965X Service Manual

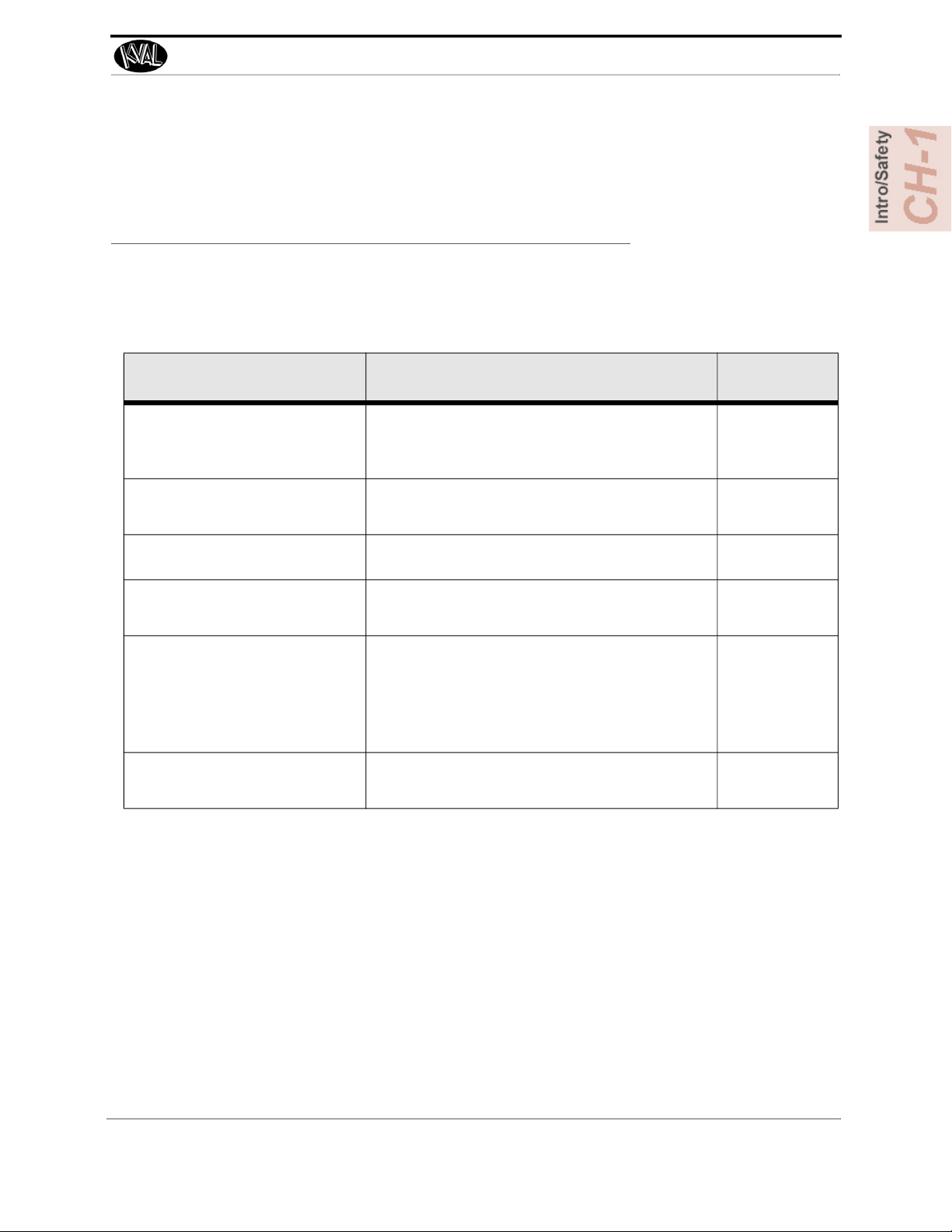

Table of Contents

Empty Dust Collection Units .................................................................3-6

3,000 Cycle Maintenance Steps .............................................. 3-7

I Inspect all Photo Eyes ........................................................................3-7

Inspect Limit Switches ..........................................................................3-7

Inspect Airlines......................................................................................3-7

Refill Lubricators...................................................................................3-8

Grease Ball Screw Bearings.................................................................3-8

Clean Bearing Shafts............................................................................3-8

12,000 Cycle Maintenance Steps............................................ 3-9

Inspect Air Cylinders .............................................................................3-9

Inspect Ball Rail Shafts and Ball Screws..............................................3-9

Clean and Lubricate Slides, Cylinder Rods and Bearing Shafts...........3-9

72,000 Cycle Maintenance Steps............................................ 3-10

Inspect Nuts and Bolts........................................................................3-10

Electrical .............................................................................................3-10

Computer Backup...............................................................................3-10

Wash Filter and Lubricator Bowls .......................................................3-10

Maintenance NO-GOES .......................................................... 3-11

Lubrication Schedule ............................................................... 3-12

Typical Lucubration Kit........................................................................3-12

Lubrication Requirements........................................................ 3-13

Pillow Block Bearing Housings ...........................................................3-13

Flange Bearing Housings ...................................................................3-14

Ball Rail Bearing .................................................................................3-14

About Taper Bearings .........................................................................3-15

Tapered Bearing Housings .................................................................3-15

Ball Screw Nut ....................................................................................3-16

Ball Screw Drive Assembly .................................................................3-16

How to Prepare the 965X for Greasing.................................... 3-17

Cutter Head Location After Park .........................................................3-17

Grease Locations for the 965X................................................ 3-18

Locations of Cutter Head Bearings.....................................................3-18

Locations of Bearings on Each Tool ...................................................3-19

Locations of Rail Bearings on the Clamp Assemblies ........................3-20

Description of Air Input System................................................ 3-22

Air Input with Lubrication ...................................................................3-22

Air Line Without Lubricator .................................................................3-23

Identifying 965X Tools.............................................................. 3-24

About the Tool Kit..................................................................... 3-25