LANDA PGHW 5-5000 • 8.913-928.0 • REV. 3/13

9

PRESSURE WASHER OPERATOR’S MANUAL

OPERATION INSTRUCTIONS

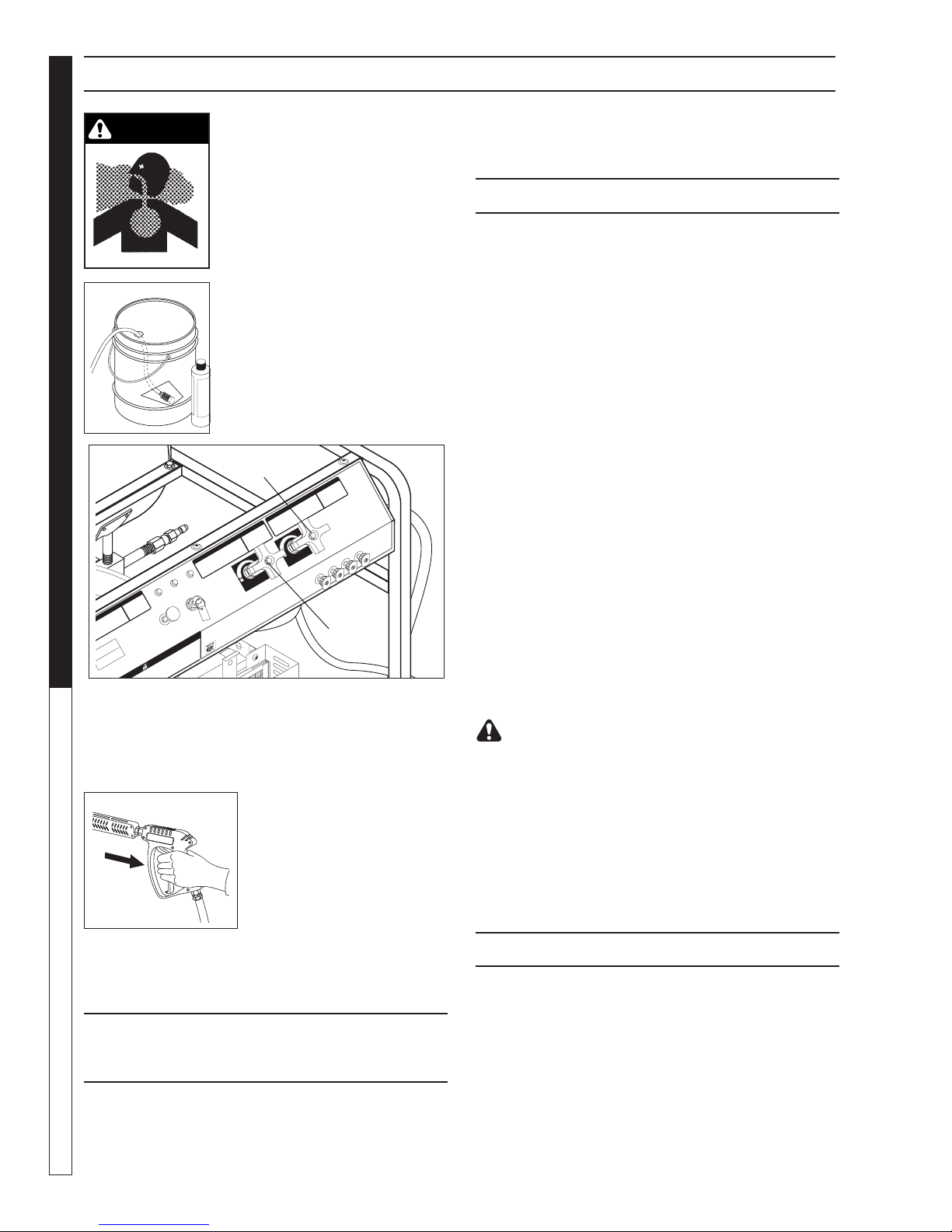

STEP 4: With spray nozzle pointed away from you or

anybody else, press trigger on spray gun to obtain

pressurized cold water spray.

