5B6339 – January 1996 3

Description Page

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

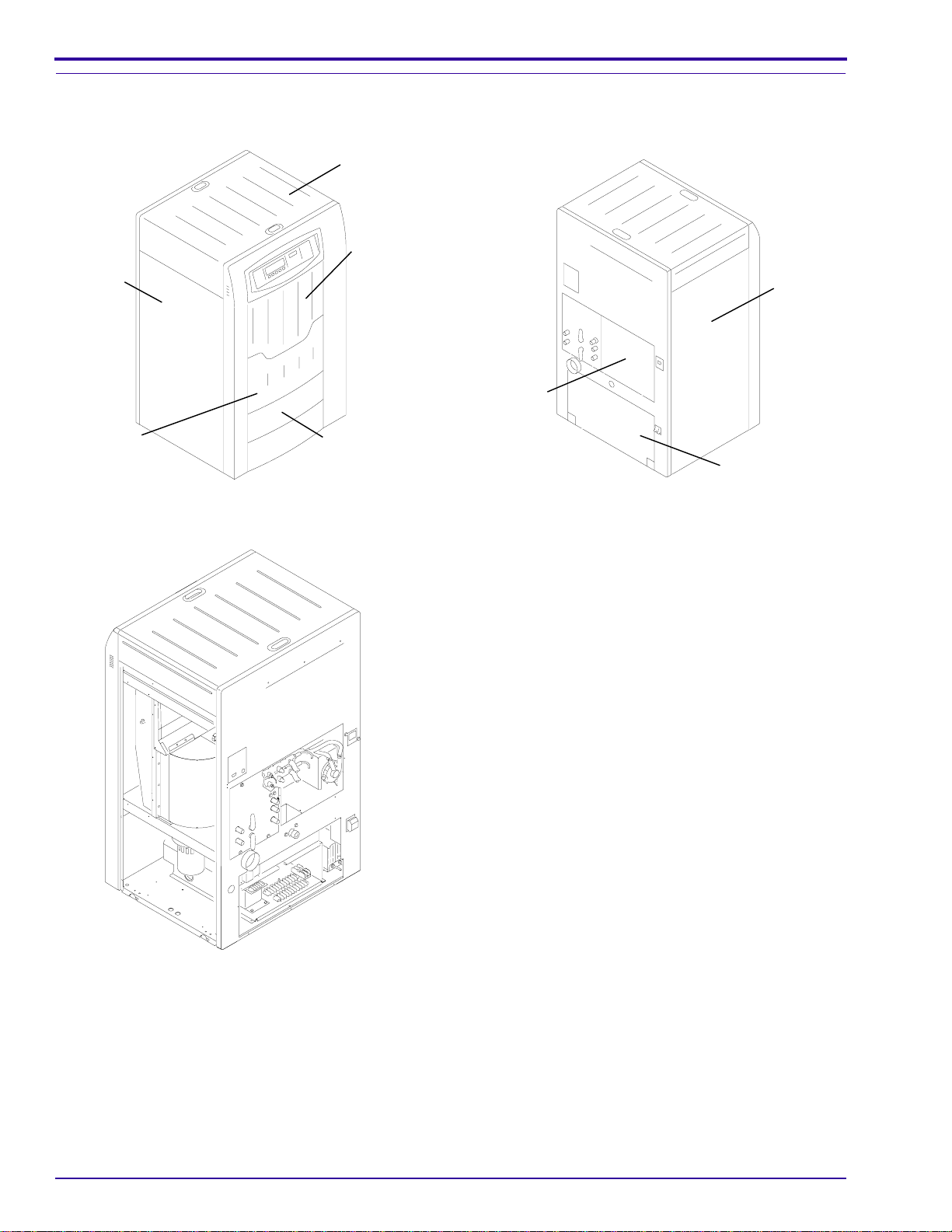

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Preventive Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Special Tools Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Preparing the PROCESSOR for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking the PROCESSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Removing the Packing Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Removing the PROCESSOR from the PALLET . . . . . . . . . . . . . . . . . . . . . . . . 6

Removing the PANELS and Checking the Packing List . . . . . . . . . . . . . . . . . . 8

