Table of contents

1 About this document ..................................................... 4

1.1 General information .......................................................4

1.2 Associated documents ..................................................4

1.3 Target groups ................................................................4

1.4 Symbols.........................................................................4

1.4.1 Danger levels ....................................................4

1.4.2 Danger signs.....................................................4

1.4.3 Symbols in this document .................................5

1.4.4 Symbols for personal protective equipment......5

2 Safety .............................................................................. 6

2.1 Proper use .....................................................................6

2.2 Foreseeable misuse ......................................................6

2.3 Obligations of the operator-owner .................................6

2.4 Safety instructions .........................................................6

2.4.1 Fundamental safety instructions .......................6

3 Identification................................................................... 7

3.1 Type code......................................................................7

3.2 Rating plate ...................................................................7

4 Technical data ................................................................ 8

4.1 Operating limits..............................................................8

4.2 Filling volume.................................................................8

4.3 Inlet pressure for heavy fuel oil......................................8

4.4 Sound pressure level.....................................................8

4.5 Mesh width strainer/filter................................................9

4.6 Weights..........................................................................9

5 Function description.................................................... 10

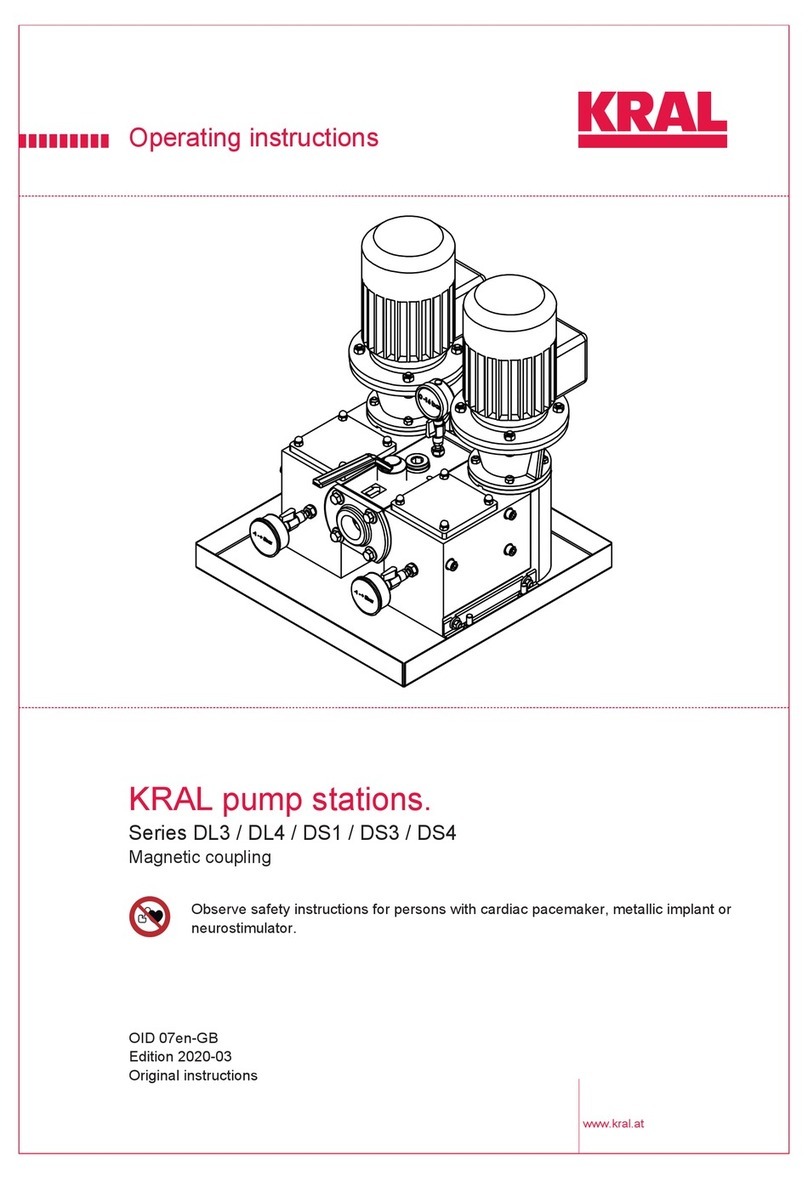

