Installation of the Electrical Wiring

Caution: This procedure should onlybe attempted by persons qualified to install electrical wiring.

All wiring must comply with applicable codes and ordinances.

1. Locate a 120V AC, 60 Hz (alternative power sources would be used in the case of the LAFC 230V units) power circuit with a junction box

near the air cleaner location.

2. Check that the circuit breaker or fuse, for that circuit is rated at 15 amperes or 20 amperes. The required copper wire size will be:

AWG #14 for 15 ampere circuits AWG #12 for

20 ampere circuits

3. Caution: Turn off the building circuit at the fuse or circuit breaker before proceeding.

4. Locate the connection box on the air cleaner and remove the outer plate which contains the knockout. You will note the presence of three

wires on the inside of the box. One blue, one brown, and one green.

5. Connect the blue and brown wires from the pigtails in the air cleaner, to the corresponding colors in the supply circuit. (See diagram on page

13.)

6. Connect green wire from the grounded terminal in the air cleaner, to the grounded circuit of the building wiring system. If the building does

not have conduit itwill have a green or bare ground-ing conductor for connection to the air cleaner green wire. DO NOT CONNECT THE

GROUNDING WIRE FROM THE AIR CLEANER TO THE WHITE WIRE OF THE BUILDING. The air cleaner frame must be electrically

connected to the frame of the building or the electrical conduit system. Input electrical power should be run through flexible conduit as

recommended by the National Electrical Code or your local authority.

Reassembly of the Unit

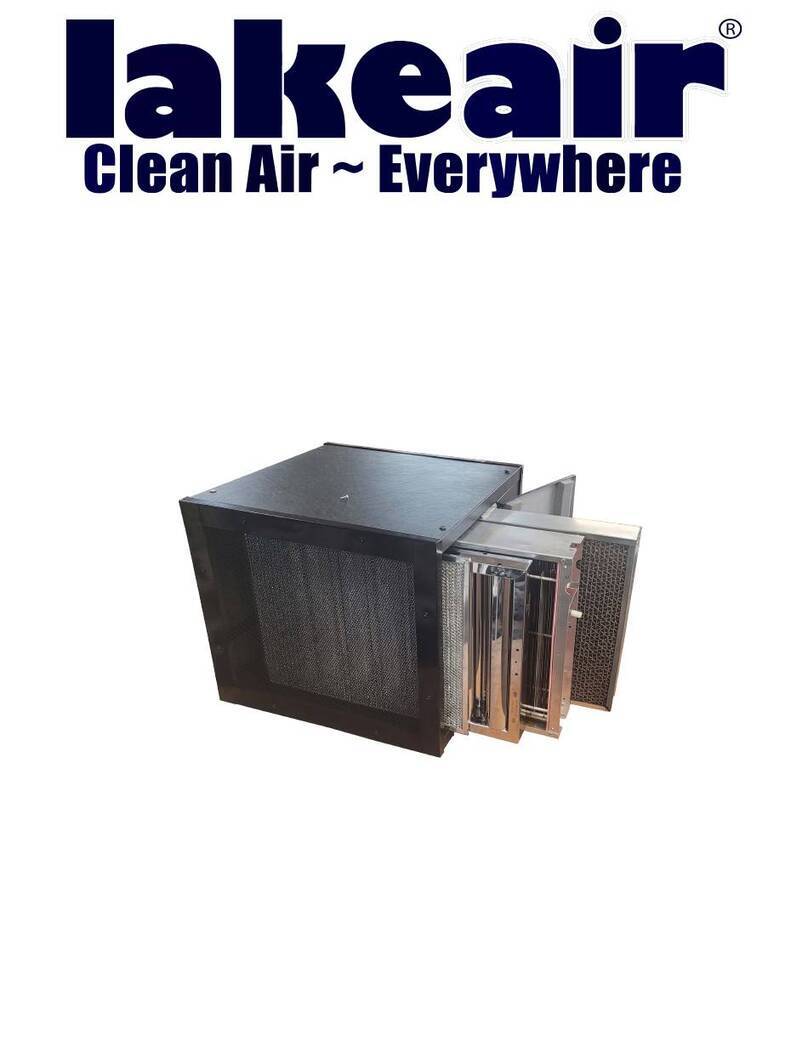

1. With the unit now in place, loosen the 1/4 turn screws on the intake grille and allow the hinged portion to drop down.

2. Replace the prefilter screen, electronic cell, and carbon afterfilter, making sure to connect the grid cap connector to the cell. REMOVE

THE PLASTIC COVER FROM THE HEPA MEDIA BEFORE REINSTALLATION OF THE FILTER PAD.

3. Close and lock the entire hinged panel into place.

Exhaust Grille Orientation

1. The exhaust grille side of your LAFC is equipped with individually movable louvers. To set them in the air pattern which bestsuits your

needs, you simply angle them in the direction that you wish to direct the airflow.

2. A good pattern would allow for dispersion of the air so that it is not blowing straight down, perpendicular to the floor.

Start-Up and Checkout of the Unit

To make sure the unit is operating correctly before leaving the installation, please check the following:

1. Check all electrical connections and make sure they are tight and properly connected.

2. Electronic cell is in place and properly oriented so that the airflow arrow points in the direction of the airflow or the HEPA Media pad is

properly oriented so that black carbon filter material is facing toward the ceiling.

3. Turn the unit on and check to see that it runs properly at all speeds. In addition, make sure the light goes on when the unit is in operation.

4. Open the intake grille section and check to see thatthe unit shuts off completely. Re-engage the panel and make sure unit turns on by

watching light.

If for any reason the unit does not appear to work correctly, refer to the Troubleshooting Guide for assistance.

7