GENERAL SAFETY INFORMATION

4

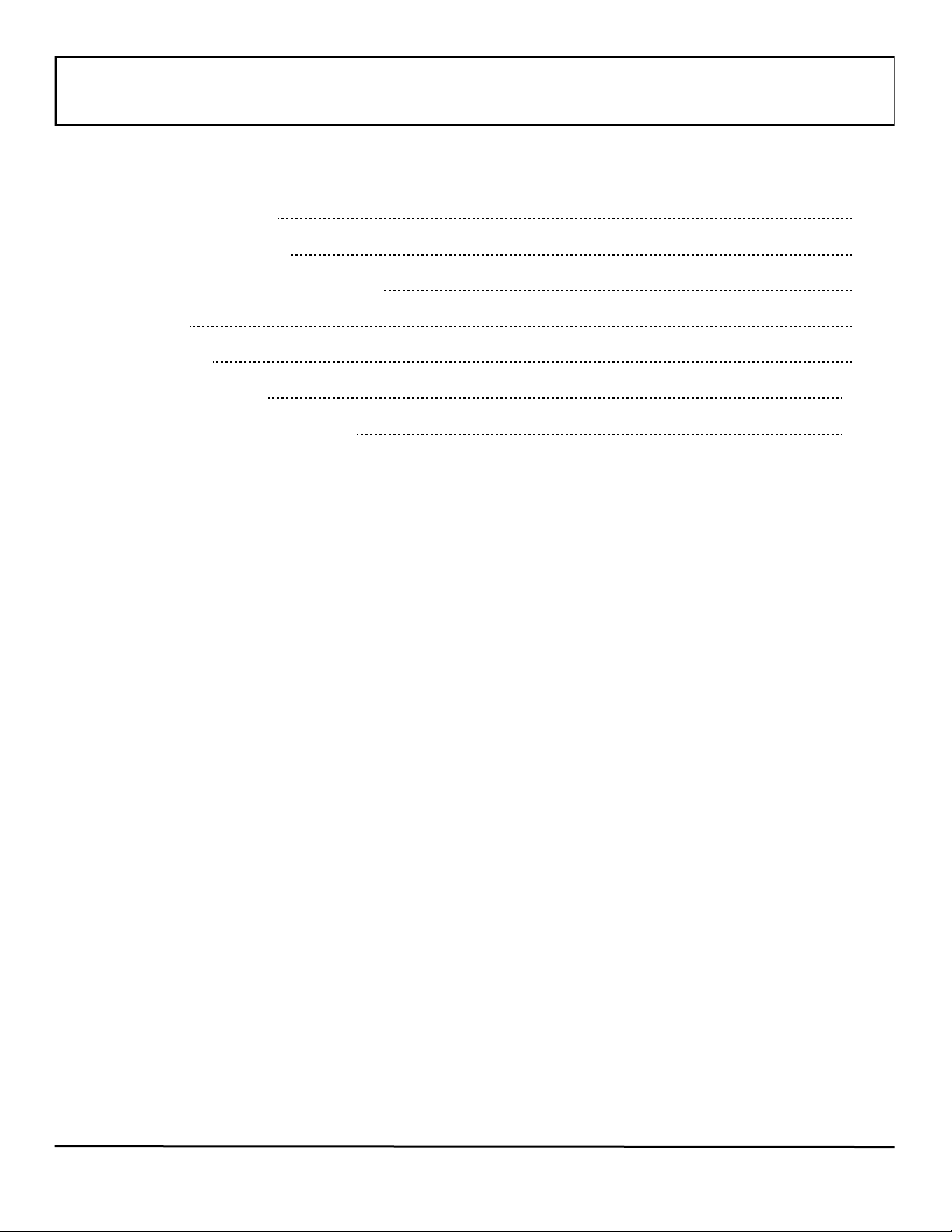

BEFORE YOU START SERVICE

• Read all instructions and safety instructions in this

manual and on your machine safety decals.

• Clean the work area and machine.

• Park the machine on a stable and level ground, and

set parking brake.

• Lower the implement to the ground.

• Stop the engine, then remove the key.

• Disconnect the battery negative cable.

• Hang a “DO NOT OPERATE” tag in the operator

station.

