Korg POLYSIX User manual

Other Korg Synthesizer manuals

Korg

Korg MONOPOLY POLYSIX MS-20 User manual

Korg

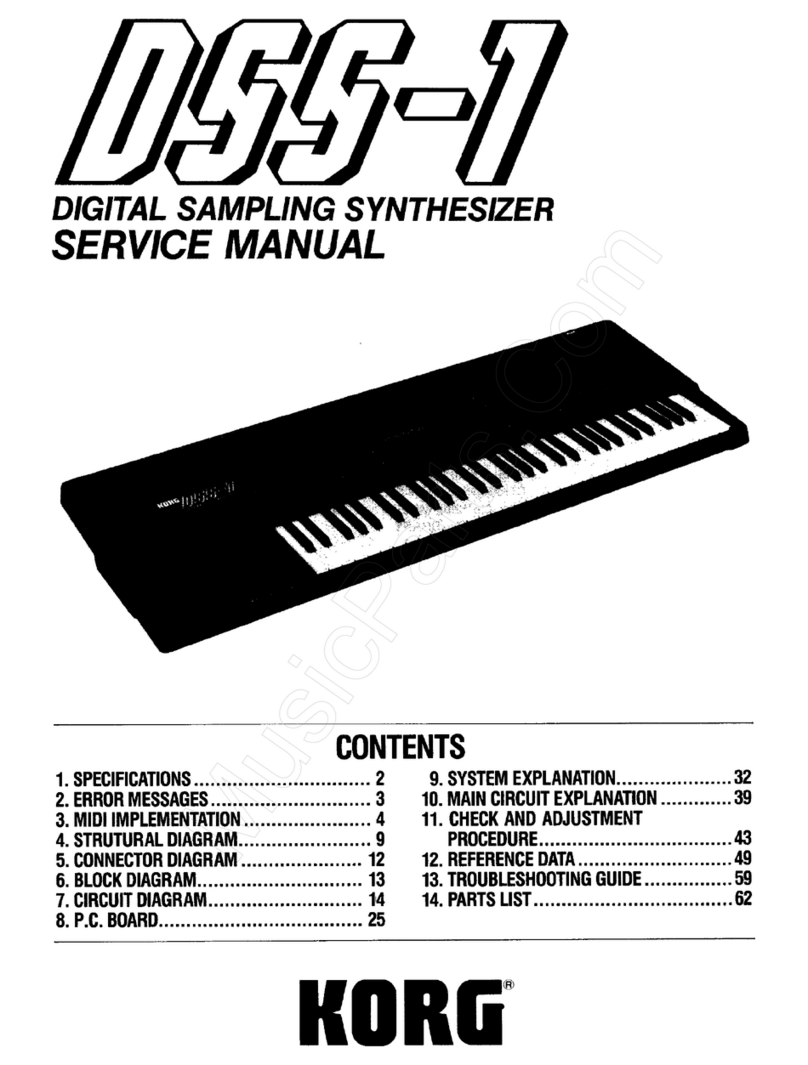

Korg DSS-1 User manual

Korg

Korg MONOPOLY POLYSIX MS-20 User manual

Korg

Korg Volca Bass User manual

