B.Insertalongstripofcuttingperformance

paperbetweenthereelandbedknife,

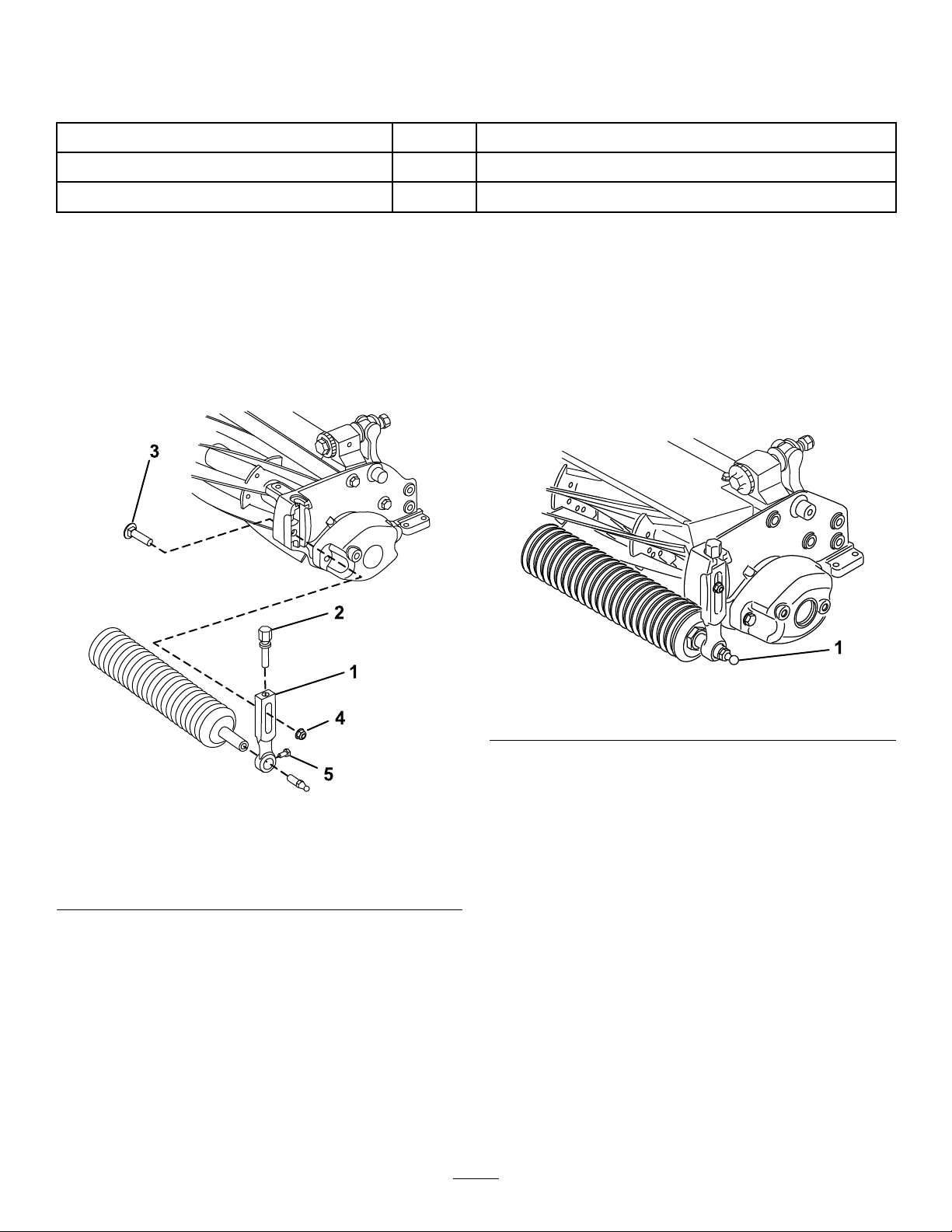

perpendiculartothebedknife(Figure

10),thenslowlyrotatethereelforward;

itshouldcutthepaper;ifnot,repeat

stepsAandBuntilitdoes.

•Ifexcessivecontact/reeldragisevident,

backlap,refacethefrontofthebedknife,or

grindthecuttingunittoachievethesharp

edgesneededforprecisioncutting(Referto

theToroManualforSharpeningReeland

RotaryMowers,FormNo.09168SL).

Important:Lightcontactispreferredatall

times.Ifyoudonotmaintainlightcontact,

thebedknife/reeledgesdonotsufciently

self-sharpen,resultingindullcuttingedges

afterashortperiodofoperation.Ifyou

maintainexcessivecontact,bedknife/reel

wearisaccelerated,unevenwearcanresult,

andthequalityofcutmaydecline.

