KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) 2

Table of Contents

1Introduction ..................................................................................................................4

1.1 Contact Information......................................................................................................4

1.2 Safety Information ........................................................................................................4

1.2.1 Safety Instructions ....................................................................................................4

1.2.2 Hazards .....................................................................................................................5

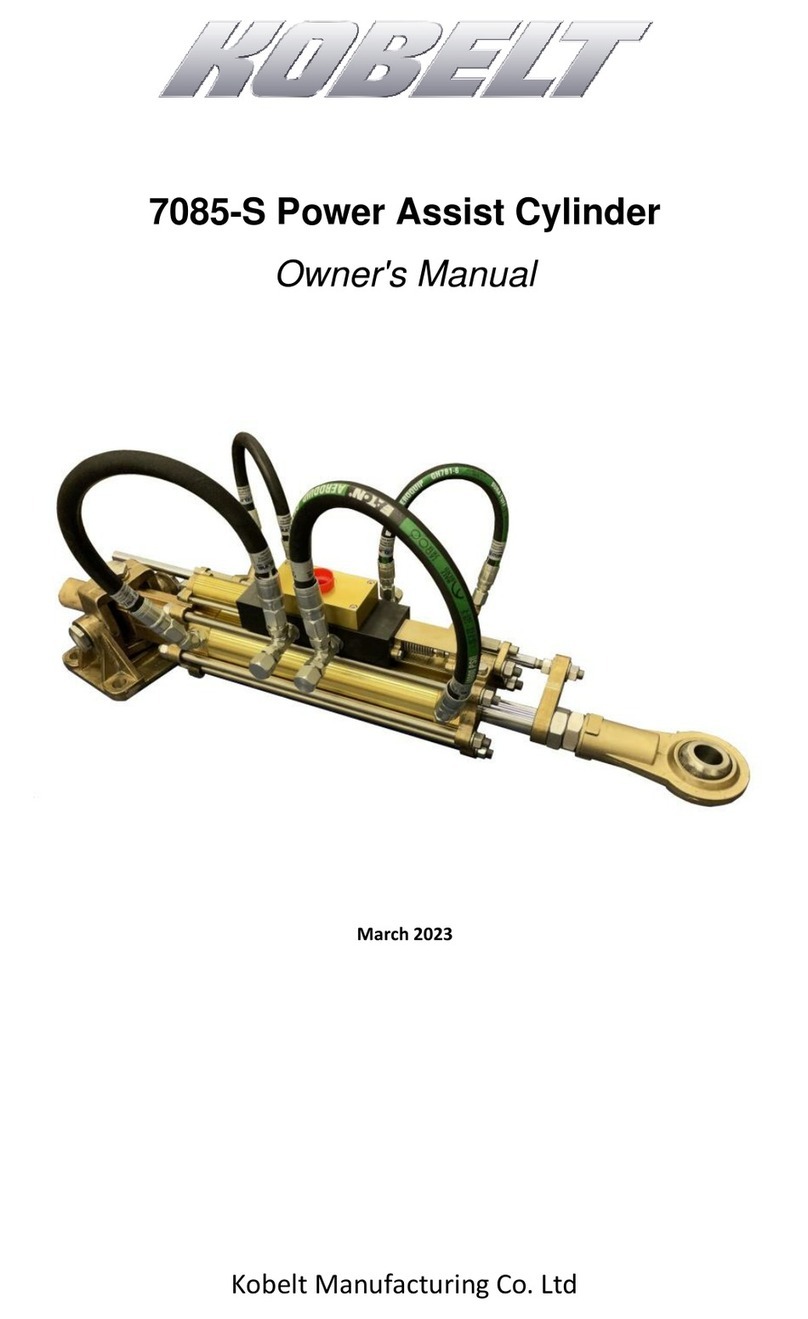

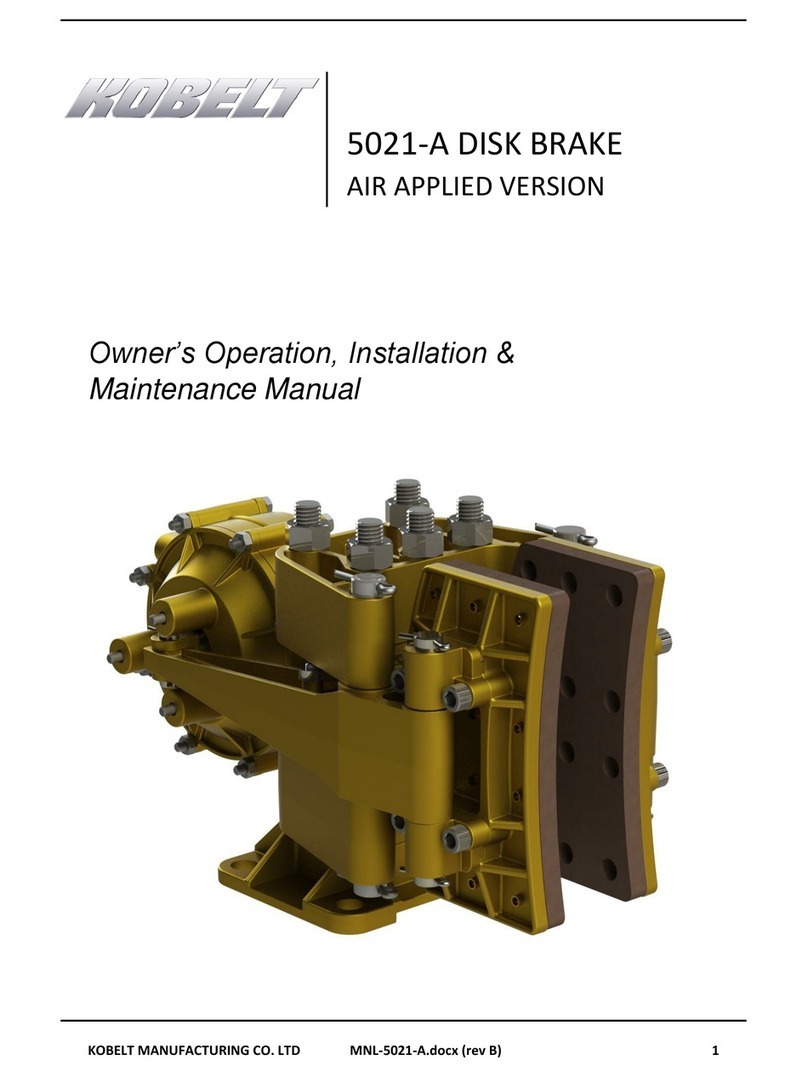

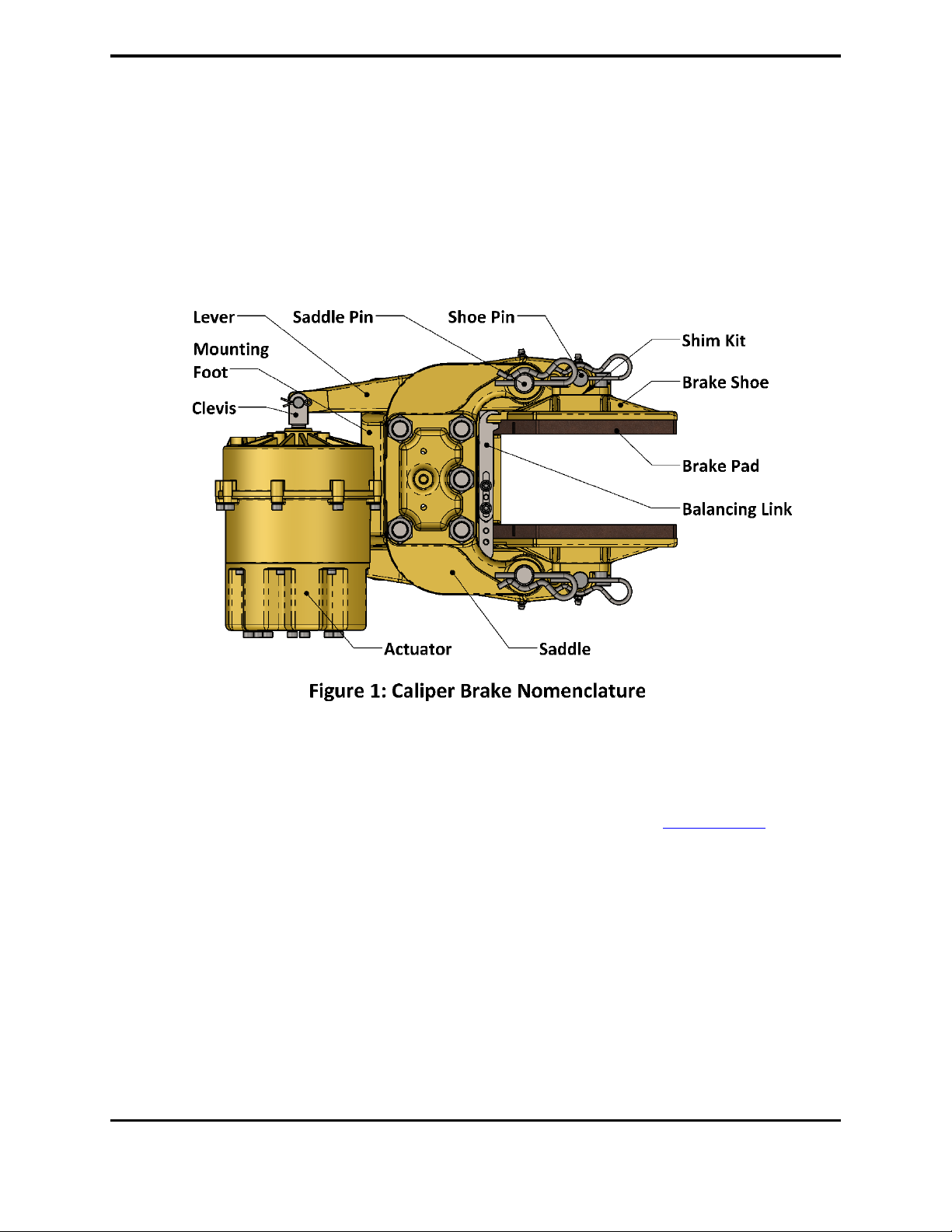

1.3 Product Description.......................................................................................................6

