4

2.0 Method of Operation

2.1 The ultrasonic cleaner is designed to clean various parts from truck radiators

to rifle barrels using the appropriate cleaning solution.

2.2 The 4002 ultrasonic generator converts line voltage at 50/60 Hz to a suitable high

voltage at 43 KHz that drives the stack transducers mounted on the tank bottom.

The applied High Frequency High voltage causes the transducers to vibrate and in

turn causes cavitation in the solution. As these cavities collapse the dislodge soils on

the object to be cleaned.

2.3 Using the correct solution allows "wetting" of water molecules to dirt/part

molecules for easier separation.

3.0 Installation Instructions

After carefully removing the ultrasonic cleaning system from its' carton and

wood box, remove all packing material and plastic covers and proceed as

follows:

3.1 Place the cleaner on a level surface, allowing for air flow at front and

rear of generator.

3.2 Check drain pipe and plug making sure that they are reasonably tight.

Use Teflon pipe thread sealer when replacing plug or cap.

3.3 Fill tank with recommended L&R solutions or equivalent to approximately two

inches from the top edge of tank. Note that solution displacement, when

submerging part to be cleaned, must be taken into consideration.

3.4 Make sure that the generator’s "Power" switch is off.

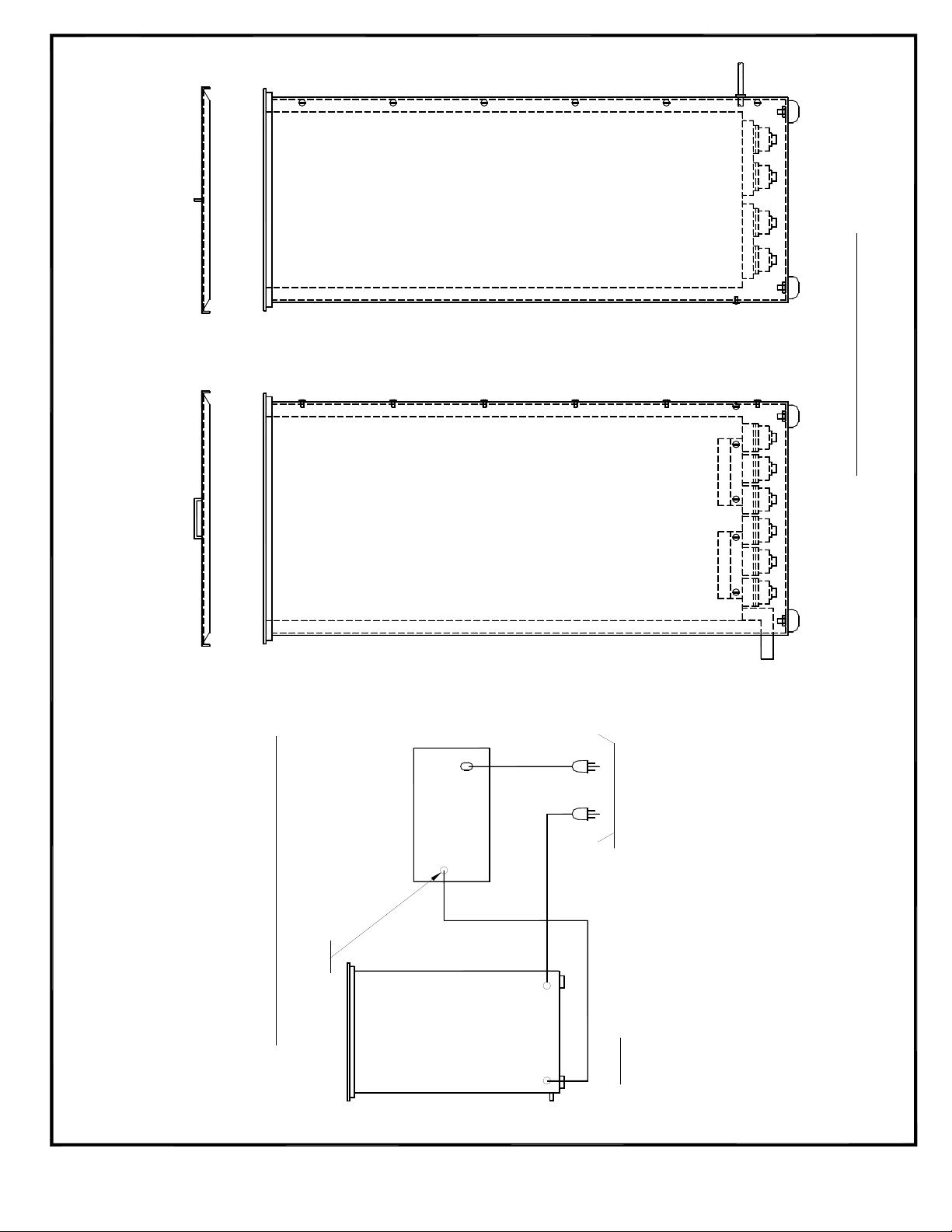

3.5 See Section 6.0 for Interconnection Wiring Diagram. Connect tank ultrasonic

power cable to its connector at rear of generator. Connect Protective Ground

wires if supplied. Make all connections prior to plugging system into the

power lines.

4.0 Operation Instructions

4.1 After filling tank with solution to an appropriate level, place item to be

cleaned in rack or on support and lower into tank. Pieces should be tilted

as needed to allow air bubbles to escape.

4.2 Turn machine on and run for an appropriate time. Usually this will be 5 to

15 minutes. Because cleaning jobs vary, testing will need to be performed

for the particular cleaning task (consult attached sheets for suggestions).

4.3 After item(s) is/are cleaned; remove, rinse off and dry as needed.

4.4 Turn generator off.