Note:Asthereelbladescontinuetorunagainst

thebedknife,aslightburrwillappearonthefront

cuttingedgesurfacealongthefulllengthofthe

bedknife.Occasionallyrunaleacrossthefront

edgetoremovethisburrtoimprovecutting.

Afterextendedrunning,aridgewilleventually

developatbothendsofthebedknife.Round

offthesenotchesorlethemushwiththe

cuttingedgeofthebedknifetoensuresmooth

operation.

AdjustingtheBedknifetotheReel

Usethisprocedureduringinitialcutting-unitsetupand

aftergrinding,backlapping,ordisassemblingthereel.

Thisisnotadailyadjustment.

1.Positionthecuttingunitonaat,levelwork

surface.

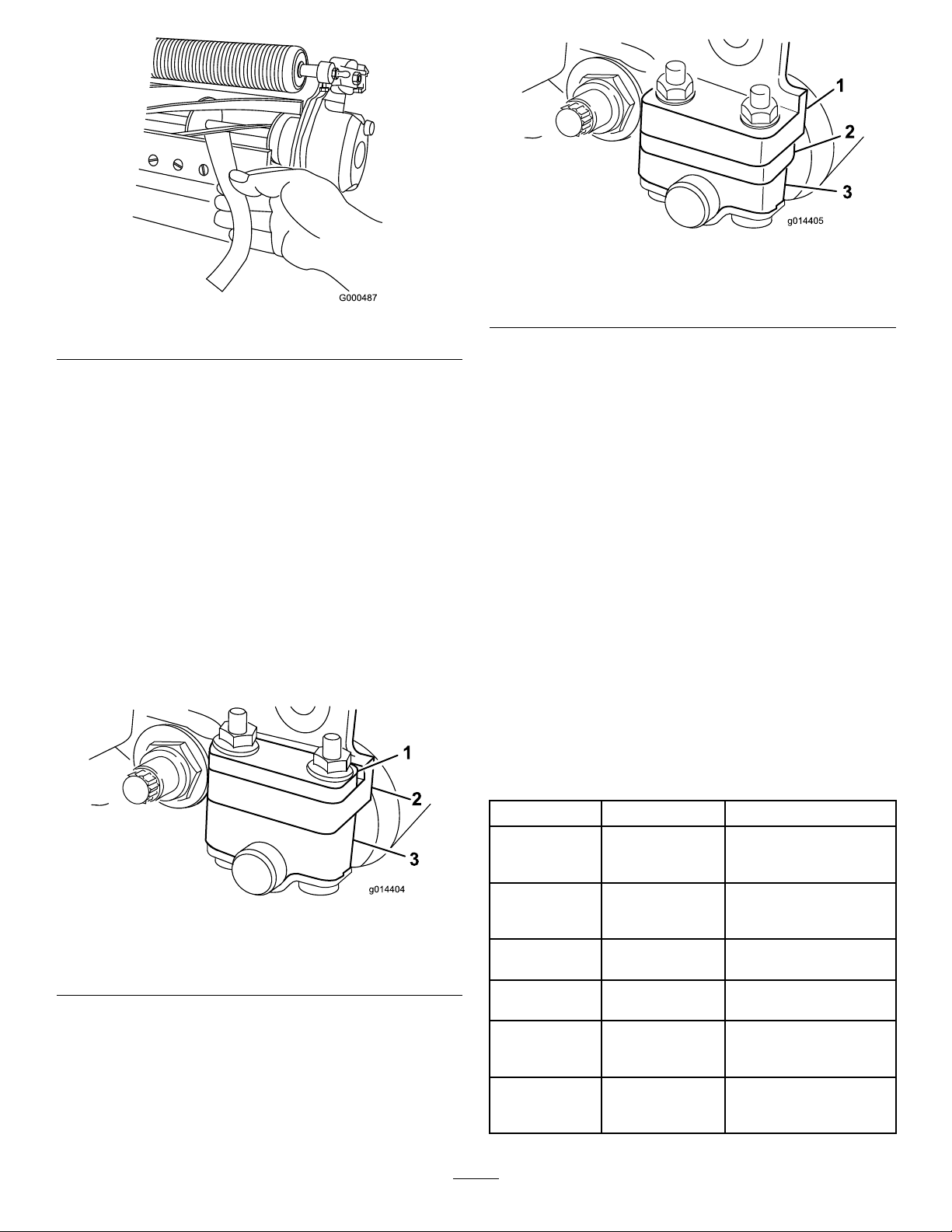

2.Tipthecuttingunittoexposethebedknifeand

reel.

Note:Ensurethatthenutsonthebackofthe

bedbaradjustingboltsarenotrestingonthe

worksurface(Figure17).

