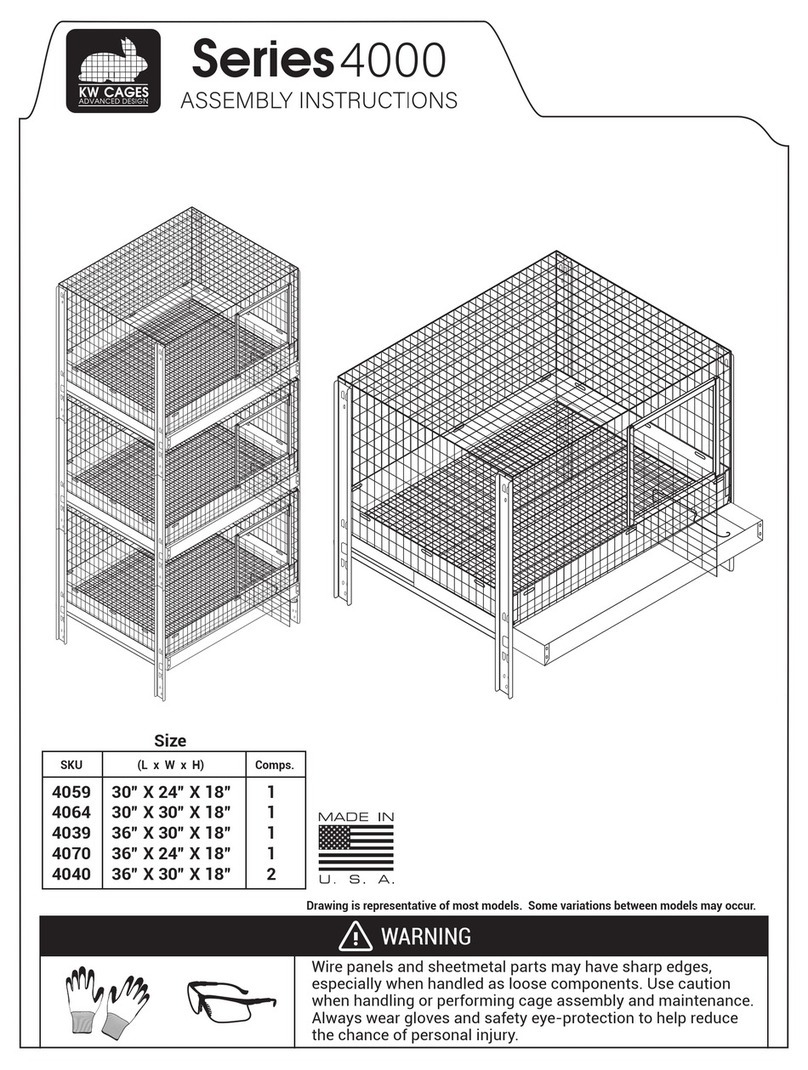

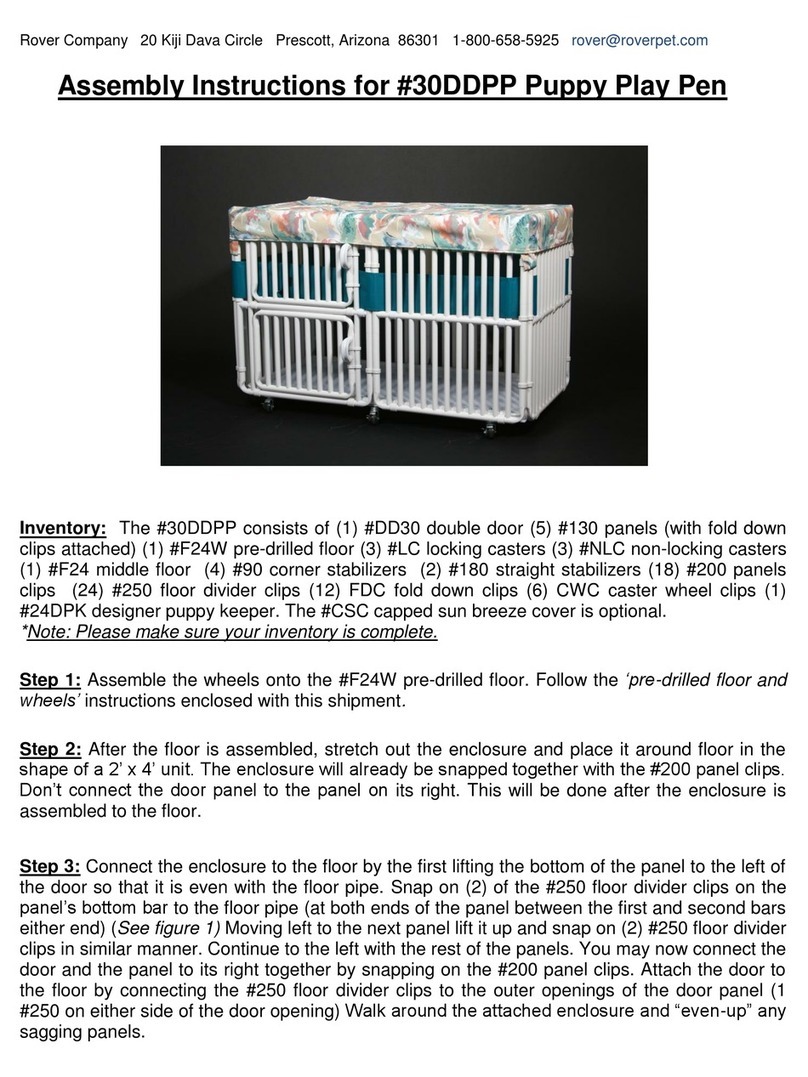