Selection of high or low pressure is accompanied by

turning the handle. NOTE: High pressure nozzle must

be inserted at end of wand to obtain high pressure.

To apply soap read operator’s manual.

Trigger

High Pressure

Wand (HP)

High

Pressure

Nozzle

STEP 5: With the spray nozzle

pointed away from you or anybody

else, press the trigger on the spray

gun to obtain pressurized cold water

spray.

STEP 6: For hot water, turn the

burner switch to ON when a steady

stream of water flows out of the

spray gun. Burner will now light

automatically.

NOTE: Do not start machine with

burner switch on.

STEP 7: To apply detergent, place

detergent pick-up tube into a con-

tainer of detergent and turn the

detergent valve counterclockwise.

For steam, open the steam valve

counterclockwise. This lowers

the pressure and raises the

temperature.

STEP 1: Read safety, installation and

preventative maintenance instructions before

starting machine.

Connect the water supply hose to the

float tank inlet swivel connector and turn

on water supply. NOTE: Before installing

pressure nozzle in wand coupler run machine

allowing water to flush through the system

until clear.

STEP 3: Pull wand coupler collar back and

insert desired pressure nozzle into wand

coupler. Then secure by pushing coupler

collar forward. CAUTION: Never replace

nozzles without engaging the safety latch

on the spray gun trigger.

I

O

WARNING

High pressure hot water di scharge—Ri skof injection or

severe injuryto persons. Keep clear of nozzle. Do not touch

ordirect discharge stream at persons. Before disconnecting

pressure hose, turn machine off and ope n gun to relieve

pressure.

Risk of electrocution—Connectonly to properly grounded

outlet. Keep all connections dry andoff the ground. Keep

spray awa y fromel ectrical w iri ngand c ompon ent s.

Disconnectfrom electrical supply before servicing.

Hot surfaces—Use onlyinsulated gripping areas of gun and

wand.

Riskof asphyxiation—Use only in well ventilated area.

Risk of explosion—Operate only where open flame or torch

ispermitted. Do not spray flammable liquids.

GunKicks Back—Holdwith both hands.

To prevent damage from occuring to the generator, do not

turnburner on until the engine has reached ful RPM.

Turnburner off before stopping engine.

Eyeprotection must be worn when operating thisequipment.

Thismachine isto be used only byqualified operators.

ReadOperator'sManual carefully before using.

Descarga de agua caliente a presión—Riesgo de penetración o

lesiones severas a personas. Mant éngase fuera de l alcance de la

boquilla. No toque ni dirija el flujo del agua aotras personas. Antes de

desconectar la manguera de presión, apague la y releve la

presiónconel gatillo.

Riesgo de electrocución—Conecte el enchufe a un adecuado enchufe

hembra con conexion atierra. Mantenga todas las conecciones secas

yarriba del suelo. No rocie componentes eléctricos. Desconec te la

corrienteeléctrica antes de dar servicio.

Supericies calientes—Use solamente las aisladas del gatillo y la

lanza.

Riesgo de e xplosión—Us e el producto en dond e el fuego o

llamasean permitidos.No rocie liquidos inflamables.

Riesgodeaspixia—Use el producto en un área deventilación adecuada.

Lapistola se mueve con la presión—Sostenga con las dos manos.

Para prevenir daños en el generador, no enciendael quemador hasta

queel motor haya alcanzado las maximas RPM

Apagueel quemador antes de parar el motor.

Protéjaselos ojos cuando se opere este equipo.

Esteequipo debe ser usado solamente por operadorescalifcados.

Leael Manual de Operación antes de usarse.

PRECAUCION

Eau chaude sous pression la sortie—Risque de ble

loin des buses. Ne pas diriger le jet d'eau vers des p

de le boyau pression, ferme r l'appa

pistoletà gachette pour relacher la pression.

Risque d'élec trocu tion—R elier des prises a vec

seulement. Tous lesfils doivent maintenus secs et

Ne jamais projeter de l' eau sur les composanteset

Couperl'alimentation électrique avant de faire une réparati

Surfa ces cha udes—Toucher seulement l es parti

poignéespistolets et lances.