WSM000001INI0010US0

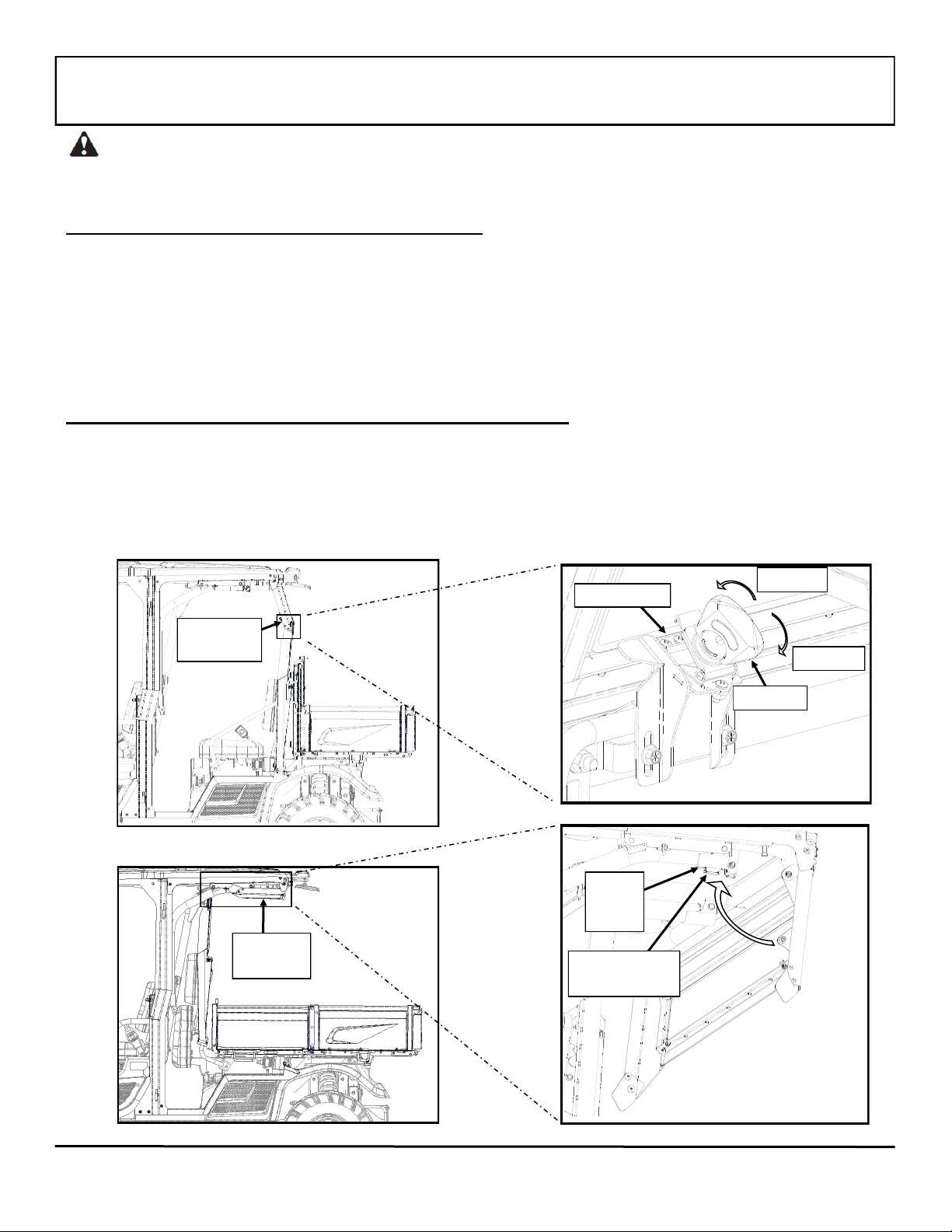

• When performing maintenance on the equipment,

hang the DO NOT OPERATE sign where it will be

obvious from and around the driver’s seat

• When performing maintenance or repairs, always

lower attachments to the ground, stop the engine

and secure the tracks with blocks.

• When performing maintenance on the equipment,

always disconnect the negative battery cable.

• Before using tools, make sure you understand how

to use them correctly and use tools in good condi-

tion and of the right size for the job.

