Megatower Operation Manual

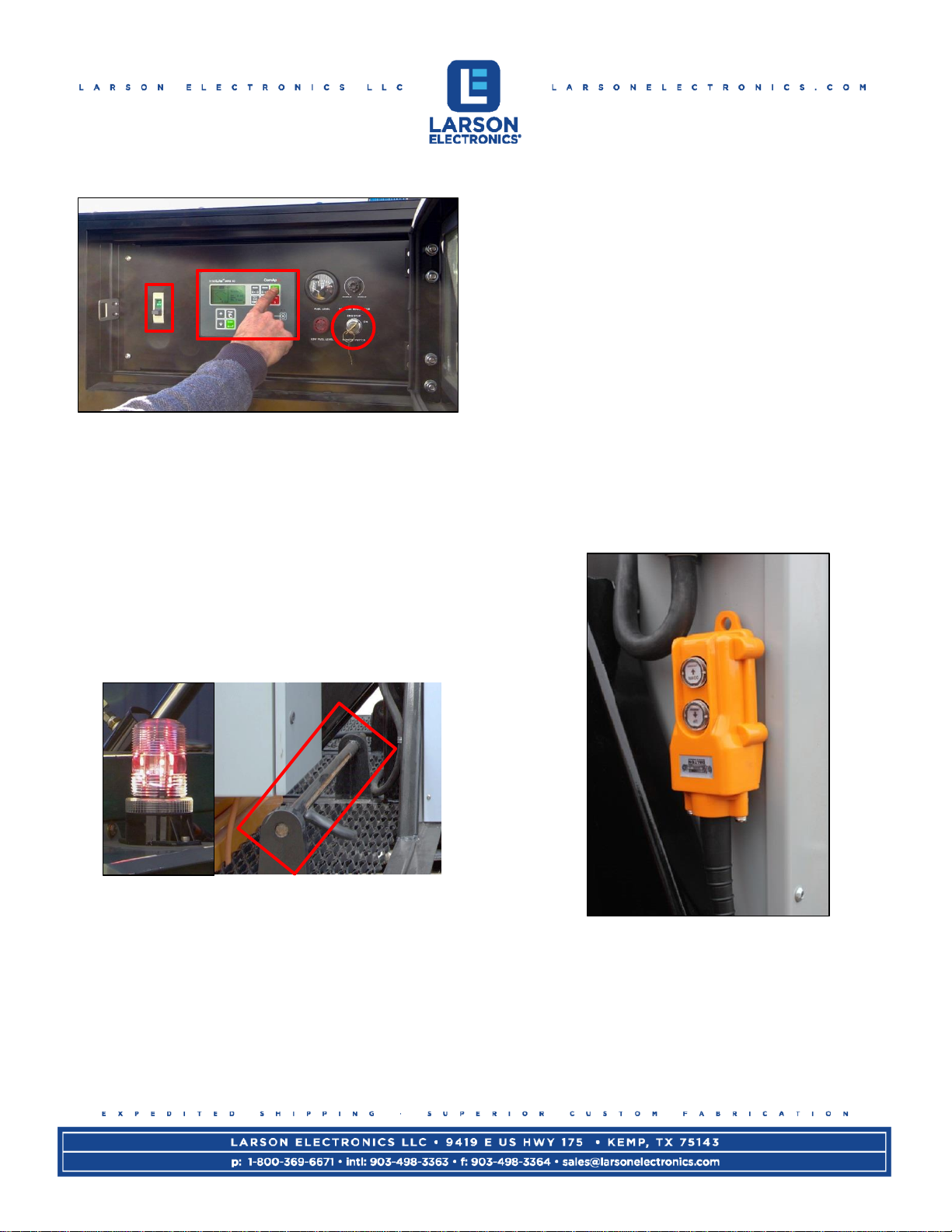

transport/storage. At this point, the mast is ready

to be elevated. Press the up button on the

orange pendant and the mast will start to elevate

horizontally to its upright position.

Elevate the mast to its full 90 degrees and verify

that the mast is still level.

8.) Once mast is elevated, install the mast retaining

pin. Push the mast retaining pin opposite of the

operator, and then rotate the pin down until it

locks into place. The red beacon light will turn off

once the pin is locked in place. At this point, the

hydraulics will no longer function while the mast

is elevated.

9.) Inside the control panel, rotate air valve to deploy

(closed) position. Locate the compressor switch

and turn switch ON. You should hear the air

compressor engage. Once enough air pressure

is built, the mast will start to vertically elevate.

The mast can take up to 20 minutes to fully

deploy and it is normal for several compressor

cycles during this time. WATCH CABLES TO

ENSURE THEY DO NOT GET SNAGGED

WHILE ELEVATING! Cables are positioned

designed to prevent snags but keep a look out

when elevating. Once fully deployed, the

compressor should only cycle every 20 minutes

for 15 seconds. The compressor switch should

remain in the ON position for the duration

deployed in order to keep the mast elevated.

10.) Once the mast is fully deployed, it is time to

power on the lights. This is done by flipping the

four switches located on the breaker box

opposite the control box. The lights are wired in

banks of four, from left to right. Each switch

operates a single bank: left, center left, center

right, right. With this setup, operators can choose

the amount of illumination required for the

specific task at hand.

At this point the mast is fully deployed and

ready for use.

WARNING:The light mast at 50’ is rated for wind

speeds up to 25 MPH. If deployed in wind speeds

higher than this, the mast must be guyed or the mast

will need to be lowered to 25’. At 25’ the mast is rated

for 40 MPH. Any higher wind speeds, and we suggest

that you lower the mast completely. Failure to do so

may result in damage to the mast.