Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

thoseinthetractionunit

Operator’ s Man ual

.Always

payattentiontothesafetyalertsymbol,which

means

Caution

,

W ar ning

,or

Danger

—personal

safetyinstruction.Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

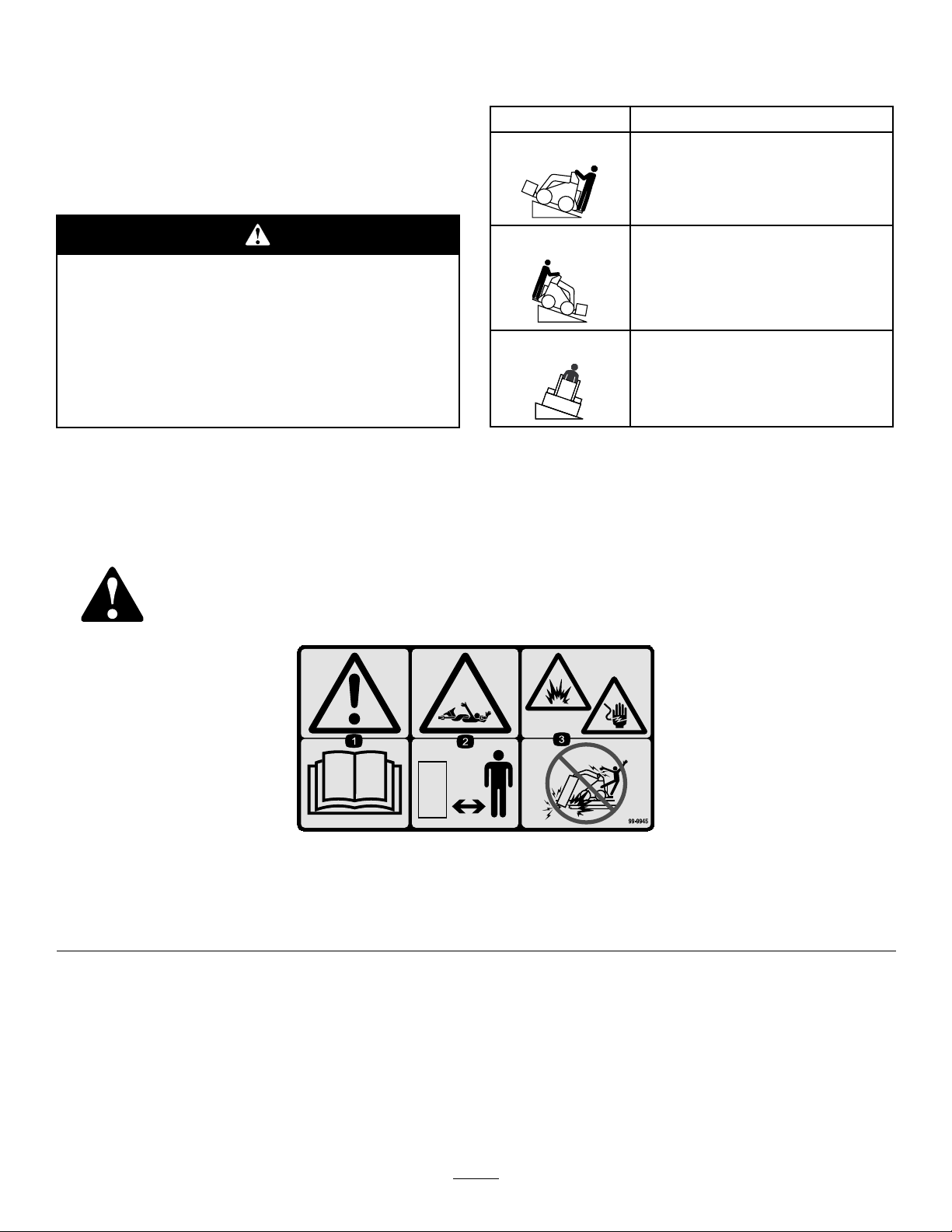

Theremaybeburiedpower,gas,and/or

telephonelinesintheworkarea.Shockor

explosionmayoccurifyoudigintothem.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUnitedStates,call811forthe

nationwidemarkingservice).