RY9212038INI0002US0

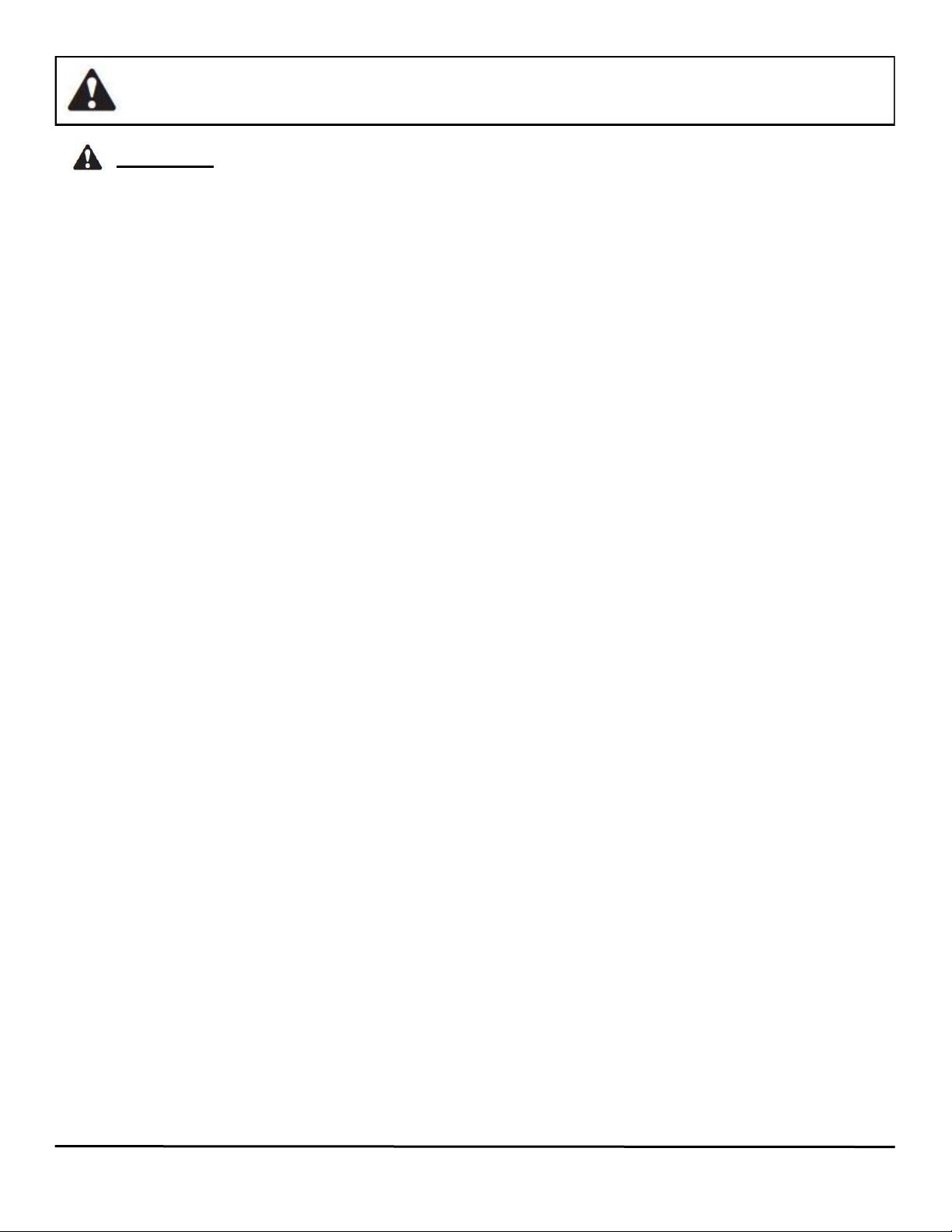

START SAFELY

• Do not do the procedures below when you start the

engine

- short across starter terminals

- bypass the safety start switch

• Do not alter or remove an part of machine safety

system.

• Before you start the engine, make sure that all shift

levers are in neutral positions or in disengaged

position.

• Do not start the engine when you stay on the

ground. Start the engine only from operator’s seat.

WSM00001INI0015US0

STARTING THE MACHINE SAFELY

• Before starting the engine, always sit in the driver’s

seat and make sure the area is safe and clear.

• As it is dangerous, never start the engine from

anywhere but the driver’s seat

• Always check and make sure control lever(s) are

not engaged before starting the engine.

• Never start the engine by hot-wiring the starter

circuit. This is not only dangerous, but many

damage the machine.