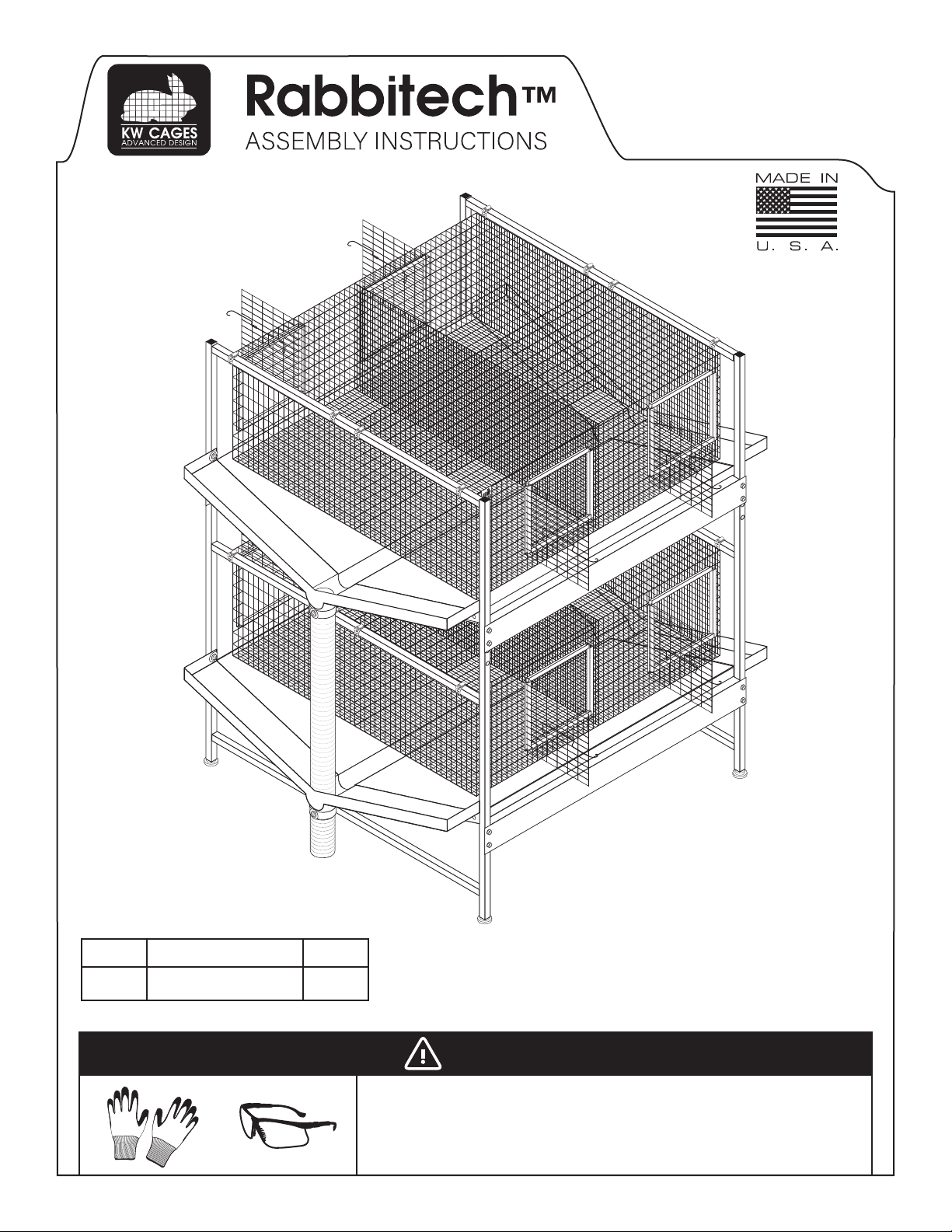

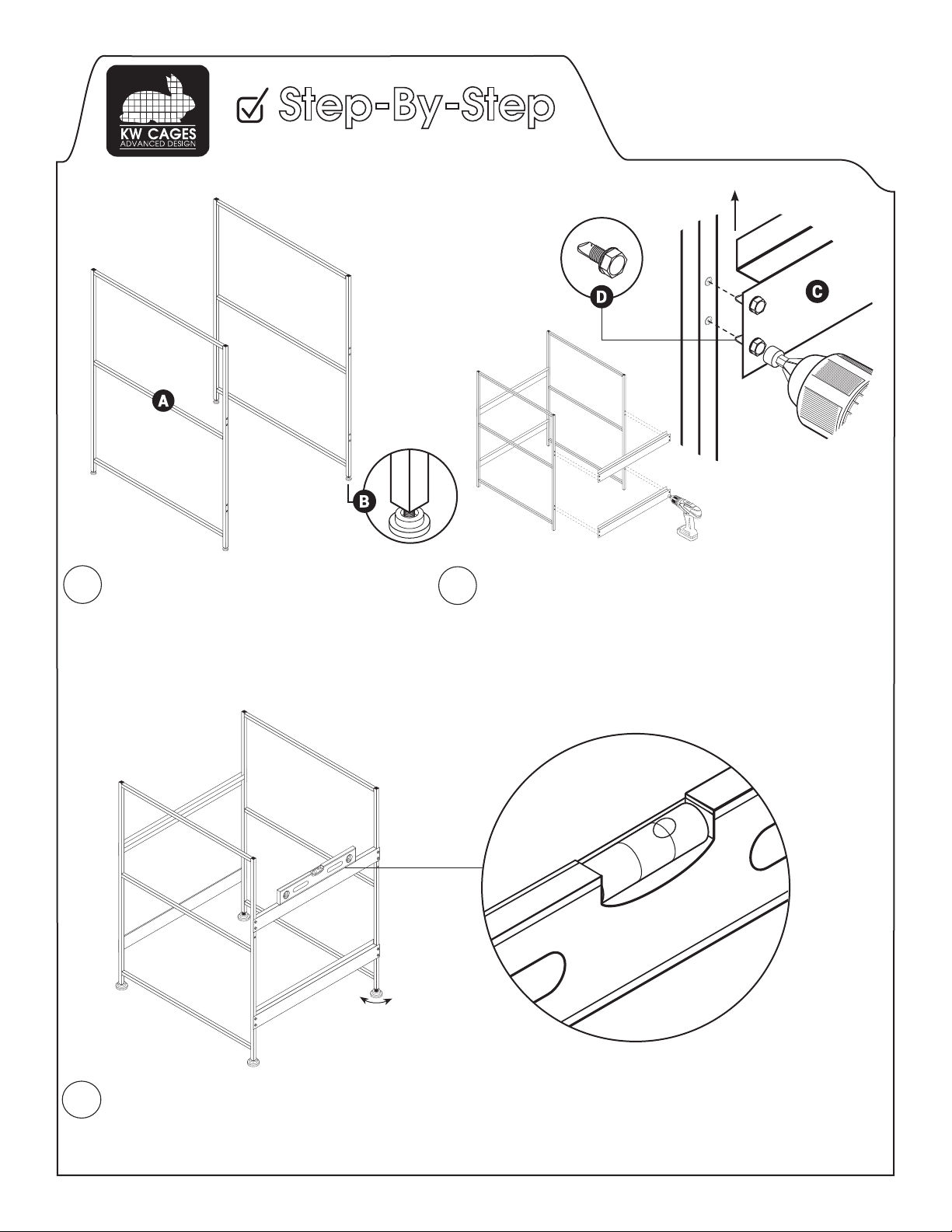