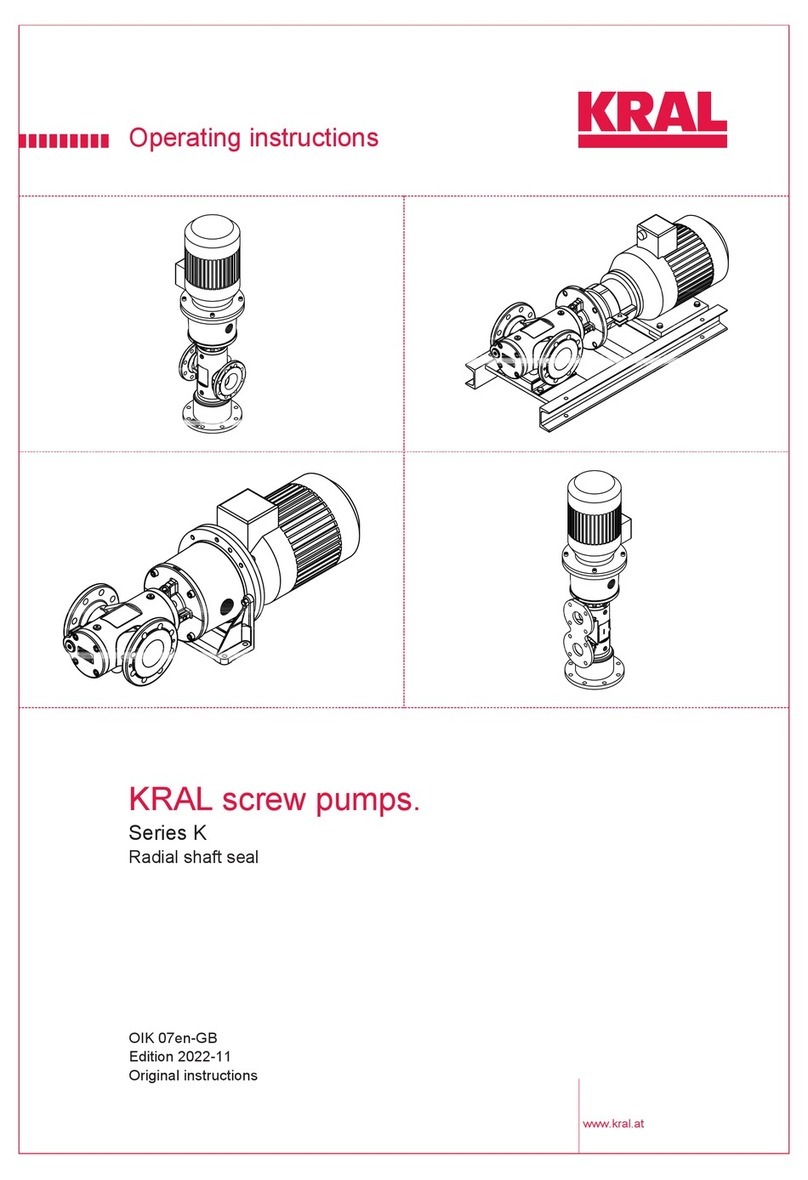

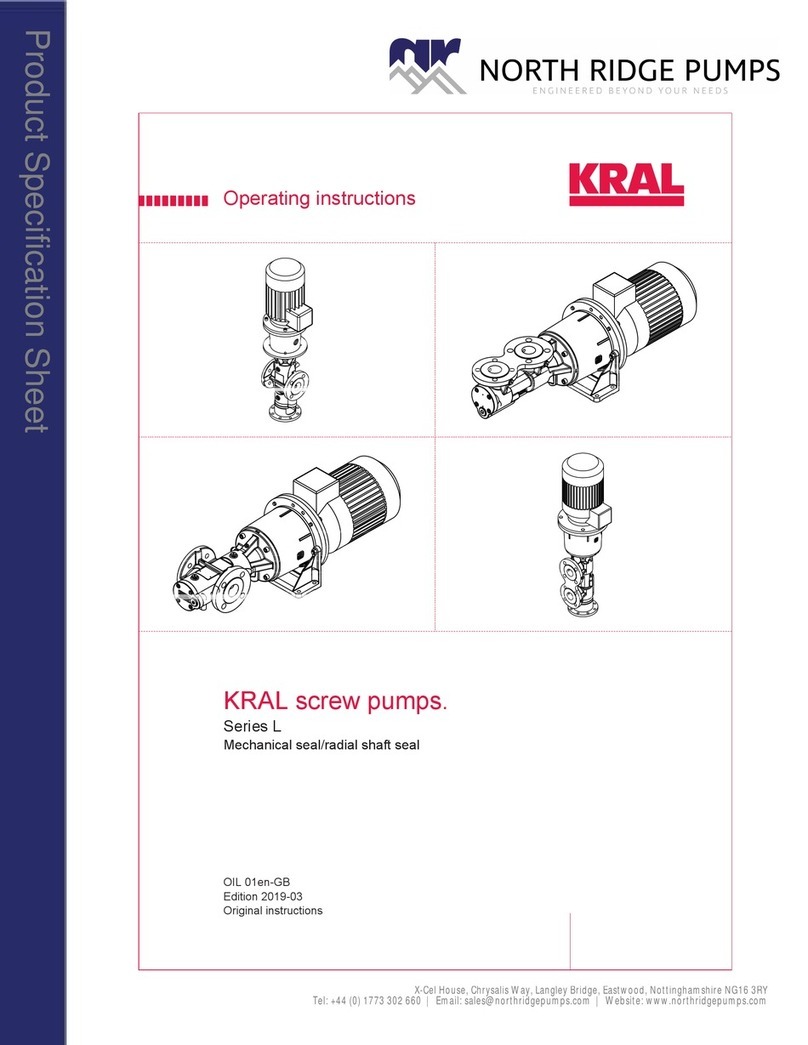

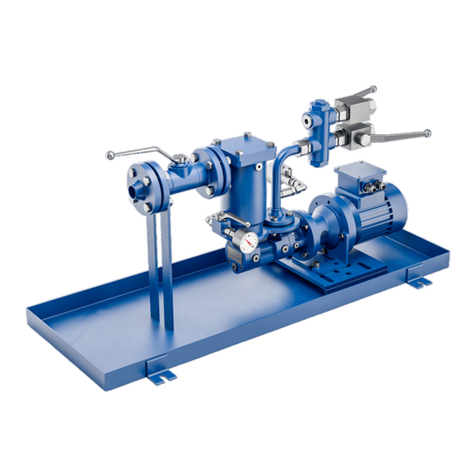

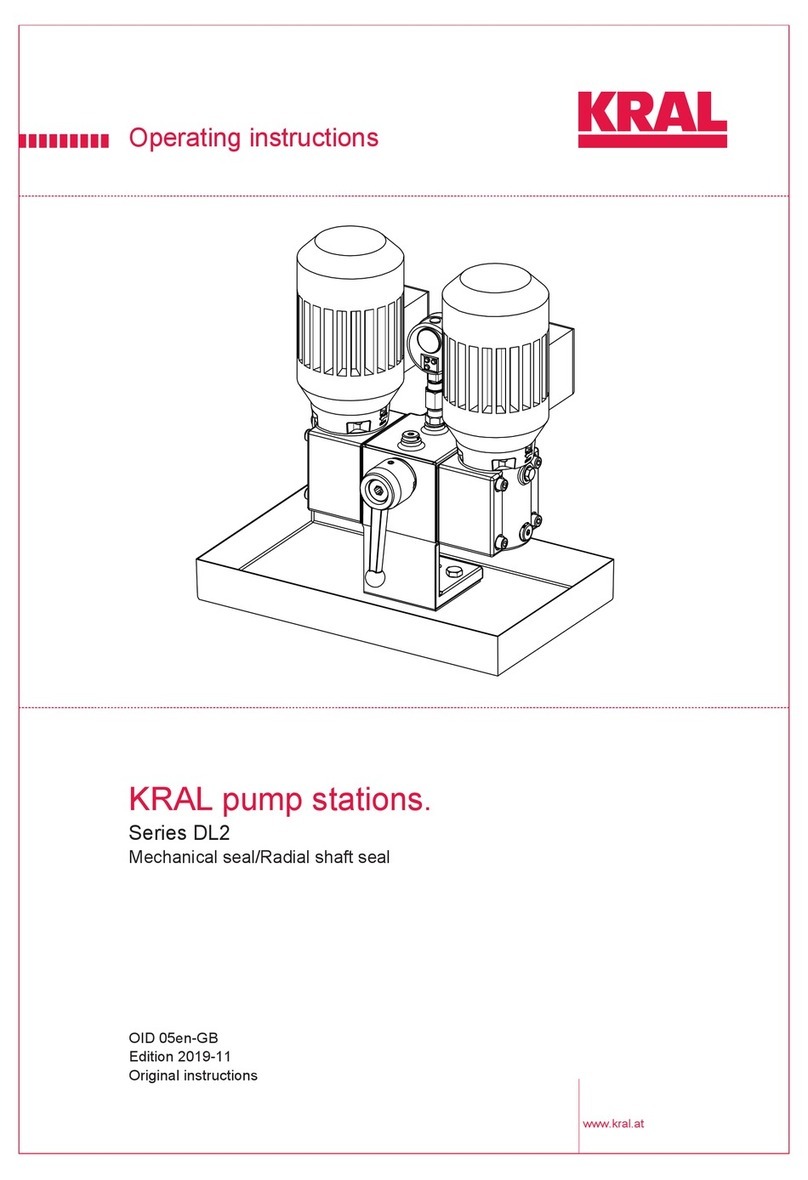

5.1 Structure ......................................................................10

5.2 Functional principle......................................................10

5.3 Assignment pump station - pump ................................11

5.4 Reversing valve ...........................................................11

5.5 Overflow valve .............................................................11

5.6 Pressure measurement ...............................................12

5.7 Strainer ........................................................................12

6 Transportation, storage............................................... 12

6.1 Dangers during transportation .....................................12

6.2 Dangers during storage ...............................................13

6.3 Unpacking and checking the state of delivery .............13

6.4 Transporting the pump station.....................................13

6.5 Storing the pump station..............................................14

7 Preservation ................................................................. 14

7.1 Preservation table........................................................14

7.2 Preserving the inner surfaces......................................14

7.3 Preserving the outer surfaces......................................15

7.4 Removing the preservation..........................................15

8 Installation, removal .................................................... 16

8.1 Dangers during installation ..........................................16

8.2 Dangers during removal ..............................................16

8.3 Mounting the pump station ..........................................16

8.4 Removing the pump station.........................................17

9 Connection ................................................................... 18

9.1 Dangers during connection work .................................18

