Vega 900 Handbook

�

Part Number 17155

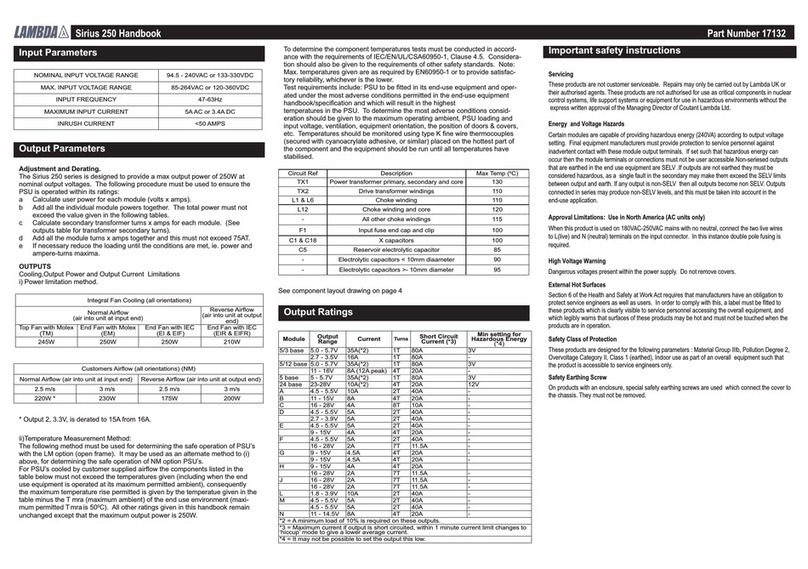

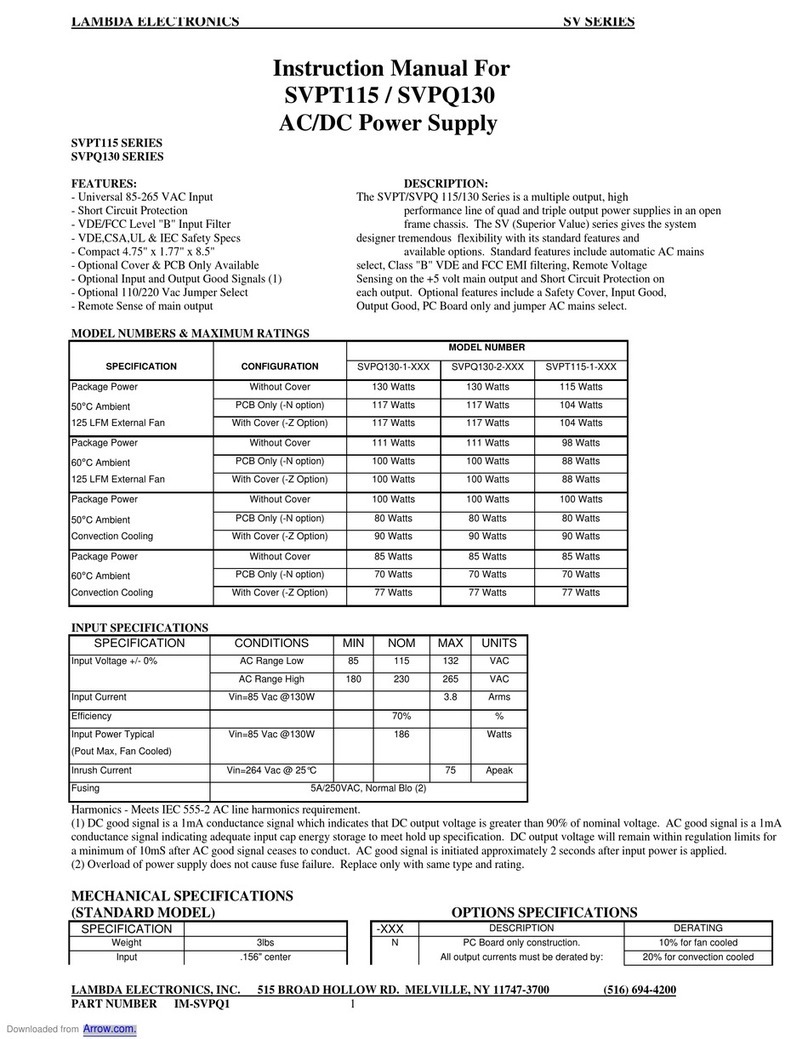

Modules Note Output Range Current Slots Turns Max. Current

Limit

Settings for hazard-

ous energy

Standard Modules

H5/3 16.2-28V 5A 15 7.5A >32V

9.1-15.5 6A 3 7.5A -

H5/4 16.2-28V 5A 15 7.5A >32V

16.3-24V 4.5A 4 6A -

Seriesed Modules

BB4 32.6-40V 10A 2 8 12.5A >19.2V

CC3 18.2-30V 18A 2 6 22.5A >10.6

CC5 48.1-60V 10A 2 10 12.5A >19.2V

DD4 28-36V 18A 3 8 22.5A >10.6V

DD5 42-56V 15A 3 10 18.75A >12.8V

EE2 7.6-15V 55A 4 4 75A >3.2V

EE4 28-38V 30A 4 8 37.5 >6.4

EE5L 40-48V 18A 4 10 33.8 >7.1

EE5H 48-56V 18A 4 10 31.3 >7.6

HH5/3 25.3-38V 5A 1 8 7.5A >32V

HH5/4 32.5-46V 4.5A 1 9 6A >40V

C5B4 43-48V 10A 2 9 12.5A >19.2V

Paralleled Modules

Z2(D1L+D1L) 1.8-3.4V 95A 3 1+1 125A >1.9V

Z3(E1+E1) 1.8-3.4V 114A 4 1+1 150A >1.6V

Z4(D1H+D1H) 3.9-5.1V 95A 3 1+1 125A >1.9V

Z6(E2+D1H) 3.9-5.1V 104.5A 3.5 2+1 137.5A >1.7V

Z7(D3+D3) 8-15V 45.6A 3 3+3 60A >4V

Z18(L1+L1) 4.2-5.1V 66.5A 2 1+1 87.5A >2.7V

Z19 (E5H+D5) 24-28V 36 3.5 5+5 40.05A >5.9

Wide Range Modules

W5 5 0.25-32V 8.5A 1 5 9.5A 18>25.2V

1 C1Y module is only permitted in slot.

2 For PSUs with three D modules fitted or two D modules and an E module in slots

4/5 then D1L & D1H in slots 2/3 is limited to 42A and in slots 4/5 is limited to 47A.

D2 in slots 2/3 is limited to 40A.

3 E2 module fitted in slots 4/5 is limited to 55A.

4 SELV and Outputs connected in Series

Outputs are SELV except as described below

- Non-earthed outputs that have secondaries with 2 or more turns are non-SELV as

a single fault in the secondary may make them exceed the SELV limit between

output and earth.

- Non-earthed ouputs that are connected in series are non-SELV unless all the

seriesed outputs use 1 turn secondaries and there are no more than 3 outputs

connected in series.

- Outputs connected in series are non-SELV if the total output voltage + 20% of the

