(P/N)738.098 Rev A • 04/09 © copyright 2009 Kaba Mas LLC

page 4 of 5

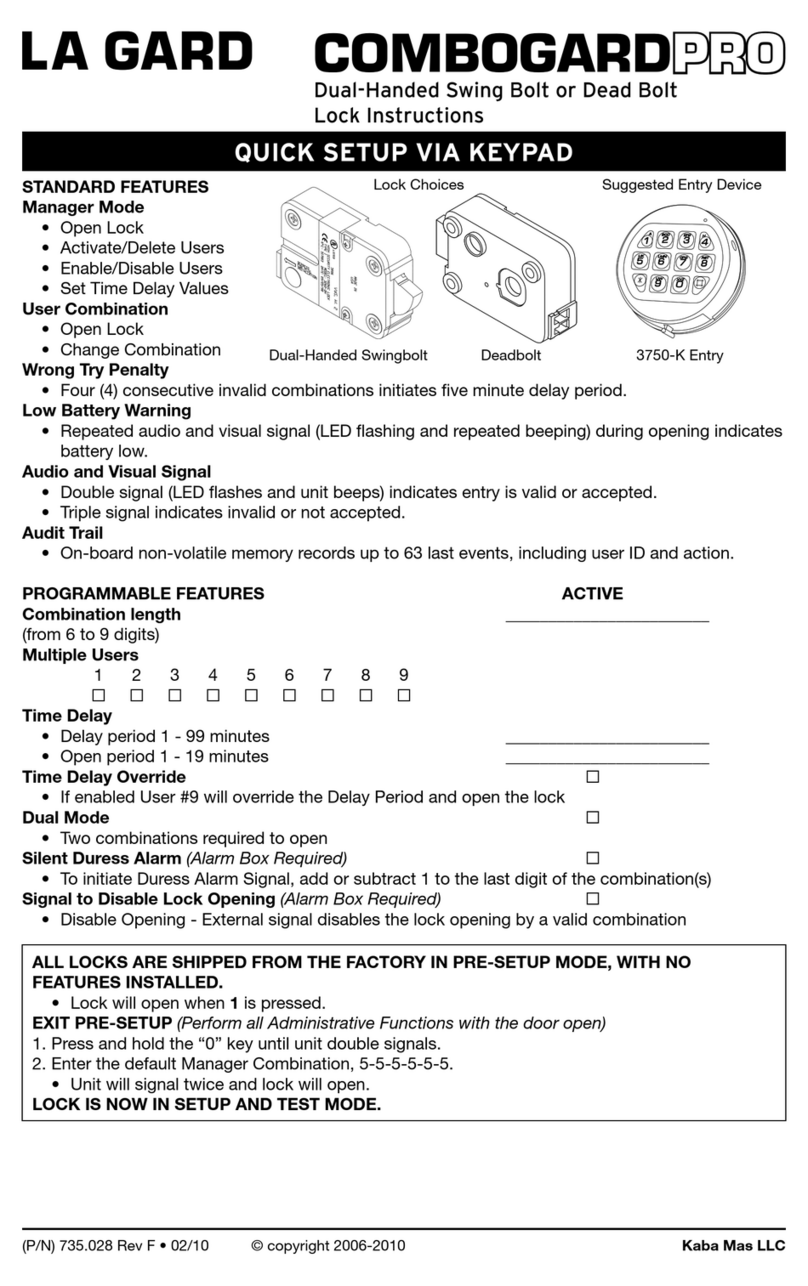

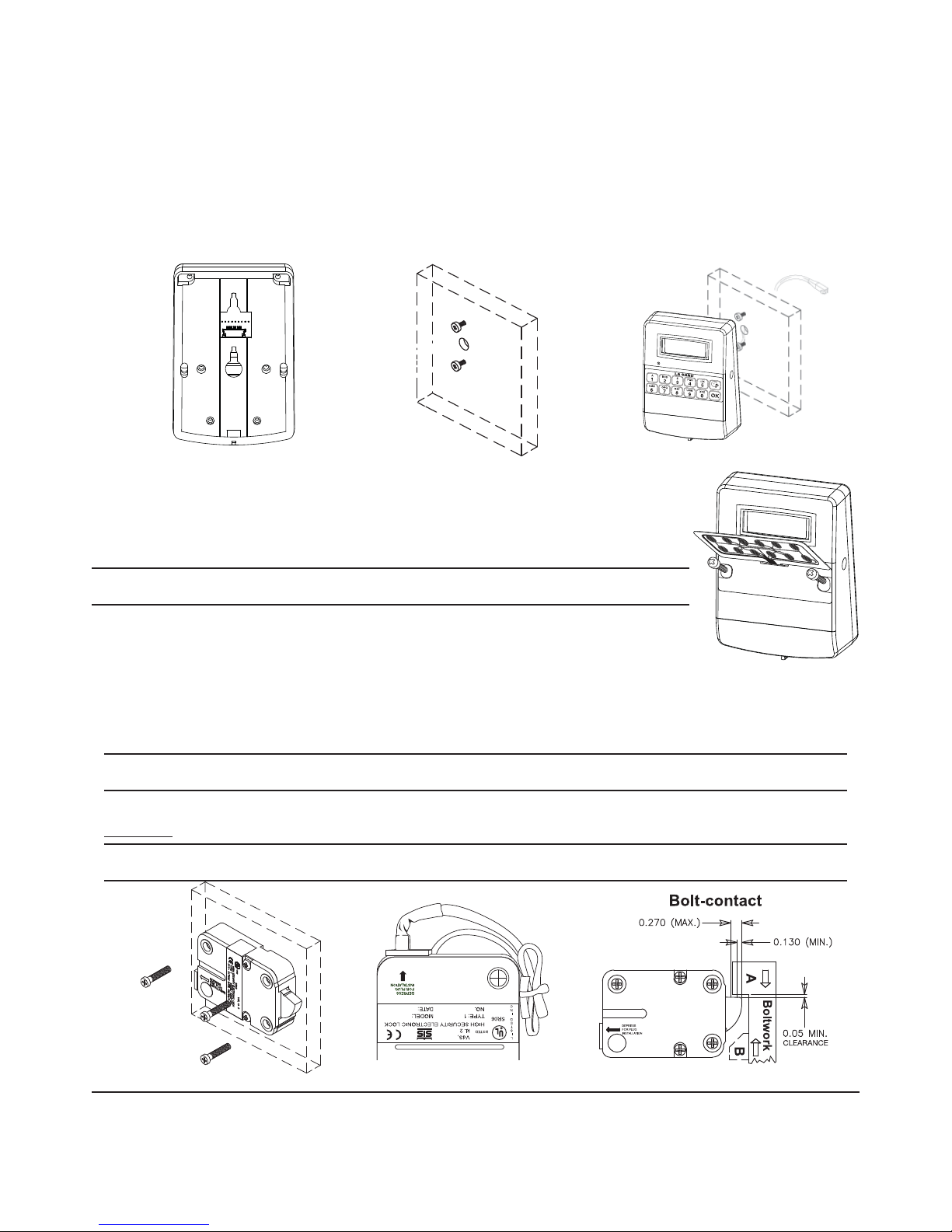

5. Connect the cable coming from the Entry Device directly into the connector port marked ENT on the lock. (Figure 6)

DEAD BOLT OR SPRING BOLT LOCKS

In order to use either the Dead bolt or Spring bolt locks, a method of retracting the bolt will be required. Knob Assembly - P/N 2666 -

(Figure 8) is recommended.

The drilling holes necessary to mount the lock correspond with the standard dimensions for mechanical locks. The spindle hole must

be well deburred and no sharp edges may remain. The holes required to mount the knob need to be drilled 1.25"apart and must be

centered over the spindle hole.

1. Locate, drill and tap holes to mount the Lock Assembly to the inside of the safe door using the installation template provided.

