6555 Control Head Kobelt Manufacturing Co. Ltd.

Rev A MNL-6555.docx 3 of 18

Table of Contents

1Introduction ..................................................................................................................4

1.1 Contact ...................................................................................................................................... 4

1.2 Safety......................................................................................................................................... 4

1.2.1 Safety Alerts .......................................................................................................................... 4

1.2.2 Notice to Installer.................................................................................................................. 4

1.2.3 Product Hazards .................................................................................................................... 5

2Product Description .......................................................................................................6

2.1 Overview.................................................................................................................................... 6

2.2 Technical Data ........................................................................................................................... 7

2.3 Model Configuration Key........................................................................................................... 7

3Installation ....................................................................................................................8

3.1 Receipt....................................................................................................................................... 8

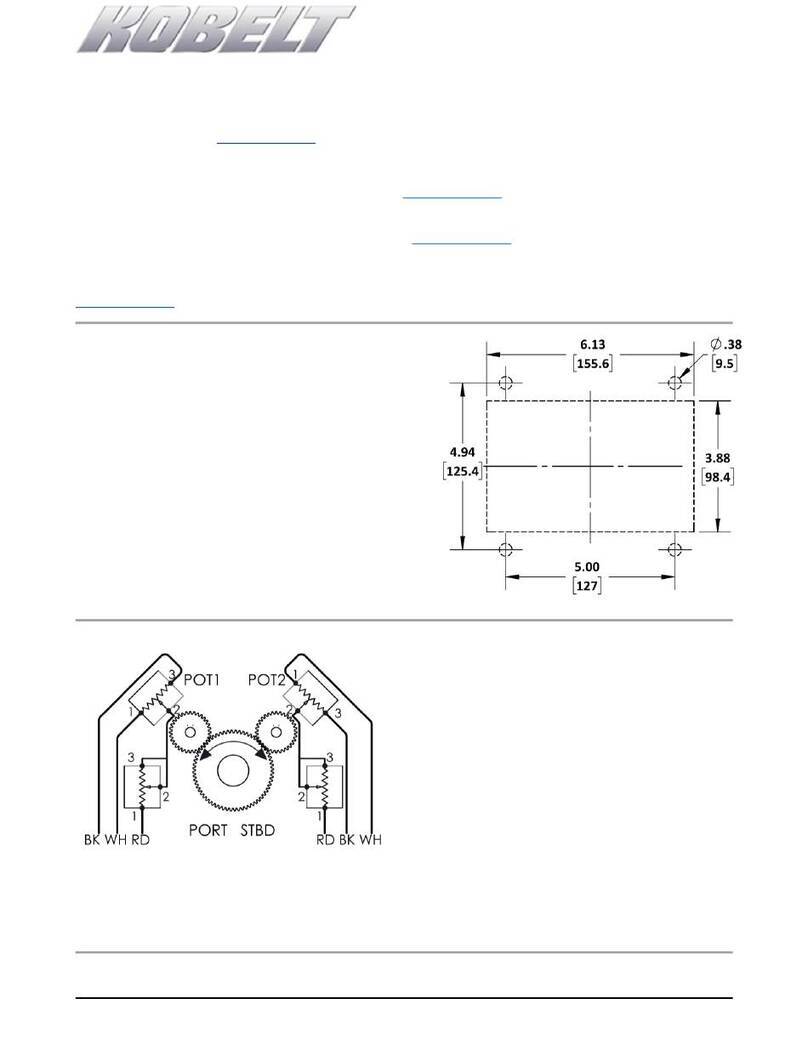

3.2 Mechanical ................................................................................................................................ 8

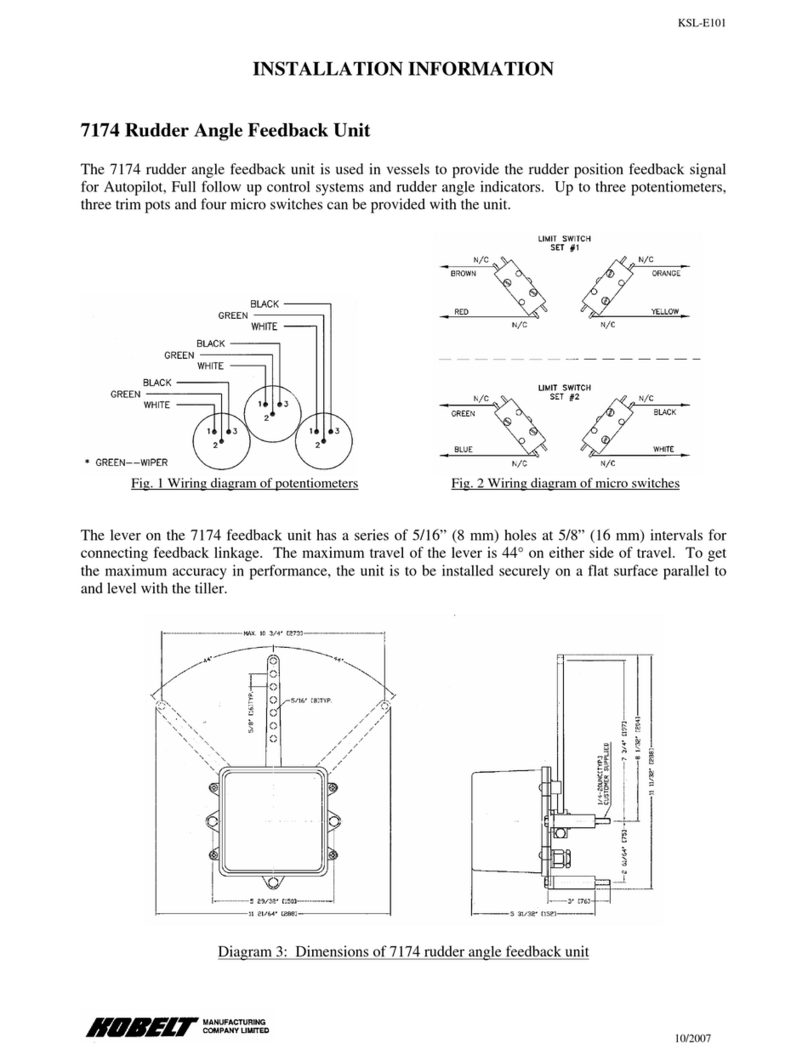

3.3 Electrical .................................................................................................................................... 8

3.4 Functional Test .......................................................................................................................... 9

4Maintenance .................................................................................................................9

4.1 Preventative Maintenance ........................................................................................................ 9

4.2 Calibration ................................................................................................................................. 9

4.3 Lubrication............................................................................................................................... 10

4.4 Recommended Spare Parts and Kits........................................................................................ 10

5Warranty.....................................................................................................................11

6Appendix A: Installation Dimensions ............................................................................12

7Appendix B: Parts List ..................................................................................................13

8Appendix C: Installation Cut-out Template....................................................................17