Korg

Korg KRONOS-61 User manual

Korg

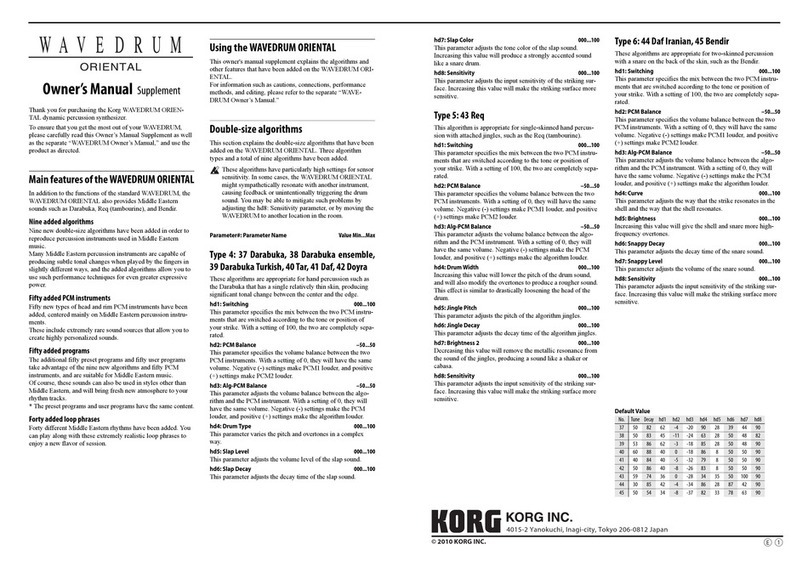

Korg WAVEDRUM ORIENTAL User manual

Korg

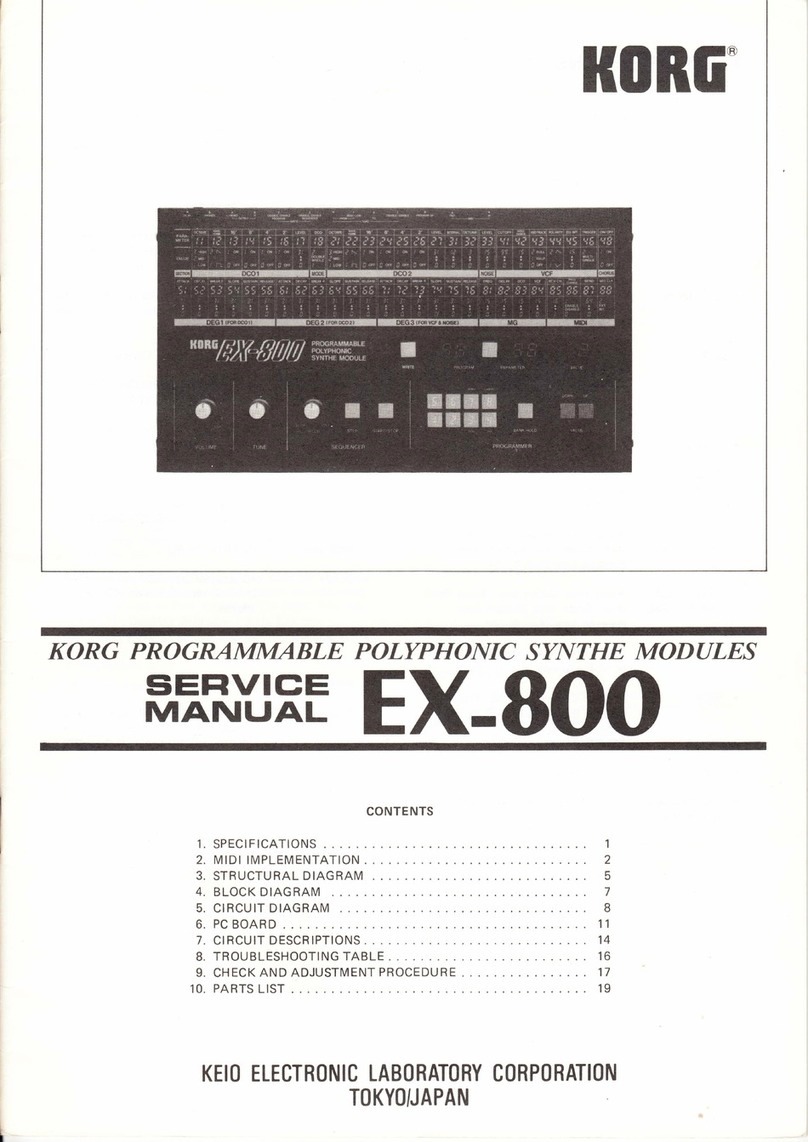

Korg EX-800 User manual

Korg

Korg M-500 User manual

Korg

Korg MONOLOGUE User manual

