IMPORTANT NOTES :

Please Read Carefully & retain these instructions for Future Reference.

1. For ease & safety we advise that two persons assemble this product.

2. Protect shower tray surfaces at all times.

3. Exposed glass corners / edges MUST NOT contact hard surfaces at any time.

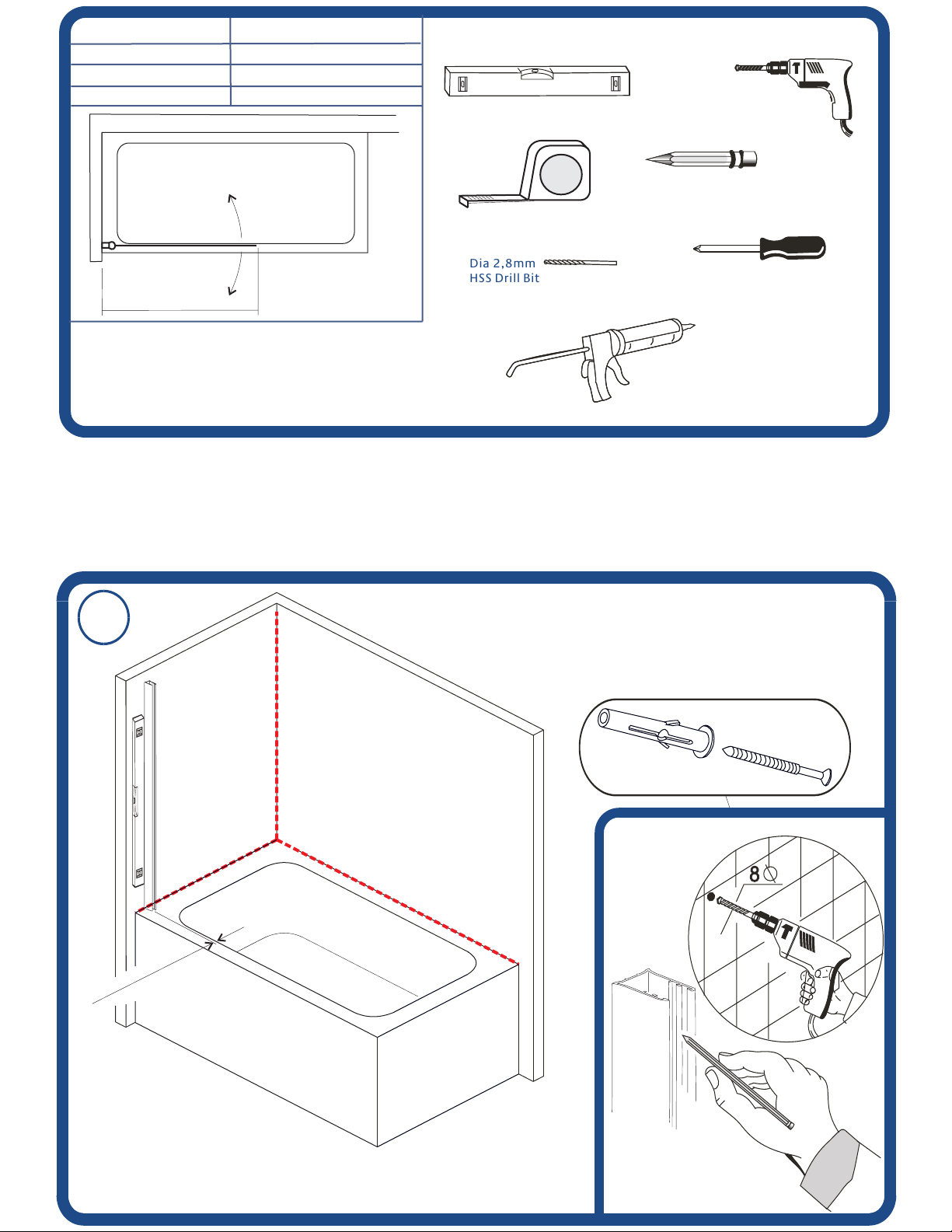

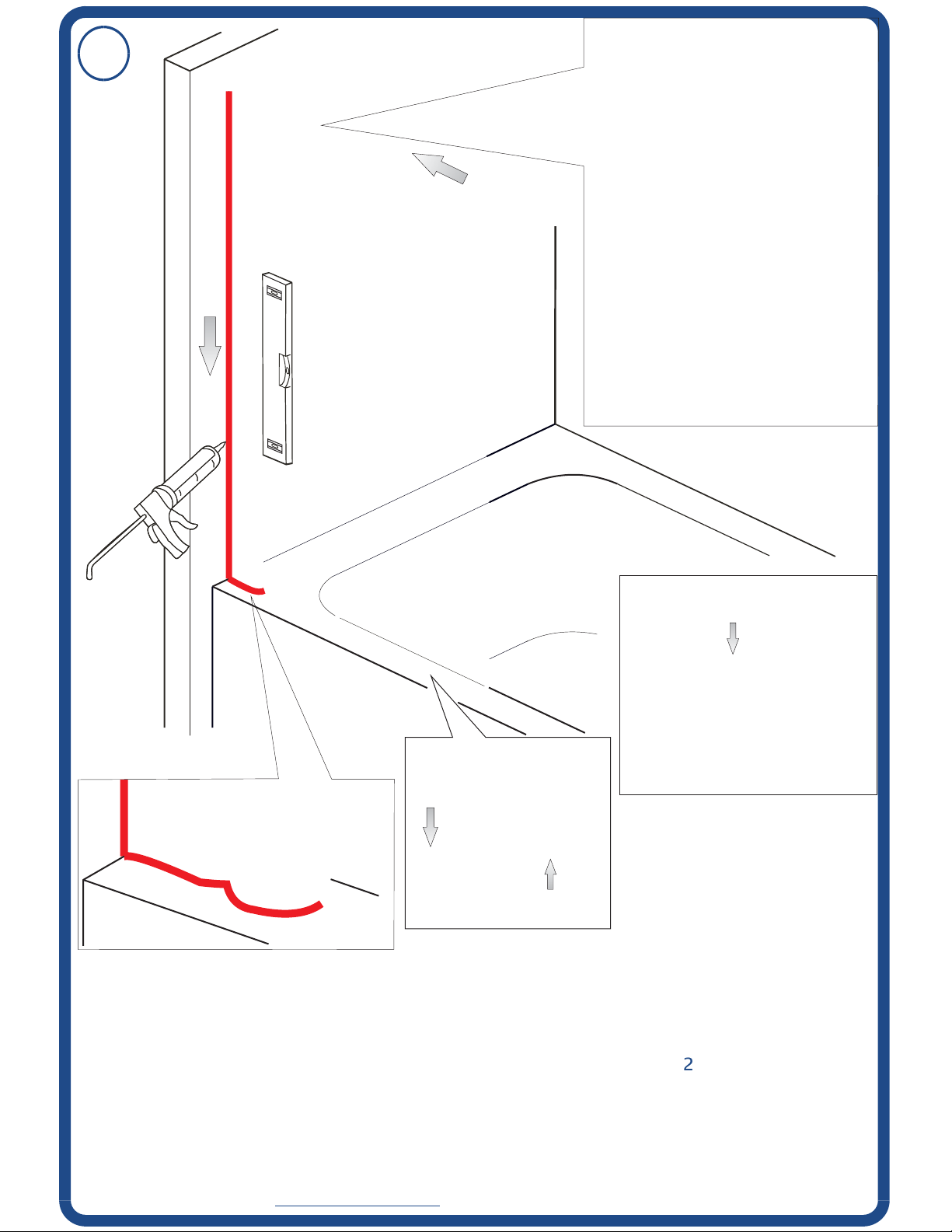

4. Check for cables, pipes etc before drilling walls.

5. Ensure all surfaces are dry, clean & free of loose debris / dust.

6. Unpack goods with care (small parts can become lodged in packaging & inadvertently discarded).

Check parts supplied against parts & fittings listed herein. Damaged parts / omissions may be

resolved by calling Lakes Bathrooms Helpline.

7. Whilst precautions are taken in manufacture, care must be taken when handling as rail ends may

have sharp edges.

8. Before commencing, check :

a) shower tray (or base) is level & completely sealed to finished / tiled walls.

b) finished walls are sound & free of cracks, loose tiles / grout.

8. AFTER INSTALLATION, DO NOT ‘WET’ ENCLOSURE FOR 48 HOURS TO ENSURE FULL CURE OF

SILICONE SEALANT.

USE :

General Care & Maintenance.

Provided this product is installed & operated in accordance with these instructions, problems should

not arise. However should maintenance be required it should be carried out by a competent person

with reference to these instructions. Before any work is carried out the root cause of the problem

must be identified. Lakes Bathrooms service engineers are available if necessary to consult / carry out

remedial work. Call Lakes Bathrooms HELPLINE.

Cleaning.

(Every one to two weeks depending on local water {hardness} conditions).

All glass panels in this product have a hydrophobic coating aiding ‘runoff’ of water droplets, reducing

the need for frequent cleaning. For best appearance / product life however, regular cleaning is

recommended.

Use ONLY mild soap / detergent solutions to clean. Rinse with water, squeegee glass panels & wipe

