Table of contents

1 About this document ..................................................... 3

1.1 General information .......................................................3

1.2 Associated documents ..................................................3

1.3 Target groups ................................................................3

1.4 Symbols.........................................................................3

1.4.1 Danger levels ....................................................3

1.4.2 Danger signs.....................................................4

1.4.3 Symbols in this document .................................4

1.4.4 Symbols for personal protective equipment......4

2 Safety .............................................................................. 5

2.1 Proper use .....................................................................5

2.2 Foreseeable misuse ......................................................5

2.3 Obligations of the operator-owner .................................5

2.4 Safety instructions .........................................................6

2.4.1 Fundamental safety instructions .......................6

3 Identification................................................................... 6

3.1 Type code......................................................................6

3.2 Rating plate ...................................................................7

4 Technical data ................................................................ 7

4.1 Operating limits..............................................................7

4.2 Required NPSH values..................................................7

4.3 Sound pressure level.....................................................8

4.4 Output tables .................................................................8

4.5 Mesh width strainer/filter................................................9

4.6 Weights..........................................................................9

5 Function description.................................................... 10

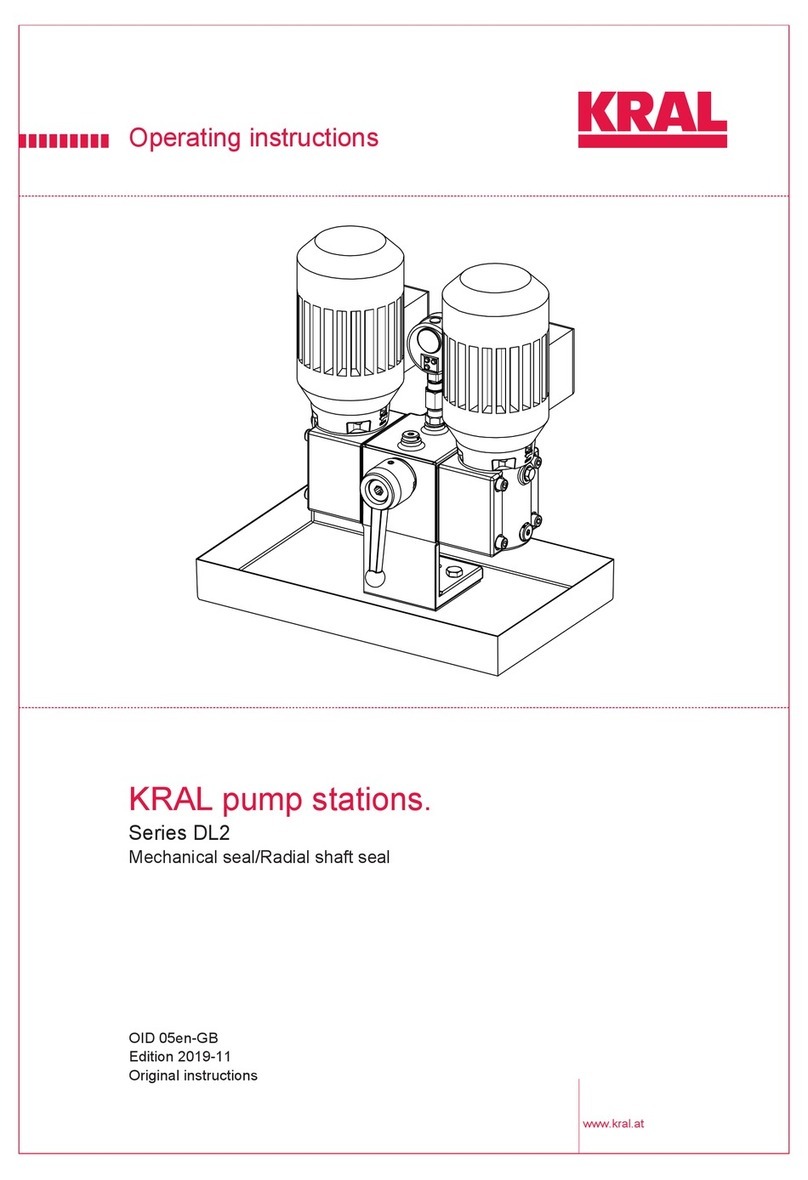

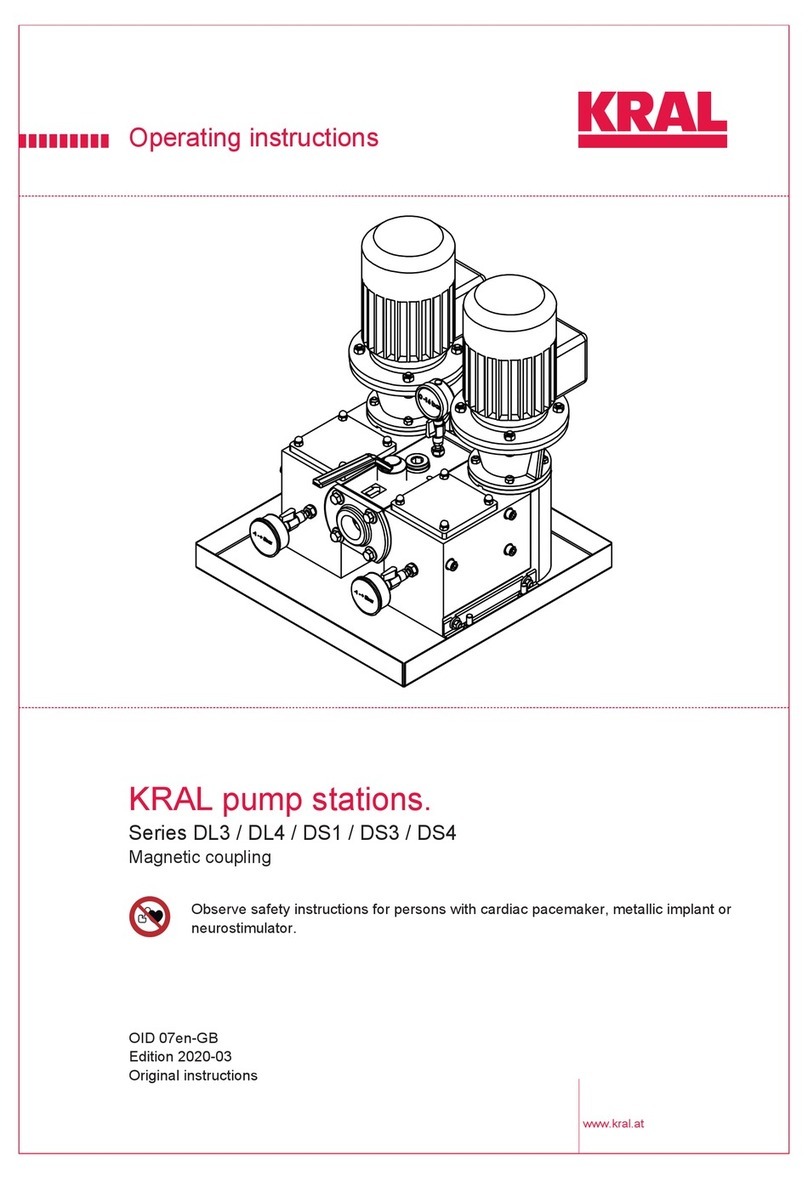

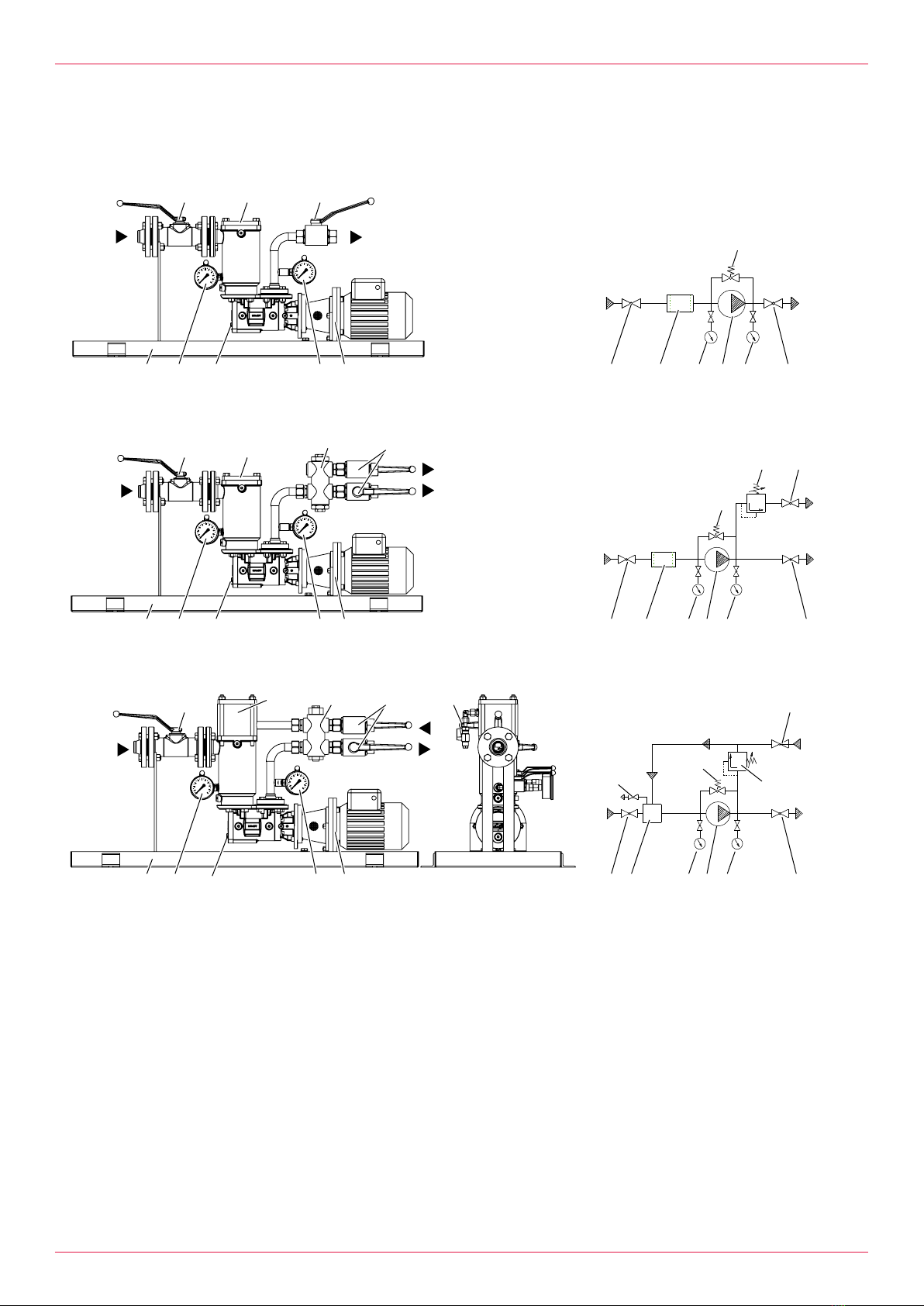

5.1 Structure of standard version ......................................10

5.2 Structure of special design ..........................................11

5.3 Functional principle......................................................11

5.4 Pressure maintaining valve .........................................11

5.5 Pulsation damper.........................................................12

5.6 Expansion valve (optional) ..........................................12