Rotatingrodandbitscanentangleloose

clothing,hands,arms,legs,andfeet,causing

deathorseriousinjury.

•Keepatleasttenfeetfromrotatingparts,

unlessyouareoperatingtherodguidetool.

•Neveruseanythingbuttherodguidetool

forstartingtherodandboringbit.

•Keepextremitiesandotherpartsofyour

bodyorclothingawayfromrotatingparts.

•Donotwearlooseclothingorjewelrywhile

operatingorassistingwiththeboringunit.

•Alwaysturnoffthetractionunitbefore

changingaccessories.

Whentheengineisoff,attachmentsinthe

raisedpositioncangraduallylower.Someone

nearbymaybepinnedorinjuredbythe

attachmentasitlowers.

Alwayslowertheattachmentlifteachtimeyou

shutoffthetractionunit.

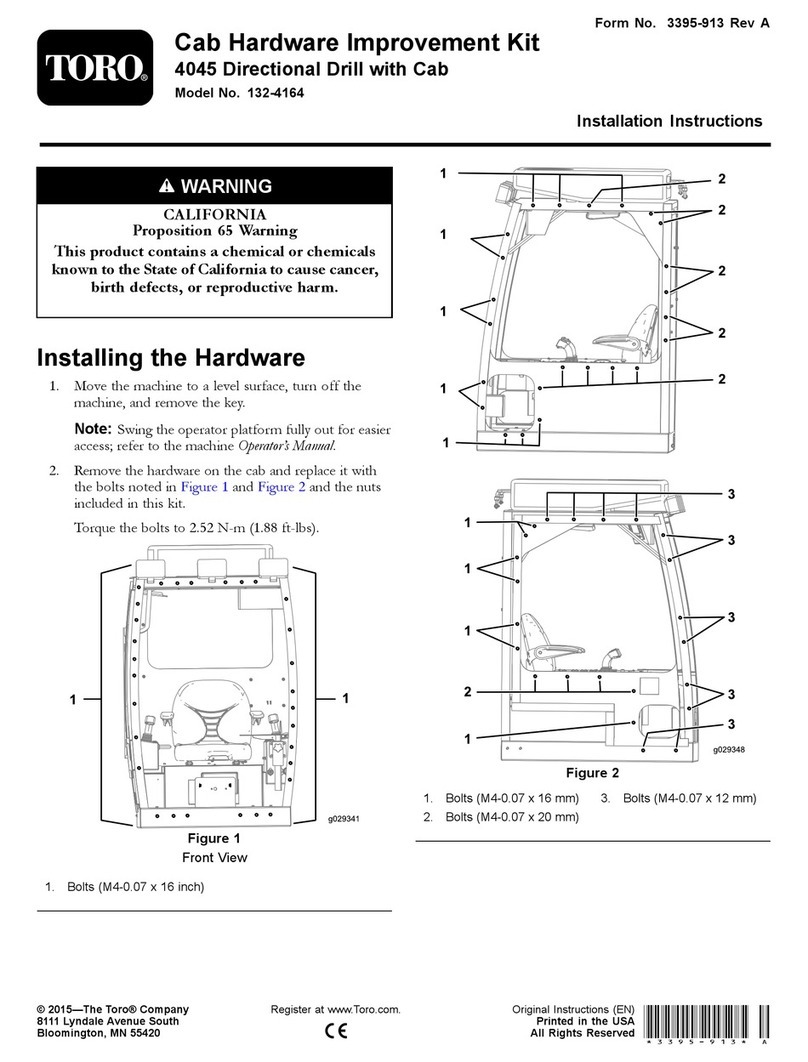

Ifyoudonotfullyseattheattachmentlocking

pinsintheattachmentmountplateholes,the

attachmentcouldfalloffofthetractionunit

severelyinjuringtheoperatororbystanders.

•Ensurethatyoufullyseattheattachment

lockingpinsthroughtheholesinthe

attachmentmountplatebeforeliftingthe

attachment.

•Ensurethattheattachmentmountplateis

freeofanydirtordebristhatmayhinder

theconnectionofthetractionunittothe

attachment.