9.2 Connecting the pump station to the pipe system.........18

9.3 Connecting the pump station to the power supply.......19

10 Operation........................................................................20

10.1 Dangers during operation ............................................20

10.2 Commissioning ............................................................20

10.2.1 Cleaning the pipe system ................................20

10.2.2 Filling and venting the pump station ................20

10.2.3 Checking the direction of rotation ....................21

10.2.4 Commissioning the pump station ....................22

10.3 During operation ..........................................................22

10.3.1 Checking the operating pressure.....................22

10.3.2 Activating the reversing valve..........................23

10.3.3 Adjusting the overflow valve ............................23

10.3.4 Switching off the pump station.........................24

10.4 Decommissioning.........................................................24

10.4.1 Taking the pump station out of operation ........24

10.5 Recommissioning.........................................................25

10.5.1 Recommissioning the pump station.................25

11 Maintenance...................................................................25

11.1 Dangers during maintenance.......................................25

11.2 Required maintenance.................................................26

11.3 Ball bearing (outer bearing) .........................................26

11.4 Ball bearing (inner bearing)..........................................26

11.5 Maintaining the pump station .......................................26

11.6 Maintaining the strainers..............................................26

12 Servicing ........................................................................27

12.1 Dangers during servicing .............................................27

12.2 Wear ............................................................................27

12.2.1 Signs of wear...................................................27

