Table of contents

1 About this document ..................................................... 4

1.1 General information .......................................................4

1.2 Associated documents ..................................................4

1.3 Target groups ................................................................4

1.4 Symbols.........................................................................5

1.4.1 Danger levels ....................................................5

1.4.2 Danger signs.....................................................5

1.4.3 Symbols in this document .................................5

2 Safety .............................................................................. 6

2.1 Proper use .....................................................................6

2.2 Foreseeable misuse ......................................................6

2.3 Obligations of the operator-owner .................................6

2.4 Safety instructions .........................................................7

2.4.1 Fundamental safety instructions .......................7

2.4.2 Dangers during transportation ..........................7

2.4.3 Dangers during storage ....................................7

2.4.4 Dangers during installation ...............................7

2.4.5 Dangers during removal....................................7

2.4.6 Dangers during connection work ......................8

2.4.7 Dangers during operation .................................8

2.4.8 Dangers during servicing ..................................8

2.4.9 Dangers during maintenance............................8

2.4.10 Dangers during disposal ...................................9

3 Identification................................................................... 9

3.1 Type code......................................................................9

3.2 Rating plate .................................................................10

4 Technical data .............................................................. 10

4.1 Operating limits............................................................10

4.2 Sound pressure level...................................................11

4.3 Required NPSH values................................................11

4.4 Weights........................................................................12

4.5 Materials ......................................................................13

4.6 Accessories .................................................................13

5 Function description.................................................... 13

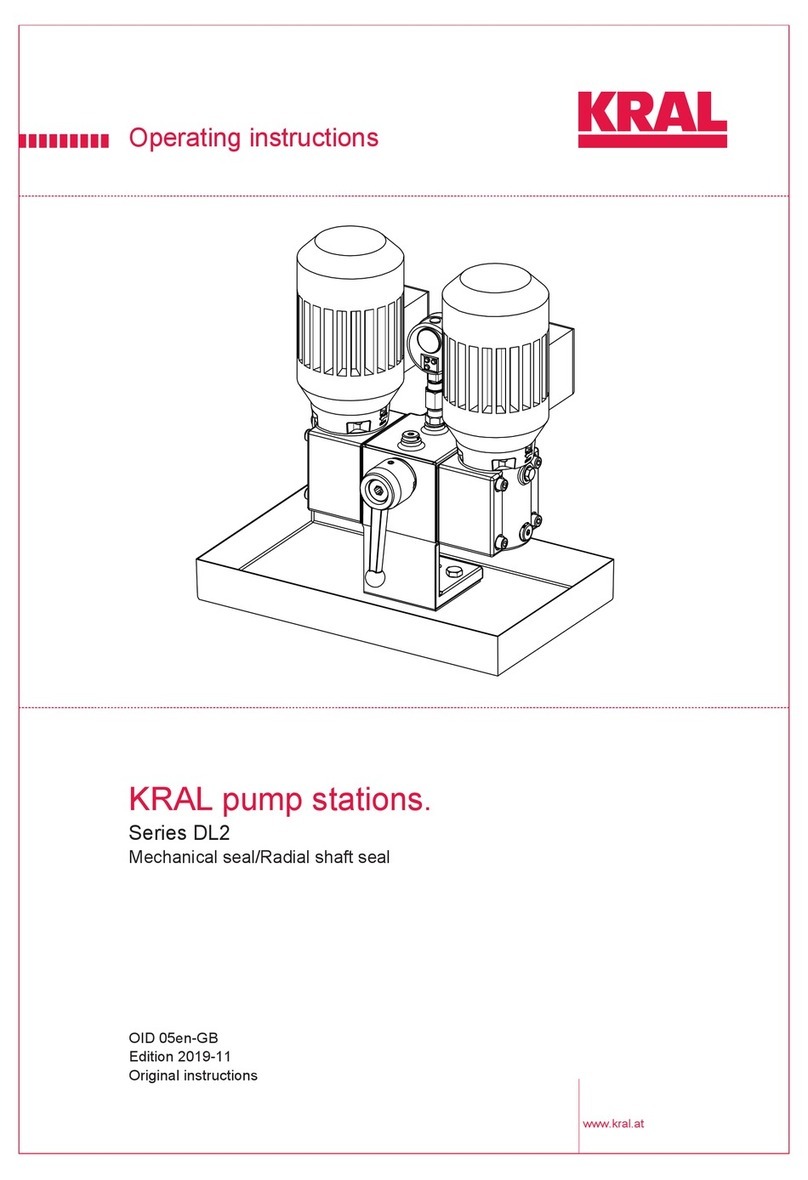

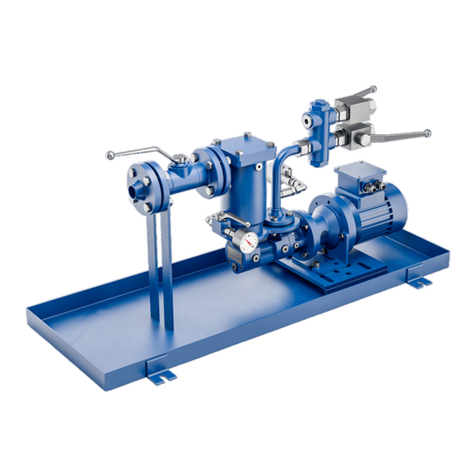

5.1 Pump structure ............................................................13

5.2 Pump unit structure .....................................................14

5.3 Functional principle......................................................14

5.4 Housing variants..........................................................15

5.5 Shaft seal.....................................................................15

5.6 Overflow valve .............................................................16

6 Transportation, storage............................................... 16

6.1 Dangers during transportation .....................................16

6.2 Dangers during storage ...............................................16

6.3 Unpacking and checking the state of delivery .............16

6.4 Transporting the pump/pump unit................................17

6.5 Storing the pump .........................................................17

7 Preservation ................................................................. 18

7.1 Preservation table........................................................18

7.2 Preserving the inner surfaces......................................18

7.3 Preserving the outer surfaces......................................18

7.4 Removing the preservation..........................................19

8 Installation, removal .................................................... 19

8.1 Dangers during installation ..........................................19