RY9212001INI0008US0

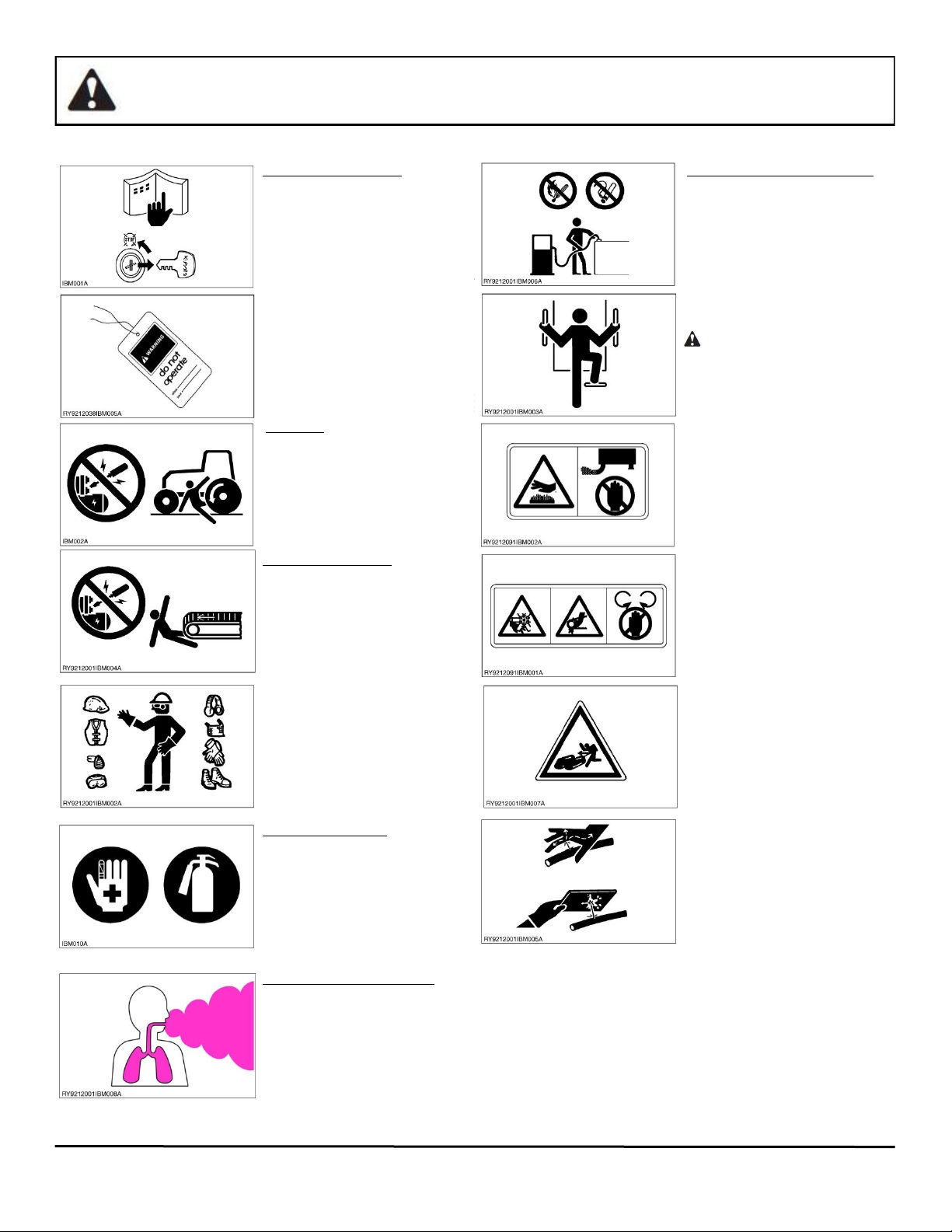

• Wear clothes appropriate for working on equip-

ment. Do not wear loose-fitting clothes as they may

catch on the machine controls.

• When working on the equipment, use all safety

gear, such as a helmet, safety glasses and shoes,

that are required by law or regulation.

• Never perform maintenance while drowsy or under

the influence of alcohol or drugs.

RY9212001INI000US0

BE READY FOR AN EMERGENCY

• Keep a first-aid kit and fire extinguisher close at

hand so you can use it when needed.

• Keep emergency contact information for doctors,

hospitals and ERs handy.

RY9212001INI0004US0

KEEP A GOOD AIRFLOW IN THE WORK AREA

• If the engine is in operation, make sure that the

area has good airflow. Do not operate the engine

in a closed area. The exhaust gas contains

poisonous carbon monoxide.