12.2.2 Mechanical seal...............................................27

12.2.3 Radial shaft seal ..............................................27

12.3 Cleaning the strainer....................................................28

12.4 Replacing the coupling.................................................29

12.4.1 Removing the coupling (inner bearing)............29

12.4.2 Installing the coupling (inner bearing)..............30

12.4.3 Removing the coupling (outer bearing) ...........31

12.4.4 Installing the coupling (outer bearing) .............32

12.5 Replacing the pump .....................................................33

12.6 Replacing the mechanical seal ....................................34

12.6.1 Removing the mechanical seal (DL2 from320/

DS1) ................................................................34

12.6.2 Installing the mechanical seal (DL2 from320/

DS1) ...............................................................34

12.6.3 Removing the mechanical seal (DL3/DL4/DS3/

DS4) ................................................................35

12.6.4 Installing the mechanical seal (DL3/DL4/DS3/

DS4) ................................................................35

12.7 Replacing the radial shaft seal.....................................36

12.7.1 Removing the radial shaft seal (DL2 as of320/

DS1) ................................................................36

12.7.2 Installing the radial shaft seal (DL2 as of320/

DS1) ................................................................36

12.7.3 Removing the radial shaft seal (DL3/DL4/DS3/

DS4) ................................................................37

12.7.4 Installing the radial shaft seal (DL3/DL4/DS3/

DS4) ................................................................37

12.8 Replacing the mechanical seal and ball bearing (outer

bearing)........................................................................38

12.9 Replacing seals............................................................39

12.9.1 Replacing seals (DL3/DL4/DS3/DS4)..............39

2OID 06en-GB Edition 2019-11 Operating instructions