CONTENTS

3

www.krohne.com03/2018 - 4003819102 - MA SENSOFIT RET 5000 R02 en

SENSOFIT RET 5000

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Certifications .................................................................................................................... 5

1.3 Safety instructions from the manufacturer ..................................................................... 6

1.3.1 Copyright and data protection ................................................................................................ 6

1.3.2 Disclaimer ............................................................................................................................... 6

1.3.3 Product liability and warranty ................................................................................................ 7

1.3.4 Information concerning the documentation........................................................................... 7

1.3.5 Warnings and symbols used................................................................................................... 8

1.4 Safety instructions for the operator................................................................................. 8

2 Device description 9

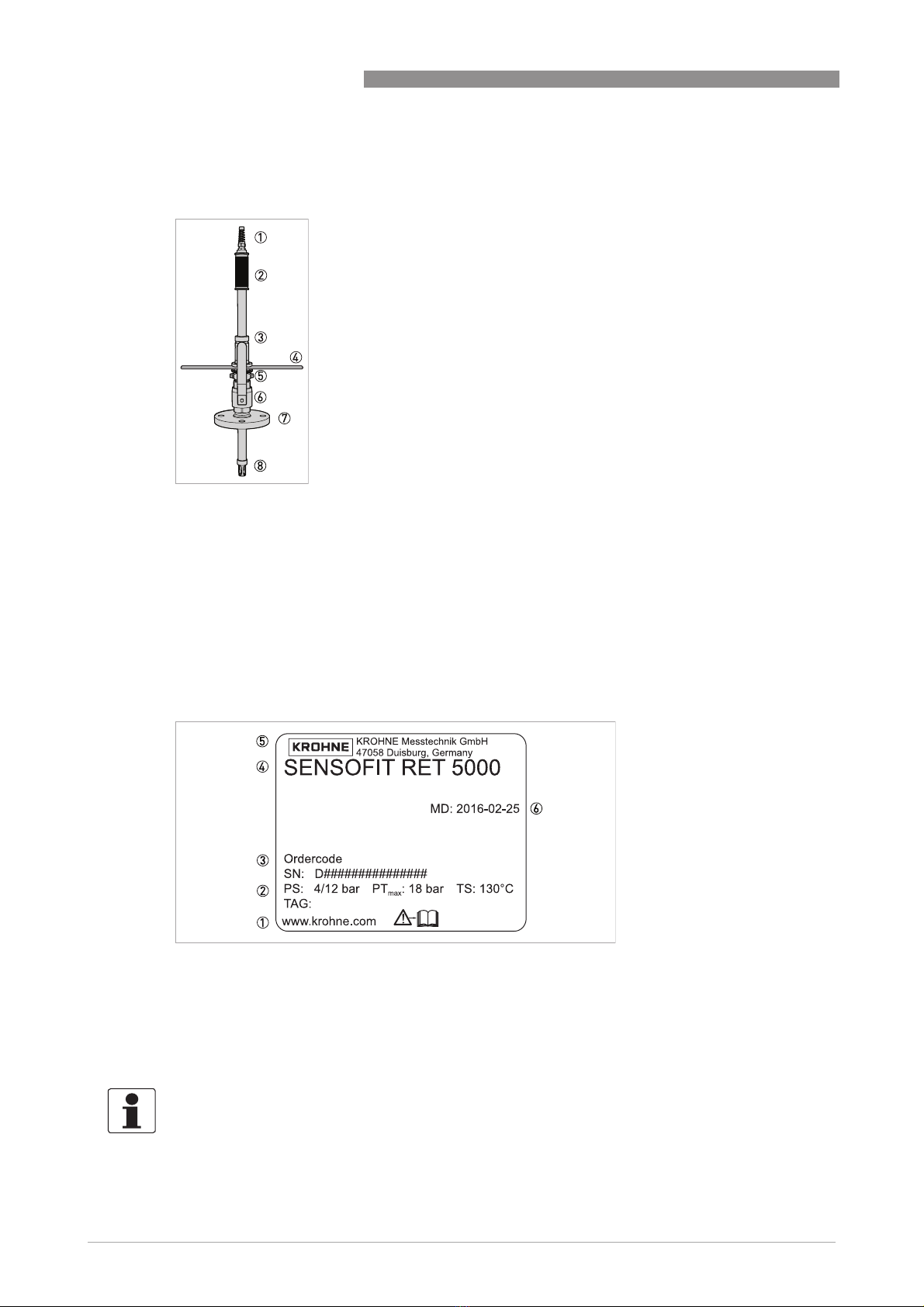

2.1 Scope of delivery............................................................................................................... 9

2.2 Device description .......................................................................................................... 10

2.3 Nameplate ...................................................................................................................... 10

3 Installation 11

3.1 General notes on installation ......................................................................................... 11

3.2 Storage and transport .................................................................................................... 12

3.3 Pre-installation requirements ....................................................................................... 12

3.4 Install the assembly .......................................................................................................13

3.4.1 Install the sensor .................................................................................................................. 14

3.4.2 Adjust the immersion depth ................................................................................................. 16

3.4.3 Install the sliding device ....................................................................................................... 17

3.4.4 Install the flush tube............................................................................................................. 18

4 Operation 21

4.1 Put the assembly into operation .................................................................................... 21

4.2 Moving the assembly manually...................................................................................... 22

4.3 Removing the sensor...................................................................................................... 23

4.4 Troubleshooting.............................................................................................................. 25

5 Service 26

5.1 Maintenance ................................................................................................................... 26

5.1.1 Replace the O-rings .............................................................................................................. 26

5.1.2 Checking for functionality and leakage ................................................................................ 29

5.1.3 Service instruction ................................................................................................................ 29

5.2 Availability of services .................................................................................................... 30

5.3 Spare parts availability...................................................................................................30

5.4 Returning the device to the manufacturer..................................................................... 30

5.4.1 General information.............................................................................................................. 30

5.4.2 Form (for copying) to accompany a returned device............................................................ 31

5.5 Disposal .......................................................................................................................... 31