7

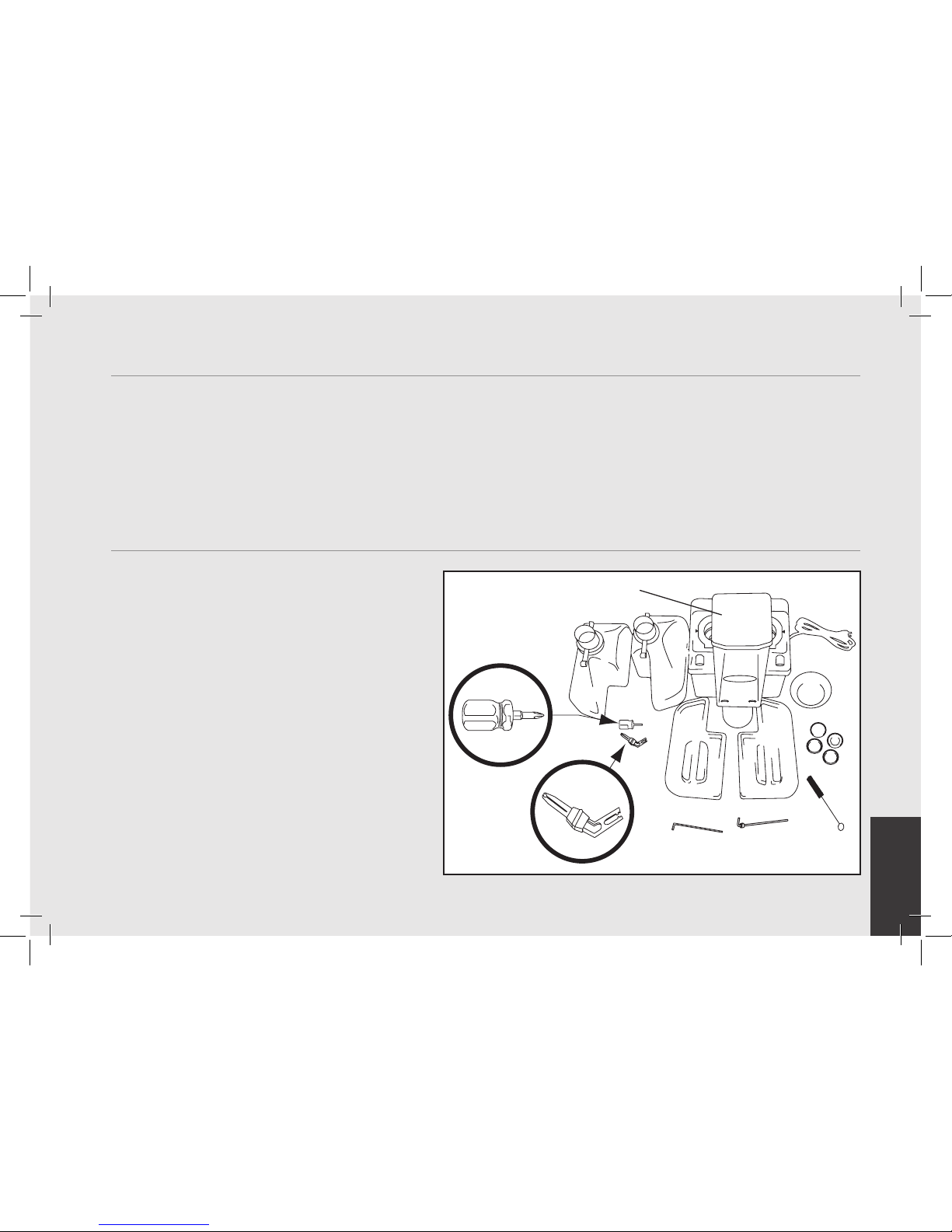

6. Operang the SWIFT EPSB

6.1 SWIFT EPSB

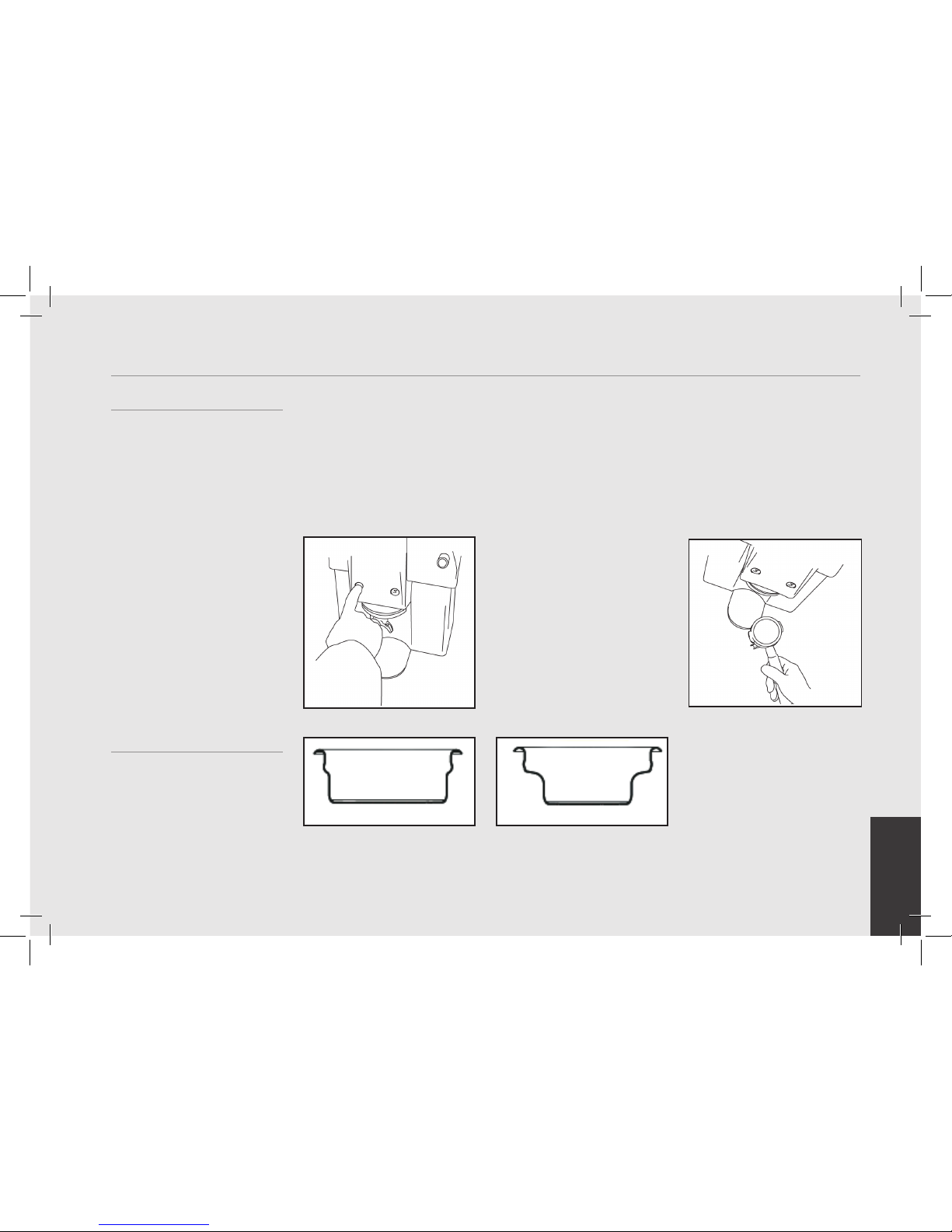

Once the portalter is

engaged, press one of the

start buons located at the

front of the SWIFT EPSB.

The right and le buons

correspond to the right and

lebean hoppers. Coee will

be ground, dosed, and tamped

from one of these locaons,

depending on which buon

you press.The red indicator

lights located above the

start buons are illuminated

when the SWIFT EPSBis

grinding and tamping. Once

the red light corresponding

to the buon selected is no

longer illuminated, you may

remove the portalter from

the SWIFT EPSBand engage

it into the espresso machine.

The SWIFT EPSBtamps the

coee as it is ground. When

the volume of ground coee

in the portalter reaches

the set level, the grinding

motorturnso.Thetamping

motor connues to run for

1-3 seconds, “polishing” the

tampedcoee.