•Refertoyourtractionunit

Operator’ s

Man ual

fordetailedinformationonsafely

connectinganattachmenttoyourtraction

unit.

Hydrauliccouplers,hydrauliclines/valves,and

hydraulicuidmaybehotandcanburnyouif

youtouchthem.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthetractionunittocoolbefore

touchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

•Donotservicetheattachmentunlessrodrotationis

stopped,theauxiliaryhydraulicsleverismovedto

neutral,andtheengineofthetractionunitisstopped.

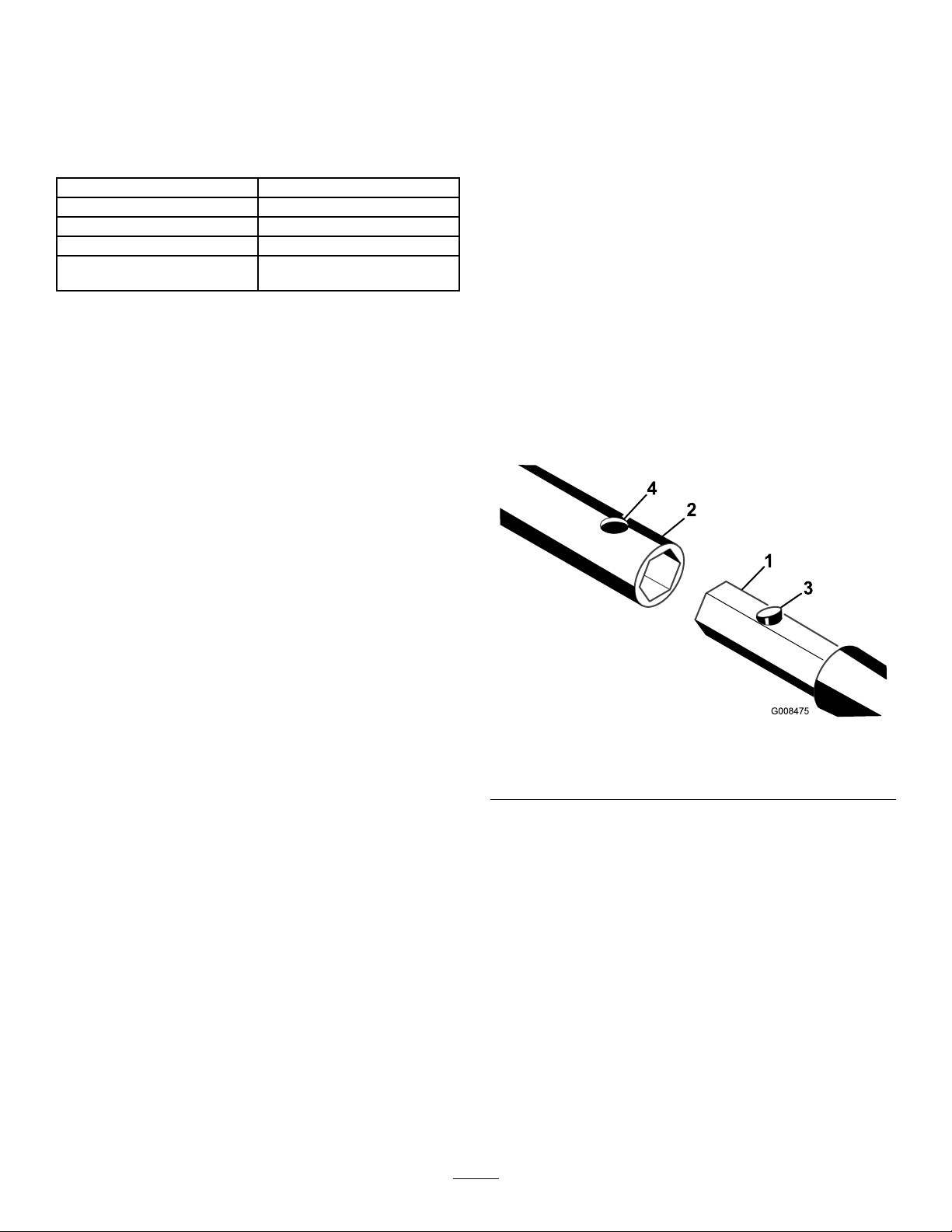

•Neveruseboltsorpinsinplaceofpushbutton

connectors.