max, rated output voltage of the output with the highest rated voltage exceeds

60dc (the 20% addition allows for a single fault in any one individual channel)

- The total voltage of a seriesed output must not exceed 160V

- If any ouput or seriesed output is non-SELV then all the outputs in the PSU must

be considered non-SELV

Note

- Non-SELV outputs must be gaurded or a deflector fitted during installation to

avoid a service

engineer making inadvertent contact with the output terminals, or dropping a tool

onto them.

- All outputs operational spacings to earth, and due consideration must be given to

this in the end product design.

5 W5 is followed by V or R indicating Voltage or Resistance programming, both

followed by #

6 Actual voltage and current output of an X module is dependent, and limited by, the

ratings of the modules from which it is fed. The ratings given above for the X module

are additional rating limitations imposed by the X module itself.

7 The maximum power output of psu’s fitted with X modules is reduced from 900W by the

following power:

Power=0.55 x (Total X1 current) + 0.7 x (Total X2 + X4 current) + 0.9 x (Total X8 cur-

Module Limitations- Notes:

Safety approvals

UL60950-1 and CSA22.2 No.60950-1 - UL Recognised. C-UL for Canada.

IEC/EN60950-1 - BSI Kitemark and CE mark.

CE marking when applied to any Vega product, indicates compliance with the Low Voltage Directive

(73/23EEC) as modified by the CE Marking Directive

(93/68/EEC) in that it complies with EN60950-1.

IEC/EN61010-1 and IEC/EN60601-1. CB Report .and BSI Kitemark

UL60601-1 and UL61010-1-UL Recognised, C-UL for Canada.

8. Adjusting output voltage beyond the stated range may cause overvoltage protection

(OVP) to operate, whereby all outputs will turn off. To reset OVP, turn back output

voltage adjustment and remove the mains supply for 30 seconds and then will switch

back on.

