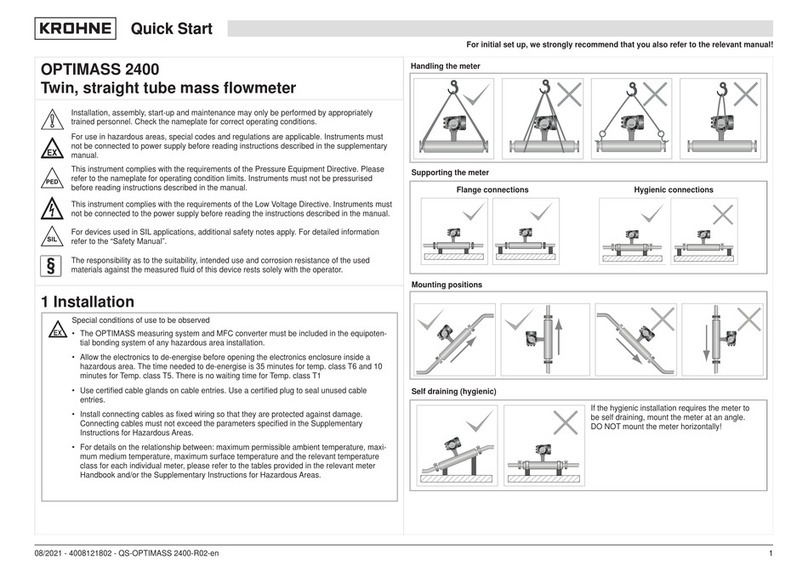

For initial set up, we strongly recommend the use of the relevant manuals in addition!

System Configuration

2

1100...230VAC (-15% / +10%), 22VA

Diameter range and rail versions

24VDC (-55% / +30%), 12W

Small

DN15...100 / 0.5...4" DN200...1250 / 8...50"

Small Large

Medium

DN50...400 / 2...16" DN200...4000 / 8...160"

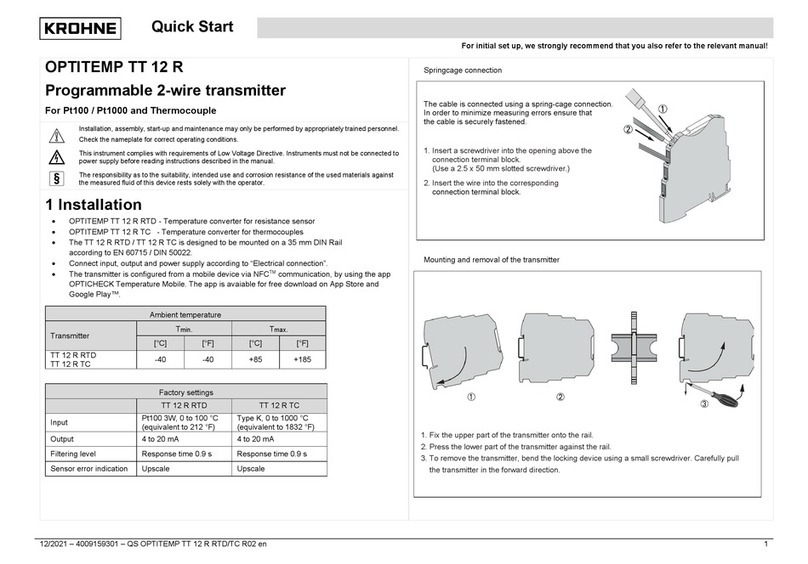

Sensor cable connections

I/O connections

3

Mains supply connection

10/2020 - 4007758002 - OPTISONIC 6300 R02 en 1

Quick Start

Check the device nameplate to ensure that the device is

delivered according to your order.

www.krohne.com/Downloads

General Device nameplate

Power supply - grounding

Observe without fail the local occupational health and safety regulations.

Any work done on the electrical components of the measuring device may only be carried out by properly

trained specialists.

All work on the electrical connections may only be carried out with the power disconnected.

Take note of the voltage data on the nameplate! Observe the national regulations for electrical installations!

2

Medium The device must be grounded in accordance with

regulations in order to protect personnel against

electric shocks.

For devices used in hazardous areas, additional

safety notes apply; please refer to the Ex

documentation.

Electrical connections signal converter

2 3

3

1

Preferred measuring modes

OPTISONIC 6300

1 Electrical connection

3

Ultrasonic clamp-on flowmeter

Installation, assembly, start-up and maintenance may only be performed by appropriately trained

personnel.

For use in hazardous areas, special codes and regulations are applicable which are supplied in a

separate document that describes all hazardous area relevant information.

The responsibility as to the suitability, intended use and corrosion resistance of the used materials

against the measured fluid of this device rests solely with the operator.

For complete documentation (manuals, supplementary manuals, data sheets and certificates) please

refer to:

Refer to the manual for connection of Ex (/i ) acc. to

NAMUR

24VAC/DC (AC: -15% / +10%; DC: -25% / +30%),

22VA or 12W