26

Improper installation and operation may lead to serious personal injury and property damage.

• Installation should be performed by trained assembly team with appropriate qualifications and authorized by KRISPOL.

• Adhere to the applicable safety regulations. Particular attention should be paid to the safety when working with electrical devices and

at heights.

• e assembly area should be properly marked and secured.

• Features of the assembly surface are described in sec. 3.

• During the assembly works, remember to:

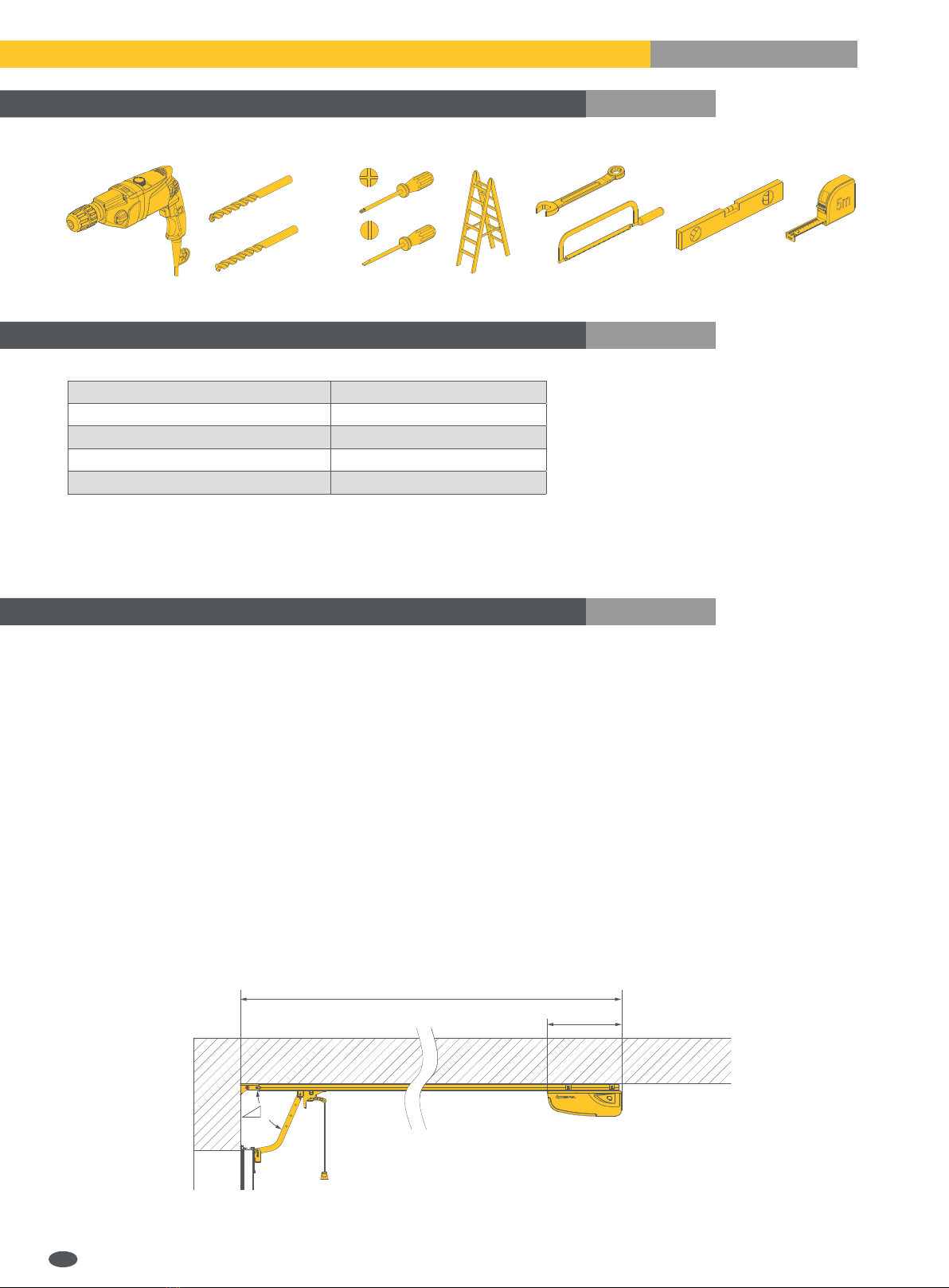

- assemble materials and tools necessary to perform the work (they are listed in section „Tools and materials”);

- use only original manufacturer’s parts;

- use stable structures for work at height;

- adequately protect face and hands during drilling;

- prevent the presence of children near the place of installation works;

- remove debris and other obstacles that could hinder the movement of the door, before starting it;

- install a device for manual lock releasing at a height of not more than 180 cm;

- install the external control unit at a minimum height of 150 cm, in the location ensuring the visibility of the whole area of

movement, but not colliding with the movement of the garage doors - away from moving parts.