1.3.1 Overview...................................................................................................................6

1.4 Technical Data...............................................................................................................6

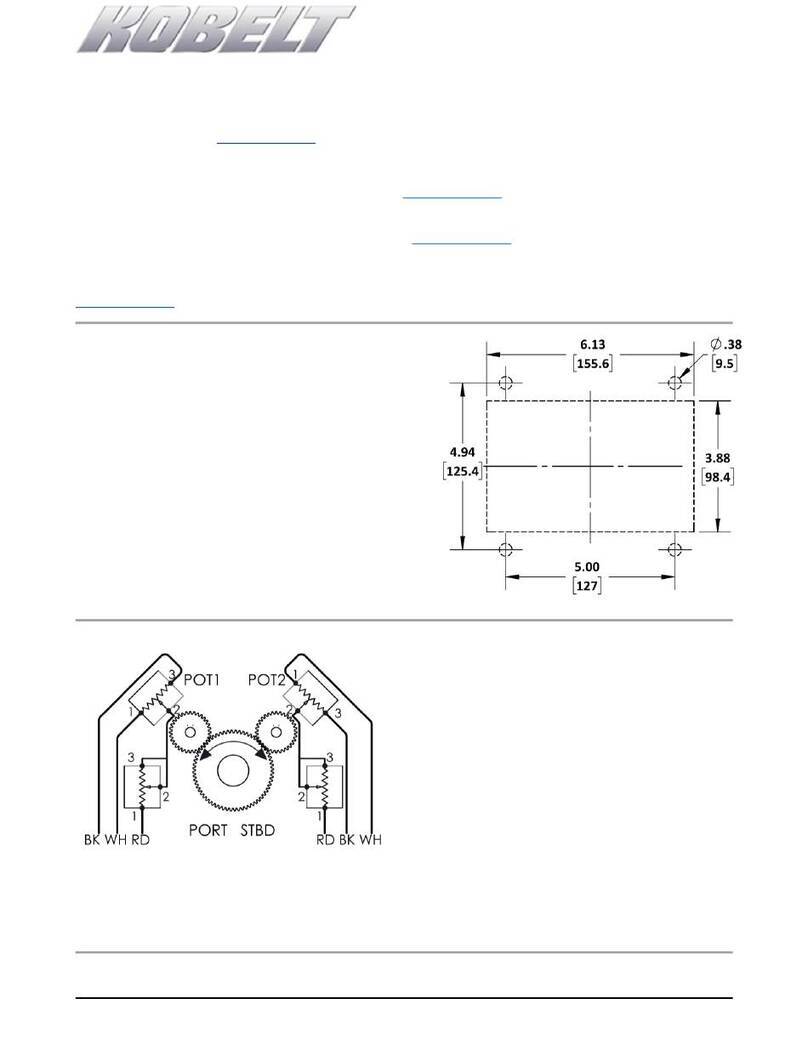

2Installation ....................................................................................................................7

