2

Important Notice

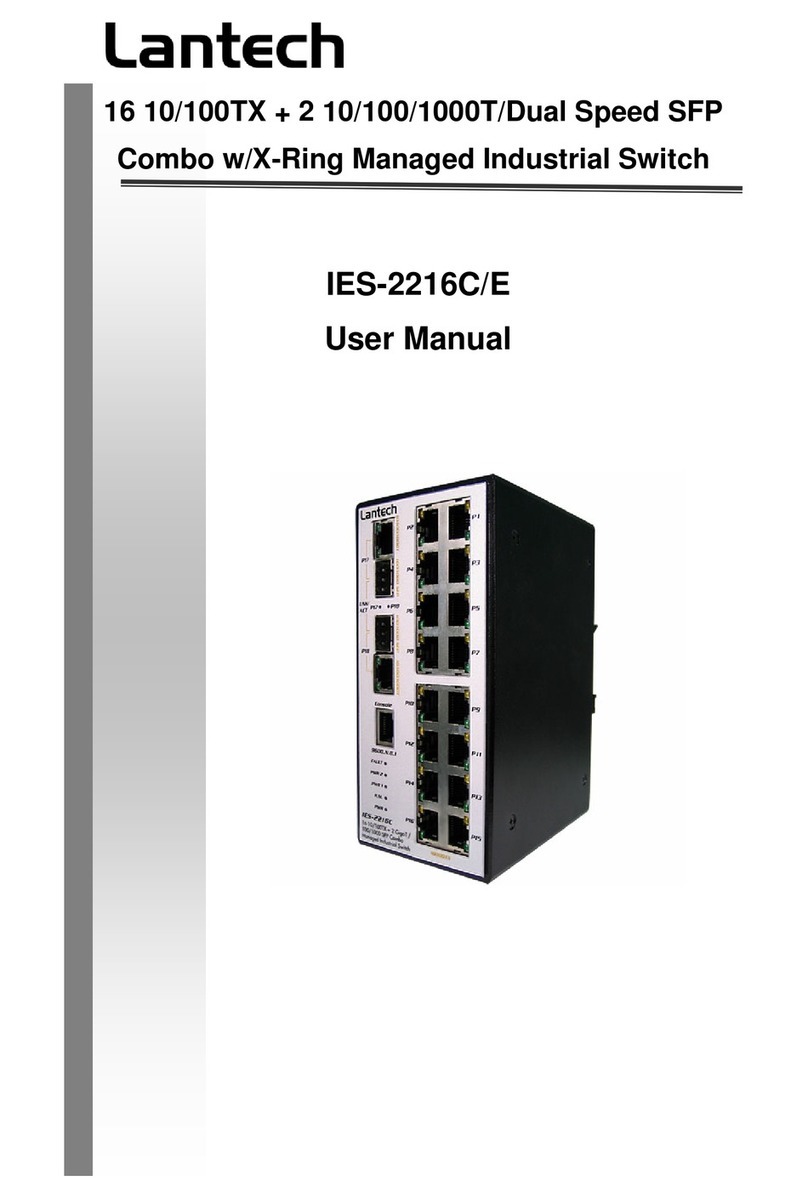

Lantech Communications Global, Inc. reserves the right to modify the

equipment, its specification or this manual without prior notice, in the

interest of improving performance, reliability, or servicing. At the time of

publication all data is correct for the operation of the equipment at the

voltage and/or temperature referred to. Performance data indicates typical

values related to the particular product.

No part of this documentation or information supplied may be divulged to

any third party without the express written consent of Lantech

Communications Global Inc. Products offered may contain software which

is proprietary to Lantech Communications Global Inc. The offer or supply of

these products and services does not include or infer any transfer of

ownership.

Interference Issues

This Equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection against harmful interference

in a commercial or industrial installation. This equipment generates, uses,

and can radiate radio frequency energy. It may cause harmful interference

to radio communications if the equipment is not installed and used in

accordance with the instructions.