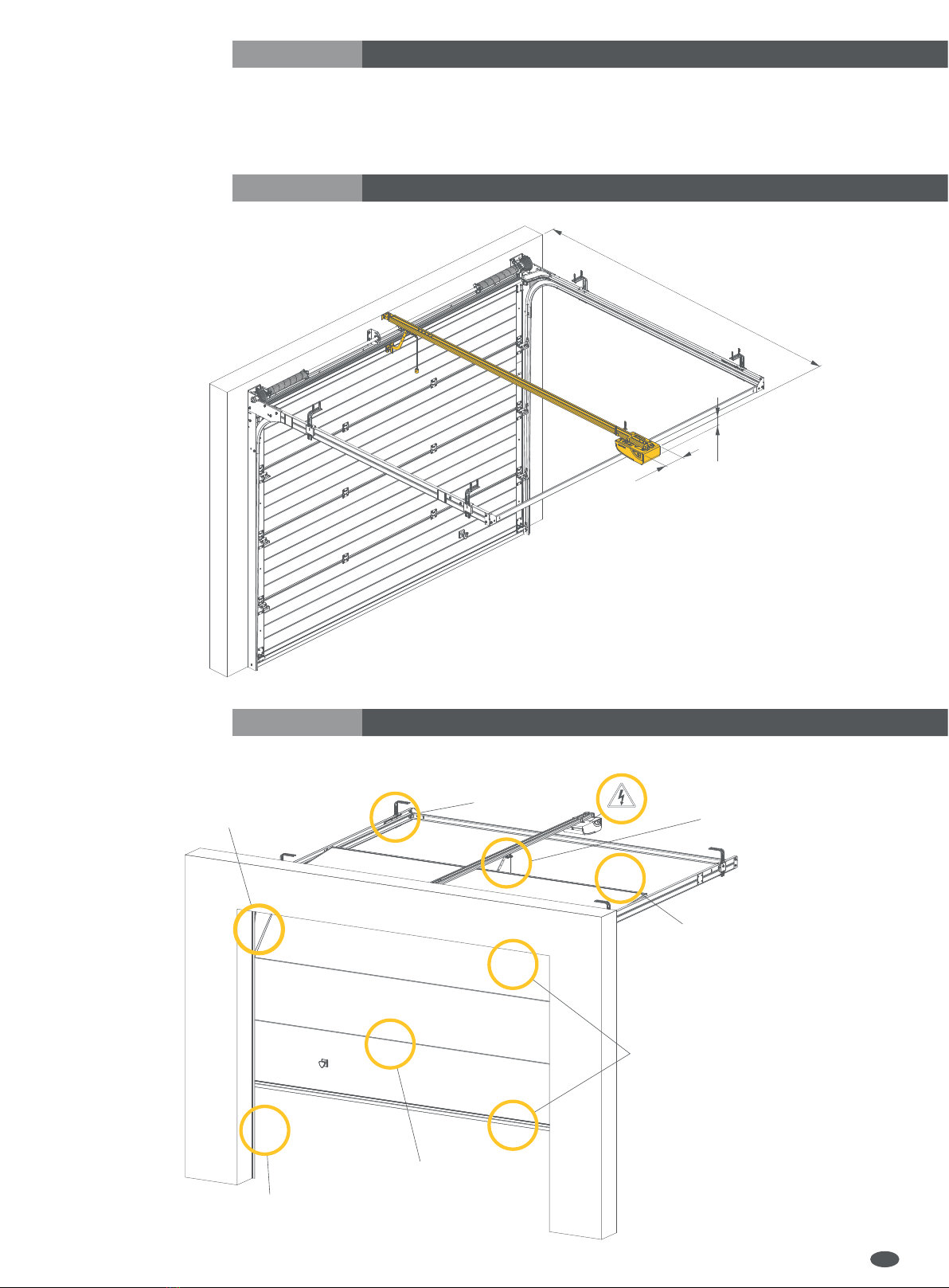

• First, install all the components, as shown in the drawings - sec. 6.4.

• Before installing the drive, make sure that the temperature range marked on the drive corresponds to local conditions.

• Connect the machine using the plug / socket set. Before connecting the drive, make sure that power supply voltage complies with the

requirements of the device to prevent the burnout of its electrical equipment due to insufficient voltage.

• Plugs must match outlets - never change the plug on other than provided by the manufacturer, do not use any additional adapters

plugs to connect the drive to the power supply.

• Before any work on the system, cut off the power supply.

In each system we recommend installing at least one warning light. Never modify the automatic drive components.

e installer should provide the user with all the information related to the manual operation of the system in case of failure and also should

provide user with the user manual.

After installation:

• Make sure that the mechanism is properly adjusted and that the door moves back or you are able to remove the obstacle when the

door touches an object with a height of 50 mm lying on the ground;

• make sure that no part of the door enters a public space, including the pavement and/or road;

• leave the work area in good order, do not leave packaging (foil, polystyrene, etc.) within reach of children as such materials may

generate a potential threat,

• pictograms warning against entrapment must be attached in a sustainable manner, near the danger area or close to the controls,

• pictogram indicating the manual release mechanism must be attached next to the mechanism.

Inform the user that the independent dismantling of the drive is unacceptable.

ese activities may be performed only by professional installers or qualified

persons designated by the manufacturer - Krispol.

4.2. Warning and safety signs

DANGER - for the user it means a risk of accidents, including fatal

NOTE - an advice on how to prevent wearing of the product

REMEMBER - key functions or useful information; pay maximum attention to the information marked with this symbol

ADDITIONAL INFORMATION

ELECTRICAL HAZARD

PROHIBITION - do not remove safety devices

COMMANDS - cut off the power supply before starting work on the device or repairs

EN