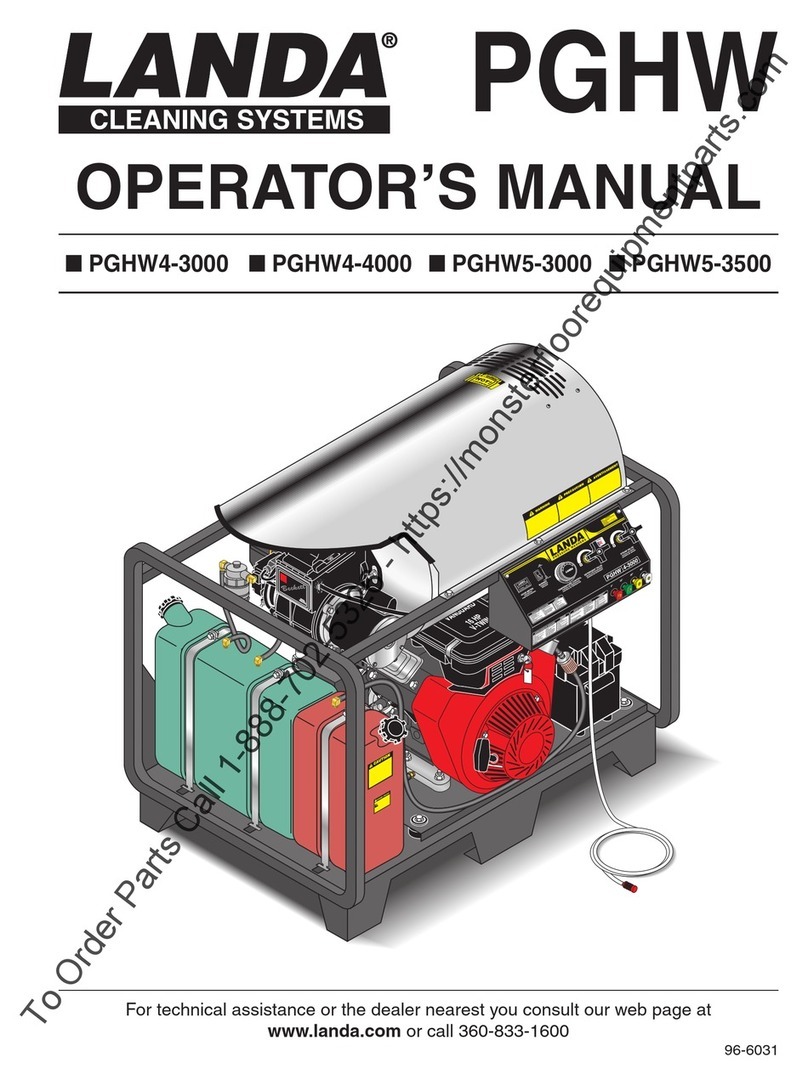

PG SERIES PRESSURE WASHER OPERATOR’S MANUAL

3

LANDA PG •REV. 9/02

INTRODUCTION

Thank you for purchasing a Landa Pressure Washer.

This manual covers the operation and maintenance of

the PG4-15321, PG4-20321, PG4-30321, PG4-25321,

PG5-35221, PG5-35221E, PG5-35321E, PG4-40221,

PG4-40221E, PG4-40321E, and PG4-35321 washers.

All information in this manual is based on the latest prod-

uct information available at the time of printing.

Landa, Inc. reserves the right to make changes at any

time without incurring any obligation.

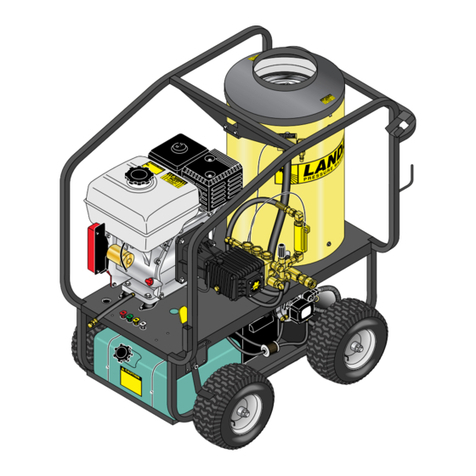

The PG Series was designed for maximum

use of 8 hours per day, 5 days per week.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this Landa pressure washer.Warning infor-

mation should be emphasized and understood. If the op-

erator is not fluent in English, the manufacturer’s instruc-

tions and warnings shall be read to and discussed with

the operator in the operator’s native language by the pur-

chaser/owner, making sure that the operator compre-

hends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

The operator must know how to stop the machine quickly

and understand the operation of all controls. Never permit

anyone to operate the engine without proper instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number.

IMPORTANT SAFETY

INFORMATION

WARNING:When using this machine basic precautions

should always be followed, including the following:

CAUTION: To reduce the risk of

injury, read operating instruc-

tions carefully before using.

1. Read the owner's manual thor-

oughly. Failure to follow instruc-

tions could cause malfunction

of the machine and result in

death, serious bodily injury and/

or property damage.

2. Know how to stop the machine and bleed pressures

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

4. All installations must comply with local codes. Con-

tact your electrician, plumber, utility company or the

selling distributor for specific details.

WARNING: Risk of asphyxiation.

Use this product only in a well

ventilated area.

5. Avoid installing machines in

small areas or near exhaust

fans. Exhaust contains poison-

ous carbon monoxide gas; ex-

posure may cause loss of con-

sciousness and may lead to

death. It also contains chemicals known, in certain

quantities, to cause cancer, birth defects or other

reproductive harm.

WARNING: Flammable liquids

can create fumes which can ig-

nite causing property damage or

severe injury.

WARNING: Risk of fire. Do not add

fuel when the product is operating.

WARNING: Risk of explosion —

do not spray flammable liquids.

6. Do not place machine near flammable objects as

the engine is hot.

7. Allow engine to cool for 2 minutes before refueling. If

any fuel is spilled, make sure the area is dry before

testing the spark plug or starting the engine. (Fire

and/or explosion may occur if this is not done.)

Gasoline engines on mobile or portable equipment

shall be refueled:

a. outdoors;

b. with the engine on the equipment stopped;

c. with no source of ignition within 10 feet of the

dispensing point; and

d. with an allowance made for expansion of the fuel

should the equipment be exposed to a higher

ambient temperature.

In an overfilling situation, additional precautions are

necessary to ensure that the situation is handled in

a safe manner.

WARNING: High pressure stream

of water that this equipment can

produce can pierce skin and its

underlying tissues, leading to se-

rious injury and possible ampu-

tation.

RISK OF

ASPHYXIATION.

USE ONLY IN A WELL

VENTILATED AREA.

WARNING

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

WARNING

READOPERATOR’S

MANUALTHOROUGHLY

PRIORTO USE.

WARNING

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

CAUTION