3.Rotatethereelsothat1ofthebladescrosses

thebedknifeedgebetweentherstandsecond

bedknifeboltheadslocatedontherightsideof

thecuttingunit.

4.Makeanidentifyingmarkonthebladewhereit

crossesthebedknifeedge.

Note:Thismakeslateradjustmentseasier.

5.Inserta0.05mm(0.002inch)shim(T oroPart

No.140-5531)betweenthebladeandthe

bedknifeedgeatthepointmarkedinstep4.

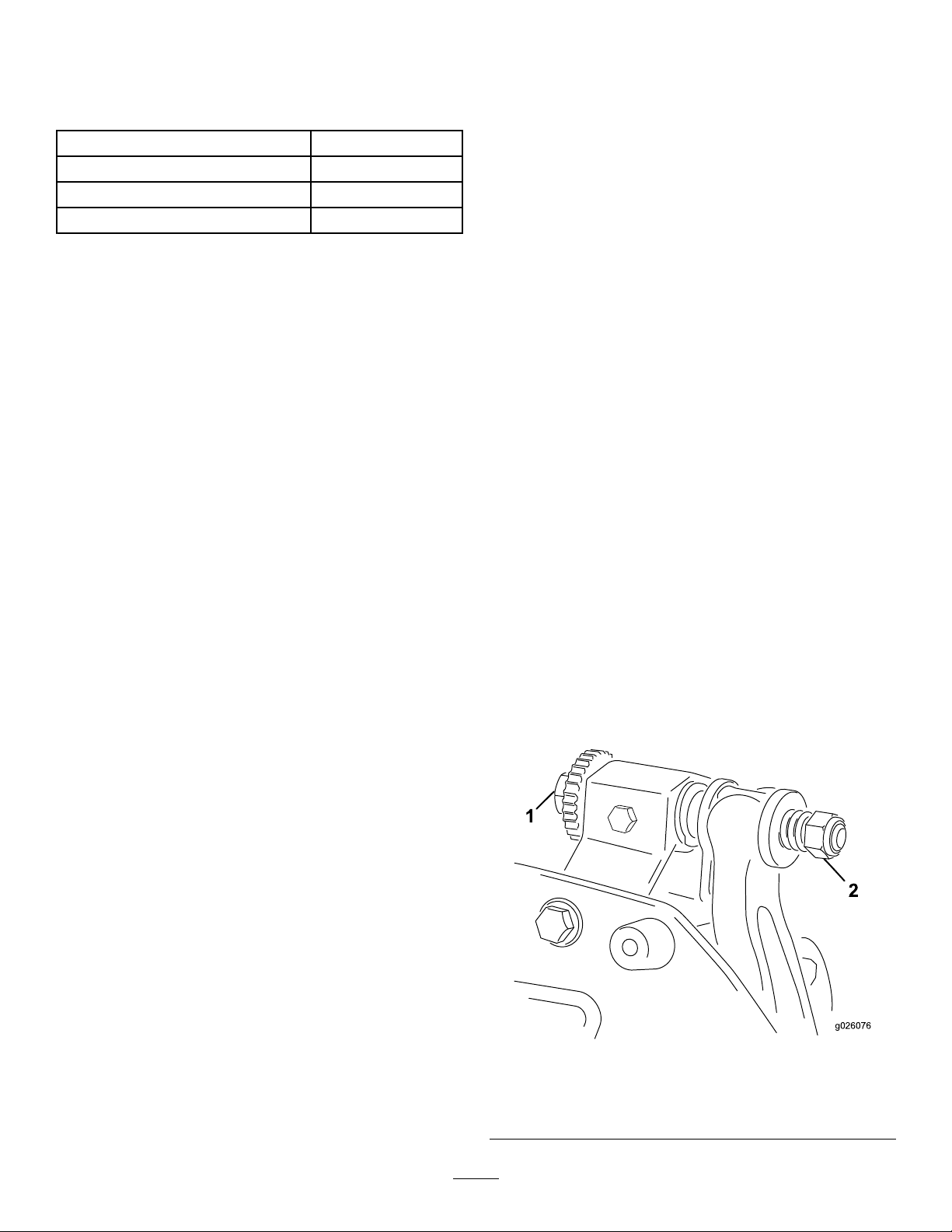

6.Turntherightbedbaradjustingbolt(Figure9)

untilyoufeellightpressureontheshimwhen

slidingitside-to-side.Removetheshim.

7.Fortheleftsideofthecuttingunit,slowlyrotate

thereelsothattheclosestbladecrossesthe

bedknifeedgebetweentherstandsecondbolt

heads.

8.Repeatsteps4through6fortheleftsideofthe

cuttingunitandleftbedbaradjustingbolt.