Korg

Korg Kaossilator Pro User manual

Korg

Korg DSS-1 User manual

Korg

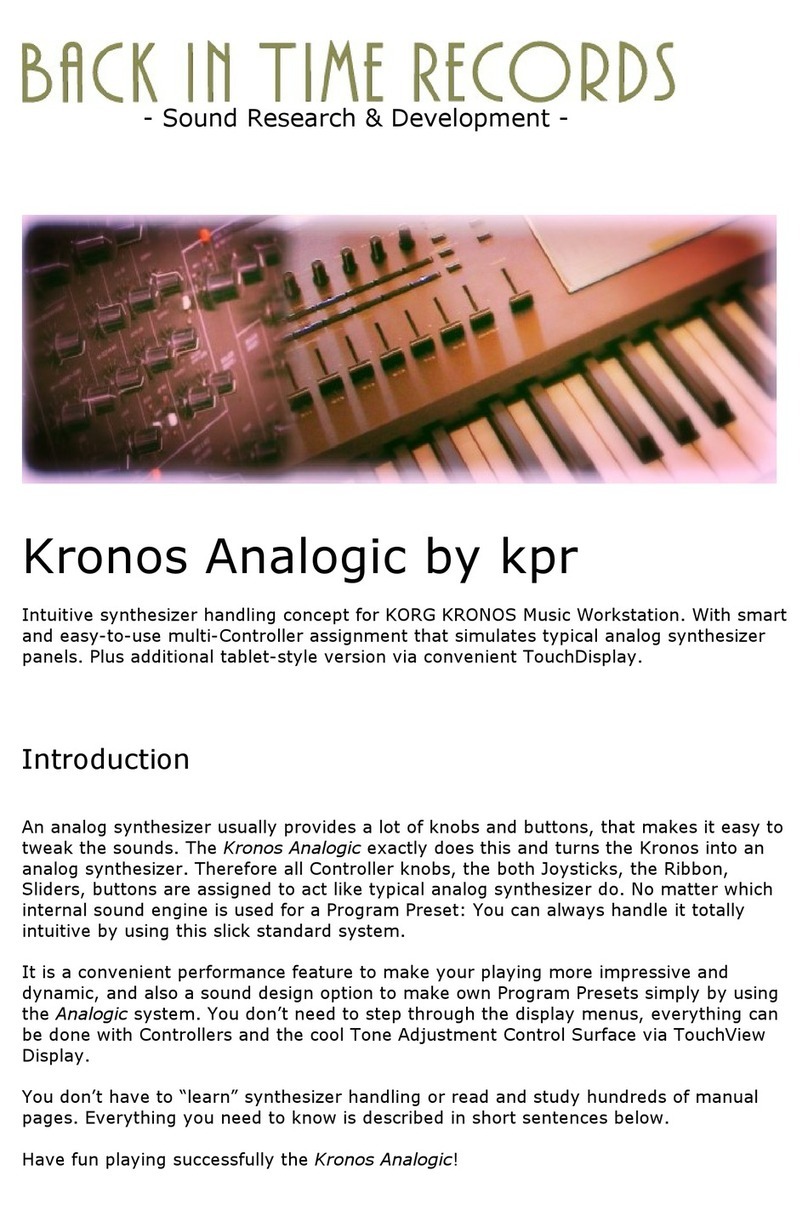

Korg Kronos Analogic User manual

Korg

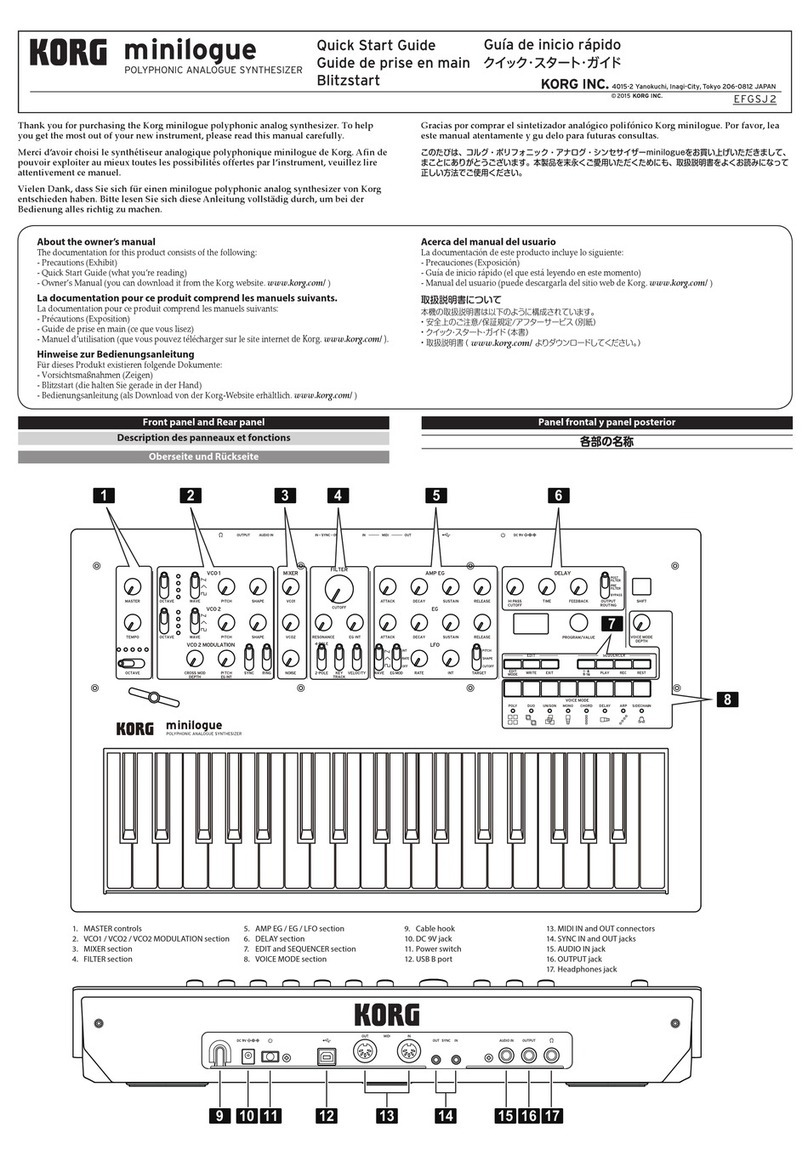

Korg minilogue User manual

Korg

Korg N1 User manual

