3

KraftPowercon Sweden AB, Hjalmar Petris väg 49, 352 46 Växjö, Sweden, Tel: 0470-705200, Fax: 0470-705201,

www.kraftpowercon.com

CONTENTS

1PRESENTATION.............................................................................................. 5

2SAFETY INSTRUCTIONS............................................................................... 6

3TECHNICAL DATA ........................................................................................ 7

3.1 ELEKTRICAL DATA.............................................................................................................................. 7

3.1.1 Assortment .......................................................................................................................................... 7

3.1.2 Common electrical input data .......................................................................................................... 7

3.1.3 Common electrical output data ........................................................................................................ 7

3.1.4 Electrical data for rectifier module................................................................................................... 8

3.2 ENVIRONMENTAL DATA .................................................................................................................. 8

3.3 MECHANICAL DATA .......................................................................................................................... 8

3.4 CONFORMITY WITH STANDARDS .................................................................................................. 9

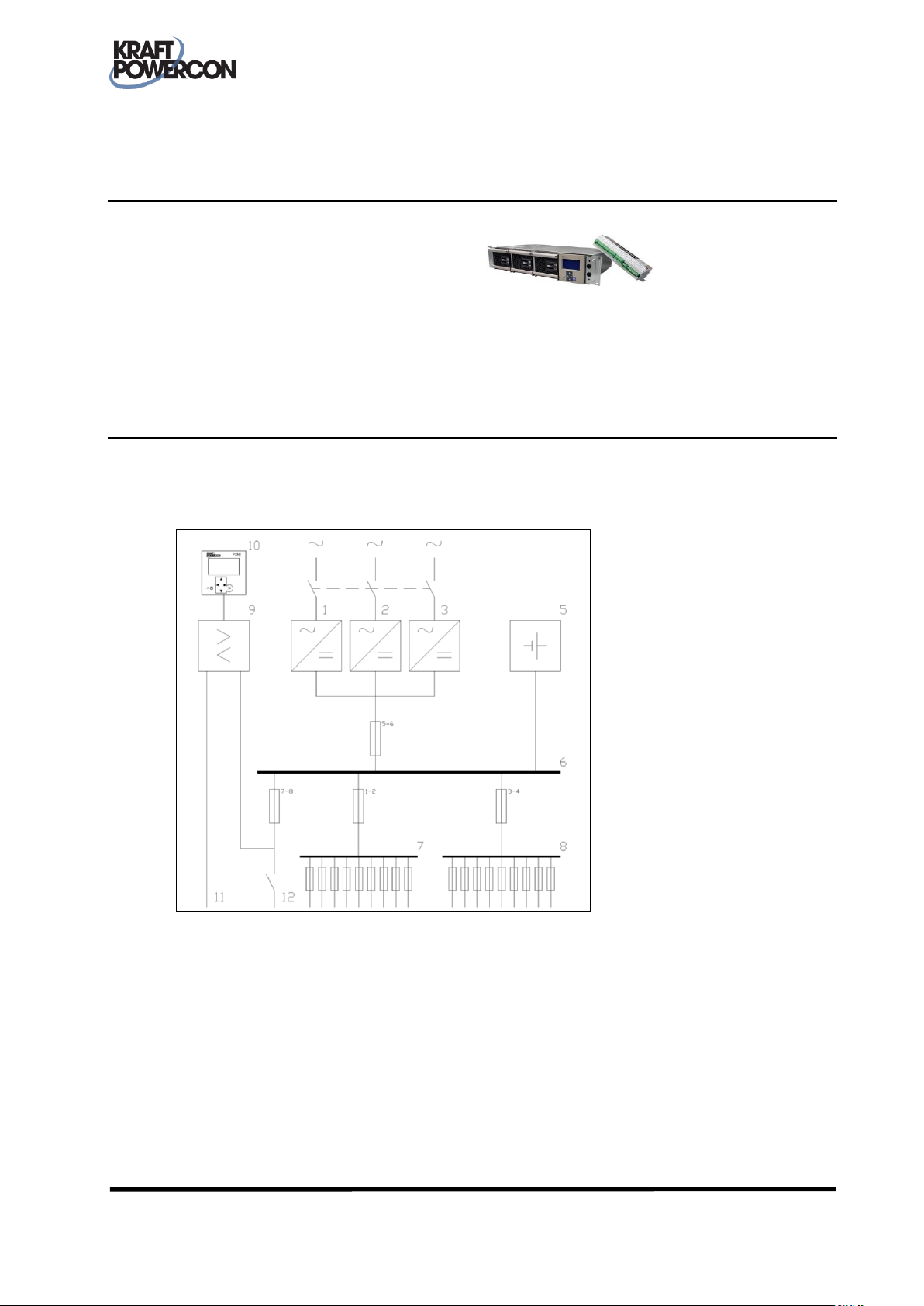

4FUNCTIONAL DESCRIPTION.................................................................... 10

4.1 GENERAL .............................................................................................................................................. 10

4.2 APPLICATION EXAMPLE ................................................................................................................. 10

4.3 LIKRIKTARMODULER ....................................................................................................................... 11

4.4 RACK FOR RECTIFIER MODULES AND OPERATOR PANEL................................................... 11

4.5 TEST CONTACTS ................................................................................................................................. 11

4.6 I/O UNIT ................................................................................................................................................ 11

4.7 FUNCTIONS.......................................................................................................................................... 11

4.7.1 General............................................................................................................................................... 11

4.7.2 Float charging ................................................................................................................................... 12

4.7.3 Equalization charging...................................................................................................................... 12

4.7.4 Battery circuit test............................................................................................................................. 12

5OPERATION ................................................................................................... 13

5.1 GENERAL .............................................................................................................................................. 13

5.2 OPERATOR PANEL............................................................................................................................. 13

5.3 RECTIFIER MODULES ........................................................................................................................ 13

5.4 MAINS SUPPLY.................................................................................................................................... 13

5.5 TEST CONTACTS ................................................................................................................................. 14

6INSTALLATION INSTRUCTIONS ............................................................. 15

6.1 SAFETY INSTRUCTIONS ................................................................................................................... 15

6.2 GENERAL .............................................................................................................................................. 15

6.3 STORAGE AND PROTECTION ......................................................................................................... 15

6.4 MOUNTING .......................................................................................................................................... 15

6.4.1 General............................................................................................................................................... 15

6.4.2 Rack .................................................................................................................................................... 15

6.4.2.1 I/O Unit ......................................................................................................................................... 15

6.5 ELECTRICAL INSTALLATION ......................................................................................................... 15

6.5.1 General............................................................................................................................................... 15

6.5.2 Earthing ............................................................................................................................................. 16

6.5.3 Mains voltage.................................................................................................................................... 16

6.5.3.1 External fuse rating ..................................................................................................................... 16

6.5.3.2 Connection.................................................................................................................................... 16

6.5.4 Battery/Load...................................................................................................................................... 16