Removing the Packing Material from the DRYER and the SHIPPING SCREW 9

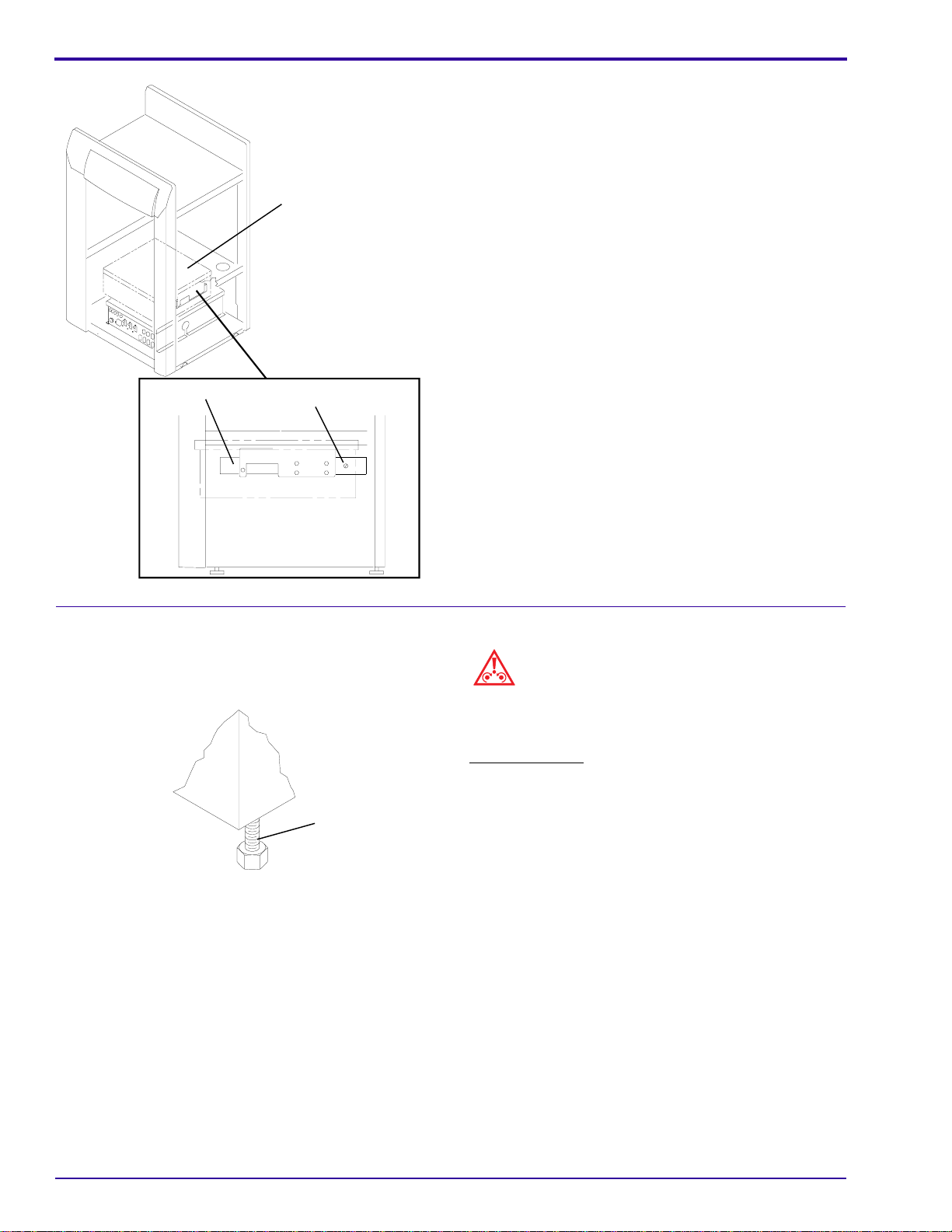

Installing the LEVELING SCREWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing the PROCESSOR Through a Wall — Feed End. . . . . . . . . . . . . . . . . . . . . 11

Installing the PROCESSOR Through a Wall — Dryer End . . . . . . . . . . . . . . . . . . . . 12

Leveling the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing the RACKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing the CROSSOVERS and the SQUEEGEE ASSEMBLY . . . . . . . . . . . . . . . 17

Connecting the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Making the Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connecting the JUMPERS at TB2 and TB3 and the Wires to TB1 . . . . . . . . . . 20

Connecting the Wires to TERMINAL STRIP TB1 . . . . . . . . . . . . . . . . . . . . . . . 22

Changing the PROCESSOR to 50 Hz Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Making the Plumbing Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing the DEVELOPER FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting the Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting the Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connecting the REPLENISHMENT TUBES . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Connecting the REPLENISHMENT TANKS . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Measuring the Static Pressure and Making the Exhaust Connections. . . . . . . . . . . . 32

Installing an AUXILIARY VENTILATION FAN KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Installing and Adjusting the FEED TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installing the FEED TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Adjusting the Height of the FEED TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Aligning the FILM GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Checking for the Correct Position of the LIGHT SHIELD . . . . . . . . . . . . . . . . . . . . . . 38

Checking the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Checking for Leakage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Checking Miscellaneous Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Checking the DISPLAY PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Checking the Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Final Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Publication History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42