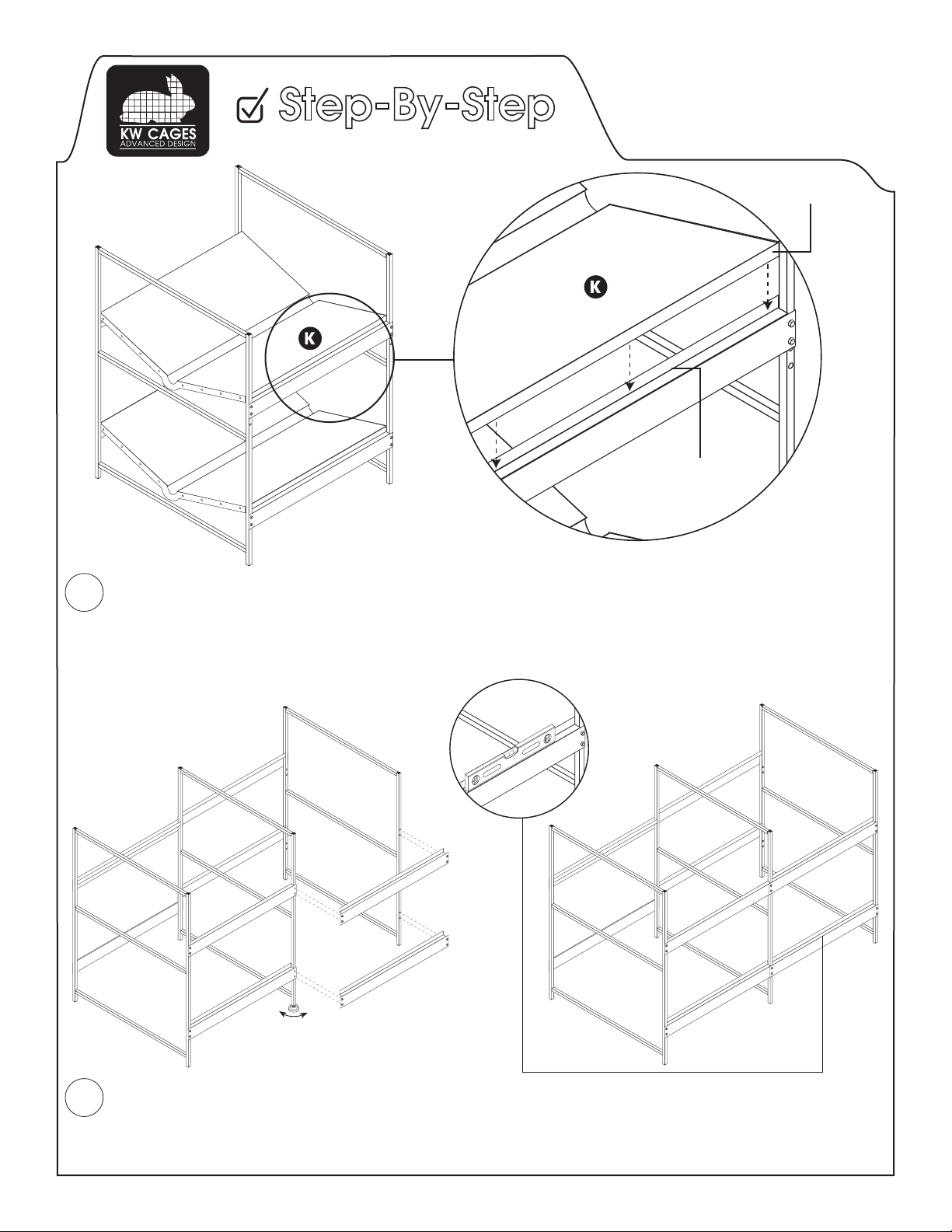

Attach self leveling feet (B) to the bottom

of each H-frame (A). Adjust leveling feet

to be approx. 1/8”-1/4” longer for each

successive section.