2. To install the Knob Assembly, remove the insert from the front of the knob.

3. Cut the spindle to a length of .820"(20.8mm) plus the mounting thickness.

4. Install the knob assembly using the two 8-32 X 5/16 phillips pan screws. (Figure 8)

5. Install the lock (always with the bolt extended) onto the spindle, placing it flush to the mounting surface.

6. Attach the lock using the three US 1/4"-20 (Metric M6X1) screws found in the hardware pack.

7. Connect the cable coming from the Entry Device directly into the connector port marked ENT on the lock. (Figure 8)

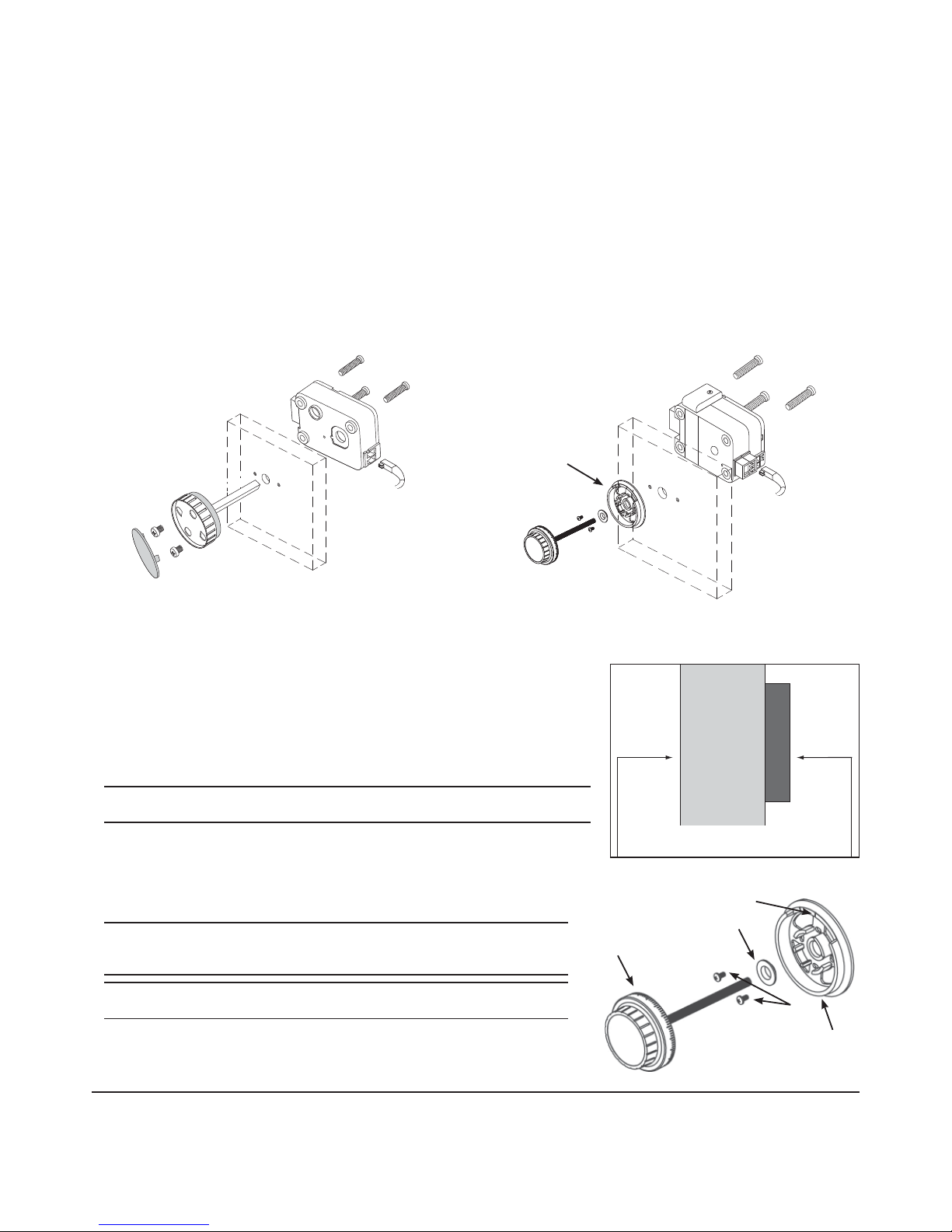

REDUNDANT MECHANICAL LOCKS

In order to use a Redundant Mechanical lock, a method of retracting the bolt is required.

Use of the VISIONGARD Dial (P/N 2085) is recommended (Figure 9). An entire range of

LA GARD dials is available for alternate dial options.

1. Locate, drill and tap holes to mount the Lock Assembly to the inside of the safe door

using the installation template provided.

2. Locate and drill the two holes for the dial ring to be mounted.

3. Attach the lock assembly to the door using the three US 1/4”-20 (Metric M6X1)

mounting screws provided. Tighten the mounting screws to a torque setting of 30

in./lbs. (3.4 N•m).

Note: Ensure the lock assembly spindle hole is properly aligned with the spindle

through hole in the safe door.

4. Measure total mounting thickness (door thickness + mounting plate). (Figure 10)

5. Cut the spindle to a length of 1.125” (28.6mm) plus the total mounting thickness.

6. Mount the dial ring centered on the through hole, and attach to the safe door using the

two mounting screws supplied with the dial assembly. The opening index reference

mark must be in the twelve o’clock position. (Figure 11)

7. Place the dial bearing onto the dial ring.

WARNING: The lock bolt MUST remain in the retracted position throughout the

installation procedure. To ensure this keep one finger over the bolt while installing

the dial spindle into the lock cam.

WARNING: Ensure that you are properly grounded to protect the system card from

Electrostatic Discharge (ESD) damage before proceeding with the next steps.

8. Remove the two cover screws from the back cover of the lock assembly, and

remove the lock back cover. (Figure 12)

9. Carefully unplug the solenoid connector from the system card. (If applicable,

unplug the bolt switch connector from the system card.) (Figure 12)

Figure 8 Figure 9

Dial ring

Figure 10

DOOR

MOUNTING PLATE

Total Mounting Thickness = door thickness

+ mounting plate

Dial

Dial

Ring

Mounting

Screws

Dial Bearing

Opening

Index

Figure 11