2.1 Preparation ...................................................................................................................7

2.2 Brake Discs ....................................................................................................................7

2.3 Caliper brakes................................................................................................................9

2.3.1 Mechanical................................................................................................................9

2.3.2 Piping ........................................................................................................................9

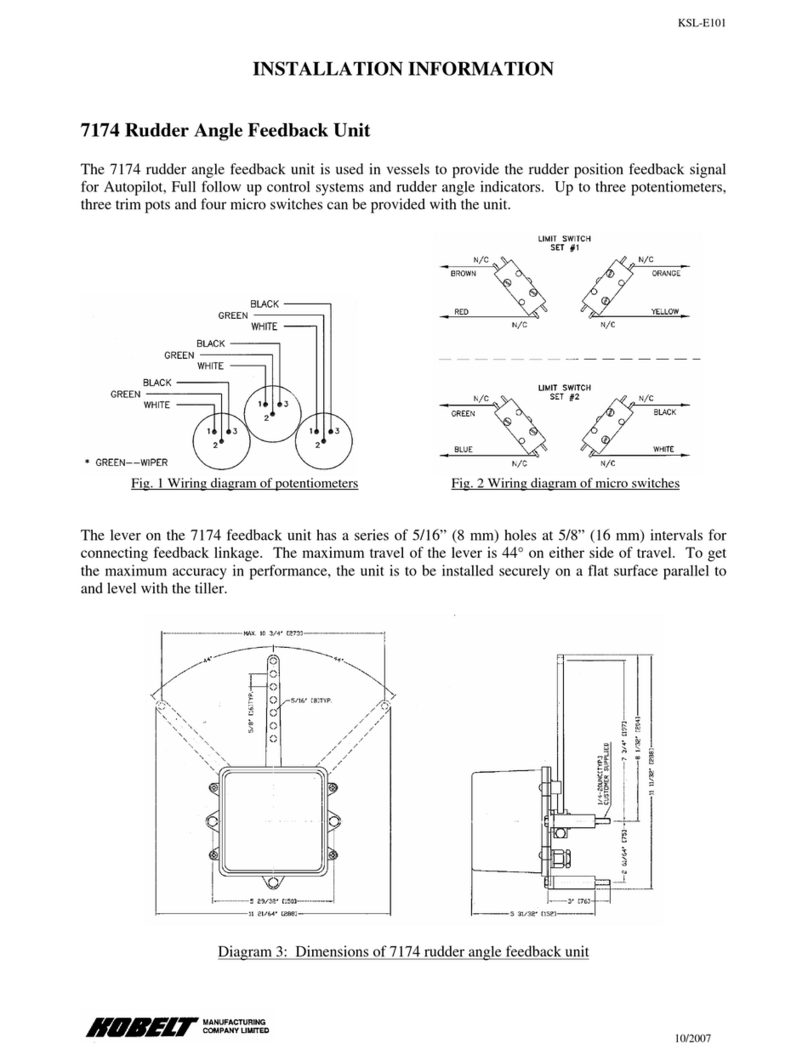

2.3.3 Instrumentation......................................................................................................10

3Commissioning ............................................................................................................11

3.1 Flushing.......................................................................................................................11

3.2 Air Gap ........................................................................................................................11

3.3 Function Test...............................................................................................................11

3.4 Burnishing ...................................................................................................................11

3.5 Torque Test .................................................................................................................12

4Operation....................................................................................................................13

4.1 Functional Requirements ............................................................................................13

4.1.1 Pressure Supply.......................................................................................................13

4.1.2 Control ....................................................................................................................14

4.2 Service Limits ..............................................................................................................14

4.2.1 Disc Temperature....................................................................................................14

4.2.2 Ambient Temperature ............................................................................................14

4.2.3 Pressure ..................................................................................................................14

4.2.4 Disc speed...............................................................................................................14

5Maintenance ...............................................................................................................15

5.1 Preventative Maintenance..........................................................................................15

5.2 Inspection....................................................................................................................15

5.2.1 Pad Wear ................................................................................................................15

5.2.2 Seals........................................................................................................................16

5.2.3 Actuator Test ..........................................................................................................16

5.2.4 Pin Wear .................................................................................................................16

5.2.5 Brake Disc ...............................................................................................................16