4605 Hydraulic Servo Cylinder Kobelt Manufacturing Co. Ltd.

Rev A mnl_4605 3 of 19

TABLE OF CONTENTS

1Introduction ............................................................................................................ 4

1.1 Contact .................................................................................................................... 4

1.2 Safety....................................................................................................................... 4

2Product Description ................................................................................................. 6

2.1 Technical Data ......................................................................................................... 7

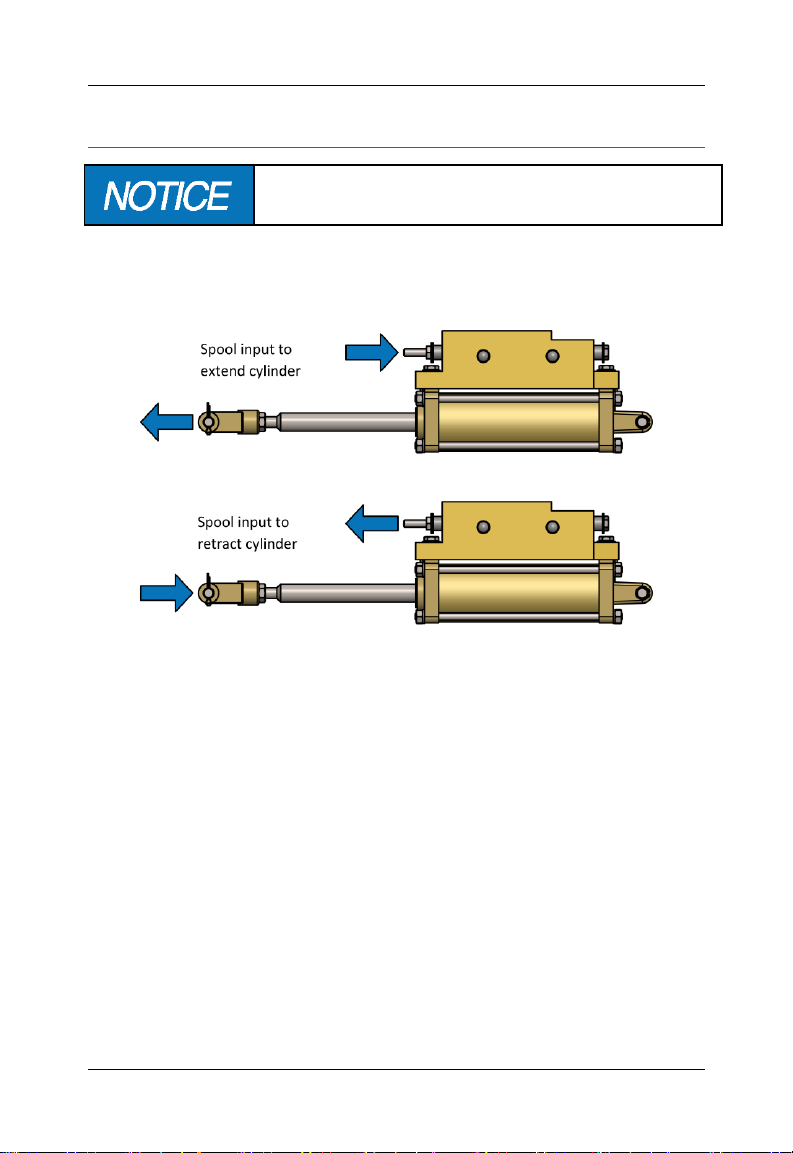

3Operation................................................................................................................ 8

4Installation .............................................................................................................. 9

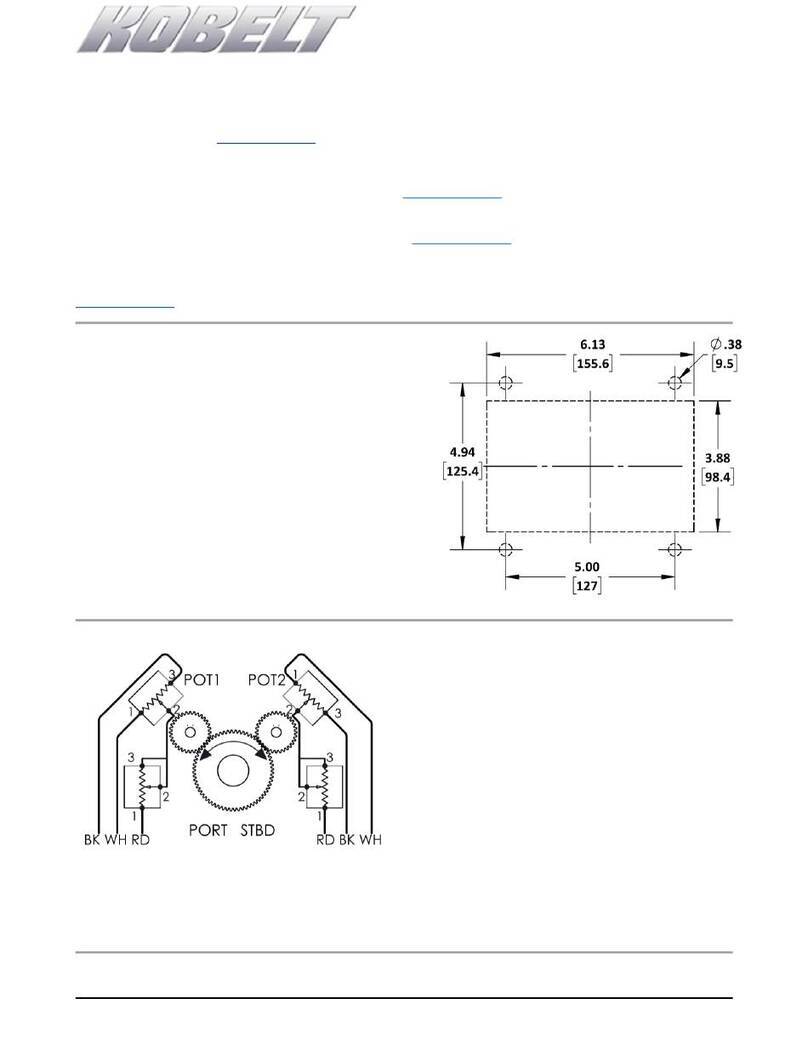

4.1 Mounting ................................................................................................................. 9

4.2 Hydraulic Installation ............................................................................................. 11

5Commissioning ...................................................................................................... 12

5.1 Hydraulic Fill & Bleed............................................................................................. 12

5.2 Functional Test ...................................................................................................... 12

6Maintenance ......................................................................................................... 13

6.1 Preventative Maintenance .................................................................................... 13

6.2 Recommended Spare Parts.................................................................................... 13

7Troubleshooting .................................................................................................... 14

8Warranty............................................................................................................... 15

9Appendix A: Parts List............................................................................................ 16

9.1 4605-4 and 4605-4S Parts Lists .............................................................................. 16

9.2 4605-6, 4605-6S, 4605-8, 4605-8S Parts Lists ........................................................ 17