OMS

page 2 OMS K01/0922

1. Contents

1.Contents ........................................................................................................ 2

2.Note .............................................................................................................. 3

3.Instrument Inspection .................................................................................... 3

4.General Information ...................................................................................... 4

5.Regulation Use ............................................................................................. 4

6.Warranty ....................................................................................................... 4

7.Operating Principle ........................................................................................ 5

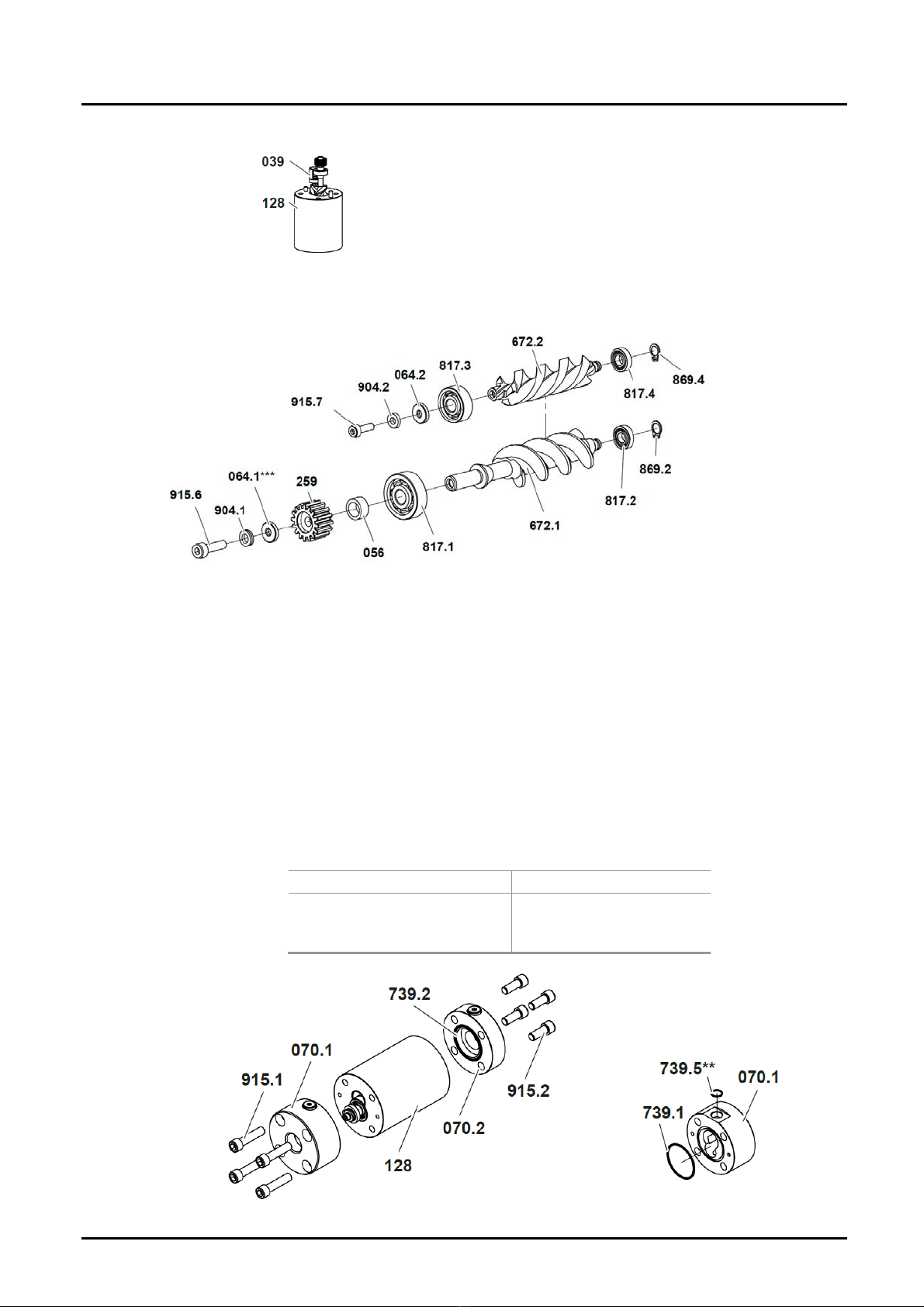

8.Mechanical Connection ................................................................................. 6

9.Electrical Connection .................................................................................... 7

10.Disassembly and Assembly .......................................................................... 9

10.1Servicing .............................................................................................. 9

11.Start up ....................................................................................................... 16

12.Troubleshooting .......................................................................................... 17

13.Maintenance ............................................................................................... 18

14.Technical Information .................................................................................. 19

15.Order Details ............................................................................................... 21

16.Dimensions and Weights ............................................................................ 22

17.Pressure loss diagram ................................................................................ 24

18.Disposal ...................................................................................................... 25

19.Appendix ..................................................................................................... 26

19.1Tightening torque for screws with metric screw threads and head

contact surfaces ................................................................................. 26

19.2Tightening torques for screw plugs with thread measured in inches

and elastomer seal ............................................................................ 26

19.3Tightening torques and widths for threaded rings .............................. 27

20.EU Declaration of conformance .................................................................. 28

Manufactured and Sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

Internet: www.kobold.com