5.7 Protection against soiling.............................................12

5.8 Options for standard version .......................................13

5.9 Options for special design ...........................................13

5.10 Heating system (optional)............................................14

5.10.1 Possible types of heating ................................14

5.10.2 Electrical heating system ................................14

6 Transportation, storage............................................... 14

6.1 Dangers during transportation .....................................14

6.2 Dangers during storage ...............................................14

6.3 Unpacking and checking the state of delivery .............15

6.4 Transporting the pump station.....................................15

6.5 Storing the pump station..............................................15

7 Preservation ................................................................. 16

7.1 Preservation table........................................................16

7.2 Preserving the inner surfaces......................................16

7.3 Preserving the outer surfaces......................................16

7.4 Removing the preservation..........................................17

8 Installation, removal .................................................... 17

8.1 Dangers during installation ..........................................17

8.2 Dangers during removing ............................................17

8.3 Mounting the pump station ..........................................18

8.4 Protecting the pump station against pressure peaks ...18

8.5 Removing the pump station .........................................19

9 Connection.....................................................................20

9.1 Dangers during connection work .................................20

9.2 Connecting the pump station to the pipe system .........20

9.2.1 Setup of the suction line ..................................20

9.2.2 Flange connection ...........................................20

9.2.3 Pipe screwed connection.................................21

9.3 Connecting the pump station to the power supply .......22

10 Operation........................................................................22

10.1 Dangers during operation ............................................22

10.2 Commissioning ............................................................23

10.2.1 Cleaning the pipe system ................................23

10.2.2 Filling and venting the pump station ................23

10.2.3 Checking the direction of rotation ....................24

