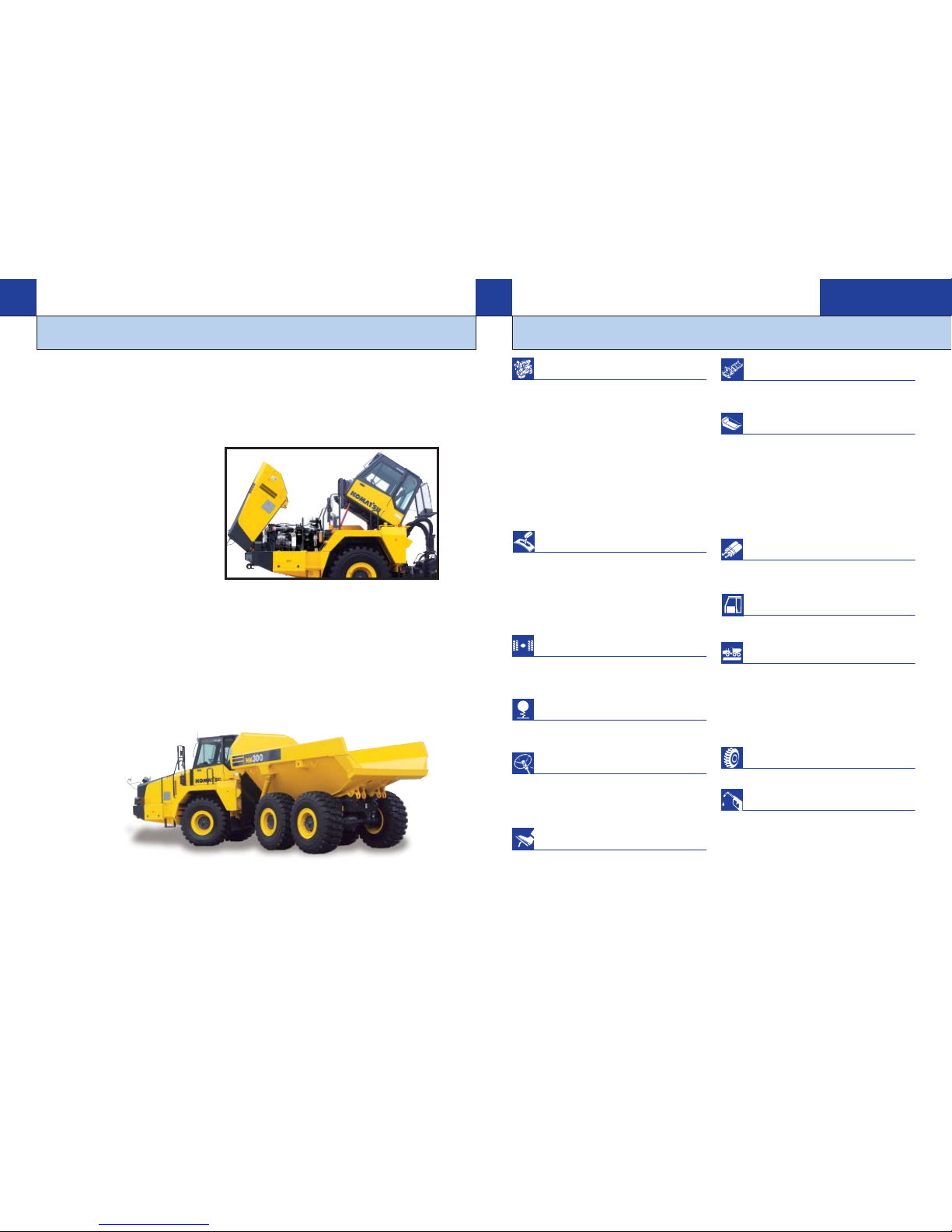

EASY MAINTENANCE

HM300-2R

ARTICULATED DUMP TRUCK

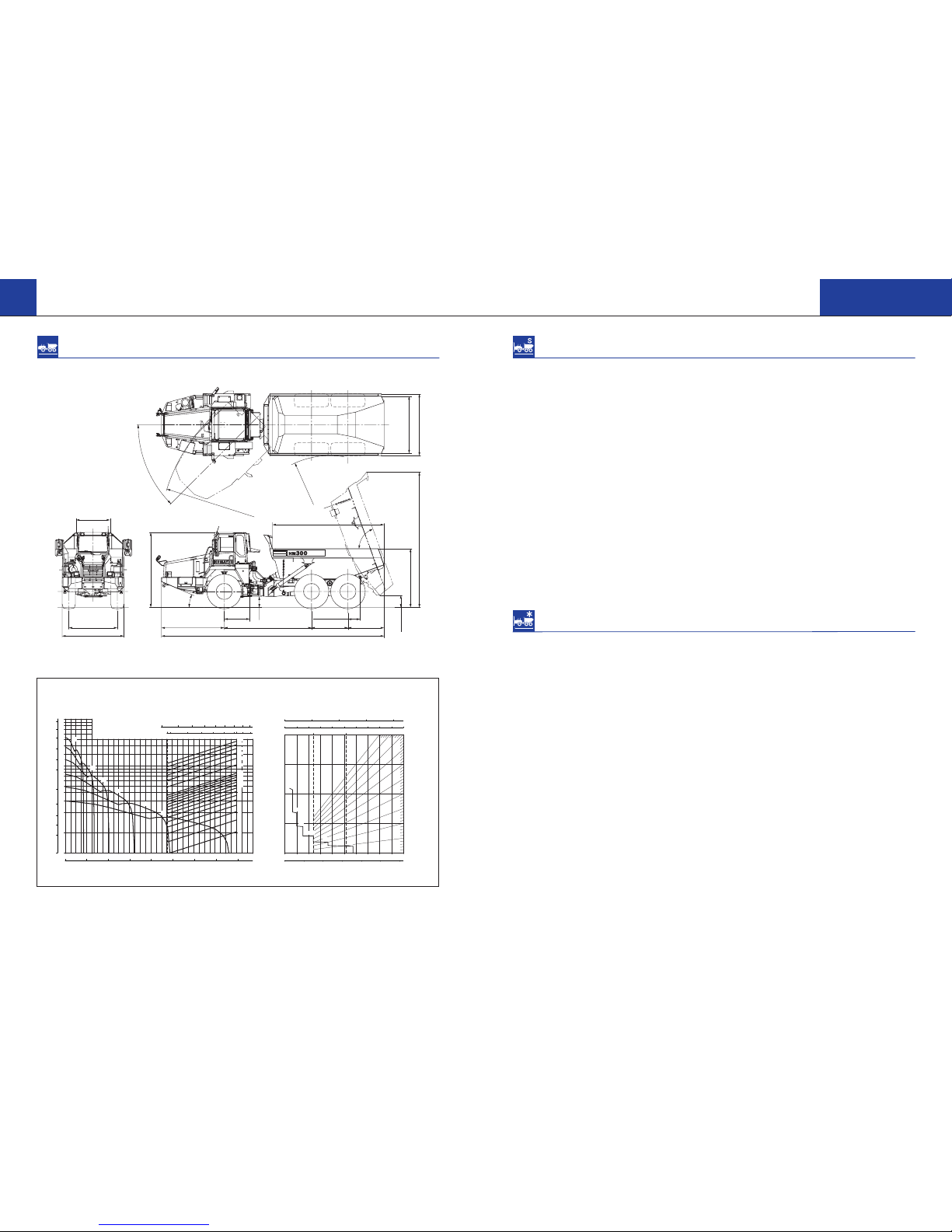

HM300-2R ARTICULATED DUMP TRUCK

SPECIFICATIONS

AXLES

Full time all wheel drive with limited slip differential in all axles.

Final drive type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Planetary gear

Ratios:

Differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.154

Planetary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.667

TRANSMISSION

Torque converter . . . . . . . . . . . . . . . . . 3-elements, 1-stage, 2-phase

Transmission . . . . . . . . . . . . . . . . . Full-automatic, counter-shaft type

Speed range . . . . . . . . . . . . . . . . . . 6 speeds forward and 2 reverse

Lockup clutch . . . . . . . . . . . . . . . . . . . . . . . . . Wet, single-disk clutch

Forward . . . . . . . . . . . . . . . . . . . . Torque converter drive in 1st gear,

direct drive in 1st lockup and all higher gears

Reverse. . . . . . . . . Torque converter drive and direct drive in all gear

Shift control . . . . . . . . . . . . . . . Electronic shift control with automatic

clutch modulation in all gear

Maximum travel speed . . . . . . . . . . . . . . . . . . 58.6 km/h 36.4 mph

ENGINE

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Komatsu SAA6D125E-5

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Water-cooled, 4-cycle

Aspiration. . . . . . . . . . . . . . . . . . . . . . . . Turbo-charged, after-cooled

Number of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 mm 4.92"

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 mm 5.91"

Piston displacement. . . . . . . . . . . . . . . . . . . . . . . . 11.04 ltr. 674 in3

Horsepower

SAE J1995 . . . . . . . . . . . . . . . . . . . . . . . . Gross 254 kW 340 HP

ISO 9249 / SAE J1349 . . . . . . . . . . . . . . . . . Net 246 kW 329 HP

Rated rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 rpm

Fan drive type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical

Maximum torque . . . . . . . . . . . . . . . . . . . . . . . 174 kg•m 1,259 lb. ft

