297444-2-AA (-)

DO IT RIGHT! Use a Kohler Certified

Installer,(KCI),fortheinstallationofyour

Kohler Shower Door. Contact your

Kohler Distributor/Showroom or call

Kohler at 1-800-456-4537 for the KCI

nearestyou.

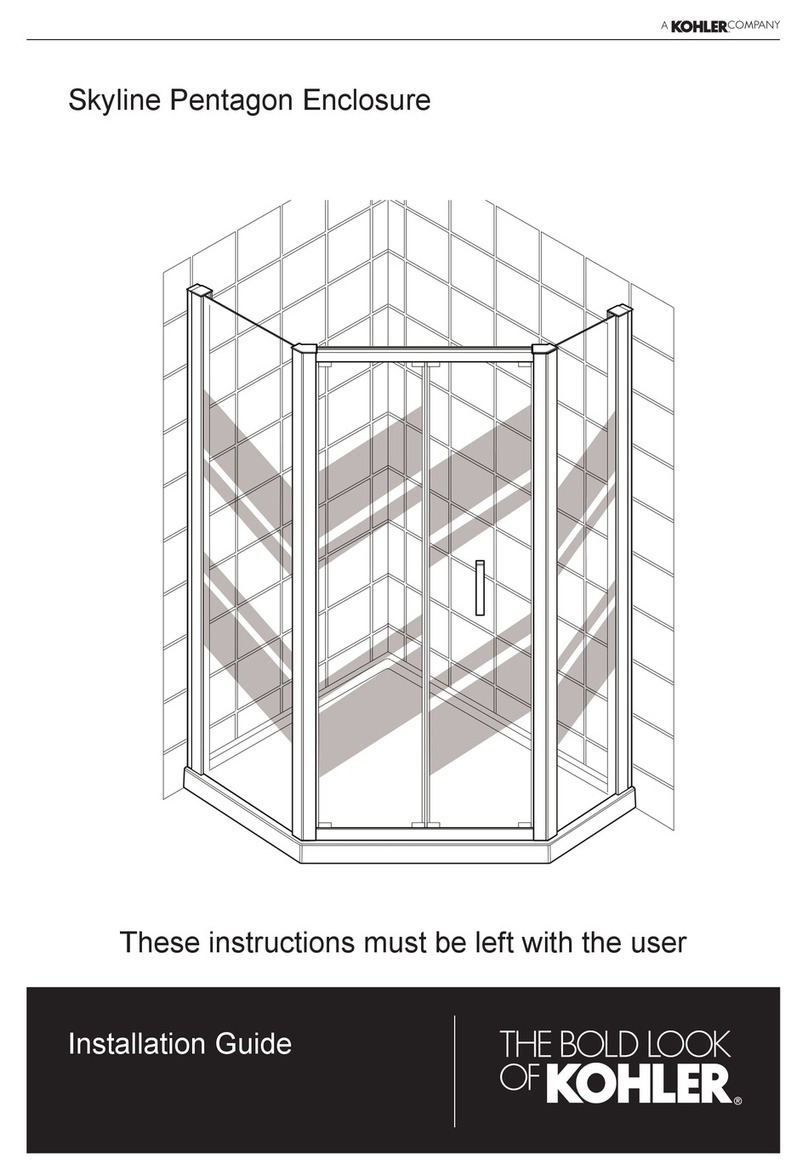

Introduction

Please read these instructions carefully to familiarize

yourself with the required tools, materials, and installation

sequences. The Exploded Diagram of the Door on page13

will also provide a helpful reference when relating the

location of the various parts.

All information in these instructions is based on the

latest product information available at the time of

publication. Kohler Co. reserves the right to make

changes in product characteristics, packaging, or

availability at any time without notice.

IMPORTANT CONSUMER INFORMATION

LIMITED ONE-YEAR WARRANTY

Kohlerplumbingfixturesandfittingsarewarrantedfreeofmanufacturing

defects.

Kohler Co. will, at its election, repair, replace, or make appropriate

adjustment where Kohler Co. inspection discloses any such defects

occurringin normalusagewithinoneyear afterinstallation.KohlerCo.

isnotresponsible forinstallationcosts.

Toobtainwarrantyservice,contactKohlerCo.eitherthroughyourDealer

orPlumbing Contractor or by writing Kohler Co., Att: Consumer Affairs

Department,Kohler, WI 53044 U.S.A.

IMPLIEDWARRANTIESINCLUDINGTHATOFMERCHANTABILITY,

ARE EXPRESSLY LIMITED IN DURATION TO THE DURATION OF

THISWARRANTY.KOHLERCO.DISCLAIMSANYRESPONSIBILITY

FORCONSEQUENTIALDAMAGES.

Some states do not allow limitations on how long an implied warranty

lasts, or the exclusion or limitation of incidental or consequential

damages, so this limitation and exclusion may not apply to you. This

warrantygivesyouspecificlegalrights.Youmayalsohaverightswhich

vary from state to state.

This is our exclusive written warranty.

KOHLER CO., KOHLER, WISCONSIN 53044

BASIC TOOLS AND MATERIALS NEEDED

TOOLS

6 foot folding rule or measuring tape

Hacksaw with 32 teeth per inch blade

Miter box or square

Hammer

Electric drill

Drill bit-3/16″

Masonry bit for ceramic tile-3/16″

Fine file

Screwdriver-Phillips

Level

Pencil

Safety glasses

Caulking gun

Knife

Pliers

MATERIALS

Masking Tape

Silicone Sealant (RTV)

HOW TO CARE FOR YOUR DOOR

NEVER USE SCOURING POWDER, PADS OR SHARP

INSTRUMENTS ON METAL WORK OR GLASS PANELS.

The use of a squeegee following each shower is

recommended to eliminate water spots on the inside of the

glass panels.

An occasional wiping down with a mild detergent diluted in

water is all that is needed to keep the panels and anodized

aluminum parts looking new.

CAUTION: TEMPERED GLASS CANNOT BE CUT.