10.2.4 Commissioning the pump station ....................24

10.2.5 Venting the deaerator ......................................25

10.3 During operation ..........................................................26

10.3.1 Checking the operating pressure.....................26

10.3.2 Adjusting the overflow valve ............................26

10.3.3 Setting the pressure maintaining valve............26

10.3.4 Switching off the pump station.........................27

10.4 Decommissioning.........................................................27

10.4.1 Taking the pump station out of operation ........27

10.5 Recommissioning.........................................................28

10.5.1 Recommissioning the pump station.................28

11 Maintenance...................................................................28

11.1 Dangers during maintenance.......................................28

11.2 Required maintenance.................................................28

11.3 Maintaining the pump station .......................................28

11.4 Maintaining the strainers..............................................29

12 Servicing ........................................................................29

12.1 Dangers during servicing .............................................29

12.2 Signs of wear ...............................................................29

12.3 Servicing the pump station...........................................29

12.4 Replacing the pump .....................................................30

12.5 Cleaning the strainer....................................................31

13 Disposal..........................................................................32

13.1 Dismantling and disposing of the pump station ...........32

14 Troubleshooting ............................................................33

14.1 Possible faults..............................................................33

14.2 Troubleshooting ...........................................................33

15 Spare parts.....................................................................36

15.1 Overview ......................................................................36

16 Appendix ........................................................................38

16.1 Tightening torques for screws with metric screw threads

with and without wedge lock washers..........................38

16.2 Tightening torques for screw plugs with thread

measured in inches and elastomer seal ......................39

16.3 Contents of the Declaration of Conformity ...................39

2OIK 10en-GB Edition 2021-06 Operation instructions