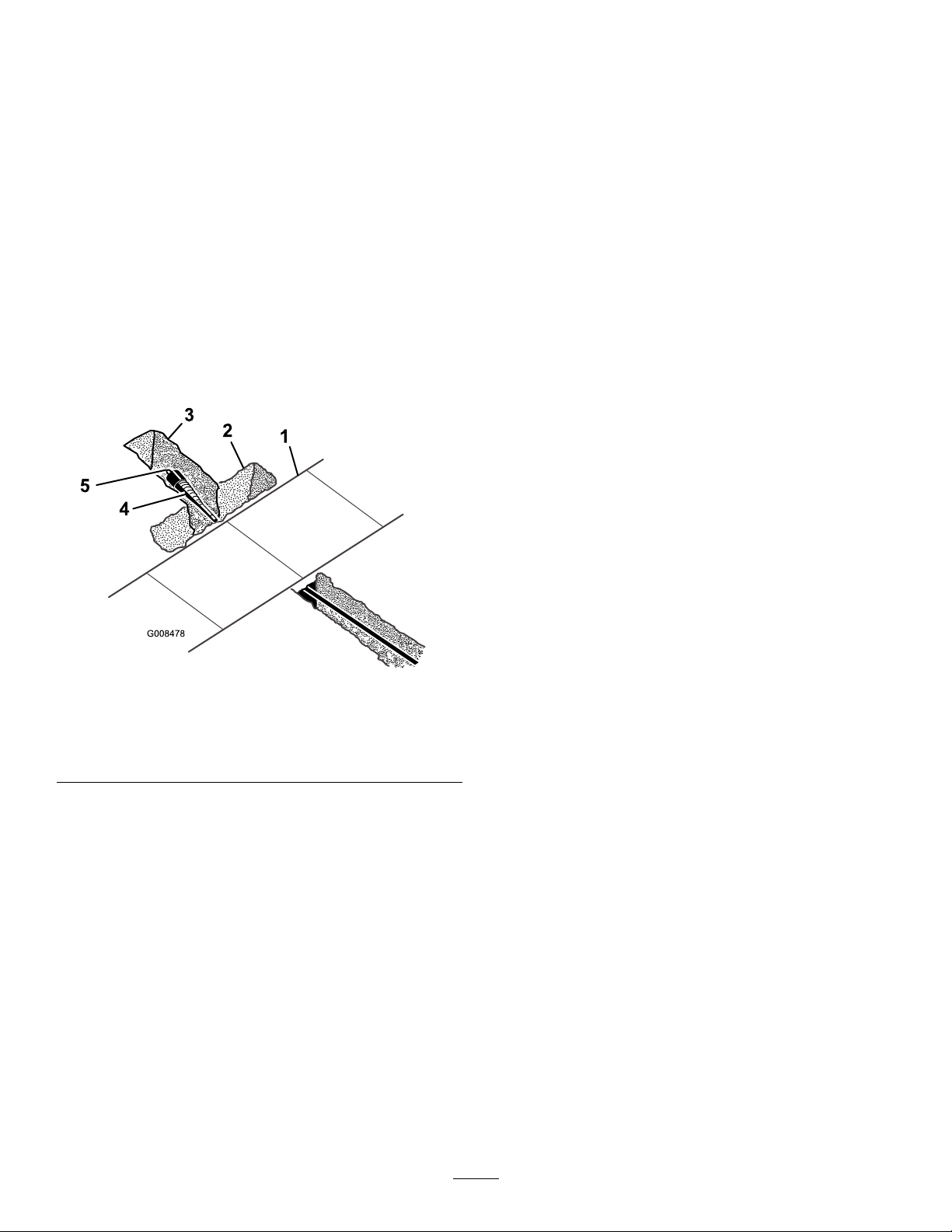

•Alwaysuse2peopletooperatetheattachment,one

tooperatethetractionunitandtheothertoguide

theboringunitwiththeguidetool.

•Alwaysusetheguidetooltoaligntheboringunit.

•Neverstraddleorstandontherodwhentheengine

isrunning.

3