8.2 Dangers during removal ..............................................19

8.3 Installing the pump.......................................................19

8.4 Removing the pump.....................................................20

9 Connection.....................................................................21

9.1 Dangers during connection work .................................21

9.2 Connecting the pump to the pipe system.....................22

9.3 Assembling the pump and motor .................................22

9.4 Connecting the pump unit to the power supply............24

10 Operation........................................................................24

10.1 Dangers during operation ............................................24

10.2 Commissioning ............................................................25

10.2.1 Cleaning the pipe system ................................25

10.2.2 Filling and venting the pump............................25

10.2.3 Checking the direction of rotation ....................27

10.2.4 Commissioning the pump ................................27

10.3 During operation ..........................................................28

10.3.1 Checking the operating pressure.....................28

10.3.2 Monitoring filters and/or strainers ....................29

10.3.3 Adjusting the overflow valve ............................29

10.3.4 Switching off the pump unit .............................30

10.4 Decommissioning.........................................................30

10.4.1 Decommissioning the pump ............................30

10.5 Recommissioning.........................................................31

10.5.1 Recommissioning the pump ............................31

11 Maintenance...................................................................31

11.1 Dangers during maintenance.......................................31

11.2 Required maintenance.................................................31

11.3 Ball bearing ..................................................................31

11.4 Maintaining the pump...................................................32

11.5 Cleaning the leakage vent hole....................................32

12 Servicing ........................................................................33

12.1 Dangers during servicing .............................................33

12.2 Wear ............................................................................33

12.2.1 Signs of wear...................................................33

12.2.2 Shaft seal.........................................................33

12.3 Replacing the overflow valve .......................................34

12.3.1 Removing the overflow valve...........................34

12.3.2 Installing the overflow valve.............................34

12.4 Replacing the coupling.................................................35

12.4.1 Removing the coupling ....................................35

12.4.2 Installing the coupling ......................................36

12.5 Replacing the ball bearing ...........................................37

12.5.1 Removing the ball bearing...............................37

12.5.2 Installing the ball bearing – mechanical seal ver-

sion ..................................................................38

12.5.3 Installing the ball bearing – radial shaft seal ver-

sion ..................................................................38

12.6 Replacing the mechanical seal ....................................40

12.6.1 Removing the mechanical seal........................40

12.6.2 Installing the mechanical seal..........................40

12.7 Replacing the radial shaft seal.....................................41

12.7.1 Removing the radial shaft seal ........................41

12.7.2 Installing the radial shaft seal ..........................42

12.8 Replacing the screw set...............................................42

12.8.1 Removing the screw set ..................................42

12.8.2 Installing the screw set ....................................43

13 Disposal..........................................................................44

2OIL 01en-GB Edition 2019-03 Operating instructions