Approval Limitations: Use in North America (AC units only)

When this product is used on 180VAC-250VAC mains with no neutral, connect the two live wires

to L(live) and N (neutral) terminals on the input connector. In this instance double pole fusing is

required.

High Voltage Warning

Dangerous voltages present within the power supply. Do not remove covers.

External Hot Surfaces

Section 6 of the Health and Safety at Work Act requires that manufacturers have an obligation to

protect service engineers as well as users. In order to comply with this, a label must be fitted to

these products which is clearly visible to service personnel accessing the overall equipment, and

which legibly warns that surfaces of these products may be hot and must not be touched when the

products are in operation.

Safety Earthing Screw

On products with an enclosure, special safety earthing screws are used which connect the cover to

the chassis. They must not be removed.

Safety Class of Protection

These products are designed for the following parameters : Material Group IIIb, Pollution Degree 2,

Overvoltage Category II, Class 1 (earthed), Indoor use as part of an overall equipment such that

the product is accessible to service engineers only.

Energy Hazards

Certain modules are capable of providing hazardous energy (240VA) according to output voltage

setting. Final equipment manufacturers must provide protection to service personnel against

inadvertent contact with these module output terminals. If set such that hazardous energy can

occur then the module terminals or connections must not be user accessible.

Servicing

These products are not customer serviceable. Repairs may only be carried out by Lambda UK or

their authorised agents. These products are not authorised for use as critical components in nuclear

control systems, life support systems or equipment for use in hazardous environments without the

express written approval of the Managing Director of Coutant Lambda Ltd.

Important safety instructions

The Vega family of component power supplies is designed for use within other equipment or

enclosures which restrict access to authorised competent personnel only. For safe installation and

operation of this product, carefully follow the instructions listed below.

i) The unit covers/chassis are designed to protect only skilled personnel from hazards and must

not be made user accessible.

ii) These products are Class 1 and must therefore be reliably earthed and professionally installed

in accordance with the prevailing electrical wiring regulations and the safety standards covered

herein.

iii) These products are IPX0, and therefore chemicals/solvents, cleaning agents and other liquids

must not be used.

iv) If the earth terminal of the Vega PSU is connected to the main incoming earth conductor of

the end equipment, the installer must cover the Vega earth symbol with a label bearing the earth

symbol of IEC60417-5019.

General installation instructions

Emissions : EN55022 Conducted RFI-Class A or B (depending on product - Consult Technical

Sales). Radiated RFI - Class A

EN61000-3-2 / A14 - Pass - Class A and D. EN61000-3-3 / A1 - Pass

Immunity: EN61000-4-2 - Level 4 Criteria B EN61000-4-3 - Level 3 Criteria B

EN61000-4-4 - Level 4 Criteria B EN61000-4-5 - Level 4 Criteria B, (Installation Class 4, Criteria B)

EN61000-4-6 - Level 3 Criteria B EN61000-4-11 - Pass

EMC performance

Dielectric Strength testing is carried out as follows

Primary mains circuit to earth - 2.25 - 2.35kVDC

Primary mains circuits to transformer core - 4.25 - 4.35kVDC*

Primary mains circuits to secondary -4.25 - 4.35kVDC*

Outputs to each other and to earth are isolated to 200VDC.

*This test is not possible with modules fitted to the unit as damage to RFI capacitors will occur)

Environmental parameters

Operation

Temperature 0 to 500C (derating 2.5%0C above 500C to 650C - Not covered by approvals).

Humidity 5 to 95% RH non-condensing. Air Pressure 78kPa to 106kPa.

Altitude -200m to 3000m.

Storage and Transportation

Temperature -250C to +850C. Humidity 5% to 95% RH non-condensing.

Air Pressure 54kPa to 106kPa. Altitude -200m to 5000m.

Vibration and shock

10-200Hz @ 1.5G sinewave, 20G for 15 minutes in 3 axes random vibration / 3000 bumps, 10G

(16mS) half sinewave.

Cooling

Provided that the fan air intake and air outlet slots are not impeded, these units may be mounted

in any of 4 orientations: Horizontal, on either side, or vertical with airflow upwards. For correct

airflow, allow 50mm clearance around the side and ends of the product.

Level of insulation

Input markings and symbols

Terminal Block

Fast-ons

N L

L

N

alternating current (a.c.)

direct current (d.c.)

danger, shock hazard

caution, refer to supplementary documents.

Earth LLive

NNeutral

Custom Model

Model: NS-THE/V9FSSF B/S 28E5HS (K90036)

Input: 90-264Vac, 47-63Hz

Maximum output: 28V, 25A, maximum output power: 700W