WSM000001IN006US0

NO SMOKING OR OPEN FLAMES WHILE FUELING

• Fuel is extremely flammable and dangerous.

Never smoke near fuel. IF fuel is spilled on the

machine, its engine, or electrical parts, it may

cause a fire. If fuel is spilled, wipe it all up

immediately.

• Never smoke while filling machine with fuel. And

always tighten the fuel cap securely and wipe up

any spilled fuel.

RY9212001INI0012US0

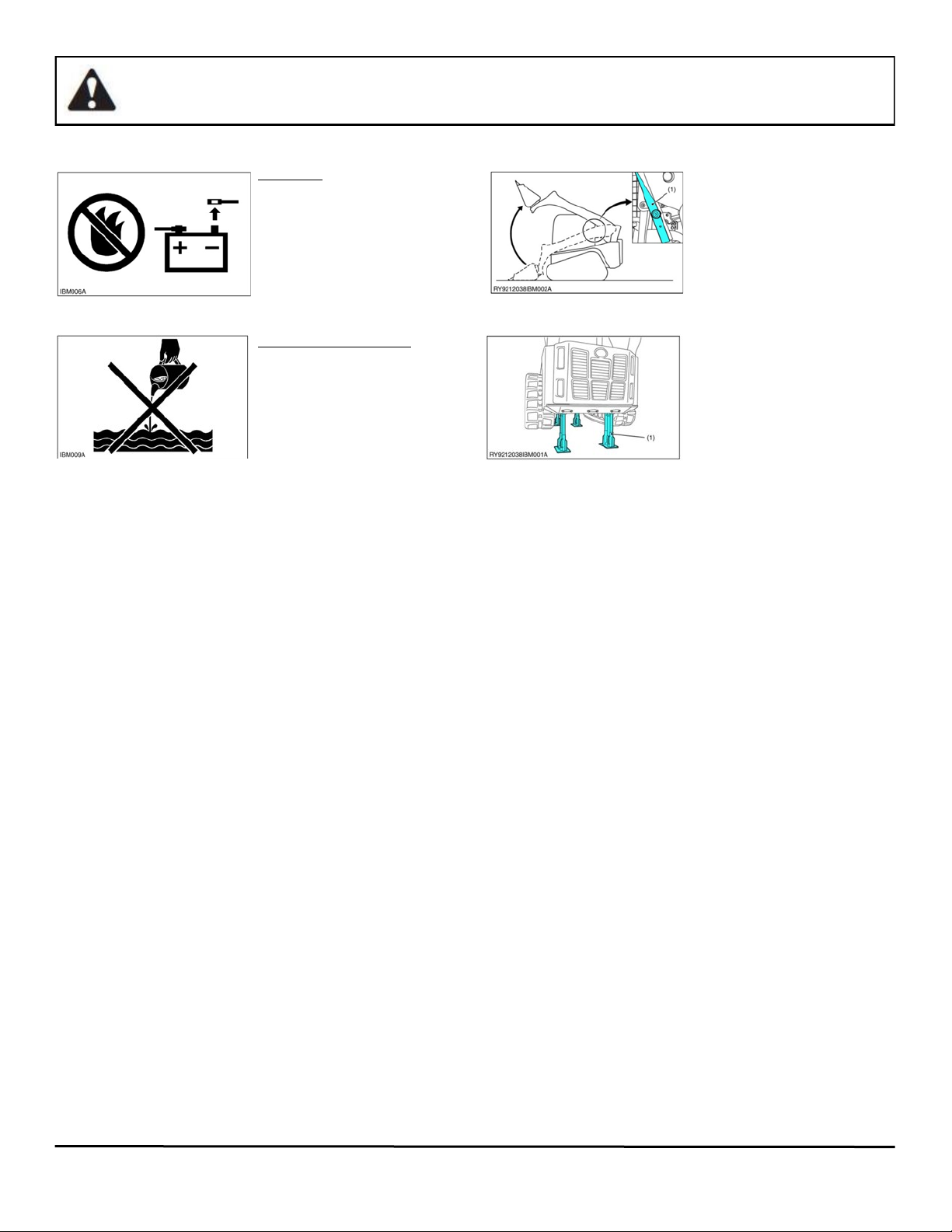

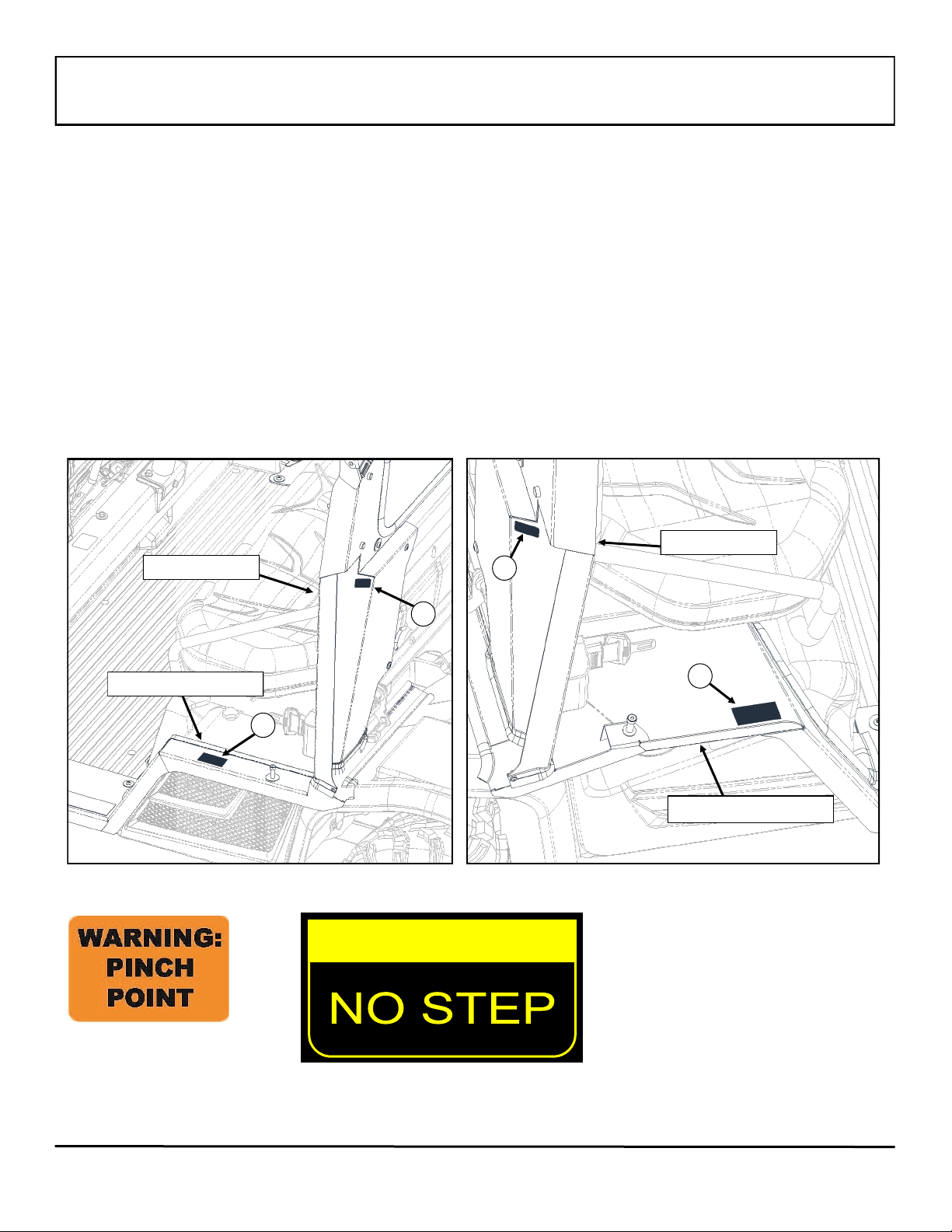

• Before getting of/off of the machine, clean off

around the steps so there is no mud on them.

Always give yourself 3-point support when getting

on/off the machine

CAUTION

• 3-point support means using both legs and

one hang or both hands and one leg as you

climb up/down.

RY9212038INI0003US0

• Do not remove the radiator cap when the engine

operates, or immediately after it stops. If not, hot

water can spout out from radiator. Only remove

the radiator cap when it is at a sufficiently low

temperature to touch with bare hangs. Slowly

loosen the cap to release the pressure before you

remove it fully.

• The engine, muffler, radiator, hydraulic line, etc.,

have parts that remain very hot even after the

engine has been stopped. Be sure to avoid these

parts, as touching them can result in burns.