Korg

Korg Kaossilator2 User manual

Korg

Korg MicroKORG XL User manual

Korg

Korg DW-6000 User manual

Korg

Korg DW-8000 User manual

Korg

Korg microSTATION User manual

Korg

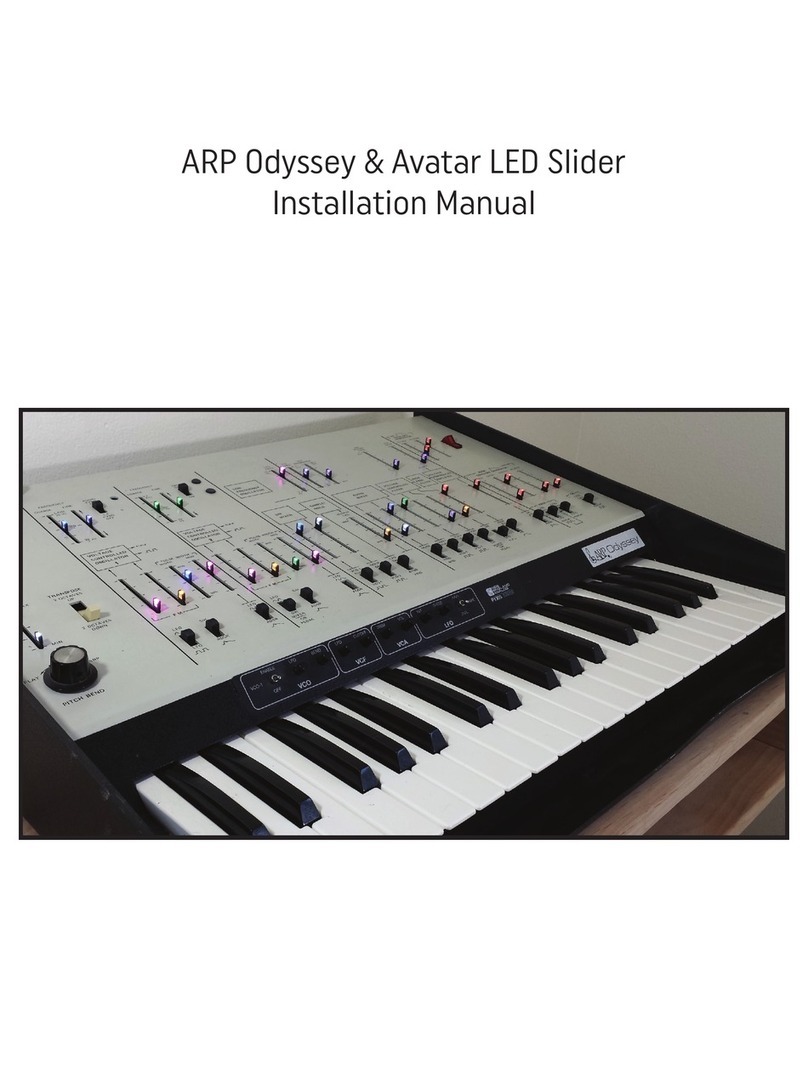

Korg LED slider User manual