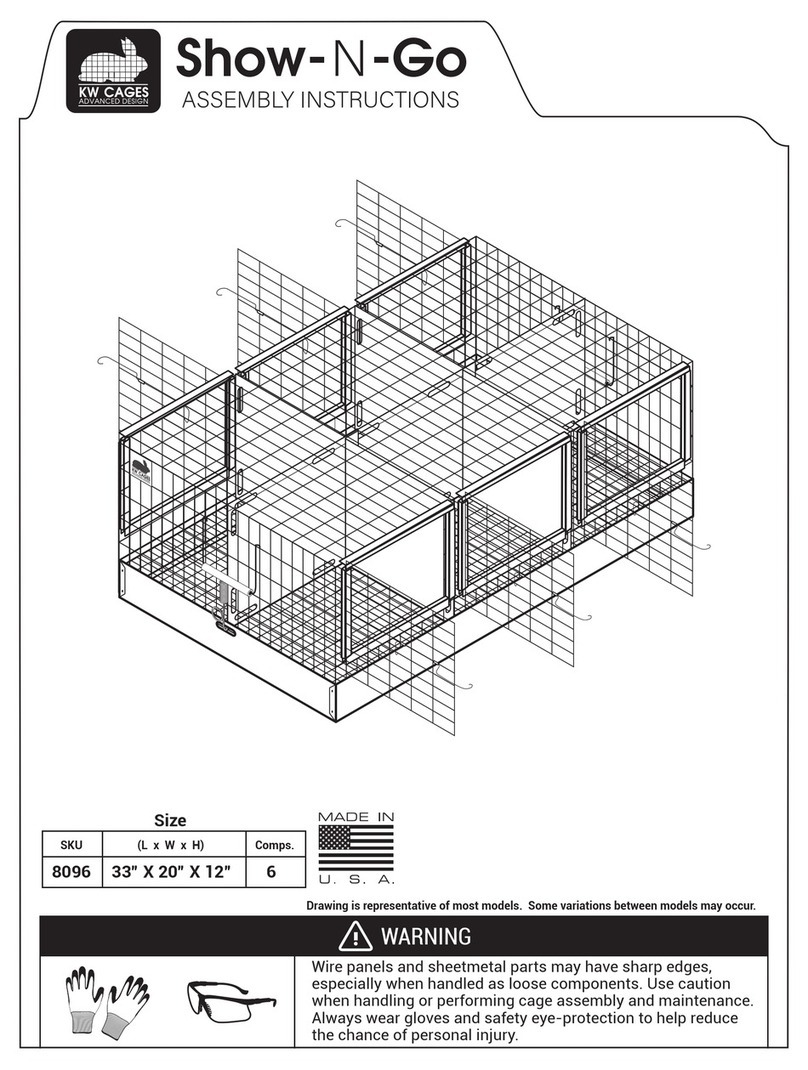

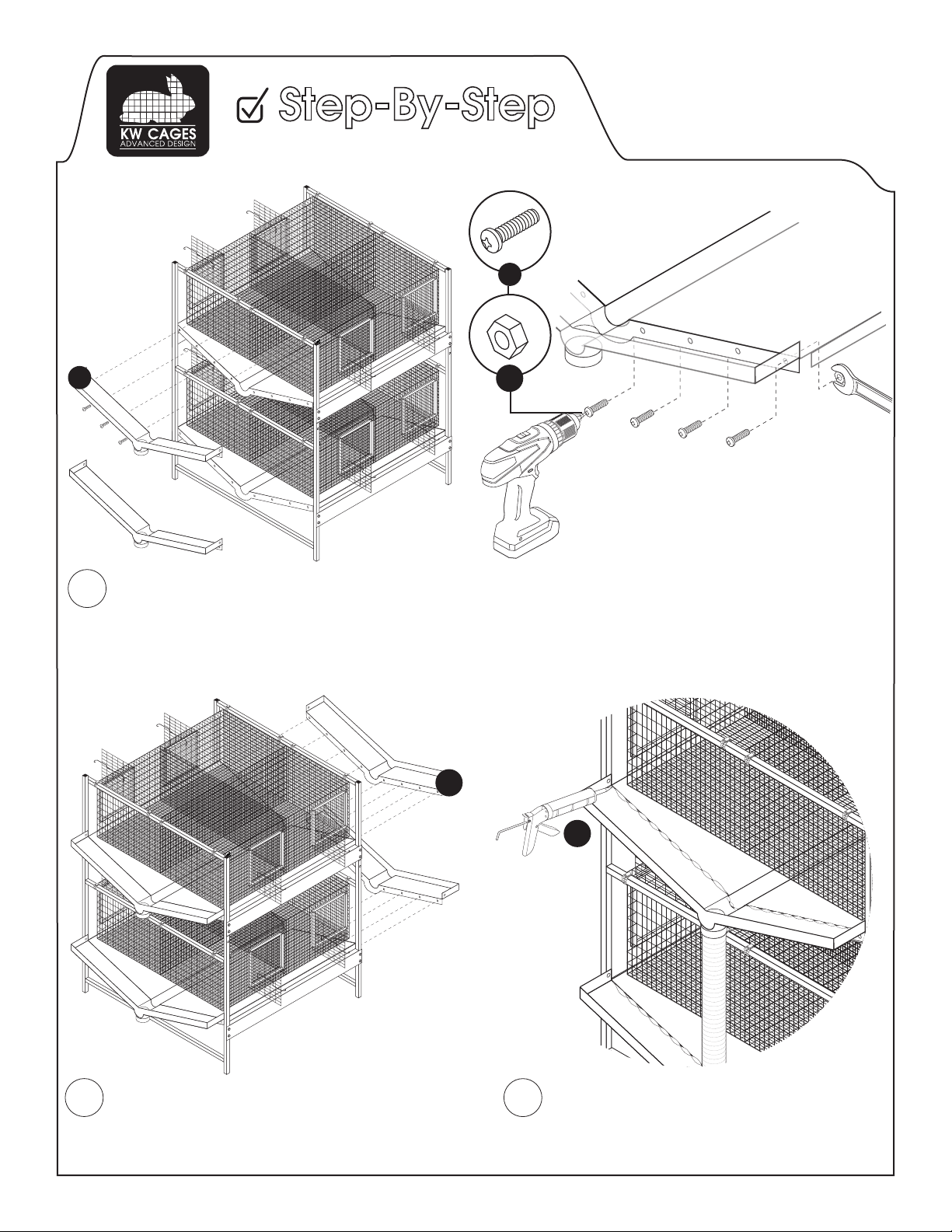

1Position support beam (C) to span across both H-Frame

sections. Attach support beam so that lip faces upward

to support plastic wash-down pan. Align holes in support

beam with dimples in H-Frame. Using drill with 3/8” hex

bit to drive stainless steel self drilling screws (D) into dim-

ple. Apply moderate pressure. Repeat on opposite side

until all four beams are attached.

2

Adjust all leveling feet such that each frame is a minimum of 1/8” taller than the preceeding frame. See step

one for detail. A carpenters level can be used to check for consistent slop by maintaining the bubble slightly

off of center. This will ensure proper drainage toward the lower drain side when cleaning the Rabbitech System.

If add-on kits are installed, make sure to maintain the proper slope as units are added for optimal drainage. If

floor of building is not level more or less adjustment may be required.