Radiator coolant, hydraulic fluid and oil also

remain hot. Therefore, do not attempt to remove

caps and plugs, etc., before these fluids have

sufficiently cooled.

• Make sure the coolant temperature has dropped

sufficiently before opening the radiator cap. Also

since the inside of the radiator is pressurized,

when removing the cap, first loosen it to release

the pressure before removing the cap completely.

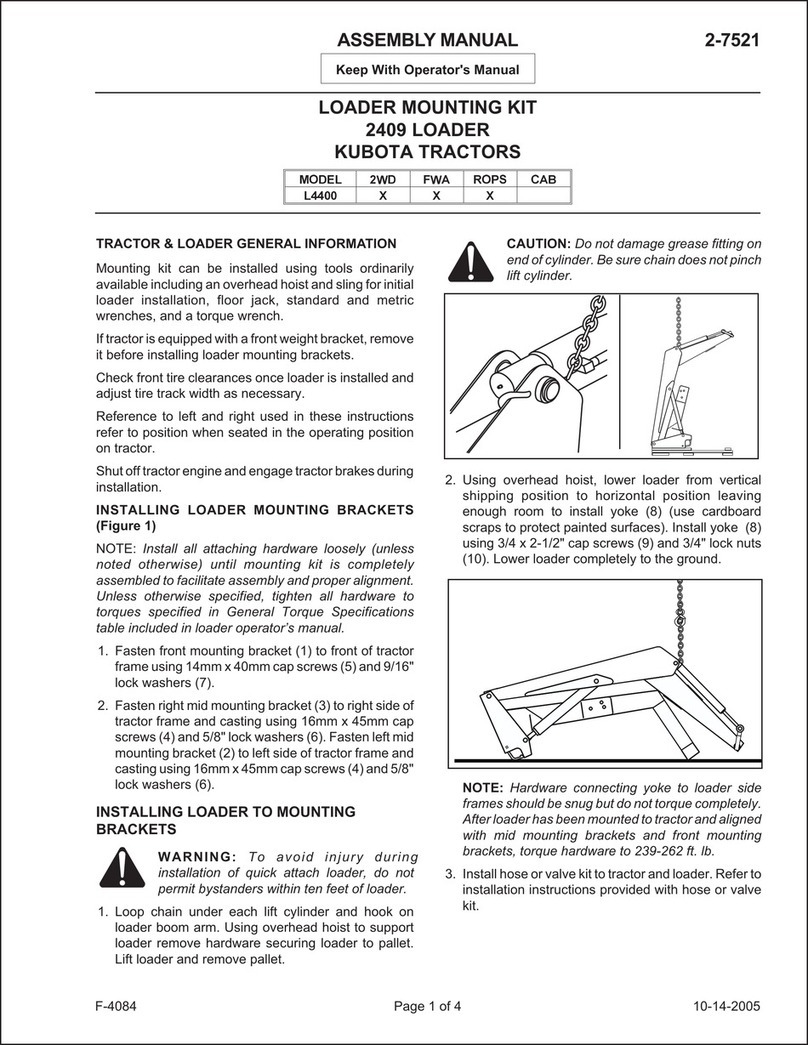

• Grease is under high pressure inside the

hydraulic cylinder. It is very dangerous to

loosen a grease nipple quickly as it may shoot

off. Always loosen grease nipples slowly.

• And never face a grease nipple while loosening

it.

• The pressure in the hydraulic circuit stays at

pressure even after the engine stops. Before

removing parts, such as hydraulic devices from

the machine, first release the pressure. Please

not that when releasing residual pressure, the

machine itself and/or implements may move

without warning, so be very careful hen releasing

the pressure.

• Oil gushing out under pressure is extremely

dangerous as it may pierce your skin or your

eyes. Similarly, oil leaking out of pinholes is not

visible. So when checking for oil leaks, always

wear safety glasses and gloves and use a piece

of cardboard or a woo block to shield yourself

from oil.

• Do no open a fuel system under high pressure.

The fluid under high pressure the stays in fuel

lines can cause serious injury. Do not disconnect

or repair the fuel lines, sensors, or any other

components between the fuel pump and injectors

on engine with a common rail fuel system under

high pressure.

• Put on an applicable ear protective device

(earmuffs or earplugs) to prevent injury against

loud noises.

• Be careful about electric shock. The engine

generates a high voltage of more that DC100 V in

the ECU and is applied to injector.