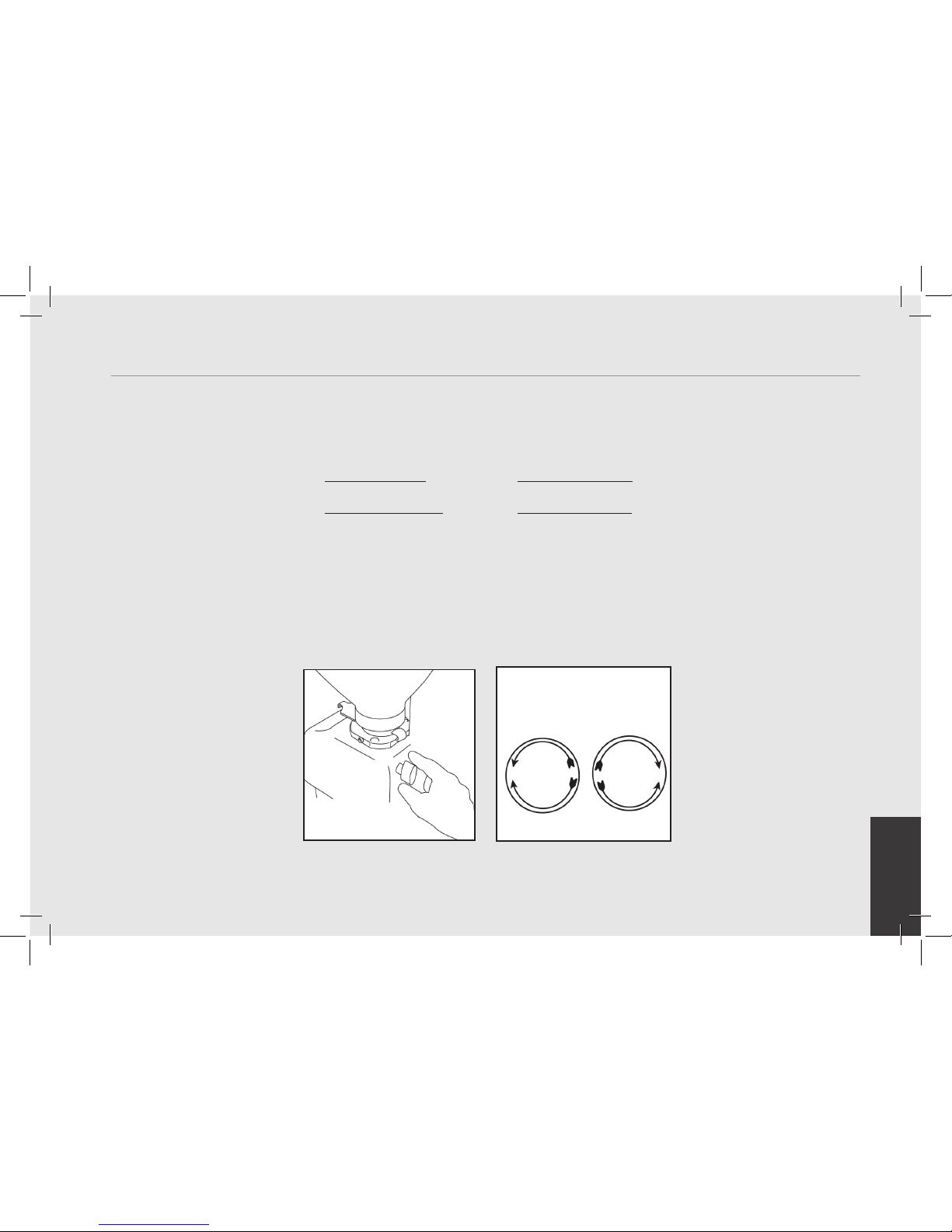

6.2 SWIFT S/D

The SWIFT is now available in

a Single/Double dose version

which permits dosing and

tamping into specic lters

for either single or double

doses.

Selecttherightorlebean

hopper.

Removepreparedportalter.

SINGLE L116/A/S

DOUBLE L115/A/S

Externallythismodelappears

likethestandardversion,but

the internal impeller, which

deposits and presses the

coee,issmallerindiameter

so that it does not get stuck

insideasinglelter.