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Direct injection

Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronically controlled

Lubrication system

Method . . . . . . . . . . . . . . . . . . . . . . . Gear pump, force-lubrication

Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-flow type

Air cleaner. . . . . . . . . . . . . . . . . . Dry type with double elements and

precleaner (cyclonpack type), plus dust indicator

SUSPENSION SYSTEM

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydro-pneumatic suspension

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Combined hydro-pneumatic

and rubber suspension system

MAIN FRAME

Type . . . . . . . . . . . . . . . . . . . . . . . . . Articulated type, box-sectioned

construction on front and rear

Connected by strong torque tubes.

STEERING SYSTEM

Type . . . . . . . . . . . . . . . Articulated type, fully hydraulic power steering

with two double-acting cylinders

Supplementary steering . . . . . . . . . . . . . . . . . . Automatically actuated,

electrically powered

Minimum turning radius, wall to wall . . . . . . . . . . . . . . . . 7.96 m 26'1"

Articulation angle . . . . . . . . . . . . . . . . . . . . . . . . . . . 45° each direction

BRAKES

Service brakes . . . . . . . . . . . . . . . . . . Full-hydraulic control, oil-cooled

multiple-disc type on front and center axles

Parking brake . . . . . . . . . . . . . . . . . . . Spring applied, caliper disc type

Retarder. . . . . . . . . . . . . . Front and center axle brakes act as retarder

WEIGHT (APPROXIMATE)

Empty weight. . . . . . . . . . . . . . . . . . . . . . . . . . 24,040 kg 53,000 lb

Gross vehicle weight . . . . . . . . . . . . . . . . . . . . 51,420 kg 113,360 lb

Weight distribution:

Empty: Front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55.8%

Center axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.6%

Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20.6%

Loaded: Front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30.3%

Center axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35.5%

Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34.2%

BODY

Capacity:

Struck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.9 m316.9 yd3

Heaped (2:1, SAE) . . . . . . . . . . . . . . . . . . . . . . . 16.6 m321.7 yd3

Payload . . . . . . . . . . . . . . . . . . . . . 27.3 metric tons 30.1 U.S. tons

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . 130 kg/mm2184,925 psi

high tensile strength steel

Material thickness:

Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 mm 0.55"

Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 mm 0.31"

Sides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 mm 0.47"

Target area

(inside length x width) . . . . . . . 5240 mm x 2685 mm 17'2" x 8'10"

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . Exhaust heating (option)

HYDRAULIC SYSTEM

Hoist cylinder . . . . . . . . . . . . . . . . . . . . Twin, 2-stage telescopic type

Relief pressure . . . . . . . . . . . . . . . . . 20.6 MPa 210 kg/cm2 2,990 psi

Hoist time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 sec

CAB

Dimensions comply with ISO 3471 ROPS (Roll-Over Protective

Structure) standards

TIRES

Standard tire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23.5 R25

SERVICE REFILL CAPACITIES

Fuel tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . 384 ltr. 101.5 U.S. Gal

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 ltr. 9.8 U.S. Gal

Torque converter, transmission and

retarder cooling . . . . . . . . . . . . . . . . . . . . . 77.5 ltr. 20.5 U.S. Gal

Differentials (total) . . . . . . . . . . . . . . . . . . . . . 63.5 ltr. 16.8 U.S. Gal

Final drives (total) . . . . . . . . . . . . . . . . . . . . . . . . 24 ltr. 6.3 U.S. Gal

Hydraulic system. . . . . . . . . . . . . . . . . . . . . . . 120 ltr. 31.7 U.S. Gal

Suspension (total) . . . . . . . . . . . . . . . . . . . . . . 10.4 ltr. 2.7 U.S. Gal

98

Tiltable Cab

The cab can be tilted rearward 32 degrees to provide easy

maintenance/service for the engine and transmission.

Note: An external hydraulic pump is required to tilt the cab

or a service crane can be used after easily remov-

ing only eight bolts...

The HM300-2R has been designed to keep service time down and productivity up by

reduced number of grease points, easy access to filters, and longer intervals between

oil changes.

Fewer Grease Points

The number of grease points are minimized by using maintenance-free

rubber bushings.

Guards

The following guards are provided as standard:

●Protective grille for rear window

●Engine underguard

●Heavy duty transmission underguard

●Propeller shaft guards

●Exhaust thermal guard

●Fire prevention covers

Extended Service Intervals

In order to minimize operating costs, service intervals have been extended:

●Engine oil 500 hours

●Transmission oil 1000 hours

●Engine oil filter 500 hours

●Transmission oil filters 1000 hours