Table of Contents 3

DG 2.1S user manual V6880, version 3.3

Table of Contents

Note: For your own safety, read the manual and always observe the warnings

and safety information on the device and in the manual!

Intended Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

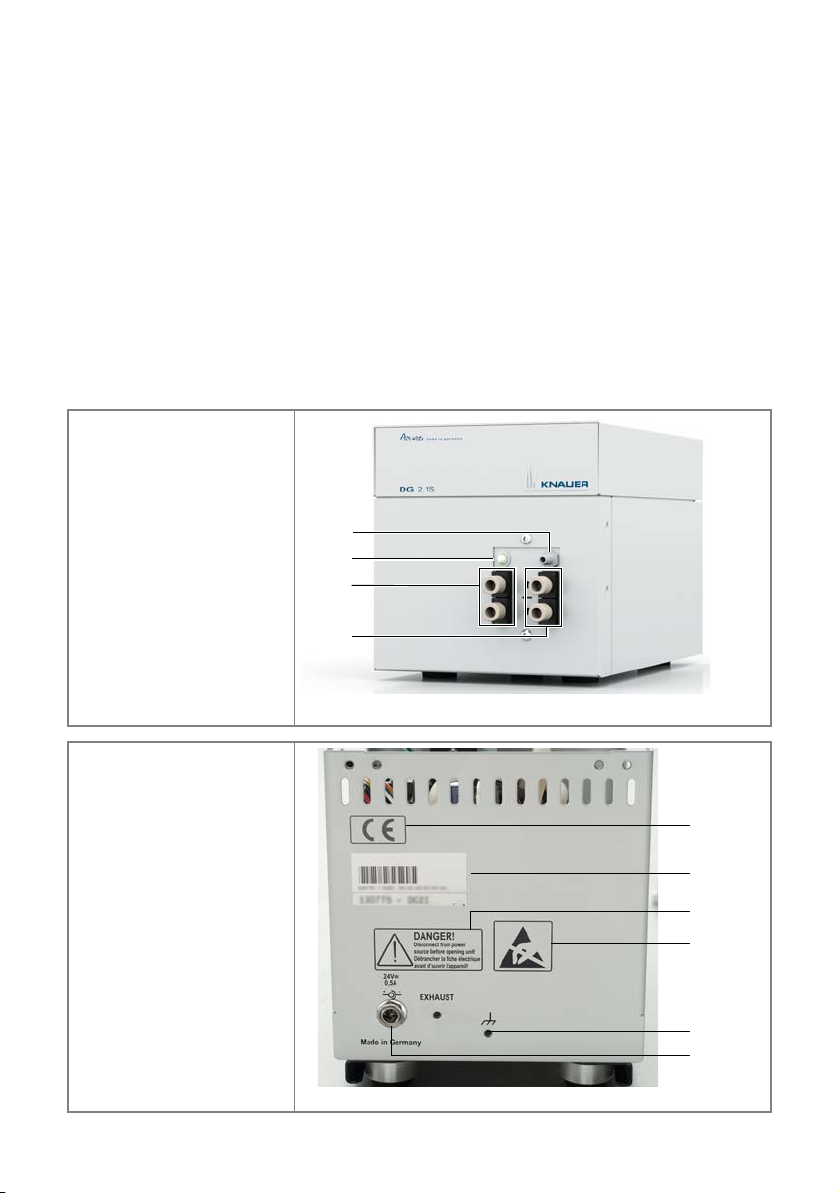

Device Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

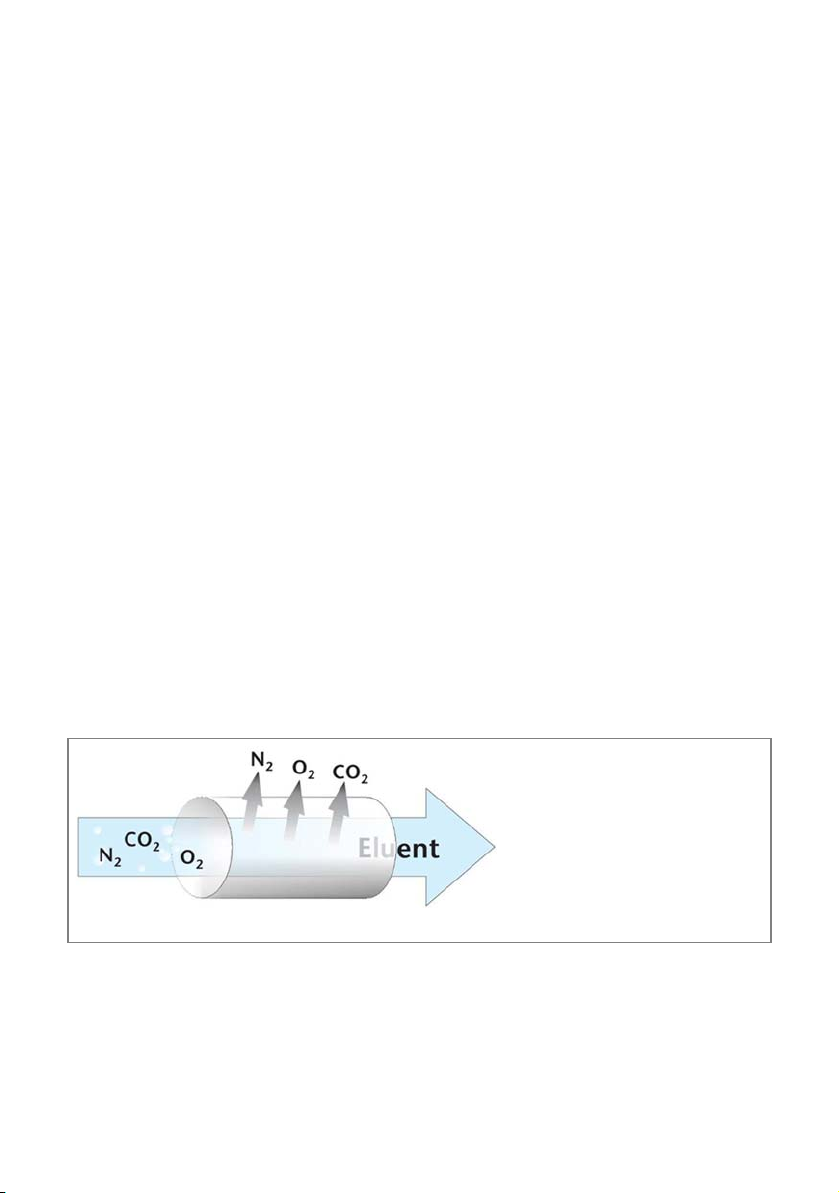

Degassing Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Eluents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety for the User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Decontamination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Symbols and Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Unpacking and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Contacting the Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Location Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Screw Fitting of the Solvent Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Solvent Tube Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connecting Degasser and Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Switching On the Degasser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Purging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Switching Off the Degasser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Short-Term Switch-Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Long-Term Switch-Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Possible Problems and Rectifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maintenance Contract . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cleaning and Caring for the Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

What is to be done if the degasser leaks? . . . . . . . . . . . . . . . . . . . . . . . . 17

Tightening Screw Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preventative Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17