frames dry with a soft cloth. Under no circumstances should abrasive, caustic or scouring products be

used. Non compliance with these cleaning instructions may cause decorative finishes to deteriorate &

could adversely affect safe operation of the enclosure.

Daily Care.

To prevent the build up of limescale, do not allow water droplets to dry on glass or frames. After

showering, rinse with water, remove droplets from glass with a squeegee & wipe frame with a soft

cloth.

Customer Service.

Quality Guarantee : Lakes Bathrooms Ltd guarantee Shower Doors & Enclosures against any

manufacturing or material defects for the lifetime of the product. We will resolve defects free of charge

by repairing / replacing parts as we feel necessary. To be ‘free of charge’ service work must be carried

out by Lakes Bathrooms or approved agents.

Seals are considered 'wear & tear' parts, as such they are guaranteed for 12 months from purchase.

Not Covered by this Guarantee : Damage or defects that result from improper installation, improper

use, or lack of maintenance (including limescale buildup). Damage or defects that result from repairs /

modifications undertaken by unauthorized persons. This guarantee is in addition to statutory & other

legal rights.

What to do if something goes wrong : Should the product not function correctly on initial use, firstly,

contact the installer to check that unit installation & commissioning are in accordance with these

instructions. Should this not resolve difficulties or should performance decline, consult

‘Troubleshooting’ section to see if simple home maintenance is needed. Alternatively our HELPLINE staff

can assist, or if necessary arrange for a service engineer to visit.

Spares : We maintain extensive spare part stocks. Spares can be ordered / purchased from your retailer

in the first instance. Parts will normally be dispatched within two working days from order placement.