3

Frame Assembly

Support Beam Lip

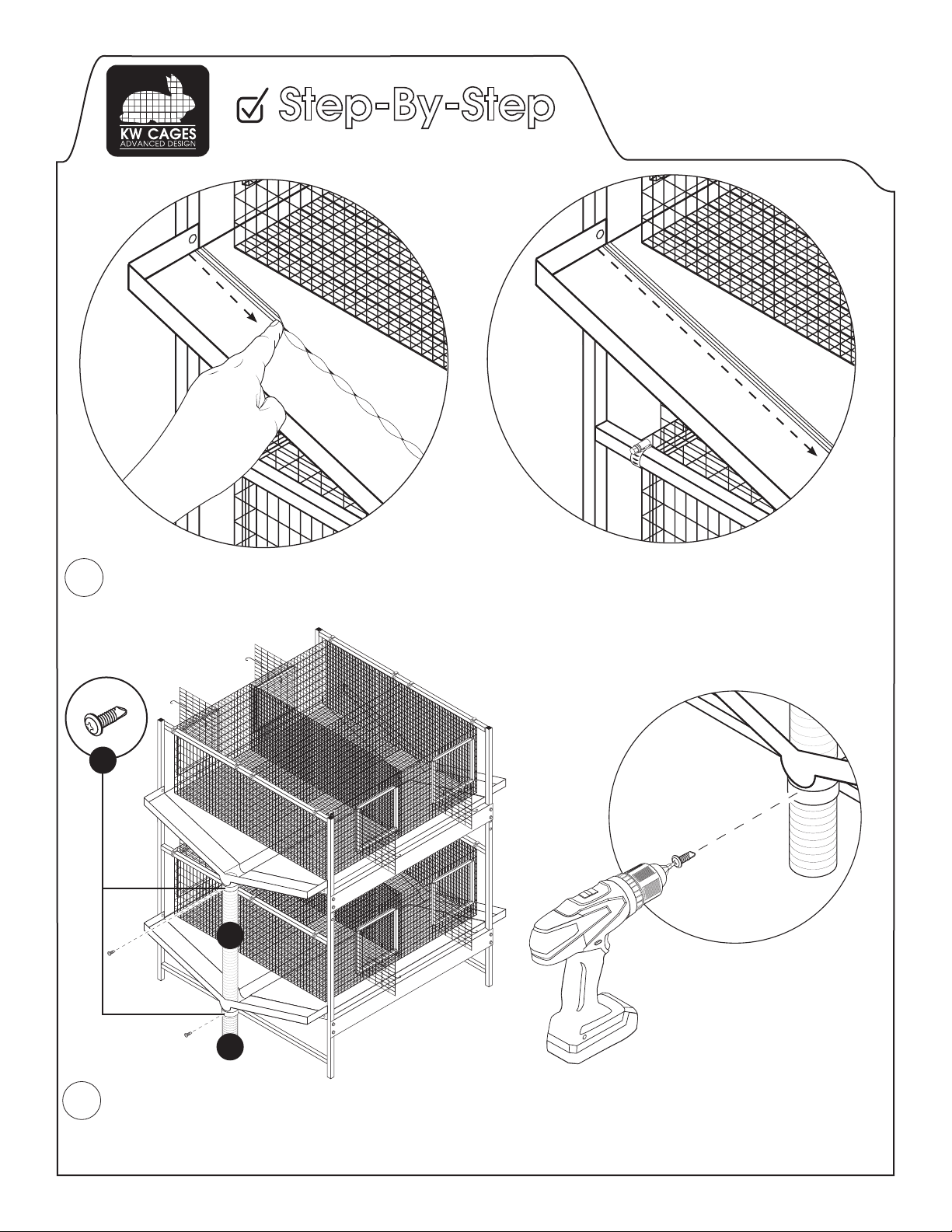

Pro Tip: Use a carpenters level to check

that consistent slope is achieved.

Short Drain

Pipe

Long Drain

Pipe

Wash-Down Pan SS Hex

Tech Screw

SS Phillips

Tech Screw

SS Bolt SS Nut Cage Clamp Clips Rings Silicone

+ -