Risqued'asphyxie—Utiliser dans un endroit bienaéré.

alta

5-

HOUR METER

HOROMETRO

COMPTEURD'HEURES

BURNER

QUEMADOR

BRULEUR

ON

PRENDER

OFF

APAGAR/ETTEINT

I

O

V

VOLTMETER

VOLTMÉTRE

OLTMÉTRE

TURE CONTROL

TEMPERA

CONTROLDE TEMPERATURA

CONTROLE DE TEMPERATURE

Burner

Switch

CAUTION

NeverUse

:

•Bleach,chlorineproductsandothercorrosivechemicals

•Liquidscontainingsolvents(i.e.paintthinner,gasoline,oil)

•Tri-sodiumphosphateproducts

•Ammoniaproducts

•Acid-basedproducts

Thesechemicalswillharm theunitand will damagethe

surfacebeingcleaned.

e d'explosion—Utiliser aux endroits une flamme nue est

e.Ne pas vaporiser de liquides inflammables.

ignéepistolet repousse—Tenir à deux mains.

'eviter d'endommager la n'allumez le bruleur que

ele moteur a atteint sa pleine vélocite.

ezvous que bruleur est eteint avant d'arreter le moteur.

pareildoit ëtre utilisé par des opérateurs qualifiés.

manuel de l'opérateur avant utilisation.

DETERGENT VALVE

SOUPAPEDEDETERGENT

SOUPAPEDEDETERGENT

STEAM VALVE

VALVULADEVAPOR

SOUPAPEDEVAPEUR

WATER PRESSURE

PRESIÓNDEAGUA

PRESSIOND'EAU

1.Apagueelequipo.

2.Abrala válvula devapor.

3.Coloqueeltermostato enla posición

devapor.

4.Sigaconlasinstruccionesnormales

deoperación.

5.

Paracambiar de vapor a agua caliente,

cierrela válvula devapor ypongael

termostatoensuposiciónoriginal.

INSTRUCTIONS D’OPÉRATIONINSTRUCCIONES DE OPERACION

OPERACION

CONVAPOR

1.Fermer tous

maximum.

4.Suivrelesinstructionsd’opératio

normales.

5.Pourretourneràl’eauchaude,fermer

lasoupapedevapeur et remettre le

thermostatenpositionnormale.

1.Leael Manual deOperaciónantes de

usarse.

2.Conecte la manguera dejardín y abra

lallavedeagua.

3.Conectela manguera dealta presión.

4.Coloquelaboquilla a lalanza.

5.Reviselosnivelesdeaceite.

6.Enciendaelmotor, abrael gatillo y

logrepresión.

7.Paracalentar agua, enciendael

quemador.

8.Paraaplicar el químico, consulte el

ManualdeOperación.

9.Alterminar, apagueel quemador,

purgueconagualamanguera del

químico,yhagacircularelaguafría

antesdeapagarel motor.Abra el

gatillopara relevar la presión.

1.Lireattentivement le manuel de

2.Relieràuneprised’eauetouvrir l’eau.

3.Relierle boyauhaute pressionà

4.

5.Insérer la buse aubout dela lance.

6.Partirle moteur et presser la gachette

delapoignéepistolet.

7.Pourchauffer l’eau, allumer le brûleur.

8.Pourappliquer duchimique, voir le

manueldel’opérateur.

9.Pourarrêter l’appareil, fermer le

brûleuret laisser refroidir l’eau. Rincer

lalignedechimiqueà l’eaupropre

avantd’arrêter le moteur. Presser la

poignéepistoletpour relacher la

pression.

Steam

Valve

Detergent

Bucket

Detergent

Valve

STEP 2: Read engine manual provided and pull choke.

Pull spray gun trigger to relieve pressure.Then turn the

engine switch to the START position and hold it there

until the engine starts. NOTE: Do not engage the elec-

tric starter for more than five (5) seconds at a time. If the

engine fails to start, release the switch, pull spray gun

trigger and wait ten seconds before operating the starter

again. When the engine starts, allow the engine switch

to return to the ON position. Push the choke in.

