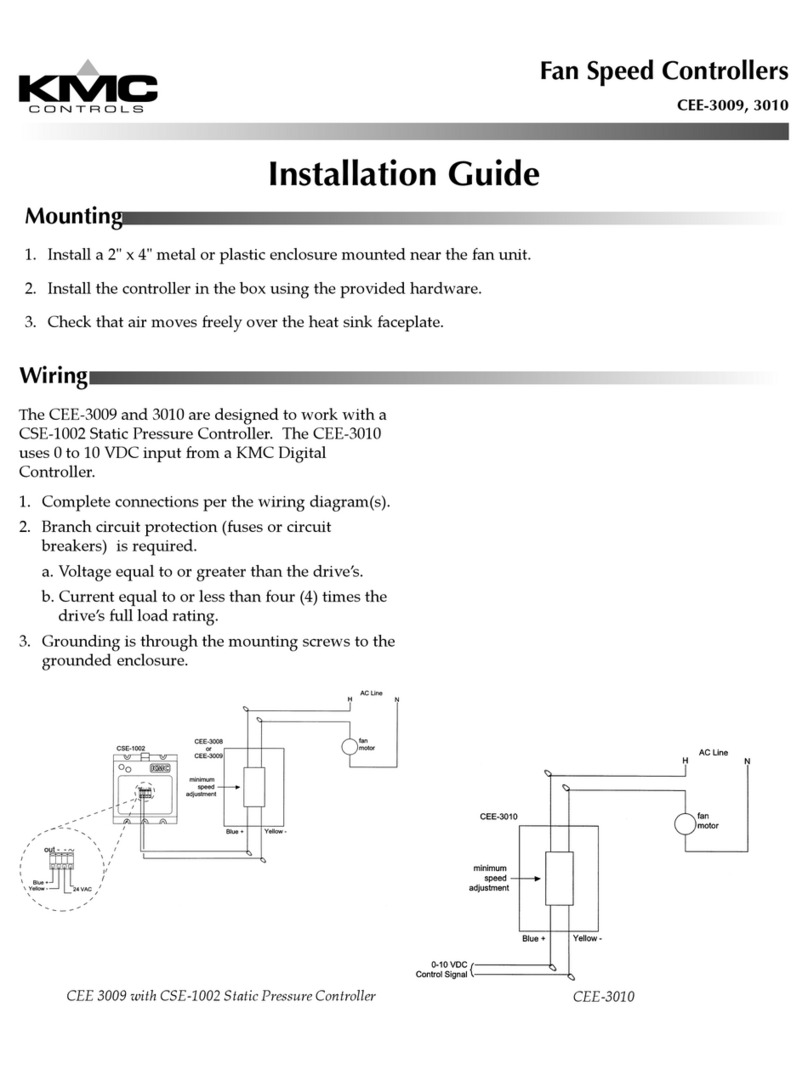

Adjusting Minimums and Maximums

When adjusting the minimum and maximum airow

seings, the output responds slowly to changes in

the setpoint. Wait for the ow rate to stabilize aer

making an adjustment (usually 20 to 30 seconds) be-

fore making further adjustments. Also, if the damper

position is all the way closed or open when starting

this step, turn the adjustment one full turn, and then

wait 20 to 30 seconds for a change in the ow read-

ing of the Magnehelic gauge. If no change occurs

aer this time, repeat until the ow rate changes.

NOTE: The direct reset illustration above assumes

no relays are connected between the

thermostat and “T” port.

For Direct Reset (DA thermostat for cooling or RA

thermostat for heating), perform the following steps:

1. Adjust the thermostat to a seing that will cause

the output pressure to be as high as possible (15

psi or more). This can be done in the following

manner:

a. For Direct Acting thermostats, lower the

seing to the lowest possible seing.

b. For Reverse Acting thermostats, raise the

seing to the highest possible seing.

2. On the CSC-3000, disconnect the “T” port.

Temporarily plug the tubing. (Do NOT plug the

port.)

3. Adjust the LO STAT ∆P (center dial) one

adjustment (1/4 to 1/2 knob rotation) at a time

until the desired Minimum airow is read at the

Magnehilic gauge and is stable.

NOTE: If the LO STAT ∆P Limit must be set at

“0” (zero minimum), do not turn the LO

STAT ∆P knob fully clockwise. The knob

will adjust one and one-half turns aer a

zero minimum is reached. Turning the LO

STAT ∆P knob fully clockwise will result

in a negative reset condition. This means

that when the controller begins to reset at

the reset start point it must rst overcome

the negative adjustment and will not begin

to reset from “0” until a higher thermostat

reset pressure is reached. This negative

reset will also reduce the eective range

of the controller by reducing the low end

reset; narrowing the reset span. If a zero

minimum is required, adjust the LO STAT

∆P knob until the controller just begins

to crack the damper open, then back-o

one-quarter turn and verify zero airow.

(This is typically 2-1/2 knob rotations

counterclockwise from the fully clockwise

position.)

4. Reconnect the thermostat tubing to the “T” port.

This will put 15 PSI or more on the “T” port.

5. Adjust the HI STAT ∆P (dial on right) one

adjustment (1/4 to 1/2 knob rotation) at a time

until the desired Maximum airow is read at the

Magnehilic gauge and is stable.

6. Repeat Steps 2 through 5 to verify the seings to

be correct and ne tune if necessary.

Primary Air Thermostat Reset Type

Cooling DA Direct Reset

RA Reverse Reset

Heating DA Reverse Reset

RA Direct Reset