9.Repeatsteps5and6untilthereislightpressure

atthecontactpointsonboththeleftandright

sidesofthecuttingunit.

10.Toobtainlightcontactbetweenthereeland

bedknife,turneachbedbaradjustingbolt

clockwise3clicks.

Note:Eachclickonthebedbaradjustingbolt

movesthebedknife0.018mm(0.0007inches).

Donotovertightentheadjustingbolts.

Turningtheadjustingboltclockwisemoves

thebedknifeedgeclosertothereel.Turning

theadjustingboltcounterclockwisemovesthe

bedknifeedgeawayfromthereel.

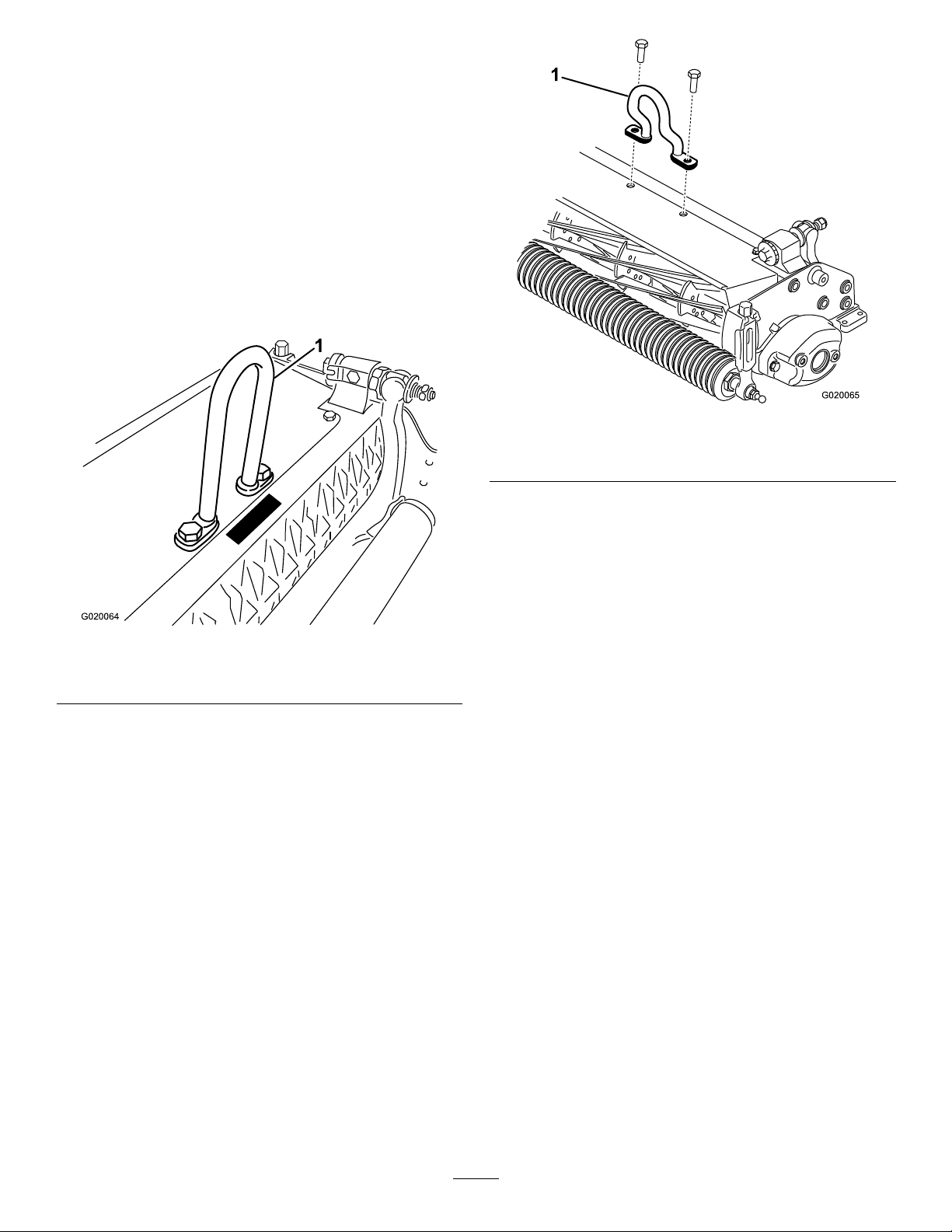

11.Insertalongstripofcuttingperformancepaper

(ToroPartNo.125-5610)betweenthereeland

bedknife,perpendiculartothebedknife(Figure

10),thenslowlyrotatethereelforward;itshould

cutthepaper;ifnot,turneachbedbaradjusting

boltclockwise1clicksandrepeatthisstepuntil

itcutsthepaper.

9