CAUTION

NeverUse

:

•Bleach,chlorineproductsandother corrosive chemicals

•Liquidscontainingsolvents (i.e. paint thinner,gasoline,oil)

•Tri-sodiumphosphateproducts

•Ammoniaproducts

•Acid-basedproducts

Thesechemicalswill harmthe unitand will damage the

surfacebeingcleaned.

AVER TISSEMENT

15°

10° 25° 40°

Risque d'explosion—Utiliser aux en droits uneflamme nue est

ermise.Nepas vaporiser de liquidesinflammables.

néepistoletrepousse—Tenir à deux mains.

d'endommager lan'allumezle bruleur que

tteintsa pleine vélocite.

steteint avant d'arreter le moteur.

qualifiés.

DETERGENT VALVE

SOUPAPEDEDETERGENT

SOUPAPEDE DETERGENT

STEAM VALVE

VALVULADEVAPOR

SOUPAPEDE VAPEUR

WATER PRESSURE

PRESIÓNDEAGUA

PRESSIOND'EAU

1.Apague el equipo.

2.Abrala válvula de vapor.

3.Coloqueeltermostato en la posición

devapor.

4.Sigacon las instrucciones normales

deoperación.

5.

Paracambiar de vapor aagua caliente,

cierrela válvula de vapor yponga el

termostatoen su posición original.

INSTRUCTIONS D’OPÉRATION

COMBINAISON

VAPEUR

INSTRUCCIONES DE OPERACION

OPERACION

CONVAPOR

1.Fermer tous les interrupteurs.

2.Ouvrirla soupapedevapeur.

3.Mettrelethermostatenposition

maximum.

4.Suivre lesinstructionsd’opération

normales.

5.Pourretourner à l’eau chaude, fermer

lasoupape de vapeur et remettre le

thermostaten positionnormale.

1.Shut down unit.

2.Opensteamvalve.

3.Turnthermostat to maximum

position.

4.Follow normal operating

instructions.

5.Toswitchfrom steamto hot

water,close steam valve and turn

thermostatto originalposition.

OPERATING INSTRUCTIONS

STEAM

COMBINATION

1.ReadEngine and Operator’s Manual

carefullybeforeusing.

2.Connect standard garden hoseto

unitand turnwater on.

3.Securehighpressure hose to

machine.

4.Securespraynozzle to endof wand.

5.Check oillevels.

6.Start engine and trigger shut-off gun.

7.Toheatwater, turn burneron.

8.To apply chemicalsee Operator’s

Manual.

9.Toshutdownunit, turn burner off

andallow pumpto run until wateris

cool.Flushchemicallineswith clean

waterbeforeturningengine off.

Triggershut-off gun to relieve

pressure.

1.Lea el Manual de Operación antesde

usarse.

2.Conectela mangueradejardín y abra

lallavede agua.

3.Conecte la manguera de alta presión.

4.Coloquelaboquilla a lalanza.

5.Reviselosniveles de aceite.

6.Encienda el motor, abra el gatillo y

logrepresión.

7.Para calentar agua,enciendael

quemador.

8.Para aplicar el químico, consulte el

Manualde Operación.

9.Al terminar, apague el quemador,

purguecon agua la mangueradel

químico,y haga circularel agua fría

antesde apagar el motor.Abra el

gatillopara relevar la presión.

1.Lire attentivement le manuelde

2.Relier à une prise d’eau et ouvrirl’eau.

3.Relierle boyau haute pressionà

4.

5.Insérerlabuse au boutde la lance.

6.Partirlemoteuret presser la gachette

dela poignée pistolet.

7.Pour chauffer l’eau, allumer le brûleur.

8.Pour appliquer du chimique, voir le

manueldel’opérateur.

9.Pourarrêter l’appareil, fermer le

brûleuret laisser refroidirl’eau. Rincer

lalignede chimique à l’eau propre

avantd’arrêter lemoteur. Presser la

poignéepistoletpour relacher la

pression.

PGHW

5-5000

Choke